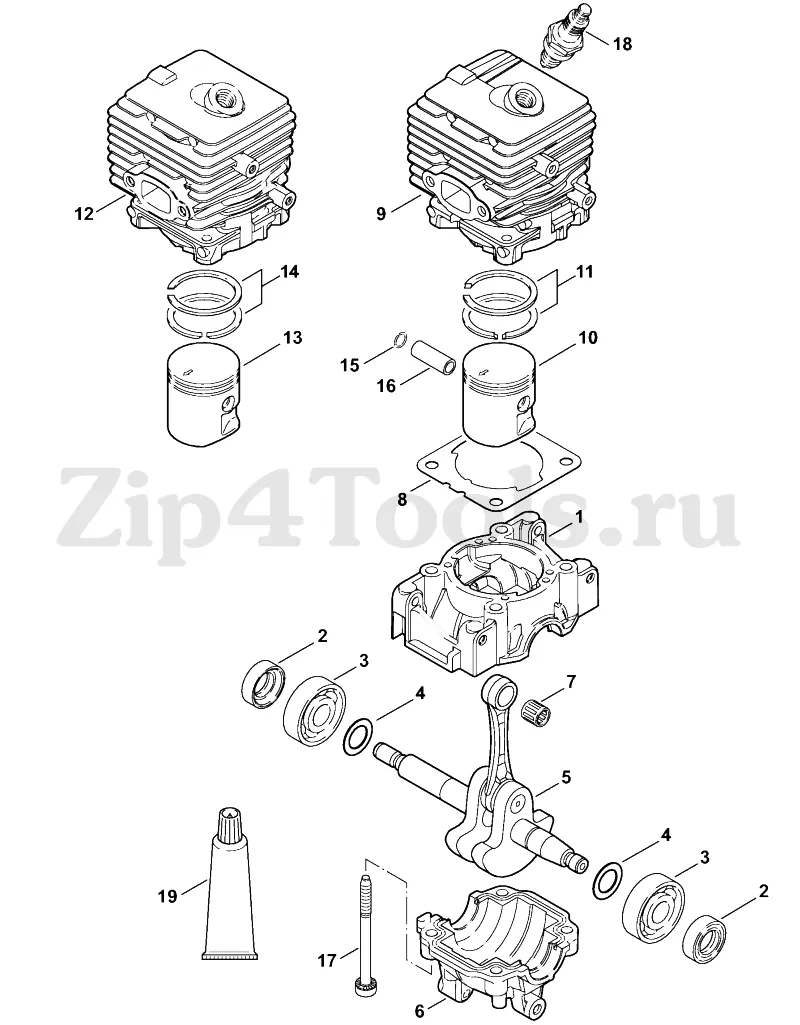

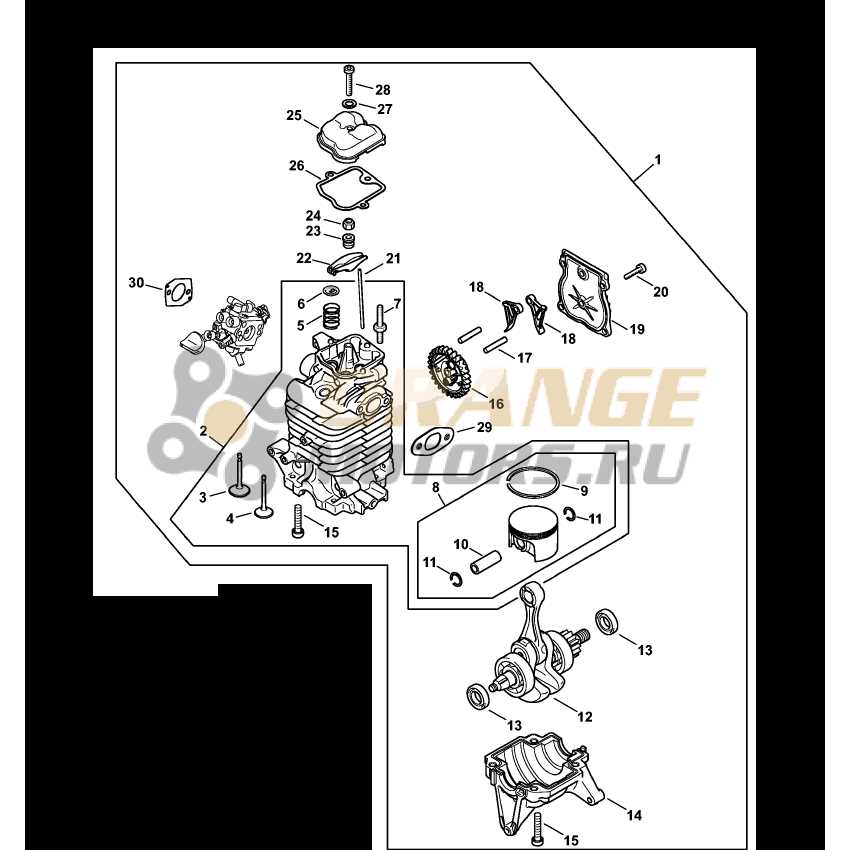

Maintaining specialized outdoor tools requires a deep understanding of their individual elements. Whether enhancing airflow efficiency or ensuring long-term reliability, every small component plays a vital role. This section offers a breakdown of key elements that contribute to the smooth operation of advanced clearing machinery.

With detailed insights, users can better identify essential elements and ensure proper maintenance routines. Such knowledge aids in optimizing performance, avoiding downtime, and prolonging the operational lifespan of the machinery.

Explore how specific internal assemblies fit together to deliver exceptional results, and gain valuable tips for selecting, replacing, or upgrading components as needed. Understanding the synergy between these elements ensures efficient usage and easy troubleshooting in case of wear or malfunction.

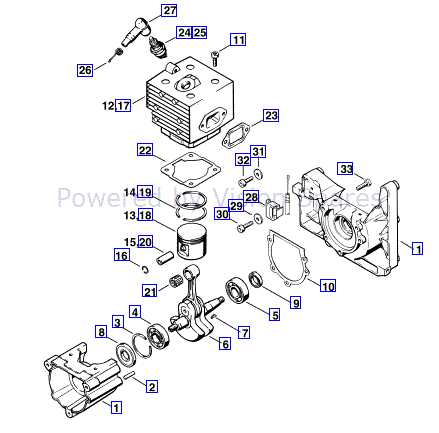

Exploring Components of Backpack Blowers

Back-mounted blowers are designed to provide powerful air output while ensuring user comfort over extended use. These machines rely on a combination of ergonomic features and mechanical elements working together to optimize performance in outdoor tasks. Understanding their structure is key to maintaining efficiency and ensuring longevity.

| Component | Description | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Provides the power needed to generate high-velocity airflow, typically fueled by gasoline or a mixture of oil and gas. | |||||||||||||||||||||

