When maintaining outdoor machinery, having a comprehensive understanding of its various elements is crucial. Each component plays a significant role in ensuring optimal performance and longevity. Familiarity with these parts not only enhances efficiency but also aids in troubleshooting and repairs.

Visual representations serve as invaluable resources for enthusiasts and professionals alike, offering clarity on the assembly and function of each piece. By analyzing these illustrations, one can gain insights into how different elements interact within the system.

In this exploration, we will delve into the intricacies of your machinery’s structure. Understanding these connections will ultimately empower you to take better care of your equipment, ensuring it remains in peak condition for years to come.

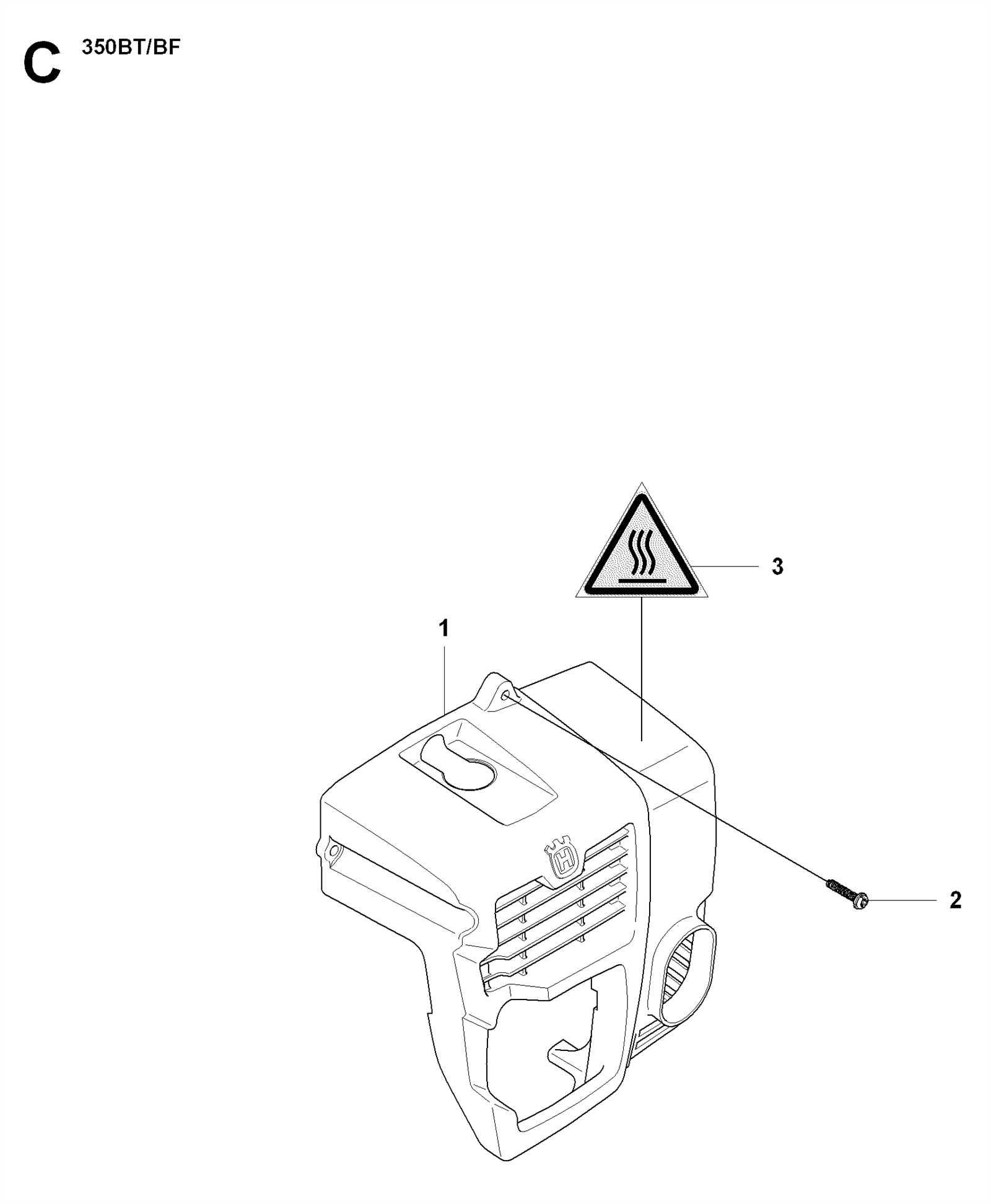

Understanding Husqvarna 350BT Components

In order to effectively operate and maintain outdoor power equipment, it is essential to comprehend the various elements that make up these machines. Each component plays a critical role in the overall functionality, contributing to efficiency and performance. By familiarizing oneself with these parts, users can better troubleshoot issues and ensure longevity in usage.

