When it comes to enhancing the quality of land for various agricultural and landscaping purposes, the intricate machinery designed for ground preparation plays a crucial role. Each element of this equipment contributes to its efficiency and effectiveness, allowing for optimal soil management.

In this section, we will explore the essential components that make up these machines, providing a comprehensive view of how each part functions within the system. By delving into the intricacies of these mechanisms, users can gain a deeper appreciation for their ultimate impact on land improvement.

Understanding the layout and functionality of each segment is vital for maintenance and operational success. With a clear grasp of these components, operators can ensure longevity and peak performance of their equipment.

Understanding Bobcat Soil Conditioners

This section delves into the essential aspects of ground preparation tools, highlighting their significance in various landscaping and agricultural projects. By examining their functionality, components, and advantages, users can make informed decisions for effective earth manipulation.

Key Features of Ground Preparation Tools

- Versatility: These implements are designed for a variety of tasks, including leveling, grading, and mixing materials.

- Durability: Constructed with robust materials, they are built to withstand challenging working conditions.

- Efficiency: Optimized for performance, these devices can significantly reduce manual labor and time spent on projects.

Components and Their Functions

- Cutting Edges: These are responsible for slicing through compacted surfaces, allowing for easier manipulation of the ground.

- Drum Mechanism: The rotating drum aids in mixing and aerating the material, ensuring an even texture.

- Mounting Frame: This component provides stability and ensures compatibility with various machinery.

By understanding the characteristics and components of these ground management tools, users can enhance their operational efficiency and achieve superior results in their projects.

Key Components of Soil Conditioners

Understanding the essential elements that contribute to the effectiveness of ground enhancers is crucial for optimizing their performance. These components work in synergy to improve the texture and quality of the earth, making it more suitable for various agricultural and landscaping applications.

1. Tines: These sharp, protruding elements penetrate the ground, breaking up compacted layers and promoting better aeration. Their design and arrangement can significantly impact the effectiveness of the overall machinery.

2. Roller: This heavy cylindrical part helps to level the surface after the earth has been treated. By pressing down the ground, it creates a smooth, even finish that is essential for planting and seeding.

