When delving into the world of high-performance outdoor power equipment, knowledge of individual components is essential for maintenance and effective operation. A comprehensive exploration of a specific chainsaw model can provide valuable insights into its functionality and longevity. Understanding how each element interacts with one another can empower users to make informed decisions about repairs and upgrades.

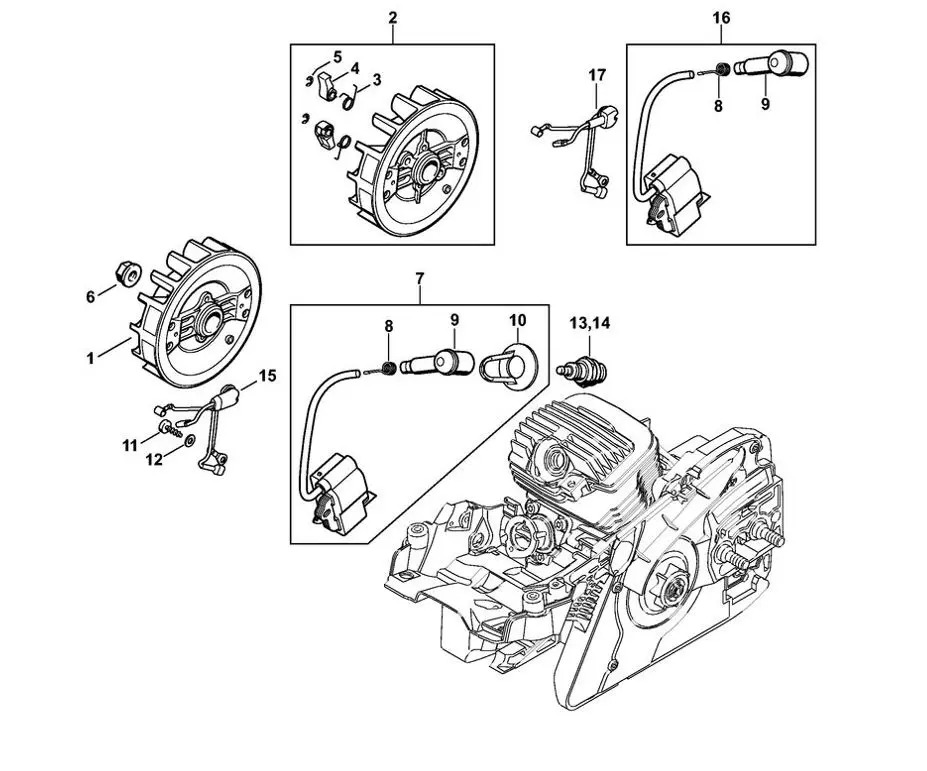

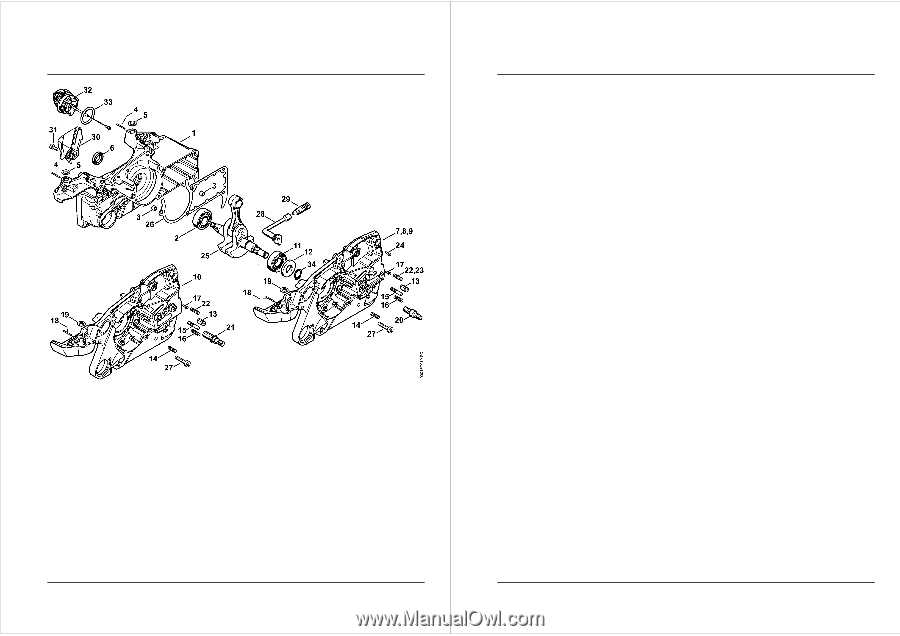

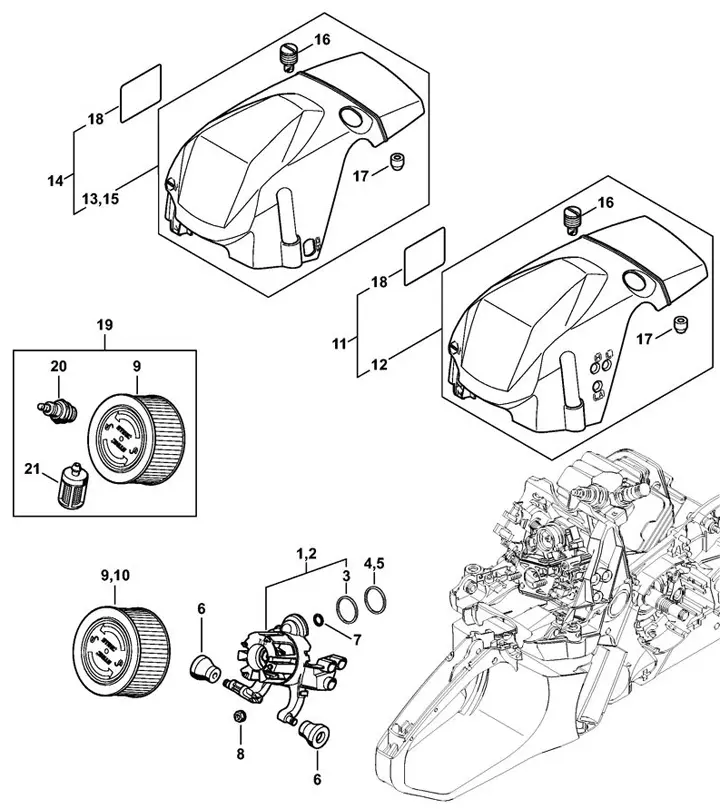

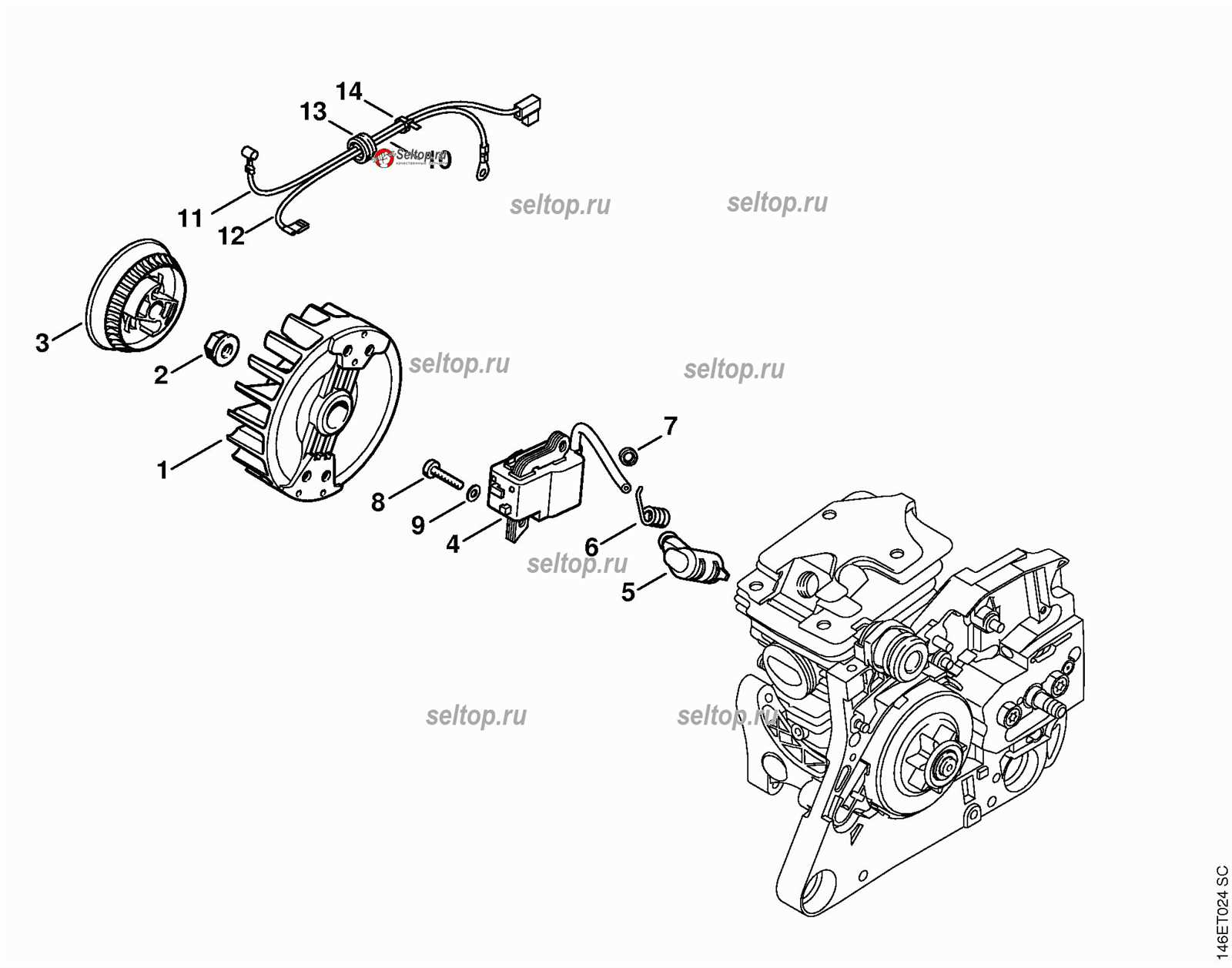

