The intricacies of modern machinery often require a detailed examination to fully grasp their functionality. Each component plays a vital role in the overall operation, and understanding these elements can enhance maintenance and repair efforts. This section aims to provide clarity on how to interpret the various sections of intricate mechanisms.

By exploring visual representations of the assembly, one can identify how each piece interacts with others. This knowledge not only aids in troubleshooting but also ensures that replacements are conducted efficiently. Such insights are crucial for anyone looking to deepen their technical expertise.

In this exploration, we will delve into the essential components and their configurations, offering a comprehensive look that simplifies complex structures. Ultimately, this understanding empowers users to engage with their machinery more effectively and confidently.

Understanding the Dxpw3425e Components

In order to fully grasp the functionality of a particular system, it is essential to delve into its individual elements. Each component plays a pivotal role in ensuring optimal performance and reliability. By examining these components closely, one can appreciate the intricate interplay that facilitates the overall operation.

Key elements to consider include:

- Power Supply: This component is crucial for providing the necessary energy for the system’s operation.

- Control Unit: Responsible for managing and directing the actions of other elements, ensuring that processes are executed efficiently.

- Motor Assembly: Vital for movement and functionality, this element converts electrical energy into mechanical action.

- Sensor Array: These devices collect data and feedback, allowing the system to adjust its operations based on external conditions.

- Frame and Housing: Provides structural support and protection for internal components, enhancing durability.

Understanding these key components not only aids in troubleshooting but also enhances the user’s ability to perform maintenance and upgrades effectively. Each part contributes to the seamless interaction that defines the entire mechanism.