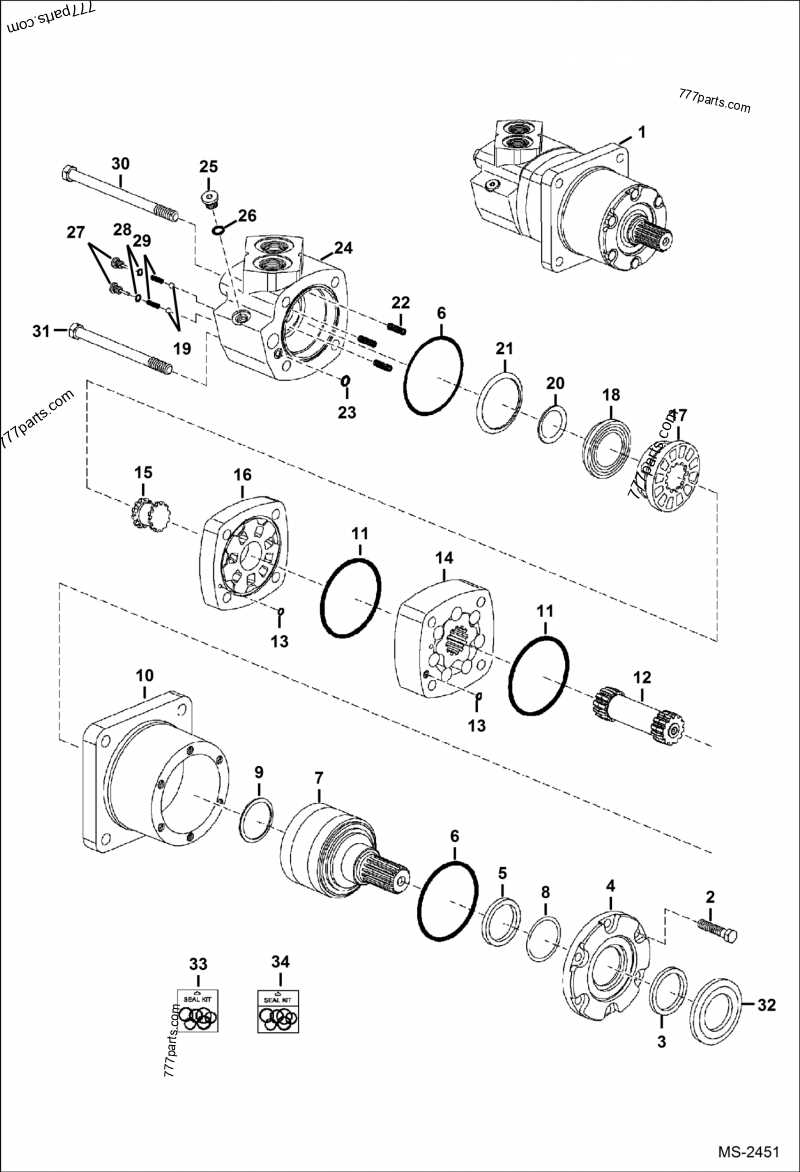

3. Hydraulic System: This system allows for the adjustment of various components, providing the operator with the ability to customize depth and intensity based on the specific needs of the terrain. It ensures efficient and effective operation.

4. Frame: The robust structure that houses all the essential elements. A well-designed frame provides stability and support, enabling the machine to withstand rigorous use while maintaining its functionality.

5. Drive Mechanism: This component powers the movement of the device, whether through wheels or tracks. Its efficiency directly influences the speed and effectiveness of the ground preparation process.

Each of these components plays a pivotal role in the overall effectiveness of ground enhancers, making them indispensable tools in agricultural and landscaping endeavors.

Benefits of Using Bobcat Equipment

Utilizing high-quality machinery can significantly enhance productivity and efficiency in various projects. This specialized equipment is designed to tackle a range of tasks, offering unique advantages that make it a preferred choice for professionals in the industry.

Enhanced Performance

One of the primary benefits is the exceptional performance that these machines deliver. Their powerful engines and advanced technology ensure:

- Higher lifting capacity

- Improved speed and maneuverability

- Consistency in challenging environments

Versatility and Adaptability

The adaptability of this equipment is another key feature. It can be used for numerous applications, including:

- Landscaping and excavation

- Material handling and transportation

- Construction and demolition tasks

This versatility allows users to switch between tasks easily, making it an invaluable asset for various industries.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By implementing effective maintenance practices, you can prolong the lifespan of your machinery and enhance its performance. Here are some essential tips to keep in mind.

Regular Inspections

Conducting frequent checks on your equipment helps identify potential issues before they escalate. Focus on the following areas:

- Hydraulic systems: Look for leaks and check fluid levels.

- Mechanical components: Inspect for wear and tear, especially on moving parts.

- Electrical systems: Ensure connections are secure and wires are intact.

Proper Cleaning

Keeping your machinery clean is vital for optimal functioning. Make it a habit to:

- Remove debris and dirt after each use to prevent buildup.

- Use appropriate cleaning agents that won’t damage surfaces.

- Inspect filters regularly and replace them as needed.

By following these guidelines, you can help maintain your equipment in peak condition, reducing the risk of unexpected failures and costly repairs.