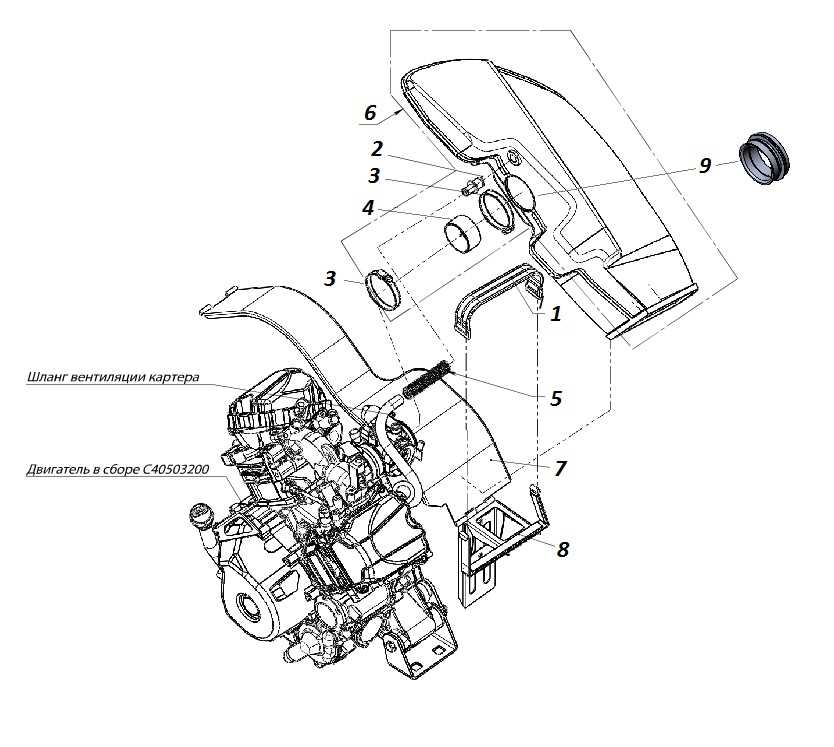

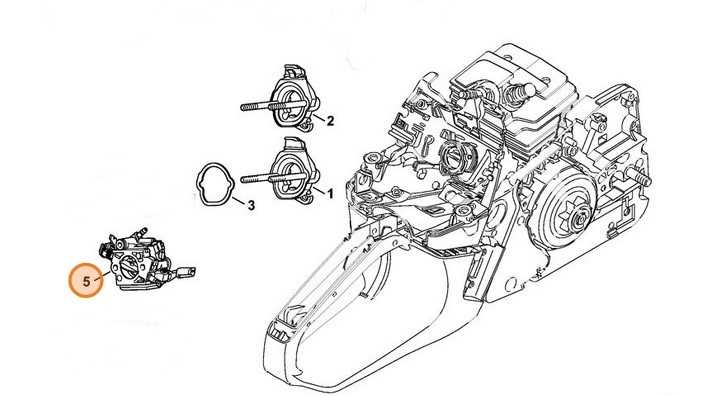

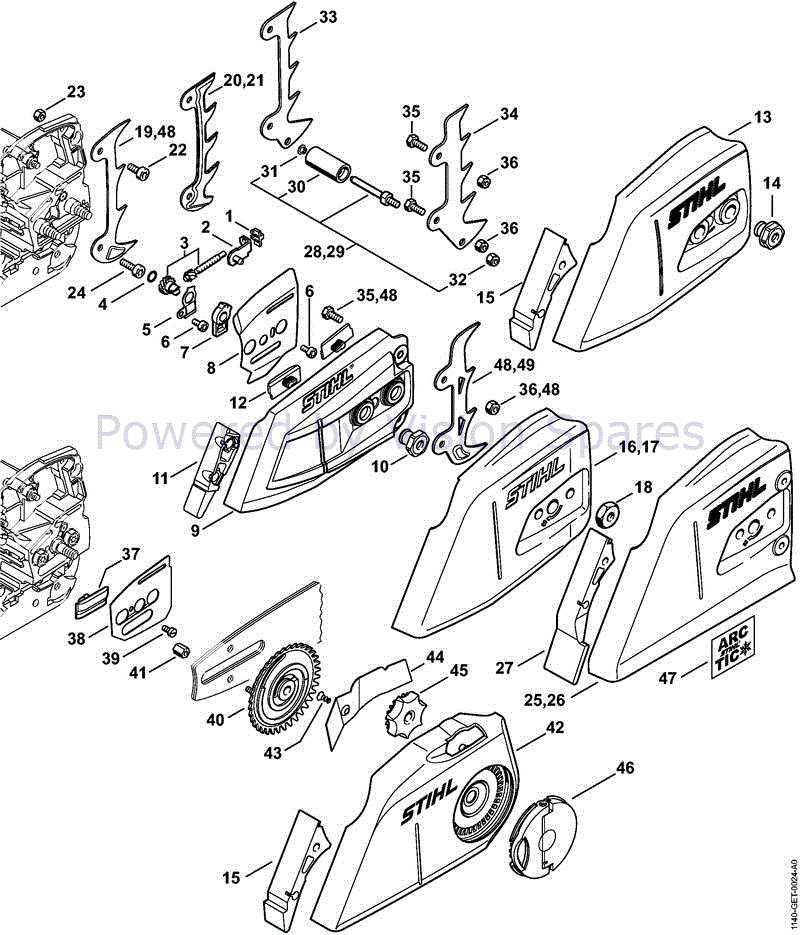

For enthusiasts and professionals alike, having access to a detailed visual representation of the various segments can greatly enhance the experience of using and maintaining such tools. These illustrations serve as a roadmap, guiding users through the intricacies of assembly and disassembly. Familiarity with these components not only ensures optimal performance but also extends the lifespan of the equipment.

In this guide, we will provide an in-depth look at the essential features and mechanisms of a widely used chainsaw model. By examining its structure, users will gain clarity on how to approach any potential issues that may arise, ultimately leading to a more efficient and effective tool usage.

Understanding the Stihl MS 362

When it comes to high-performance outdoor power equipment, certain models stand out for their efficiency, reliability, and ease of use. This particular machine has garnered attention among enthusiasts and professionals alike due to its powerful capabilities and innovative design. In this section, we will explore its key features, components, and maintenance tips to help you maximize its potential.

Key Features

- Powerful engine designed for heavy-duty tasks.

- Lightweight construction for enhanced maneuverability.

- Advanced anti-vibration technology for user comfort.

- Fuel-efficient operation, reducing running costs.

Essential Components

- Engine: Delivers robust performance for various cutting applications.

- Guide Bar: Critical for accurate cutting and maneuverability.

- Chain: Designed for durability and precision in slicing through materials.

- Air Filter: Ensures optimal airflow and engine performance.

