When it comes to maintaining your cutting tool, having a clear grasp of its intricate assembly is essential. Each element plays a vital role in ensuring optimal performance and longevity. By exploring these individual parts, you can enhance your familiarity and boost your maintenance skills.

Within this section, we will delve into a comprehensive overview of the essential components that make up this powerful device. Understanding how each piece functions not only aids in troubleshooting but also empowers you to make informed decisions during repairs or upgrades.

Ultimately, a thorough knowledge of these elements will enhance your overall experience, enabling you to tackle tasks with confidence and efficiency. Whether you’re a novice or an experienced user, this exploration will equip you with the insights needed to keep your tool running smoothly.

Understanding Stihl MS 251 C

This section explores the features and components of a popular model designed for cutting tasks. It highlights the essential elements that contribute to its efficiency and performance, making it a favored choice among users.

| Component | Description |

|---|---|

| Engine | Powerful unit providing reliable performance for various tasks. |

| Guide Bar | Durable and designed for smooth cutting through wood. |

| Chain | Sharp links ensure precision and quick cuts in different materials. |

| Fuel System | Efficient design allowing longer operational time with minimal refueling. |

| Safety Features | Integrated mechanisms to enhance user protection during operation. |

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting through wood efficiently. Understanding its essential elements is crucial for effective operation and maintenance. Each component plays a specific role in ensuring the device performs optimally, making it important to familiarize oneself with these parts.

Engine and Power Source

The engine serves as the heart of the chainsaw, providing the necessary power for cutting. Typically, it is either gas-powered or electric, influencing the tool’s portability and performance. A reliable power source is essential for achieving consistent cutting speeds and handling various types of wood.

Cutting Bar and Chain

The cutting bar is the elongated metal piece that holds the chain, which is equipped with sharp teeth designed for slicing through timber. The combination of the bar’s length and the chain’s design affects the cutting efficiency and capability of the tool. Regular inspection and maintenance of these components are vital to ensure safe and effective operation.

