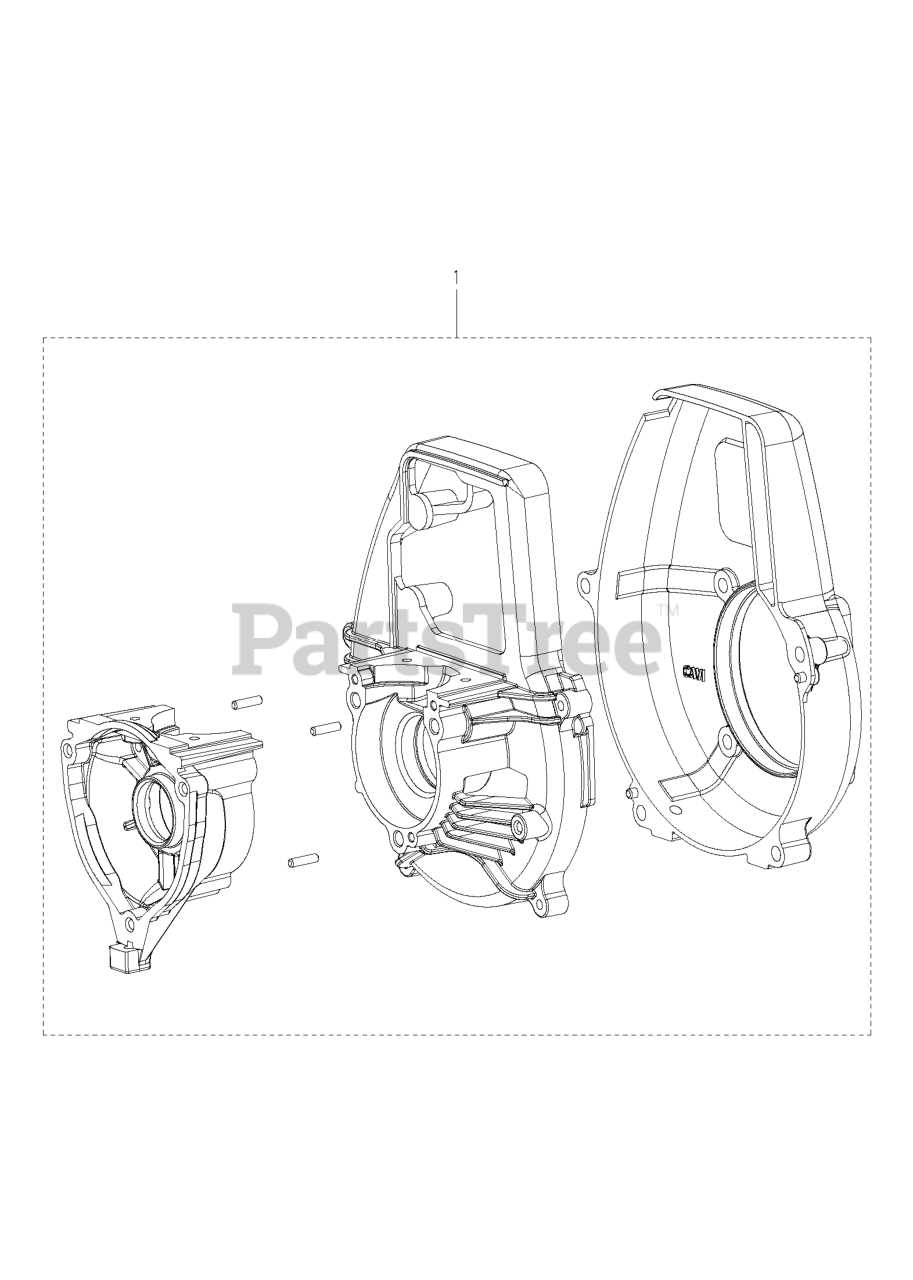

In the realm of outdoor maintenance, effective tools play a crucial role in achieving optimal results. Familiarity with the internal structure of your equipment is essential for ensuring its longevity and performance. A clear grasp of each element allows users to perform necessary repairs and maintenance efficiently.