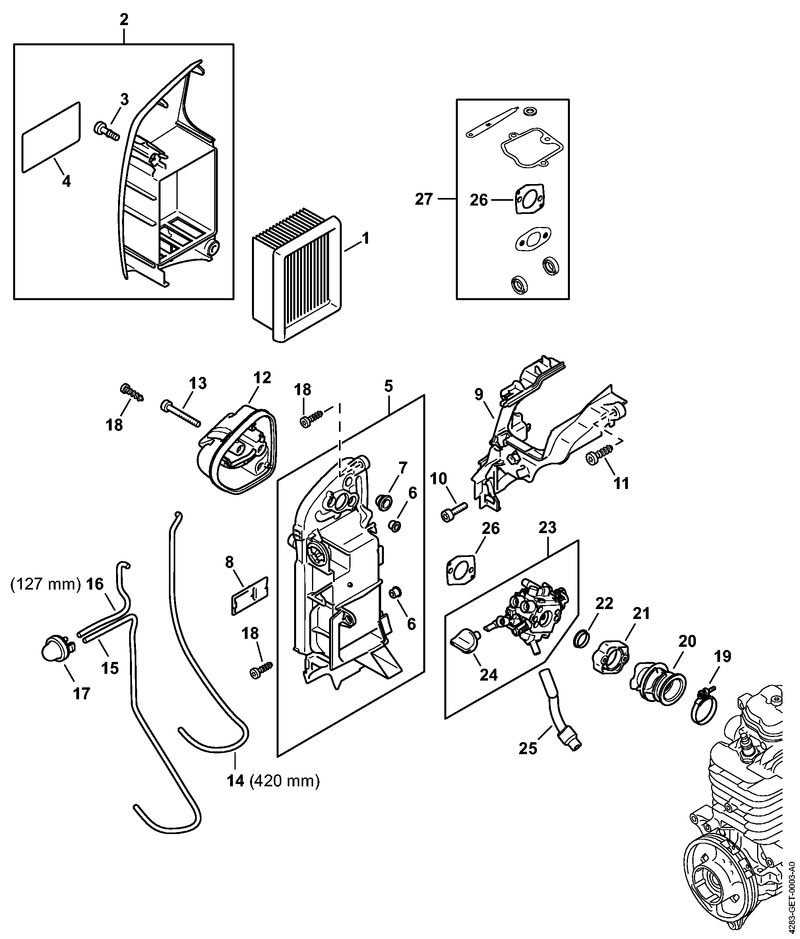

| Air Intake System |

| Component | Description |

|---|---|

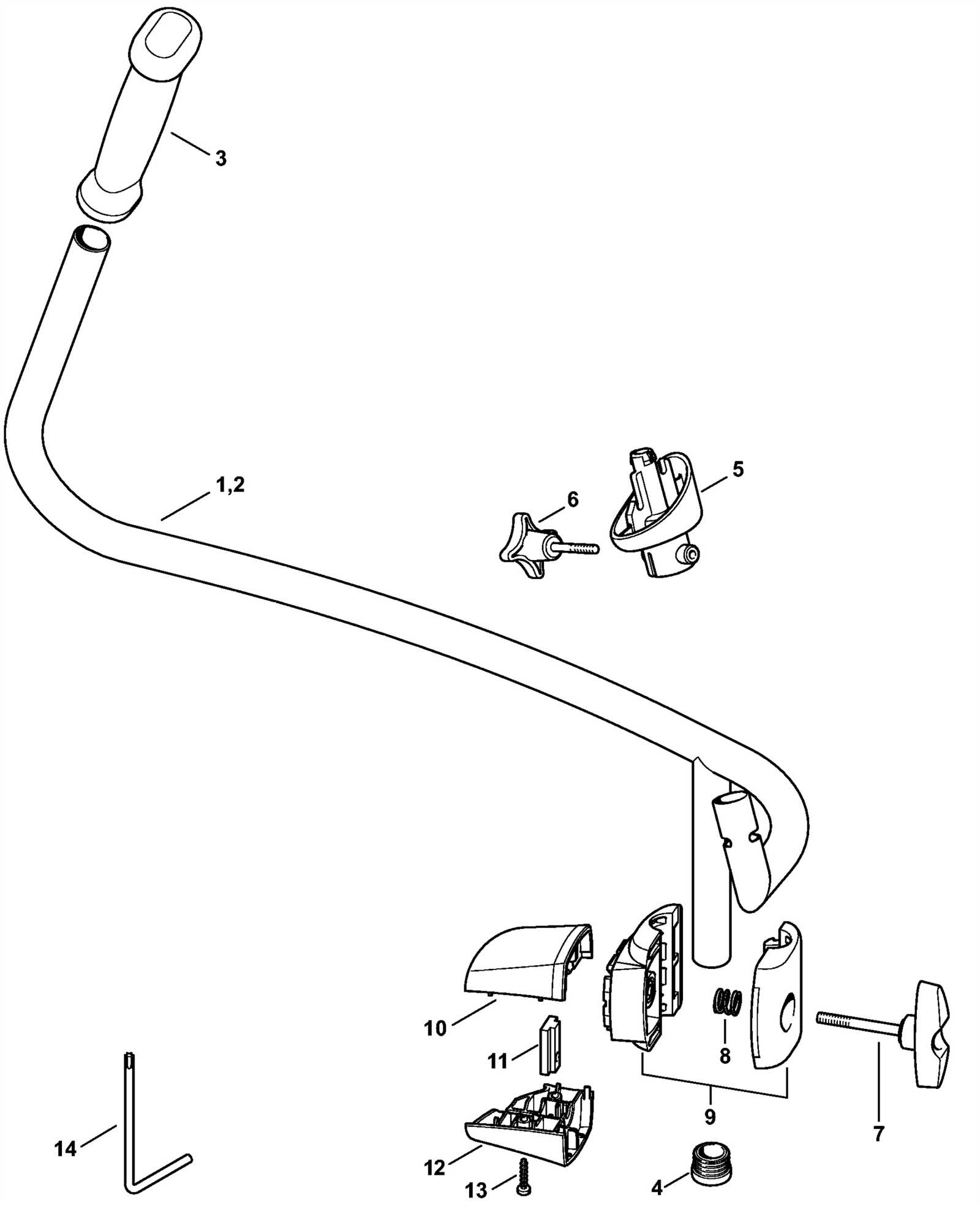

| Throttle Lever | The user-operated mechanism that initiates throttle movement. |