Understanding these elements not only aids in effective usage but also enhances the longevity of the equipment. Regular maintenance and careful handling are key to keeping this powerful tool in top condition, ensuring it meets the demands of any task with ease.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations provide clarity, allowing users to identify specific elements quickly and accurately. This knowledge not only streamlines the repair process but also enhances the overall efficiency of equipment management.

Such illustrations serve as valuable references, ensuring that individuals can troubleshoot issues and order the correct replacements without confusion. They bridge the gap between complex mechanical systems and the user, facilitating a deeper comprehension of how each part interacts within the whole. Ultimately, this fosters better care and longevity of the equipment.

Where to Find PDF Diagrams

Locating detailed illustrations and breakdowns for various equipment can be essential for maintenance and repair. Understanding where to access these resources can significantly enhance your ability to troubleshoot and perform tasks effectively.

Online Resources

Numerous websites specialize in providing manuals and visuals for machinery. Here are some reliable platforms:

| Website | Description |

|---|---|

| Manufacturer’s Site | Official pages often offer comprehensive resources directly from the source. |

| Repair Forums | Community-driven sites can provide valuable insights and shared documents from fellow users. |

| Parts Retailers | Online stores frequently have downloadable resources to assist customers with their purchases. |

Local Libraries and Shops

Physical locations may also have printed resources or offer access to databases. Checking with local libraries or repair shops can yield useful materials that aren’t readily available online.

Common Replacement Parts for MS 362

Maintaining a high-performance chainsaw involves regularly replacing certain components to ensure optimal functionality. This section highlights essential items that often require substitution, helping users keep their equipment in prime condition.

Fuel Filter: A clean fuel filter is crucial for proper fuel flow. Regular replacement prevents clogs that can affect performance.

Air Filter: Ensuring the air filter is free from debris is vital for engine efficiency. A fresh filter allows for better airflow and enhances combustion.

Chain: Over time, chains can become dull or damaged. Replacing them ensures smooth cutting and extends the life of the saw.

Bar: The guide bar may wear down, leading to ineffective cutting. Regular inspection and replacement are necessary to maintain cutting precision.

Sprocket: This component plays a key role in the chain’s movement. A worn sprocket can lead to chain slippage, necessitating its timely replacement.

Plug: The spark plug is essential for ignition. A faulty plug can hinder starting and overall engine performance, so it should be checked and replaced as needed.

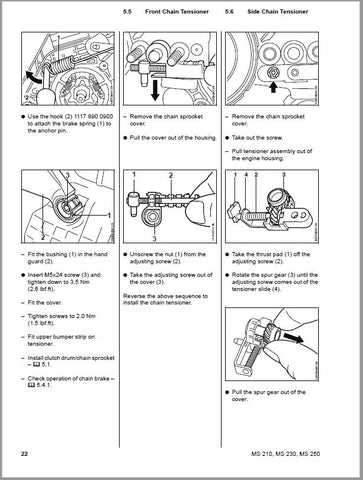

How to Use the Diagram Effectively

Understanding the visual representation of components is essential for any repair or maintenance task. A well-structured illustration serves as a valuable guide, allowing users to identify each element clearly and facilitate efficient assembly or disassembly. By familiarizing yourself with this resource, you can streamline your workflow and reduce the risk of errors.

Familiarize Yourself with the Layout

Before diving into repairs, take a moment to study the layout of the visual guide. Recognize the organization of parts and their connections. This foundational knowledge will empower you to navigate through the process with confidence, making it easier to pinpoint the specific areas requiring attention.

Use for Reference During Repairs

Keep the illustration close at hand while performing maintenance tasks. Referencing it frequently can help ensure that each component is correctly positioned and secured. Moreover, this resource can assist in troubleshooting issues by highlighting how parts interact with one another. Always approach the task methodically, checking off each element as you go.

Utilizing this visual tool effectively can enhance your understanding and execution of necessary repairs, leading to better outcomes and prolonged equipment life.

Maintenance Tips for Stihl Chainsaws

Proper upkeep is essential for ensuring the longevity and performance of your cutting tool. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few straightforward guidelines, you can keep your equipment in excellent working condition and ready for any task.