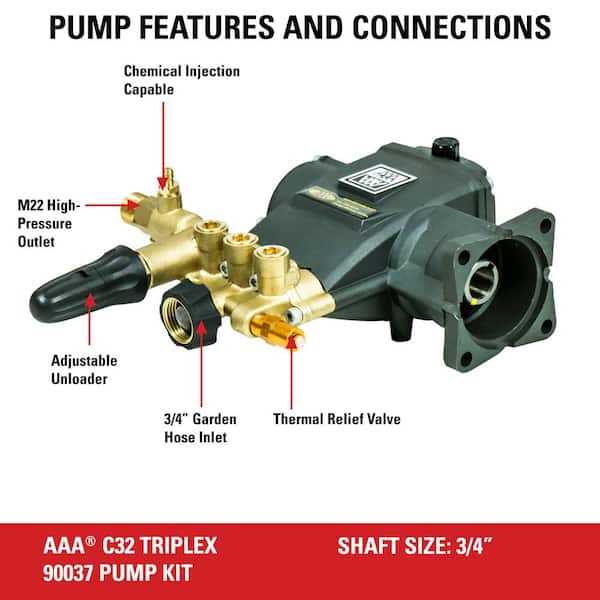

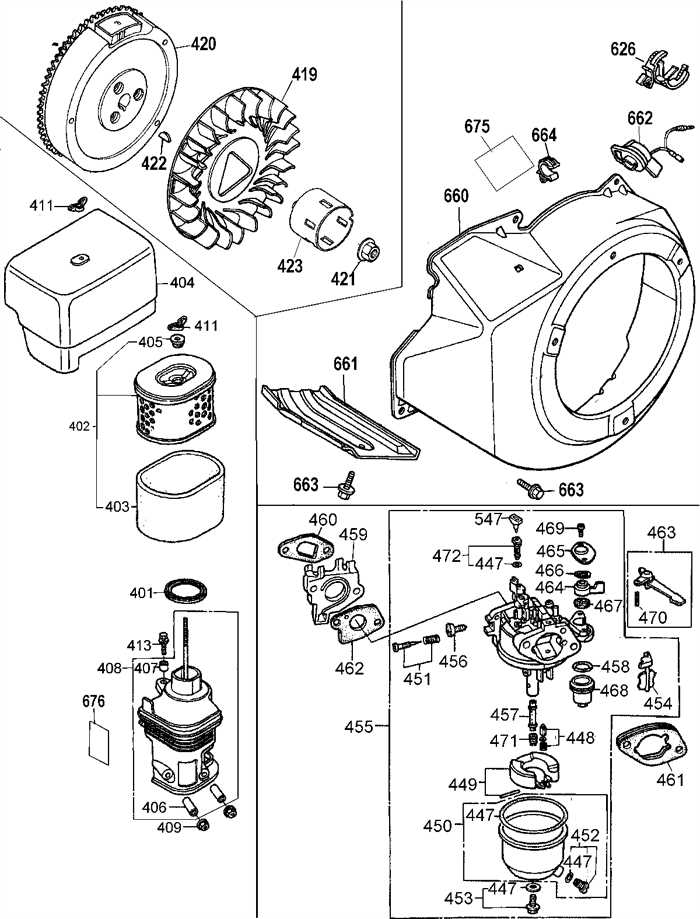

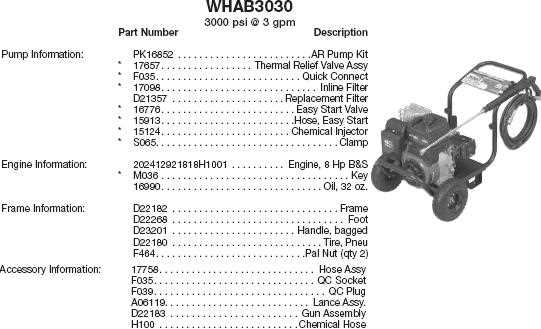

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate assembly and functionality of machinery. These illustrations serve as essential tools for both professionals and enthusiasts, enabling clearer insights into the relationships and arrangements of individual elements. With detailed schematics, users can navigate complex structures with ease, enhancing their ability to perform repairs, maintenance, or upgrades.

Facilitating Repairs and Maintenance

When faced with issues, having access to comprehensive visuals allows technicians to quickly identify faulty components and the surrounding elements that may require attention. This streamlines the repair process, reducing downtime and increasing efficiency. Furthermore, such resources often provide step-by-step guidance, making it easier for less experienced individuals to tackle challenges with confidence.

Enhancing Communication and Collaboration

In collaborative environments, clear visual aids bridge communication gaps among team members. Engineers, designers, and technicians can discuss specific parts more effectively when referring to standardized illustrations. This shared understanding fosters teamwork and ensures that everyone is aligned on objectives, ultimately contributing to more successful project outcomes.

Common Issues with Dxpw3425e

When using high-performance equipment, it’s not uncommon to encounter specific problems that can affect functionality and efficiency. Understanding the typical challenges that might arise can help in diagnosing and addressing these issues promptly. These problems may vary from minor malfunctions to more complex failures, but early identification can prevent costly repairs or extended downtime.

One of the frequent concerns involves improper operation due to power or connectivity issues. In many cases, the power supply may not deliver consistent energy, leading to irregular functioning or complete failure of the unit. Additionally, blockages in the internal components can significantly reduce performance, especially if the device is used under heavy loads or in harsh environments.

Another common issue is wear and tear on mechanical elements, such as moving parts, which can lead to misalignment or malfunction. Over time, friction and stress can cause these components to deteriorate, affecting the overall performance and requiring timely replacements to maintain peak efficiency. Lubrication and routine maintenance can help reduce the likelihood of such wear.

Temperature fluctuations can also have a notable impact on performance. Excessive heat or cold can interfere with the internal systems, leading to overheating or underperformance. Regularly checking the cooling mechanisms and ensuring they are functioning as expected can help mitigate these effects.

Finally, software-related problems, such as outdated firmware or incorrect settings, can also cause operational glitches. Keeping the system software updated and properly configured is essential for avoiding delays and ensuring smooth operation. Regular diagnostics and software checks are recommended to avoid unexpected malfunctions.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective assembly, repair, or maintenance of various machinery and equipment. These visual representations serve as guides, offering insights into the components and their relationships. Mastering the interpretation of these images can greatly enhance your ability to navigate complex systems.

To effectively decode these illustrations, it’s important to familiarize yourself with common symbols, labels, and numbering conventions used within the visual aids. Each element typically corresponds to a specific item, which may include a brief description or reference number for clarity.

| Element | Description |

|---|---|

| Symbols | Represent different components, often standardized for ease of understanding. |

| Numbers | Reference unique items, usually linked to a list for detailed specifications. |

| Lines | Indicate connections or relationships between various components. |

| Shading | Often used to differentiate between types of materials or to indicate specific areas of focus. |

By paying close attention to these elements, you can quickly identify what each part is and how it fits within the overall assembly. Regular practice will enhance your proficiency, making it easier to approach even the most intricate visual guides with confidence.