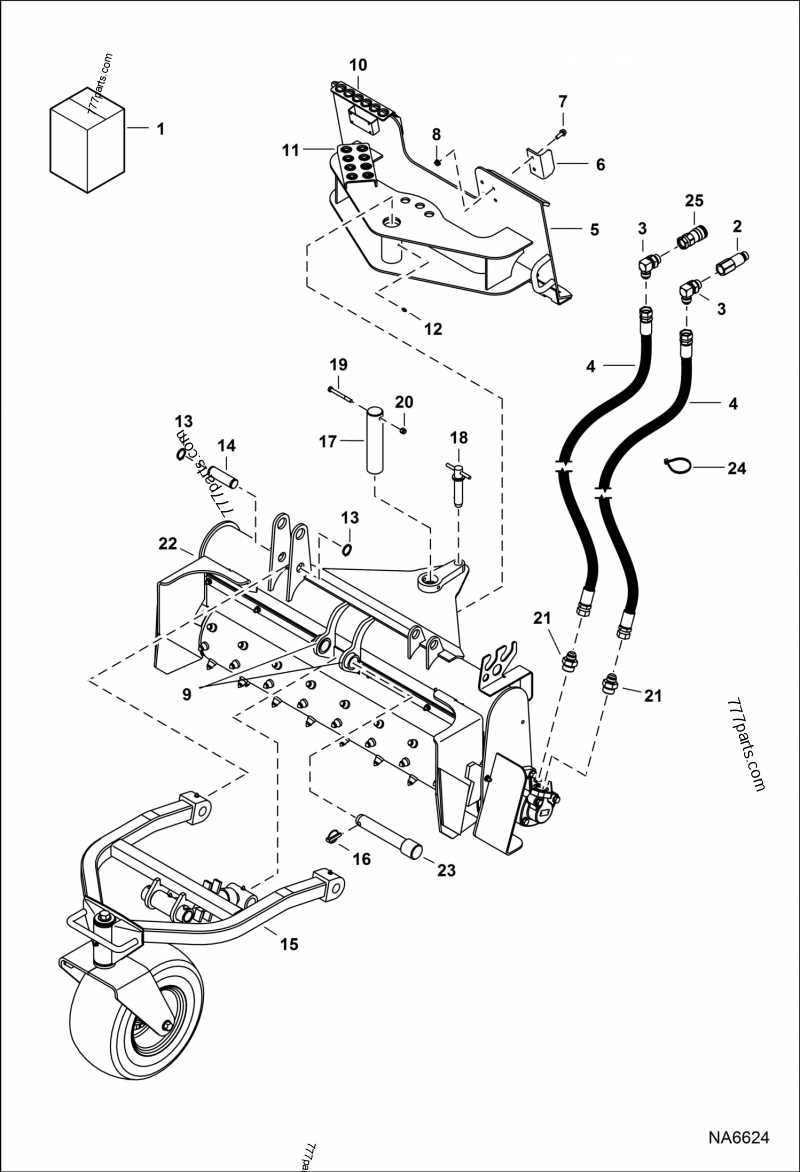

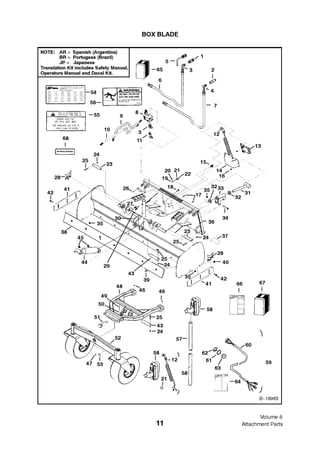

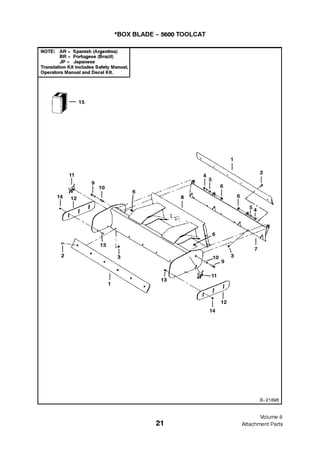

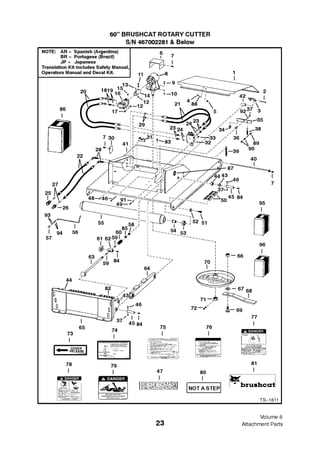

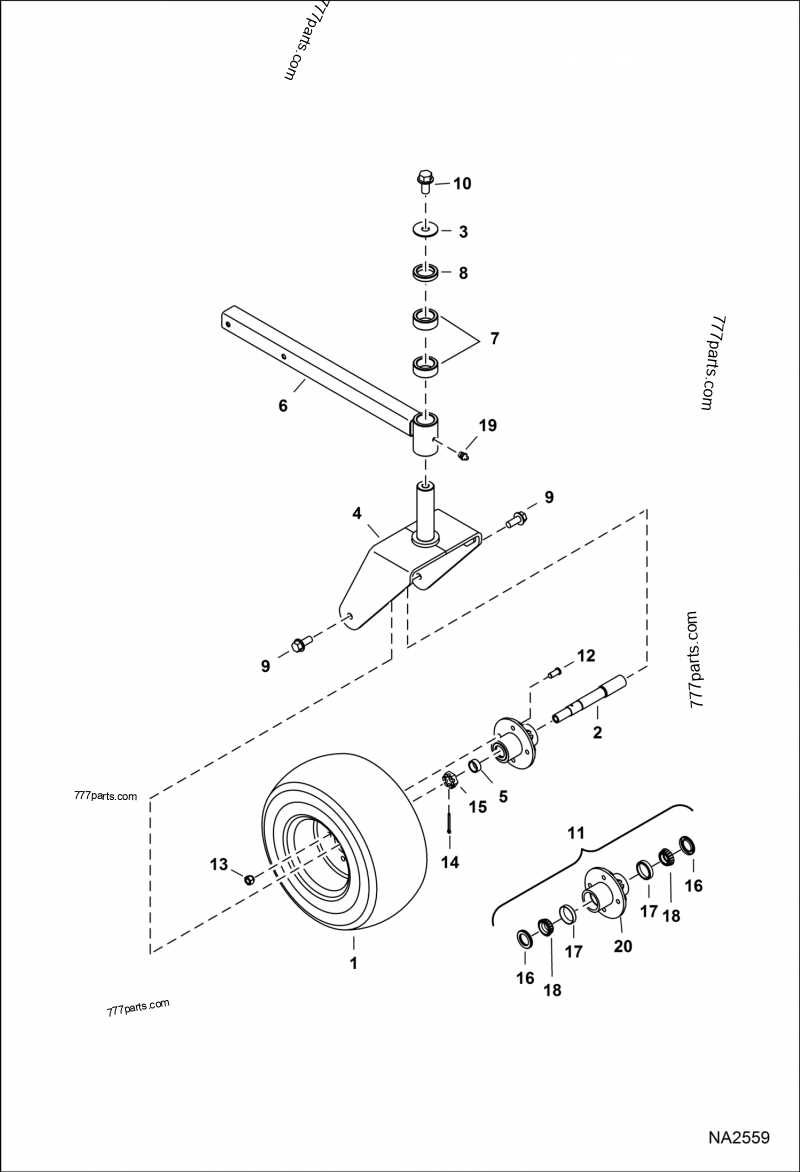

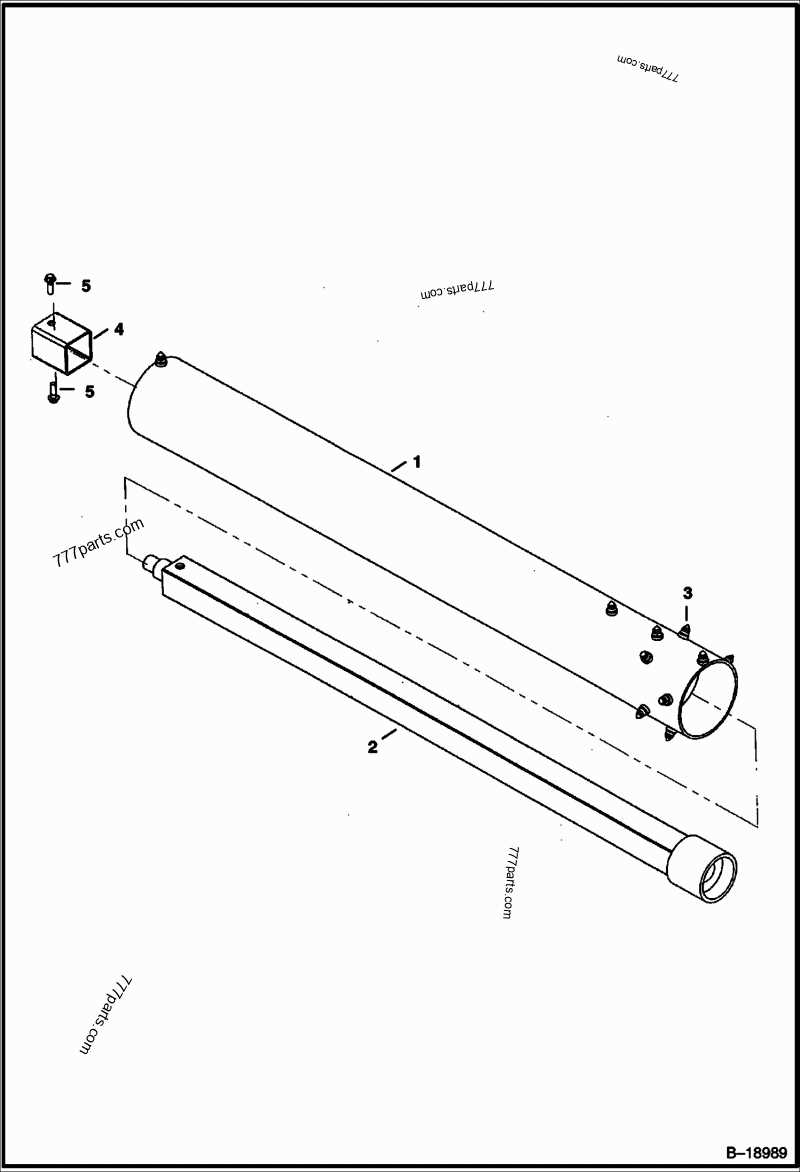

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide a structured overview, helping users identify each element and its relationship to the whole assembly. By grasping the layout and notation, you can streamline the troubleshooting process and ensure accurate replacements.

Begin by familiarizing yourself with the legend or key, which explains the symbols and notations used throughout the illustration. This will clarify any unfamiliar terms or icons. Next, observe the arrangement of items; often, they are displayed in a logical sequence that reflects their assembly order. Pay attention to numbers or letters that may correspond to a list of components, which usually details specifications or quantities.