Regular Inspection

Routine checks of your equipment can help identify potential issues before they escalate. Focus on the following components during your inspection:

| Component | Inspection Frequency | Key Checks |

|---|---|---|

| Chain | Before each use | Sharpness, tension, and wear |

| Bar | Weekly | Wear patterns and lubrication |

| Air Filter | Every 5 uses | Cleanliness and damage |

| Fuel System | Monthly | Fuel quality and leaks |

Cleaning and Lubrication

Keeping your equipment clean is vital for optimal performance. Regularly clean the exterior, especially after heavy use. Pay special attention to the air filter and chain oil system. Proper lubrication ensures smooth operation and reduces wear, making it essential to maintain adequate oil levels and replace the oil as necessary.

Troubleshooting Common Issues

When operating a power tool, encountering difficulties can be frustrating. However, many common problems can be identified and resolved with a bit of knowledge. This section outlines several frequent issues and offers practical solutions to help maintain optimal performance.

Here are some typical challenges and their remedies:

- Starting Difficulties:

- Check the fuel mixture; improper ratios can prevent ignition.

- Inspect the spark plug for wear or fouling; cleaning or replacing may be necessary.

- Ensure the air filter is clean; a clogged filter can restrict airflow.

- Power Loss:

- Examine the fuel system for blockages; clean fuel lines if needed.

- Assess the carburetor for adjustments; improper settings can affect power.

- Check the chain tension; a loose chain can lead to reduced performance.

- Excessive Vibration:

- Inspect the chain for damage; a dull or broken chain can cause instability.

- Ensure all fasteners are secure; loose components can create vibrations.

- Examine the guide bar for wear; a bent or damaged bar should be replaced.

- Overheating:

- Ensure proper lubrication; insufficient oil can lead to overheating.

- Check for blockages in the cooling system; clean any debris that may hinder airflow.

- Monitor operation time; prolonged use without breaks can cause overheating.

By following these guidelines, users can effectively troubleshoot and resolve common issues, ensuring a longer lifespan and better performance of their equipment.

Comparing MS 362 to Other Models

This section explores the differences and similarities between a specific chainsaw model and its competitors within the same category. By examining various aspects such as performance, weight, and user-friendliness, we can better understand how this particular model stands out or falls short in relation to others in its class.

One of the key factors to consider is engine power. This model boasts a robust engine that provides excellent cutting capabilities, making it suitable for both professional and residential use. In comparison, other models may offer either lower power or features that cater to different user needs, such as lightweight designs for ease of handling.

Durability is another important aspect. This chainsaw is known for its solid construction and longevity, which can be a deciding factor for users who require a reliable tool for frequent use. Competing models may vary in build quality, affecting their lifespan and overall performance in demanding conditions.

When it comes to ease of use, this model often receives high marks for its ergonomic design and intuitive controls. In contrast, some alternatives may be less user-friendly, potentially leading to operator fatigue during extended tasks. Analyzing user feedback can provide insights into which options are most comfortable for various applications.

Finally, maintenance requirements can greatly influence a user’s experience. This particular model typically requires minimal upkeep, while others might demand more frequent attention to keep them running efficiently. Understanding these differences can help potential buyers choose the right tool for their specific needs.

Benefits of Using Genuine Parts

When it comes to maintaining and enhancing the performance of your equipment, opting for authentic components offers numerous advantages. Genuine products are designed specifically for your model, ensuring a perfect fit and optimal functionality. This not only prolongs the lifespan of the machine but also enhances safety during operation.

Quality Assurance: One of the primary benefits of using authentic components is the assurance of quality. These items are manufactured to stringent standards, reducing the risk of failures or malfunctions. With high-quality materials and precise engineering, they provide reliability and durability that aftermarket alternatives often cannot match.

Performance Consistency: Using original components ensures that your equipment operates at peak efficiency. These items are tailored to work seamlessly with the machinery, delivering consistent performance that enhances productivity. When every part functions as intended, the overall effectiveness of the machine is maximized.

Warranty Protection: Many manufacturers offer warranties on their products, which can be voided if non-genuine components are used. By choosing authentic parts, you safeguard your investment and maintain coverage against defects or failures. This peace of mind is invaluable for both personal and professional use.

Support and Guidance: When purchasing genuine items, you often gain access to expert support and guidance. Manufacturers typically provide resources, such as manuals and customer service, which can be beneficial for troubleshooting or maintenance. This added support can save time and effort in the long run.

In summary, the choice of authentic components greatly impacts the reliability, efficiency, and longevity of your machinery. Prioritizing quality and compatibility leads to a better overall experience and enhanced performance, making it a smart decision for any user.