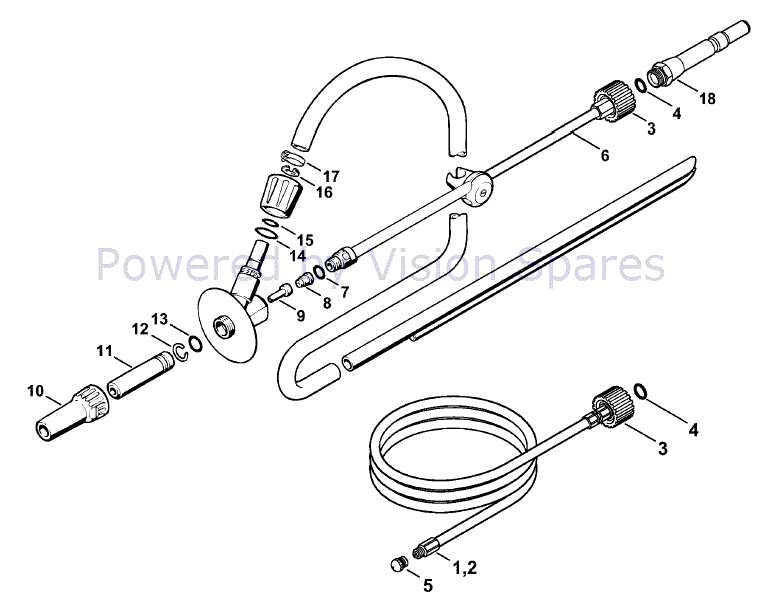

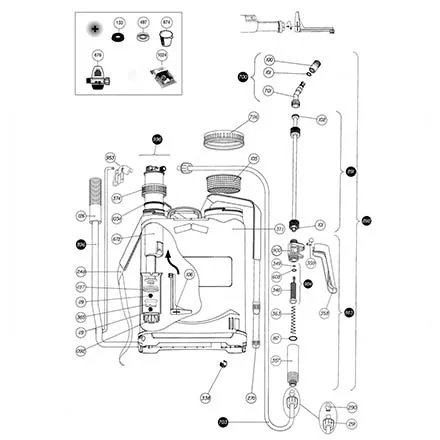

The layout of these tools comprises various sections, each contributing to the overall functionality. Identifying these individual components empowers users to troubleshoot issues and make informed decisions regarding replacements or upgrades. A well-organized illustration of the equipment’s makeup serves as a valuable reference for both novice and seasoned users.

By exploring the intricate relationships between these elements, one can delve deeper into the mechanics behind successful outdoor tasks. Ultimately, this understanding can lead to improved user experience and satisfaction, transforming routine chores into manageable and enjoyable activities.

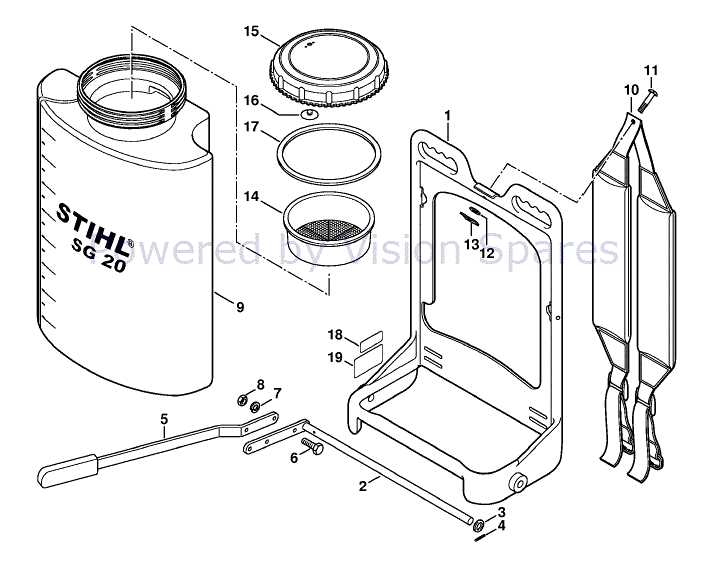

Understanding Stihl Backpack Sprayers

This section explores the functionality and components of a popular gardening tool designed for efficient liquid application. By examining its construction, users can gain insights into maintenance and optimal usage, enhancing their overall experience with the device.