Key Elements of the Equipment

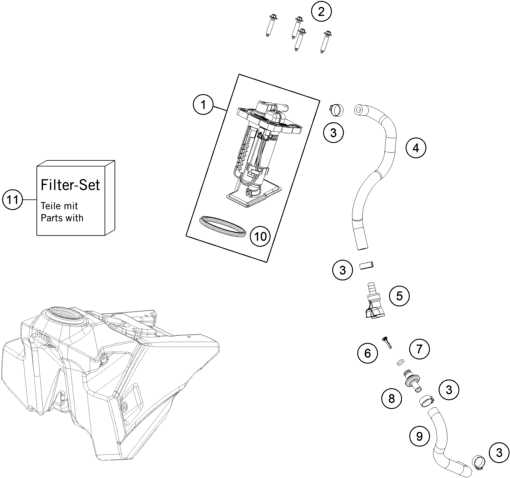

The primary sections of this machinery include the engine, fuel system, and air filtration components. The engine serves as the heart, providing the necessary power for operation. Meanwhile, the fuel system ensures that the right amount of fuel is delivered to the engine, while the air filtration system protects against debris, allowing for optimal combustion.

Importance of Maintenance

Importance of Parts Diagrams

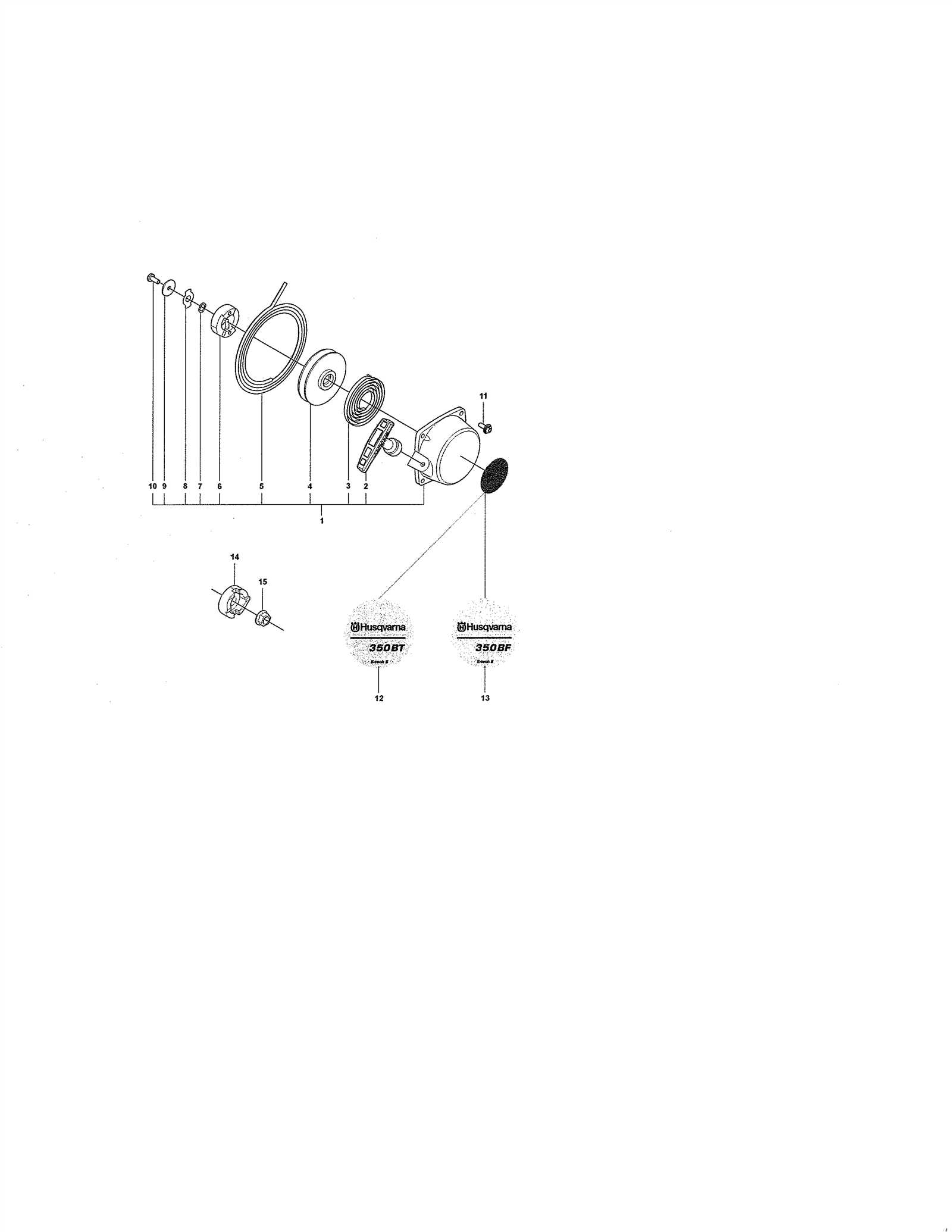

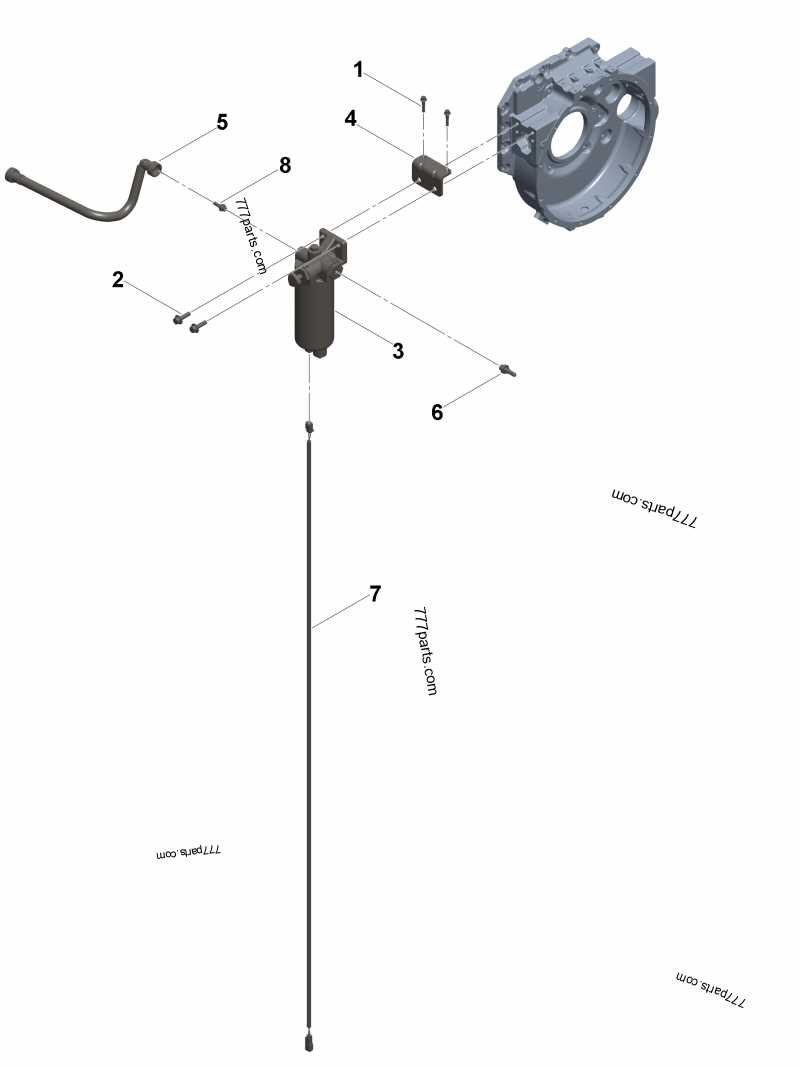

Understanding the structure and components of machinery is essential for maintaining its efficiency and extending its lifespan. A visual representation of the internal setup allows users to easily identify individual elements, facilitating smoother repairs and upkeep. These schematics are valuable tools for both experienced technicians and novices alike, ensuring that each component is correctly aligned and functions as intended.

Ensuring Accurate Repairs

Having access to detailed visual guides significantly reduces the risk of mistakes during repairs. By following a clear layout, users can confidently replace or fix components without the guesswork. This level of clarity also saves time, as it simplifies the disassembly and reassembly process, ensuring that every part is properly placed and secured.

Improved Maintenance

Routine maintenance is made more efficient when each element of a machine is clearly illustrated. These visual references help prevent damage from neglect or improper handling by showing exactly how each component interacts with the system as a whole. This organized approach minimizes errors and prolongs the equipment’s functionality.

How to Interpret the Diagram

Understanding a component layout is essential when it comes to maintaining or repairing your equipment. A clear visual representation allows you to identify various elements and their connections, ensuring that you approach repairs efficiently and accurately. This guide will walk you through the key elements of interpreting such visual aids, helping you navigate each section with ease.

Main Symbols and Labels

Each diagram typically uses a variety of symbols and labels to denote different components. It’s important to familiarize yourself with these icons as they often indicate crucial details, such as specific parts or their alignment within the system. Pay close attention to how the labels correspond to the parts list, as this helps in identifying correct replacement pieces.

