In the world of outdoor machinery, the intricacies of various models can often be a source of confusion for users. Familiarity with the essential elements that make up these devices is crucial for efficient operation and maintenance. This section delves into the key features that constitute a specific model, helping enthusiasts and professionals alike gain a clearer perspective.

With an emphasis on identifying individual elements, this guide will provide insights into how each part contributes to the overall functionality. Knowing how components interact can enhance your ability to troubleshoot issues and ensure optimal performance. Whether you’re a seasoned user or a newcomer, understanding the layout of your equipment can be immensely beneficial.

Moreover, recognizing the specifics of each segment can assist in making informed decisions during repairs or upgrades. This knowledge not only empowers you but also promotes a deeper appreciation for the engineering behind these tools. Explore the nuances of your machinery and unlock its full potential through a comprehensive understanding of its construction.

Overview of Stihl HL 91 K

The HL 91 K is a versatile tool designed for efficient gardening and landscaping tasks. Its innovative engineering combines power and ease of use, making it a preferred choice for both professionals and enthusiasts. With a focus on performance and reliability, this equipment is built to tackle a variety of challenging tasks, ensuring that users can achieve exceptional results with minimal effort.

This model features an adjustable length, allowing for extended reach without compromising control. Its ergonomic design minimizes fatigue during prolonged use, promoting comfort and precision. The engine is optimized for fuel efficiency and reduced emissions, aligning with contemporary environmental standards while maintaining robust performance.

Additionally, the HL 91 K comes equipped with a range of attachments, enhancing its functionality for different applications. Whether trimming, shaping, or maintaining green spaces, this tool adapts seamlessly to various requirements, making it an essential addition to any outdoor toolkit.

Key Features of the Model

This model is designed to offer exceptional performance and efficiency for a variety of tasks. Its innovative design combines power with user-friendly features, making it suitable for both professionals and hobbyists. From its lightweight construction to advanced technology, every aspect enhances usability and effectiveness.

Ergonomic Design

The thoughtful design prioritizes user comfort, featuring a well-balanced frame that reduces fatigue during extended use. The adjustable components allow for customization, ensuring that operators of all sizes can achieve optimal handling and control.

Powerful Engine

Equipped with a robust engine, this model delivers impressive cutting power while maintaining fuel efficiency. The advanced technology minimizes emissions, contributing to a cleaner environment without sacrificing performance.

In summary, this model stands out due to its ergonomic design and powerful engine, making it an ideal choice for various landscaping and maintenance tasks.