Key Components

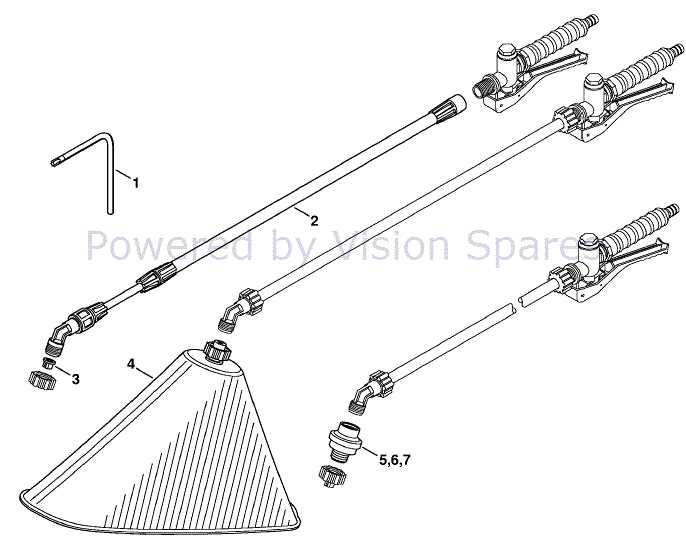

The primary elements of this tool include a tank for storage, a pumping mechanism for pressure generation, and a nozzle for targeted distribution. Each component plays a crucial role in ensuring that the liquid reaches its intended area effectively and efficiently.

Maintenance Tips

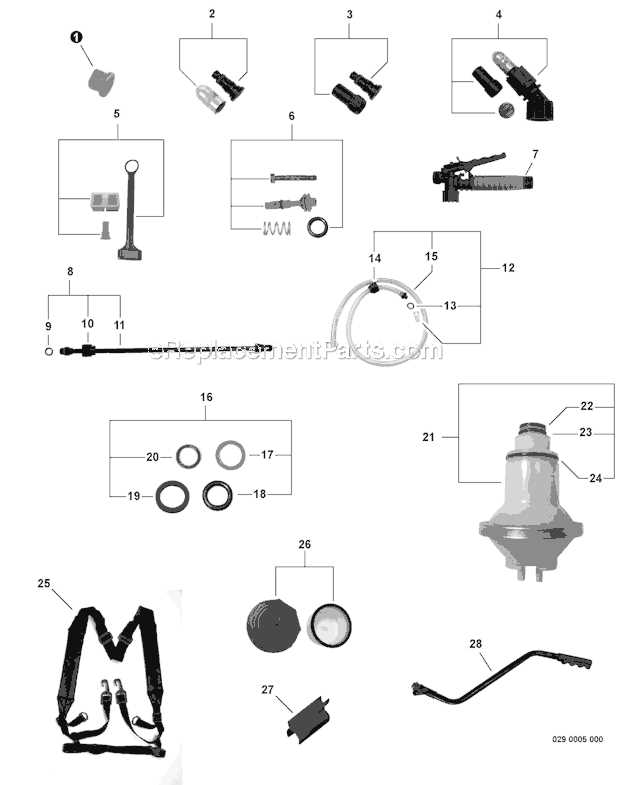

Key Components of the Sprayer

Understanding the essential elements of a liquid application device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity of the equipment. Familiarity with these key elements can enhance user experience and efficiency.

1. Pump Mechanism

The heart of the equipment is the pump, responsible for generating pressure that propels the fluid. Different types of pumps offer varying flow rates and pressures, allowing users to select the most suitable option for their specific tasks. A well-maintained pump ensures consistent delivery and effective coverage.

2. Nozzle Selection

Nozzles are vital for controlling the dispersion of the liquid. They come in various shapes and sizes, designed to achieve different spray patterns and droplet sizes. Choosing the right nozzle not only improves application efficiency but also minimizes waste and environmental impact.

Regular inspection and replacement of these components are essential for maintaining the device’s functionality. By understanding these critical parts, users can ensure their equipment operates at peak performance.

Importance of Proper Maintenance

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to diminished efficiency, increased wear and tear, and ultimately, costly repairs or replacements. A well-maintained tool not only operates better but also provides a safer experience for the user.

Enhancing Performance

Consistent maintenance helps to keep machinery running at peak efficiency. By routinely checking and replacing worn components, users can avoid interruptions in their tasks and maintain consistent output. Proactive care can also enhance precision, which is vital for achieving desired results.

Cost-Effectiveness

Investing time in maintenance can save money in the long run. Regular inspections and minor repairs can prevent major breakdowns that require expensive fixes. Moreover, efficient equipment consumes less energy and resources, contributing to overall savings and a smaller environmental footprint.