| Cable | A flexible conduit that transmits movement from the throttle lever to the throttle body. |

| Return Spring | Provides resistance to throttle movement, ensuring it returns to a neutral position when released. |

| Throttle Body | The assembly where the throttle plate is located, controlling the airflow into the engine. |

Functionality of the Cable Mechanism

The cable mechanism operates through a system of tension and flexibility, allowing the throttle lever to manipulate the throttle body effectively. When the operator pulls the lever, the cable tightens, opening the throttle plate to increase engine speed. Conversely, releasing the lever allows the return spring to pull the cable back, closing the throttle and reducing power output. This dynamic interplay is essential for achieving the desired performance and responsiveness of the equipment.

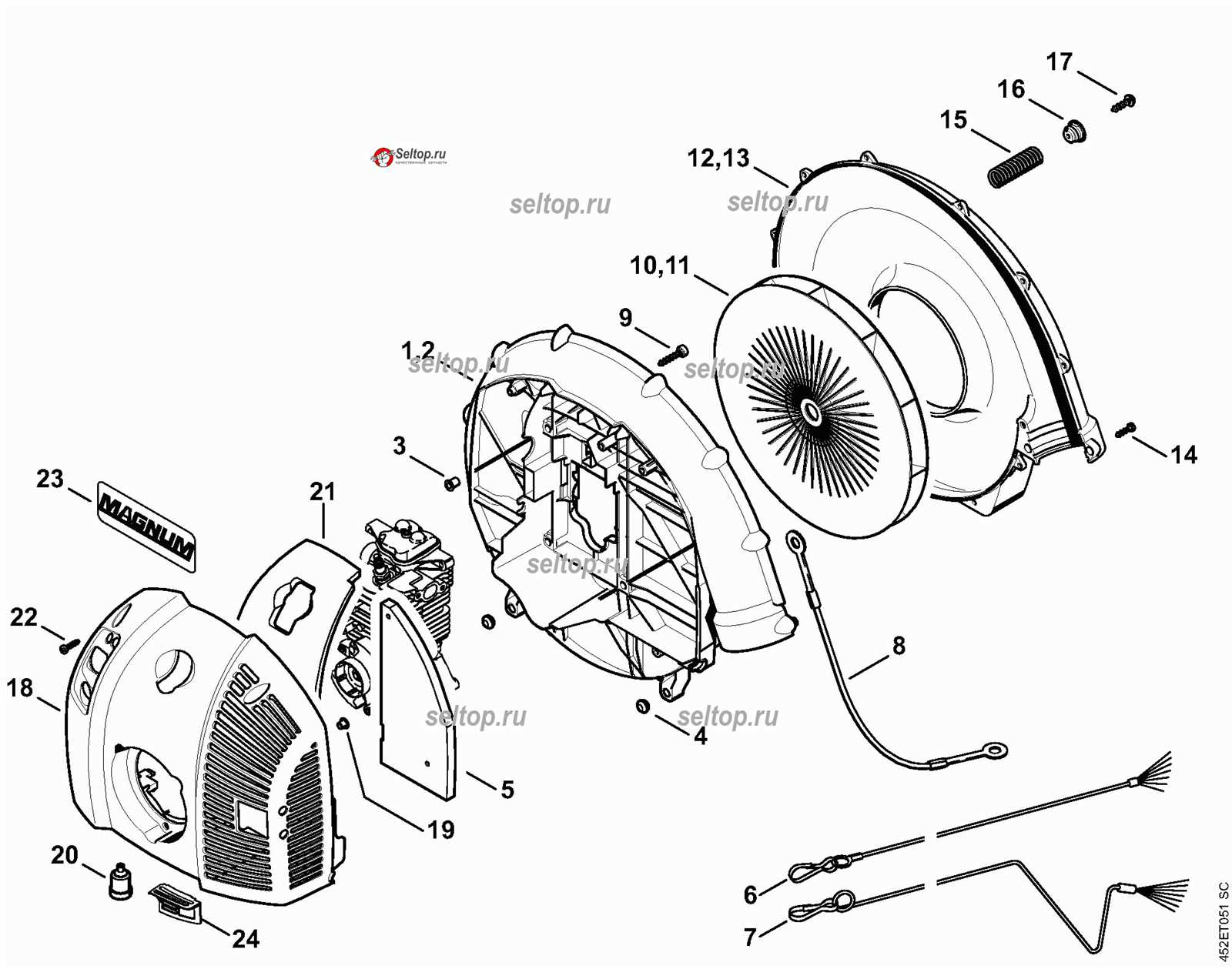

Fan System and Airflow Optimization

The efficiency of any outdoor power equipment heavily relies on its airflow management. An optimized fan system plays a crucial role in ensuring that the engine maintains optimal performance levels. This section explores the significance of effective airflow and how a well-designed fan system contributes to overall operational excellence.

Importance of Effective Airflow

Proper airflow is essential for several reasons:

- Cooling: Adequate air circulation helps in regulating the temperature of the engine, preventing overheating and ensuring longevity.

- Fuel Efficiency: A well-ventilated engine operates more efficiently, enhancing fuel consumption and reducing operational costs.

- Performance: Optimal airflow contributes to improved engine performance, enabling it to operate at its full potential.

Components of the Fan System

The fan system comprises several key components that work together to optimize airflow:

- Fan Blades: Designed to maximize airflow while minimizing resistance.

- Housing: Guides the air towards the engine and prevents turbulence.

- Intake Vents: Allows external air to enter the system efficiently.

- Exhaust Ports: Facilitates the exit of hot air, maintaining a balanced temperature.

In summary, a well-engineered fan system is vital for maintaining optimal performance in outdoor power tools. By prioritizing airflow optimization, users can enhance efficiency, performance, and the overall lifespan of their equipment.

Shoulder Straps and Comfort Enhancements

Ergonomic accessories play a crucial role in improving user experience during prolonged use of outdoor equipment. The incorporation of padded shoulder straps and supportive features significantly reduces strain and enhances overall comfort. This section discusses the importance of these enhancements and how they contribute to user efficiency and well-being.