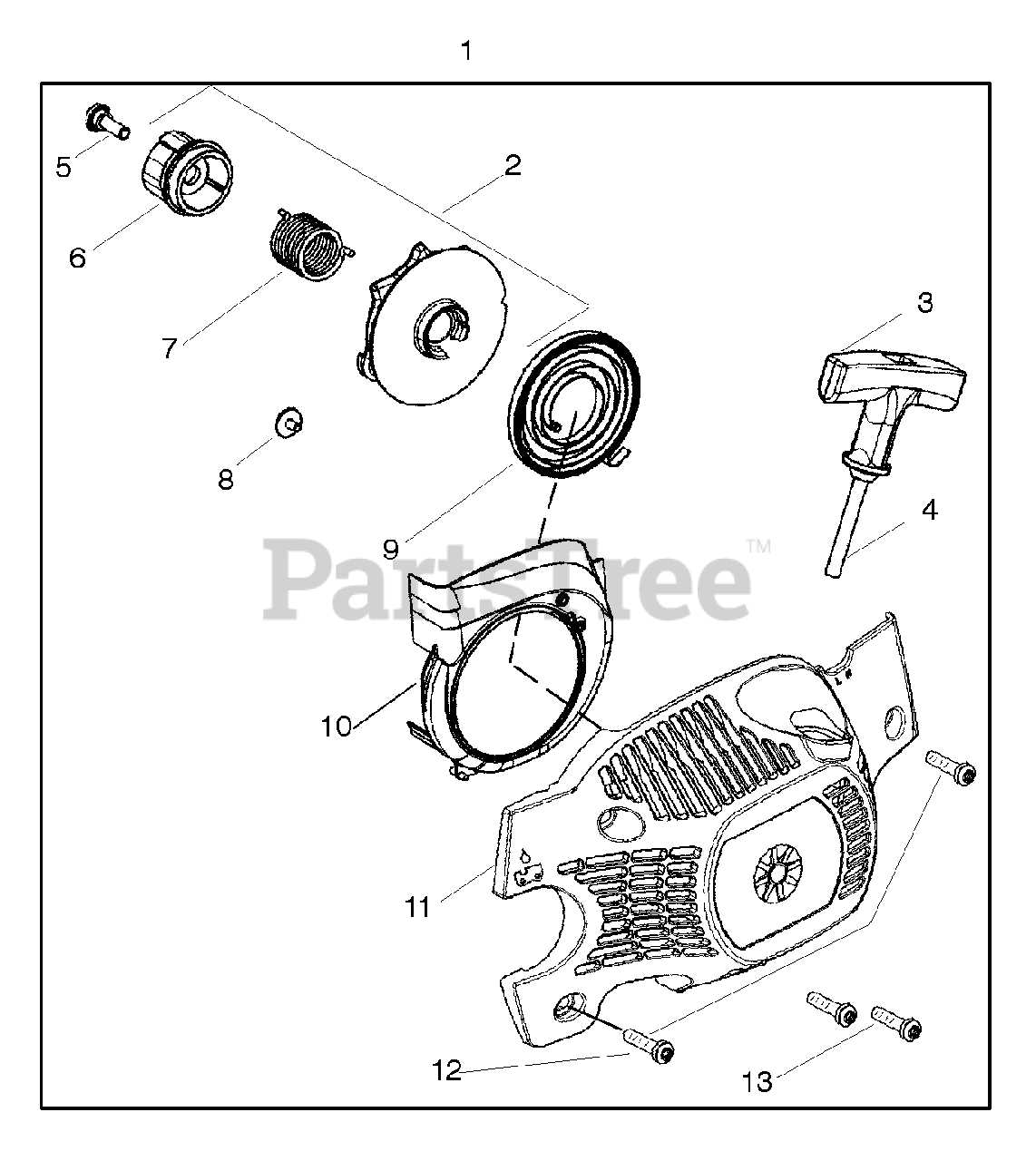

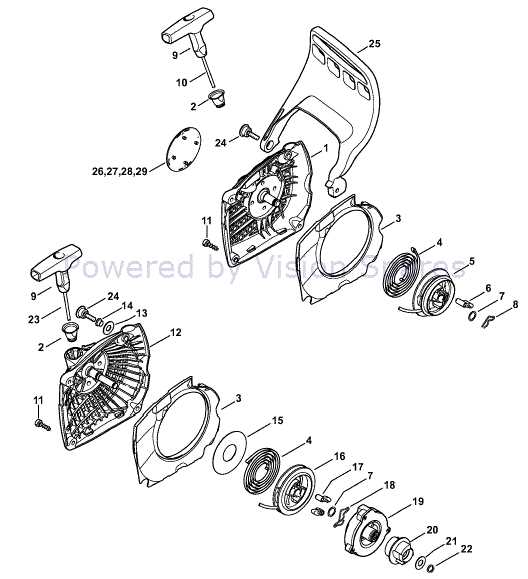

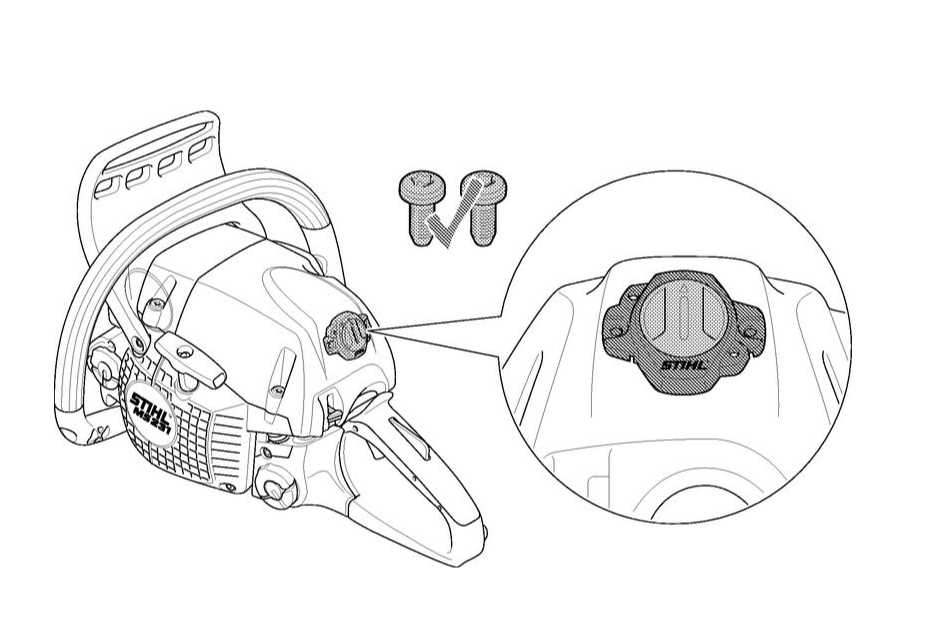

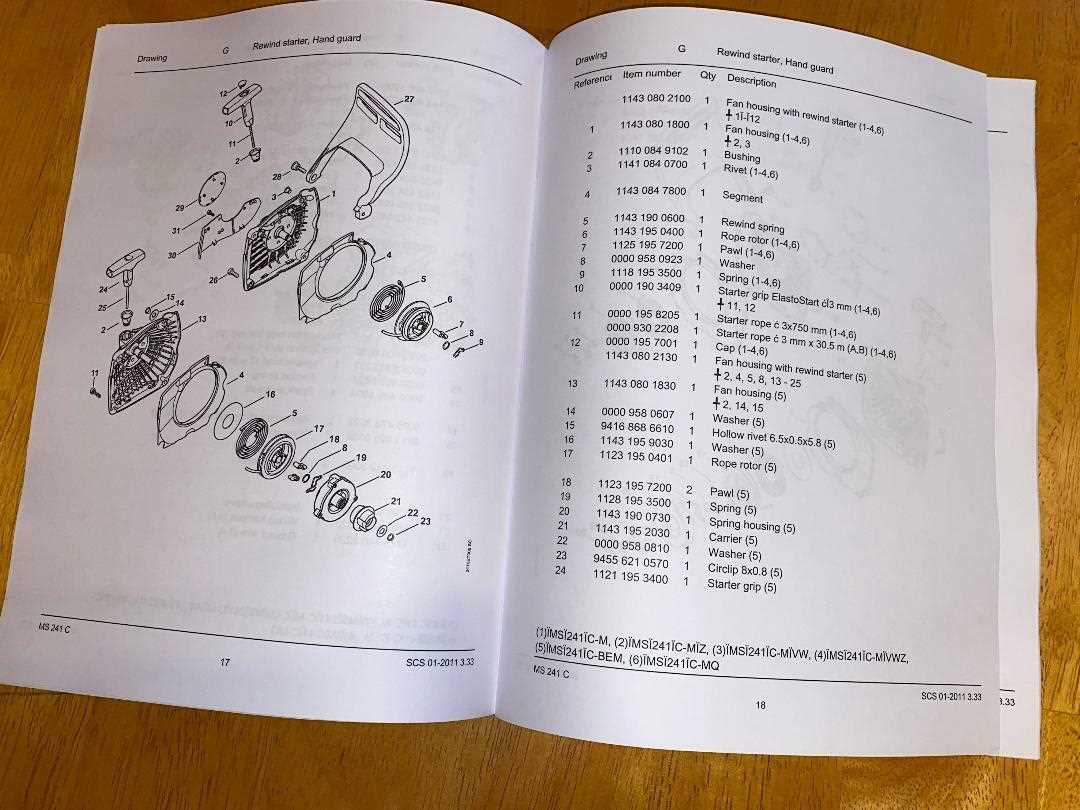

How to Read the Parts Diagram

Understanding a component illustration is essential for effective maintenance and repair. These visuals serve as a roadmap, guiding users through the various elements of the machine and their relationships. By familiarizing yourself with the structure and symbols used, you can streamline the process of identifying and ordering necessary components.

Typically, these illustrations include a variety of symbols and numbers that correspond to specific elements within the machine. Here’s a basic breakdown of what you might encounter:

| Symbol | Description |

|---|---|

| Circle | Indicates a specific part or assembly |

| Arrow | Shows the direction of movement or flow |

| Number | Corresponds to a list or key for easy reference |

| Line | Connects related components to show their association |

When reviewing the illustration, it’s beneficial to cross-reference the numbers with a detailed list to gain further insights into each component’s specifications. This will not only aid in identifying parts but also enhance your understanding of the overall assembly.

Familiarizing yourself with these visuals can significantly improve your repair skills and confidence in handling the equipment effectively.

Common Replacement Parts Overview

Maintaining your outdoor power equipment often requires the replacement of various essential components to ensure optimal performance. Understanding these key elements can help you keep your machinery running smoothly and efficiently.

- Air Filter: Essential for keeping debris out of the engine.

- Fuel Filter: Prevents contaminants from entering the fuel system.

- Spark Plug: Crucial for proper ignition and engine functionality.

- Chain: A vital component for cutting efficiency and precision.

- Bar: Supports the chain and affects cutting performance.

Regular inspection and timely replacement of these components can significantly enhance the longevity and reliability of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following a few straightforward guidelines, you can significantly extend its lifespan and maintain optimal performance.