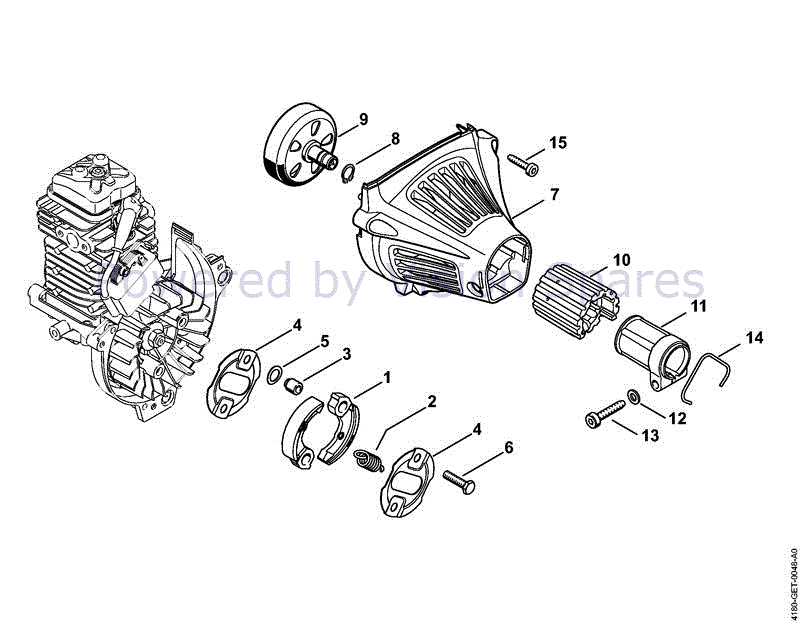

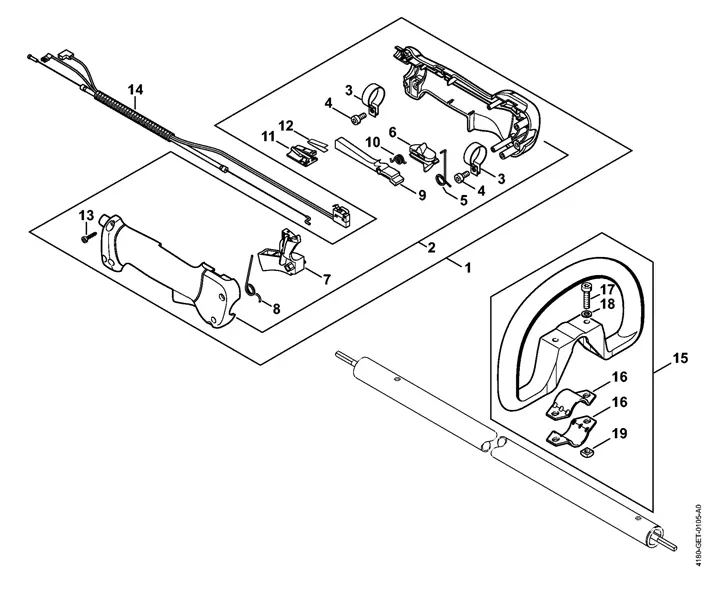

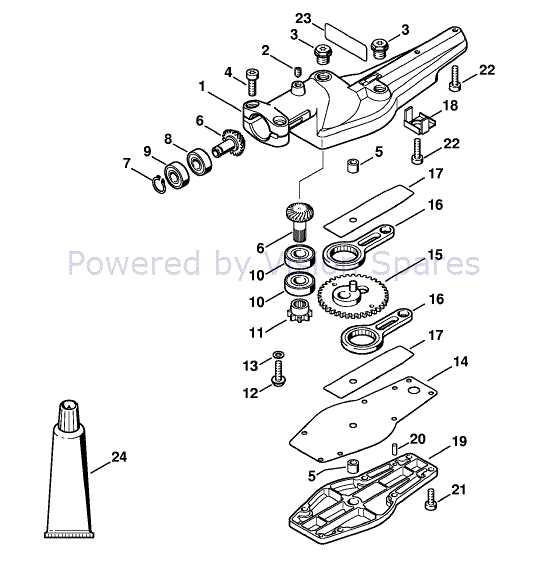

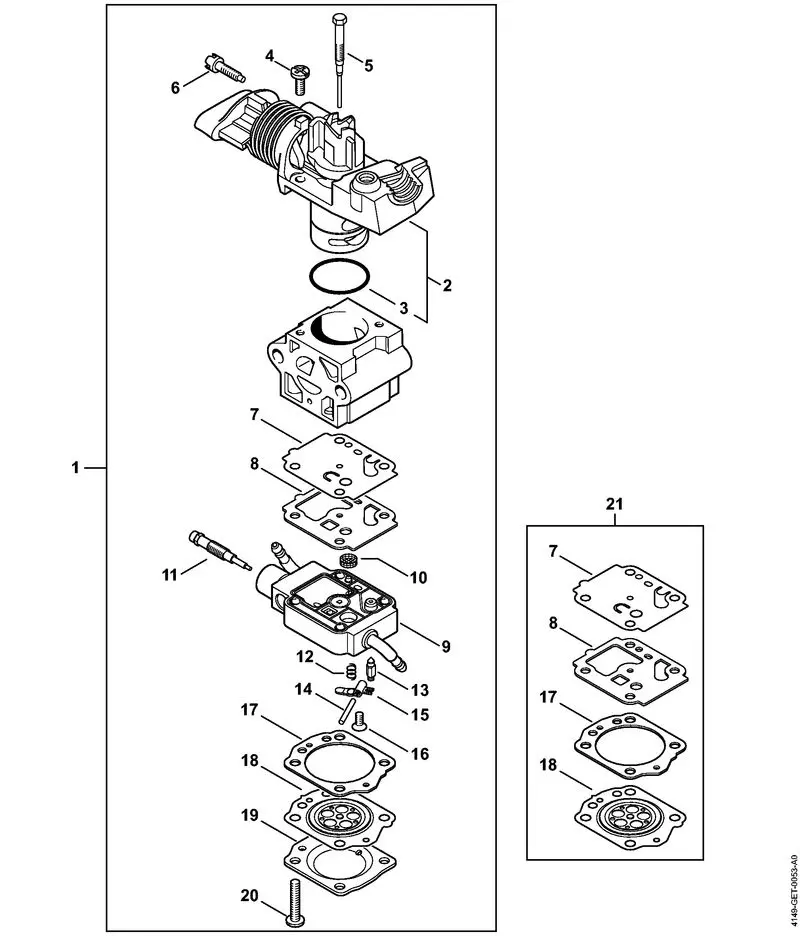

Understanding Parts and Components

Grasping the intricacies of tools and their respective elements is essential for optimal functionality and maintenance. Each component plays a vital role in ensuring the machine operates efficiently. Familiarity with these elements allows users to troubleshoot issues, perform repairs, and carry out regular upkeep more effectively.

Key Elements to Know

- Engine: The powerhouse that drives the entire system.

- Fuel System: Critical for providing the necessary energy.

- Transmission: Connects the engine to the working parts, enabling movement.

- Handle: Provides control and maneuverability for the operator.

- Cutting Mechanism: The part responsible for achieving the desired results.

Importance of Regular Maintenance

- Enhances Longevity: Regular checks can prevent premature wear and tear.

- Ensures Safety: Proper functioning minimizes the risk of accidents.

- Optimizes Performance: Well-maintained tools operate at their best.

- Reduces Repair Costs: Early detection of issues can save on major repairs.

Understanding the various elements and their roles not only aids in efficient operation but also fosters a greater appreciation for the craftsmanship involved in creating these tools.