Benefits of Padded Shoulder Straps

Padded shoulder straps offer numerous advantages that enhance comfort during operation:

- Weight Distribution: Evenly distributes the weight of the equipment across the shoulders, minimizing fatigue.

- Shock Absorption: Soft padding helps absorb shocks from vibrations, reducing stress on the body.

- Improved Stability: Secure fit prevents excessive movement, allowing for better control and precision.

Additional Comfort Features

In addition to padded straps, various comfort features can enhance user experience:

- Adjustable Straps: Allow for personalized fitting to accommodate different body types.

- Breathable Materials: Fabrics that promote airflow help keep the user cool and comfortable during extended use.

- Back Support: Integrated lumbar support reduces strain on the lower back, providing additional comfort.

Repair Tips for Wearable Parts

Maintaining the functionality of components that undergo regular wear is crucial for the longevity of any outdoor power equipment. These parts, often subject to friction, heat, and environmental factors, require attentive care and timely replacement to ensure optimal performance. Understanding the common issues and implementing effective repair strategies can significantly enhance the reliability of your equipment.

Regular inspections play a vital role in identifying signs of wear and tear. Look for cracks, unusual noises, or decreased performance, which can indicate that certain components may need attention. Here are some helpful tips for repairing these essential parts:

| Tip | Description |

|---|---|

| Inspect Regularly | Check components frequently for any signs of damage or degradation to catch issues early. |

| Replace Worn Parts | Swap out any parts that show significant wear to prevent further damage to the equipment. |

| Use Quality Replacements | Always choose high-quality replacement parts to ensure compatibility and longevity. |

| Lubricate Moving Parts | Keep moving components well-lubricated to reduce friction and prolong their lifespan. |

| Follow Manufacturer Guidelines | Adhere to the recommended maintenance schedules and repair protocols provided by the manufacturer. |

Implementing these strategies not only extends the life of your equipment but also enhances its overall efficiency. Regular maintenance and timely repairs ensure that your outdoor power tools remain reliable and effective for all your landscaping needs.