1. Clean After Use: Always remove debris and dirt after each session. This helps prevent corrosion and damage to sensitive components.

2. Check Oil Levels: Regularly inspect and top off lubrication to ensure smooth operation. Proper oil levels reduce friction and wear on moving parts.

3. Inspect Filters: Clean or replace air and fuel filters as needed. Clogged filters can lead to reduced performance and potential engine issues.

4. Sharpen Blades: Keeping cutting edges sharp enhances efficiency and reduces strain on the engine. Regular sharpening prevents unnecessary wear.

5. Store Properly: When not in use, store your equipment in a dry, cool place. Proper storage prevents damage from environmental factors.

6. Follow Manufacturer Guidelines: Adhering to specific instructions from the manufacturer ensures that you are using and maintaining your equipment correctly.

By implementing these practices, you can delve deeper into the art of maintenance, ultimately leading to a longer, more productive life for your tools.

Identifying Parts by Model Number

Understanding how to recognize components through their specific model identifiers is crucial for effective maintenance and repair. Each unit has a unique reference that assists users in pinpointing the exact elements needed for replacement or repair. This process not only streamlines the identification but also ensures compatibility and efficiency in operations.

Model identifiers are typically located on the equipment itself, often in visible areas for easy access. These numbers can vary in format, but they usually include a combination of letters and digits. When searching for replacements, it’s essential to accurately note this identifier, as it plays a significant role in finding the right match.

In many cases, the manufacturer’s website or authorized dealers provide comprehensive listings based on these identifiers. Utilizing such resources can greatly enhance the likelihood of obtaining the correct components, thus minimizing downtime and optimizing functionality. Always cross-reference the model number with available resources to ensure precision in your selections.

When in doubt, consulting with a professional or referencing user manuals can provide additional guidance. This proactive approach not only saves time but also contributes to the longevity of the equipment, ensuring it operates at peak performance for years to come.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for optimal performance and longevity. Genuine replacements ensure compatibility and reliability, allowing your machine to operate at its best. This section explores the best sources to acquire these essential items.

Authorized Dealers

Your first stop should be authorized retailers who specialize in equipment sales. These dealers often stock a wide range of original replacements and can provide expert advice on selecting the right items for your needs.

Online Retailers

Numerous online platforms offer genuine components with the convenience of home delivery. Ensure you choose reputable websites that guarantee authenticity to avoid counterfeit products that may compromise your equipment’s performance.

DIY Repairs: A Step-by-Step Guide

Embarking on a do-it-yourself repair journey can be both rewarding and cost-effective. By understanding the essential components and their functions, you can tackle maintenance tasks and minor fixes with confidence. This guide aims to empower you with practical steps, enabling you to address common issues and enhance the longevity of your equipment.

Before diving into repairs, ensure you have a clean workspace and the necessary tools at hand. Familiarize yourself with the device’s structure and consult any available resources for a clearer understanding of each part’s role. This foundational knowledge will streamline the process and minimize frustration.

Begin by disassembling the equipment carefully, noting the arrangement of components. Use labeled containers to keep small parts organized. As you inspect each section, look for signs of wear or damage, such as cracks or corrosion, and determine which pieces require replacement or repair.

Once you’ve identified the problematic areas, proceed with caution. For replacements, select high-quality materials that match the specifications of the original components. Follow the installation instructions closely, ensuring a secure fit to prevent future issues. If repairs are feasible, use appropriate adhesives or seals designed for durability.

After reassembling the device, conduct thorough checks to ensure everything is functioning correctly. Test the equipment in a controlled environment to confirm that repairs were successful. Regular maintenance will help prolong its life and keep it operating at peak performance.

Safety Precautions During Maintenance

When performing upkeep on any machinery, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Understanding and following specific guidelines is essential for effective and safe maintenance practices.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always don safety goggles, gloves, and appropriate clothing to shield against debris and sharp components. |

| Disconnect Power Source | Before starting any work, ensure that the power supply is disconnected to prevent accidental activation. |

| Work in a Well-Ventilated Area | Maintain airflow to avoid inhaling harmful fumes and to reduce the risk of fire hazards. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damaging components and ensure efficiency during maintenance. |

| Read the Manual | Consult the manufacturer’s guide for specific safety measures and maintenance recommendations unique to the equipment. |

| Keep Workspace Organized | Maintain a tidy area free from clutter to minimize the risk of accidents and to easily locate necessary tools. |