Finding Replacement Parts Effectively

When it comes to maintaining or repairing machinery, identifying the correct components for replacement is crucial for both functionality and longevity. With a wide variety of options available, navigating the selection process efficiently can save time, money, and effort. Understanding how to source these components with precision is the key to ensuring that your equipment remains in optimal condition.

One of the most effective methods is to start by consulting the manufacturer’s documentation or reference guides. These resources often provide detailed specifications, making it easier to find the right match. Additionally, ensuring compatibility between the existing parts and the replacements is vital to avoid potential malfunctions or mismatches in size and design.

Another valuable approach is to utilize trusted online platforms that specialize in these components. These platforms typically offer search filters based on model, part number, or category, streamlining the selection process. However, verifying the authenticity of the source and the quality of the items is essential to avoid counterfeit or subpar replacements.

In some cases, consulting with professionals or experts in the field can also help in making informed decisions. They can offer advice based on experience and ensure that the selected replacements meet the performance standards required for your specific needs.

Maintenance Tips for Longevity

To ensure that your equipment continues to perform at its best over time, regular maintenance is essential. Proper care not only enhances efficiency but also extends the overall lifespan of the machine, preventing costly repairs and downtime. Adopting a proactive maintenance routine can help you avoid unnecessary issues and keep your system running smoothly for years to come.

Regular Inspection

Conducting periodic inspections is crucial to identifying wear and tear early. Pay attention to any unusual sounds, vibrations, or performance inconsistencies. A thorough check of all essential components allows you to detect potential issues before they become significant problems. Regularly clean and lubricate moving parts to reduce friction and minimize the risk of breakdowns.

Follow Manufacturer Guidelines

Always adhere to the manufacturer’s recommended maintenance schedule. These guidelines are designed to optimize the performance and longevity of your equipment. Ensure that all necessary adjustments and replacements are made on time. Using genuine components and recommended fluids will help maintain the integrity of your machine.

Routine maintenance not only prevents sudden failures but also ensures optimal performance under various conditions. By staying on top of essential tasks, you can protect your investment and reduce the need for expensive repairs.

Assembly Instructions for Components

When assembling complex machinery or equipment, following precise instructions ensures that all components fit together properly and function as intended. A step-by-step approach is crucial for maintaining efficiency, safety, and the overall performance of the final product. Understanding the proper placement, orientation, and connection of each individual piece is essential to avoid errors and ensure a smooth assembly process.

Step 1: Prepare All Components

Before starting the assembly, make sure all the necessary parts are available and organized. Check that each item is undamaged and matches the specifications required for the project. Having everything laid out in front of you will help you follow the instructions easily and prevent mistakes during the process.

