The realm of performance enhancements in modern engines often revolves around the utilization of advanced mechanisms designed to increase air intake and boost efficiency. These systems play a crucial role in enhancing engine power output while maintaining optimal fuel economy. A thorough comprehension of these mechanisms is essential for enthusiasts and professionals alike, facilitating better maintenance and performance tuning.

In this section, we will explore the various elements that constitute these high-performance systems. By breaking down the functions and interconnections of each component, we aim to provide a clear and concise understanding of how they work together to enhance engine performance. Whether for personal knowledge or practical application, gaining insight into these systems is invaluable.

From the intricate assemblies that compress air to the innovative designs that ensure effective heat management, every element contributes to the overall functionality of the system. As we delve into the specifics, you will discover how these components interact and their significance in achieving superior engine performance.

Understanding Turbocharger Components

The efficiency of modern engines can be significantly enhanced through the utilization of various mechanisms designed to optimize performance. One such mechanism involves a sophisticated assembly that utilizes pressure differentials to increase air intake. A deeper comprehension of the elements involved in this system is essential for understanding its operation and benefits.

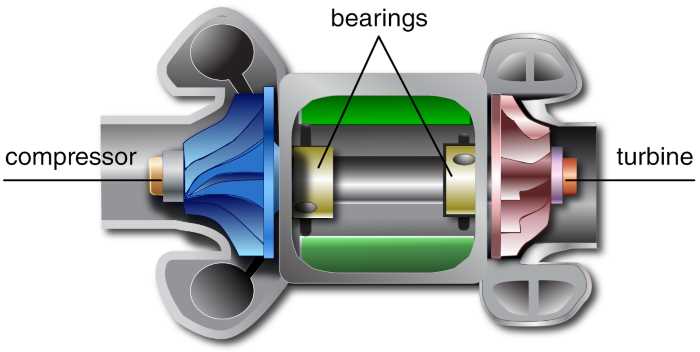

At the heart of this assembly lies a central component that compresses incoming air, allowing for a greater volume to enter the combustion chamber. This process results in improved power output and efficiency. Surrounding this central unit are various accessories that play crucial roles, such as the exhaust housing, which facilitates the expulsion of gases, and the compressor housing, responsible for directing the compressed air into the engine.

Additionally, an essential feature of this system is the wastegate, a control device that regulates the flow of exhaust gases, ensuring optimal pressure levels are maintained. Another critical component is the intercooler, which cools the compressed air before it enters the combustion chamber, enhancing density and efficiency. Understanding the interaction between these elements is vital for optimizing performance and maintaining the longevity of the system.

In conclusion, grasping the function and significance of each element within this assembly is crucial for anyone looking to improve engine performance or engage in maintenance activities. A well-maintained and correctly configured system can lead to substantial gains in both power and efficiency.

How Turbochargers Function in Engines

Supercharging mechanisms play a crucial role in enhancing engine performance by increasing airflow. They utilize exhaust gases to compress the intake air, leading to more efficient combustion. This process allows for greater power output without significantly increasing the engine size or weight.

The operation of these mechanisms can be summarized in several key stages:

| Stage | Description |

|---|---|

| Exhaust Flow | Exhaust gases exit the combustion chamber, flowing into the supercharging unit. |

| Compressor Action | The energy from the exhaust spins a turbine connected to a compressor, drawing in fresh air. |

| Air Compression | The compressor increases the air’s pressure and density before it enters the engine’s cylinders. |

| Enhanced Combustion | The denser air mixture allows for more fuel to be burned, resulting in increased power output. |

This process not only boosts the engine’s power but also improves its efficiency. By harnessing waste gases, it contributes to a more sustainable operation while maintaining high performance levels.

Key Parts of a Turbo System

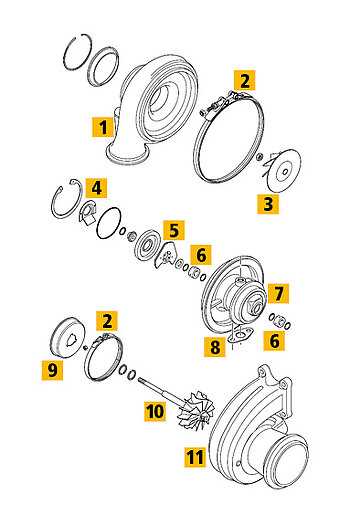

Understanding the fundamental components of a forced induction system is essential for enhancing engine performance. Each element plays a crucial role in ensuring optimal functionality, contributing to the overall efficiency and power output. This section explores the essential elements that comprise this complex assembly.

Essential Components

The following table outlines the primary components involved in the forced induction setup, highlighting their functions and significance:

| Component | Function |

|---|---|

| Compressor | Increases the intake air pressure, improving engine efficiency. |

| Turbine | Converts exhaust gases into mechanical energy to drive the compressor. |

| Wastegate | Regulates the exhaust flow to control boost pressure and prevent overboosting. |

| Intercooler | Reduces the temperature of the compressed air, increasing density and performance. |

| Blow-off Valve | Releases excess pressure in the intake system when the throttle is closed, preventing compressor surge. |

Conclusion

Each element within this assembly works in harmony to enhance engine performance, enabling vehicles to achieve greater power and efficiency. A thorough understanding of these components is vital for effective tuning and maintenance of high-performance engines.