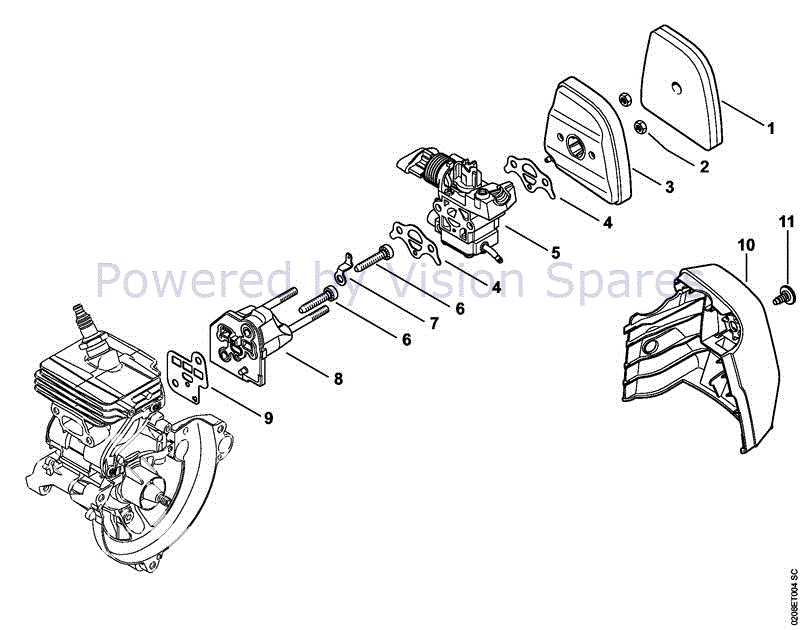

Importance of a Parts Diagram

Understanding the intricate details of machinery is crucial for effective maintenance and repair. A visual representation of components serves as an invaluable resource for users, allowing them to identify and manage the various elements within a device. This clarity not only enhances comprehension but also streamlines the troubleshooting process.

Here are several key reasons why having a visual guide is essential:

- Efficient Repairs: Clear illustrations enable quick identification of faulty components, saving time during repairs.

- Improved Communication: Sharing a visual reference among technicians enhances discussions and ensures everyone is on the same page.

- Enhanced Understanding: A visual aid allows users to familiarize themselves with the layout and function of individual parts, leading to better overall knowledge.

- Accurate Replacements: Knowing the exact configuration assists in selecting the correct replacements, reducing the risk of errors.

- Organized Maintenance: A structured overview helps in scheduling regular upkeep by highlighting critical areas that require attention.

Ultimately, utilizing a visual reference fosters a more efficient and effective approach to managing and maintaining equipment. Whether for personal use or professional applications, this resource is indispensable for anyone involved with machinery.