How to Identify Each Part

Understanding the components of your equipment is essential for effective maintenance and operation. Each element plays a specific role, and recognizing them can enhance your experience and prolong the lifespan of your tools.

Start by examining the structure. Look for the main body, which houses the engine and reservoir. Then, identify the nozzle, crucial for directing the flow of liquid. Next, locate the hose, which connects the reservoir to the nozzle, ensuring proper distribution.

Don’t overlook the pump, responsible for generating pressure. Familiarize yourself with the filter, vital for keeping contaminants at bay, and the straps that aid in comfortable transportation. Lastly, check for any additional components like the valve, which regulates flow, to ensure everything is in optimal condition.

Common Issues and Solutions

When utilizing portable spraying equipment, users often encounter various challenges that can hinder performance. Understanding these common problems and their solutions is essential for maintaining efficiency and prolonging the lifespan of the device.

Frequent Problems

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Loss of pressure | Clogged nozzle, damaged seals | Clean or replace nozzle; inspect and replace seals as needed. |

| Uneven spray pattern | Blocked filter, incorrect nozzle size | Check and clean the filter; ensure the correct nozzle is installed. |

| Difficulty in starting | Old fuel, air leaks | Use fresh fuel; inspect hoses and connections for leaks. |

| Equipment leaks | Worn-out hoses, loose connections | Replace damaged hoses; tighten all connections securely. |

Maintenance Tips

Regular maintenance can prevent many issues. Always clean the equipment after each use, check for wear and tear on components, and ensure proper storage conditions. By staying proactive, users can avoid common pitfalls and enjoy reliable performance.

Exploring Replacement Options

When maintaining equipment, identifying suitable alternatives for worn or damaged components is essential for optimal performance. This section delves into the various possibilities available for upgrading or substituting essential items, ensuring continued functionality and efficiency.

Identifying Compatible Components

To enhance your device, begin by researching compatible alternatives. Various manufacturers provide high-quality replacements that can meet or exceed original specifications, offering durability and reliability.

Evaluating Quality and Cost

While exploring options, consider both quality and cost. Investing in superior materials can result in long-term savings, as they often reduce the frequency of replacements. Always read reviews and compare different brands to make informed decisions.

Benefits of Using Backpack Sprayers

Utilizing a portable liquid application device offers numerous advantages for those involved in gardening, landscaping, and agriculture. This equipment provides an efficient and ergonomic solution for distributing various substances, ensuring that tasks are completed effectively and with minimal effort.

Enhanced Mobility and Efficiency

One of the primary benefits is the ease of movement it allows. Users can navigate through tight spaces and uneven terrain without the constraints of wheeled equipment. This mobility ensures that treatment is evenly applied, leading to better results in pest control and fertilization.

Ergonomic Design for Comfort

The design of these devices prioritizes user comfort, often featuring padded straps and adjustable components. This ergonomic approach reduces fatigue during prolonged use, making it easier to cover larger areas without compromising performance or causing physical strain.

Tips for Efficient Usage

Maximizing the effectiveness of your application equipment involves understanding both the device and the best practices for operation. Proper handling not only enhances performance but also ensures a thorough and even distribution of the liquid, leading to better results.

Preparation is Key

Before starting, inspect your equipment to ensure all components are functioning correctly. Clean any filters and check for leaks. Filling the tank properly is crucial; avoid overfilling to prevent spills. Always prepare the solution according to the manufacturer’s recommendations to achieve optimal results.

Technique Matters

Adopt a steady and methodical approach while applying the liquid. Maintain a consistent distance from the target surface to ensure uniform coverage. Utilize overlapping passes to prevent streaking or missed spots. Adjust the nozzle settings based on the specific task for improved efficiency.

Where to Find Diagrams Online

Locating detailed illustrations for equipment components can enhance maintenance and repair efforts significantly. Numerous online resources offer access to these valuable visual aids, making it easier for users to understand assembly and functionality.

Online Resources

Various websites provide comprehensive illustrations and manuals. Here are some reliable sources:

| Website | Description |

|---|---|

| Manufacturer’s Official Site | Offers original documentation and illustrations directly from the producer. |

| Online Retailers | Many sellers include diagrams in product listings for reference. |

| DIY Forums | Community-driven sites often share user-generated illustrations and guides. |

Tips for Searching

Utilize specific keywords related to your equipment when searching online. Combine terms like “illustration,” “exploded view,” and “assembly guide” for more precise results.