Common Issues with Turbo Parts

Components that enhance engine performance can encounter various challenges that affect their functionality. Understanding these common problems is crucial for maintaining optimal performance and ensuring the longevity of the system.

One frequent issue is inadequate lubrication, which can lead to increased friction and premature wear. Insufficient oil supply can stem from clogged filters or leaks in the lubrication system. Regular maintenance and timely oil changes can help mitigate this risk.

Another concern is overheating, often caused by excessive boost pressure or inefficient cooling. When temperatures rise beyond acceptable limits, it can result in damage to the internal components. Ensuring proper cooling systems and monitoring operating temperatures are essential to prevent this issue.

Boost leaks also present a common problem, where pressurized air escapes due to faulty connections or damaged hoses. This can lead to a decrease in performance and engine efficiency. Regular inspection of all connections and hoses can help identify and rectify leaks promptly.

Lastly, the buildup of carbon deposits can impede airflow and reduce overall efficiency. This accumulation often occurs in the intake manifold and can be addressed through periodic cleaning. Maintaining a clean system is vital for optimal performance and longevity.

Importance of Turbocharger Maintenance

Proper upkeep of forced induction systems is crucial for optimal performance and longevity. These components play a significant role in enhancing engine efficiency, and neglecting their care can lead to diminished functionality, reduced power output, and costly repairs. Regular inspections and maintenance practices are essential to ensure these systems operate smoothly and reliably.

Maintaining these systems not only improves their lifespan but also enhances overall vehicle performance. A well-maintained system can lead to better fuel efficiency and increased horsepower, making it a vital aspect for enthusiasts and daily drivers alike. Understanding the importance of upkeep helps prevent issues that could disrupt normal operation.

| Maintenance Activity | Description | Frequency |

|---|---|---|

| Inspection | Regular visual checks for signs of wear or damage. | Every 5,000 miles |

| Oil Change | Changing oil to ensure proper lubrication and reduce wear. | Every 7,500 miles |

| Clean Air Filter | Ensuring the air intake system is clear for optimal airflow. | Every 10,000 miles |

| Check Boost Pressure | Monitoring the system’s boost levels for proper operation. | Every service interval |

Upgrading Turbo Parts for Performance

Enhancing the components of a forced induction system can significantly elevate engine efficiency and responsiveness. By focusing on specific elements within the setup, enthusiasts can achieve noticeable improvements in power output and overall vehicle performance. This section explores key areas to consider when looking to upgrade these crucial components.

Key Components for Enhancement

When seeking to optimize the efficiency of the system, several elements come into play. Key upgrades include the compressor, intercooler, exhaust manifold, and wastegate. Each of these components contributes to the overall performance, allowing for improved airflow, reduced temperatures, and enhanced boost control.

Comparison of Upgrade Options

| Component | Stock Performance | Upgraded Performance |

|---|---|---|

| Compressor | Limited airflow | Increased airflow capacity |

| Intercooler | Higher intake temperatures | Lower intake temperatures |

| Exhaust Manifold | Restrictive flow | Improved exhaust flow |

| Wastegate | Inaccurate boost control | Precise boost management |

By carefully selecting and upgrading these components, individuals can achieve remarkable gains in vehicle performance, leading to a more exhilarating driving experience.

Differences Between Turbo Types

Understanding the distinctions among various forced induction systems is essential for optimizing engine performance and efficiency. Each variation possesses unique characteristics that influence functionality, responsiveness, and application suitability. This section explores the primary types of these systems and highlights their individual advantages and drawbacks.

-

Sequential System:

This configuration utilizes two or more compressors that activate at different engine speeds, enhancing responsiveness and power across a broader RPM range.

-

Single Compressor System:

Featuring one compressor, this type is simpler and often lighter. It is ideal for applications where weight and complexity must be minimized.

-

Variable Geometry System:

This design allows for adjustable vanes that modify the airflow path, providing improved efficiency at varying engine speeds and conditions.

-

Electric Boost System:

Using electric motors, this type can provide immediate boost, reducing turbo lag significantly. It is often found in modern hybrid or electric vehicles.

Each system serves distinct purposes and is suited for different driving experiences. Selecting the appropriate type depends on factors like vehicle application, desired performance characteristics, and personal preferences.

Choosing the Right Turbocharger for Your Vehicle

Selecting the ideal forced induction system for your automobile is crucial for enhancing its performance. Various factors influence this decision, including engine specifications, intended use, and compatibility with existing components. Understanding these elements ensures you make an informed choice that meets your vehicle’s requirements and your personal preferences.

Consider Engine Specifications

Your engine’s characteristics, such as displacement, power output, and fuel type, play a significant role in determining the most suitable forced induction system. It’s essential to match the system’s capabilities with your engine’s specifications to achieve optimal performance and reliability. Consulting your vehicle’s manual or an expert can help clarify these details.

Evaluate Intended Use

The purpose for which you plan to use your vehicle should guide your selection. If you require increased power for racing, a high-performance system may be necessary. Conversely, for everyday driving, a more moderate option might suffice. Consider factors such as driving conditions and your performance goals when making your choice.