Common Issues with Stihl HL 91 K

Users often encounter several challenges when operating this versatile tool. Recognizing these common problems can facilitate timely maintenance and enhance performance.

1. Engine Performance Problems

One of the most frequent complaints involves the engine not starting or running inefficiently. Common causes include:

- Fuel quality issues

- Clogged air filters

- Defective spark plugs

2. Cutting Head Issues

Another prevalent concern is related to the cutting head. Users may experience:

- Unusual vibrations

- Difficulty in feeding line

- Excessive wear on the cutting attachments

How to Maintain Your Equipment

Proper upkeep of your tools is essential for ensuring their longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs and replacements in the long run. By adopting a systematic approach to care, you can keep your machinery in excellent working condition.

Start with Regular Cleaning: Keeping your equipment clean is fundamental. After each use, remove dirt, debris, and other contaminants that can accumulate. Use a soft brush or cloth to wipe surfaces, ensuring that all moving parts remain free from obstruction.

Check Fluid Levels: Regularly inspect and replenish fluids as needed. This includes checking oil, fuel, and any other necessary liquids. Maintaining proper levels helps to avoid mechanical issues and ensures that your equipment operates smoothly.

Inspect for Wear and Tear: Periodic checks for signs of damage are crucial. Look for frayed wires, cracked components, or worn-out parts. Addressing these issues early can prevent further damage and maintain the overall integrity of your machinery.

Sharpen Blades and Tools: Keeping cutting tools sharp is vital for efficiency. Dull blades can strain the engine and lead to poor performance. Regular sharpening helps achieve clean cuts and reduces the risk of injury.

Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance schedules and recommendations. Adhering to these guidelines ensures that you perform the correct maintenance tasks at the appropriate intervals.

Store Properly: When not in use, store your equipment in a dry, safe location. Protect it from extreme temperatures and humidity, which can cause deterioration over time. Using covers or cases can provide additional protection.

By implementing these maintenance practices, you can enhance the reliability and lifespan of your tools, ensuring they perform optimally when you need them most.

Where to Find Replacement Parts

Locating the necessary components for maintenance or repair can be essential for keeping your equipment in top condition. Various resources are available to ensure you find the right items to get your tools operating smoothly again.

Authorized Dealers

One of the most reliable sources for acquiring components is through authorized retailers. These establishments typically offer genuine replacements, ensuring compatibility and quality. You can often consult with knowledgeable staff who can assist in identifying the correct items you need.

Online Marketplaces

Numerous online platforms provide a vast selection of components for different tools. When shopping online, it is crucial to verify the seller’s credibility and check for customer reviews to ensure you receive quality goods. Additionally, many websites offer detailed specifications to help you make informed decisions.

Local Repair Shops may also be a valuable resource, as they often have a selection of items on hand and can provide expert advice on what to choose. No matter where you decide to purchase, ensuring you obtain the right components is key to successful maintenance.

Tips for Assembly and Disassembly

When working with outdoor power equipment, understanding the correct methods for putting together and taking apart components is essential for maintaining optimal performance and longevity. This guide provides useful strategies to streamline the process and avoid common pitfalls.

- Organize Your Workspace: Clear your area of clutter. Ensure all tools and components are easily accessible to avoid losing parts during the process.

- Consult the Manual: Always refer to the manufacturer’s guide for specific instructions and diagrams. This ensures you follow the recommended procedures.

- Take Notes: Document each step as you disassemble parts. This will help you remember the order and method for reassembly.

- Use the Right Tools: Employ the appropriate tools for each task. Using incorrect tools can damage components and lead to unnecessary frustration.

During disassembly, follow these practices:

- Work Methodically: Remove components one at a time, keeping track of where each piece belongs.

- Check for Damage: Inspect each part for wear or damage as you disassemble. Replace any faulty items before reassembling.

- Keep Hardware Together: Place screws, bolts, and small parts in labeled containers to prevent misplacement.

For reassembly, consider the following:

- Follow the Reverse Order: Reassemble components in the reverse order of disassembly, ensuring each piece is properly aligned.

- Tighten Gradually: When securing parts, tighten them incrementally to avoid overtightening and damaging the equipment.

- Test Functionality: After reassembly, run a functionality test to ensure everything is working correctly before putting the equipment back into service.