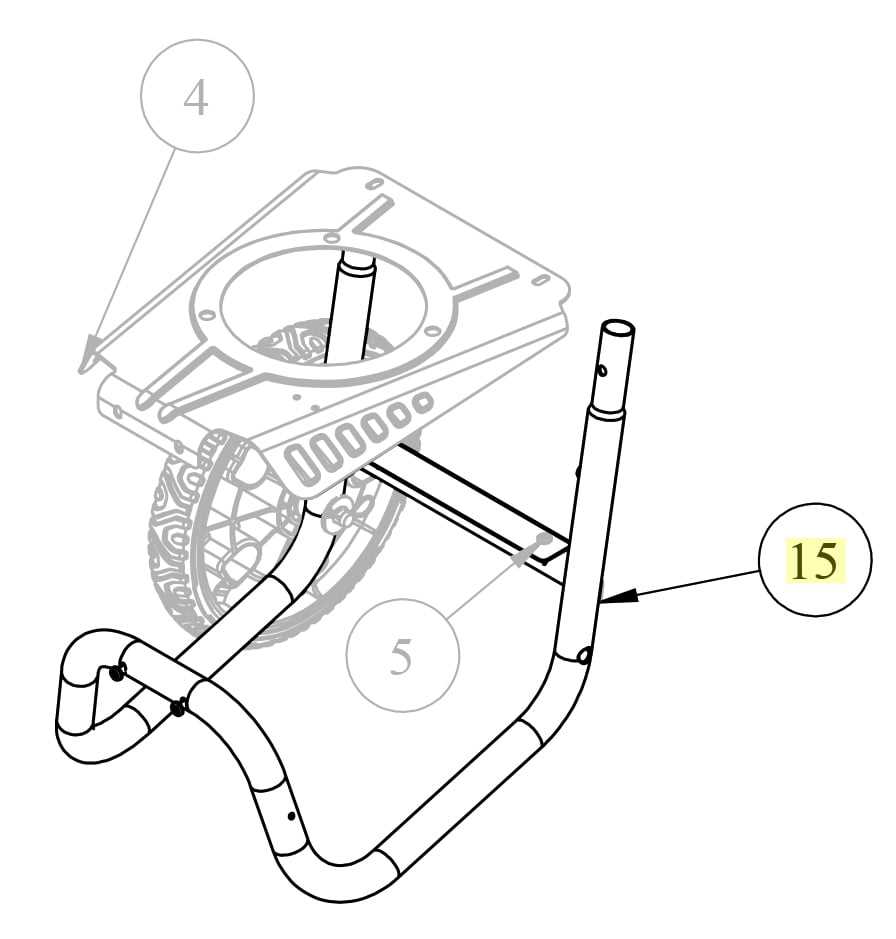

Step 2: Begin with the Base Structure

The initial focus should be on assembling the core or main framework. This often involves securing larger elements that will serve as the foundation for additional components. Ensure that all connections are tight and that the structure is level and stable before moving on to smaller parts.

Step 3: Attach Supporting Components

After establishing the primary structure, proceed with the attachment of auxiliary elements. These parts are typically smaller and might require special tools or fasteners. It is important to follow the sequence outlined in the instructions to ensure that these components are placed in the correct order and are properly secured.

Step 4: Install Functional Parts

Next, install the functional components that contribute to the operation of the system. These might include mechanisms, connectors, or electrical elements. Double-check the alignment of each part to avoid misplacement and ensure smooth operation once everything is connected.

Step 5: Final Adjustments

After assembling all components, conduct a thorough inspection. Tighten any loose fasteners, verify that moving parts operate smoothly, and check the integrity of all connections. If necessary, make small adjustments to ensure optimal performance. It is also recommended to test the assembly under conditions similar to normal operation before finalizing the process.

Resources for Further Information

For those seeking to enhance their understanding of complex machinery and components, a variety of resources are available. These can provide in-depth knowledge, troubleshooting tips, and insights into maintenance practices.

- Manufacturer Websites: Often the best source for detailed specifications and user manuals.

- Technical Forums: Online communities where enthusiasts and experts share experiences and solutions.

- Instructional Videos: Platforms like YouTube host countless tutorials that visually guide users through various processes.

- Books and Guides: Comprehensive texts that cover a wide range of topics related to machinery and components.

- Online Courses: Websites offering structured learning on machinery operation and repair.

Utilizing these resources can significantly improve one’s expertise and confidence in handling related subjects effectively.

Frequently Asked Questions

This section provides answers to common inquiries regarding the maintenance and repair of machinery components. Whether you’re seeking guidance on identifying specific parts, understanding assembly, or troubleshooting issues, you’ll find useful insights here to assist in your process.

1. How do I identify the correct components for my machine?

Start by referring to the machine’s manual, which typically includes a comprehensive list of components and their specifications. Additionally, consult online resources or the manufacturer’s website for detailed descriptions and images.

2. What should I do if a part is damaged or broken?

If you encounter a damaged component, it’s crucial to inspect the extent of the damage. If the part is replaceable, ensure you source a high-quality replacement. Always follow the recommended guidelines for installation and check for compatibility with your model.

3. Where can I purchase replacement parts?

Replacement parts can be found through official distributors, online stores, or specialized repair centers. Make sure to verify that the parts are genuine and meet the manufacturer’s standards to avoid issues down the line.

4. How do I properly assemble the different parts?

Assembly typically follows a step-by-step guide provided in the instruction manual. Ensure you have all the necessary tools and double-check that each component is correctly aligned before securing it in place.

5. Can I perform repairs myself, or should I hire a professional?

If you’re confident in your technical skills and have the proper tools, minor repairs can be done independently. However, for complex issues or if you’re unsure, it’s recommended to consult a professional technician to ensure safety and proper functioning.