When analyzing the layout, look for connections between parts, as this can reveal how components interact with one another. Understanding these relationships is crucial for efficient disassembly or installation. Take note of any specific instructions or warnings that may be indicated, as they are vital for safe and proper handling.

Lastly, if available, refer to the accompanying documentation for further context. This additional information can provide insights into compatibility and performance, ensuring that you have all necessary details for successful maintenance tasks. By mastering the interpretation of these visual guides, you can enhance your overall efficiency and effectiveness in handling equipment.

Common Issues and Troubleshooting

Understanding potential problems and their solutions is essential for maintaining optimal performance of your equipment. Whether you are dealing with inefficiencies or mechanical failures, knowing the common issues can help you diagnose and address them effectively.

1. Uneven Performance: If the machinery is not operating uniformly, check for blockages or wear on the components. Inspect the cutting blades or working tools for signs of damage, as these can significantly impact functionality.

2. Overheating: Excessive heat can lead to performance issues and even permanent damage. Ensure that the cooling system is functioning properly and clean any debris that may be obstructing airflow.

3. Hydraulic Problems: Fluid leaks or inadequate pressure can hinder operation. Regularly examine the hydraulic lines and connections for any signs of wear or leakage, and maintain the correct fluid levels.

4. Noise Issues: Unusual sounds during operation may indicate loose or damaged components. Inspect all fittings and fasteners to ensure everything is secure, and consider lubricating moving parts to reduce friction.

5. Electrical Failures: If the machinery fails to start or operate as expected, check the electrical connections and fuses. Ensure that all wires are intact and replace any faulty components as necessary.

By being proactive in identifying and addressing these common issues, you can enhance the longevity and efficiency of your machinery.

Upgrading Parts for Better Performance

Enhancing machinery through the incorporation of advanced components can significantly boost efficiency and functionality. By selecting superior replacements, operators can achieve improved operational results, reduced downtime, and increased longevity of equipment. The right upgrades not only enhance performance but also contribute to a more productive work environment.

Benefits of Upgrading

- Increased efficiency in operation

- Improved reliability and durability

- Enhanced capabilities for various tasks

- Reduction in maintenance costs over time

Key Components to Consider

- Cutting edges: Upgrading to higher-grade materials can improve cutting efficiency.

- Hydraulic systems: Enhanced hydraulic components provide greater power and responsiveness.

- Drive belts: Stronger, more durable belts can reduce slippage and wear.

- Filters: Upgrading to high-efficiency filters can enhance overall performance and protect engine components.

Investing in quality upgrades ensures that equipment performs at its best, leading to greater satisfaction and success in various applications.

Finding Replacement Parts Online

Locating suitable components for machinery can be a straightforward task with the right approach. The internet offers a wealth of resources to help users identify and acquire the necessary items efficiently. Here are some strategies to simplify the search for replacement components.

- Utilize Manufacturer Websites: Start by visiting the official website of the equipment manufacturer. They often provide comprehensive catalogs and detailed specifications for each item.

- Online Marketplaces: Platforms such as eBay, Amazon, and specialized equipment sites can be invaluable. These marketplaces frequently have listings from various sellers, offering both new and used options.

- Forums and Community Groups: Engaging in online forums or social media groups dedicated to machinery can yield recommendations and insights from experienced users.

- Parts Retailers: Dedicated retailers specializing in machinery components often have extensive inventories. Check for customer service options to assist in finding the right match.

When searching online, it’s important to have the specific model number or serial number at hand to ensure compatibility. By leveraging these resources, users can efficiently navigate the vast selection available and find the components they need.

Comparing Bobcat Models and Features

When evaluating different models from a renowned compact equipment manufacturer, it is essential to analyze the unique characteristics and capabilities each option offers. By understanding these distinctions, users can select machinery that best meets their operational needs and enhances productivity.

Key Features Overview

Each model presents a range of features tailored to various tasks, from landscaping to construction. Assessing specifications such as engine power, hydraulic capacity, and attachment compatibility is crucial for making an informed decision.

| Model | Engine Power (HP) | Hydraulic Flow (GPM) | Operating Weight (lbs) |

|---|---|---|---|

| Model A | 50 | 20 | 3,500 |

| Model B | 70 | 25 | 4,200 |

| Model C | 90 | 30 | 5,000 |

Choosing the Right Equipment

Understanding the specific demands of each job is vital when selecting equipment. Factors such as terrain type, attachment needs, and job scale play significant roles in determining the best fit. By comparing available models, users can optimize their investment and ensure efficient performance in their projects.