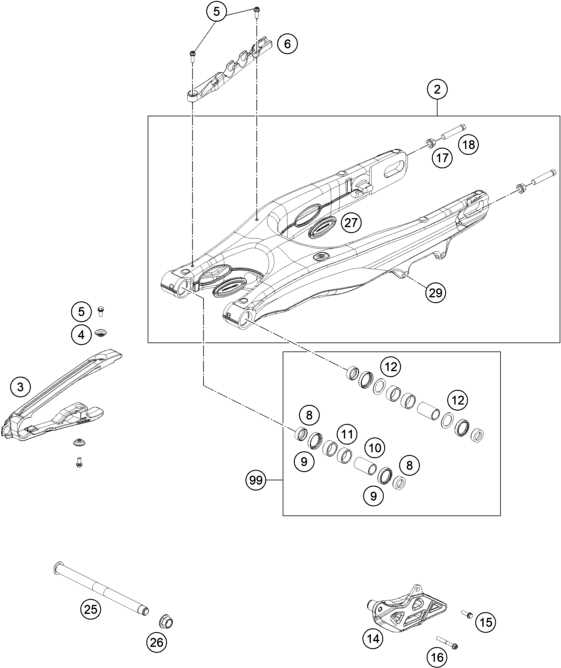

Understanding Component Relationships

Another vital aspect is recognizing how different components interact. The layout will often illustrate connections and pathways, showing the order in which certain elements should be assembled or disassembled. Make sure to trace these lines carefully, as they provide a roadmap for reassembly, preventing mistakes during the process.

Common Replacement Parts Explained

When maintaining any outdoor equipment, it’s essential to understand the components that typically wear out over time. Regular upkeep ensures longevity and optimal performance. The following section outlines some of the most frequently replaced elements, providing clarity on what to watch for during routine checks.

Engine Components

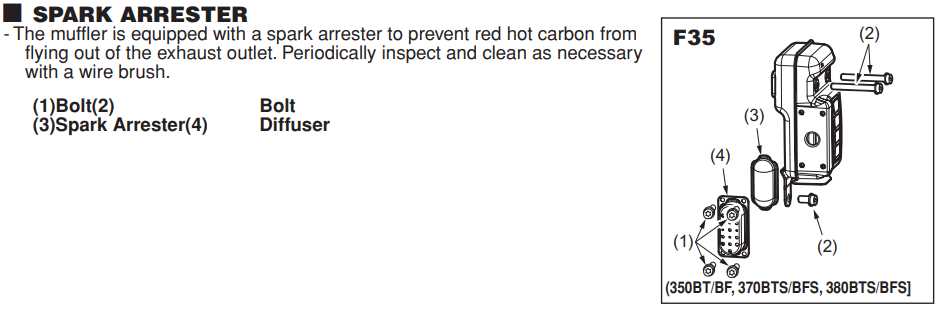

The motor is the heart of any machine, and several elements within it may need periodic attention. Key components such as filters, spark plugs, and gaskets are vital to maintaining smooth operation. Ensuring these parts are replaced as needed helps avoid costly repairs in the future.

Fuel and Air Systems

Clean fuel and proper air circulation are crucial for efficient performance. Items like air filters and fuel lines can degrade over time due to regular use. Replacing these elements is a simple way to ensure the machine runs smoothly and efficiently. Regular inspection can help detect any signs of wear early.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure your equipment lasts for years to come. By following a few simple steps, you can maintain optimal performance and avoid costly repairs. Regular inspections, cleaning, and timely replacements of key components are vital for keeping your machine in excellent working condition.

Regular Cleaning and Inspection

One of the easiest ways to extend the life of your machine is by keeping it clean. Remove any debris or dirt that may accumulate after each use. Additionally, inspect the system for wear and tear to spot any issues early. Tightening loose parts and lubricating moving components can prevent premature failure.

Timely Replacement of Worn Components

As part of routine maintenance, it’s important to replace components that show signs of wear. Ignoring these signs can lead to further damage and reduce the overall efficiency of the machine. Be proactive by replacing filters, belts, and other consumable items to keep the system running smoothly.

Where to Find Authentic Parts

When it comes to maintaining your equipment, sourcing genuine components is essential for ensuring long-lasting performance. Using original items guarantees compatibility, extends the life of your machine, and helps to avoid unnecessary repairs.

Official Retailers and Dealers

The most reliable place to obtain authentic components is through certified sellers. These outlets provide items directly from the manufacturer, ensuring their quality and fit. Authorized dealers often have access to the full range of available items, allowing you to find exactly what you need.

- Check for licensed vendors through the manufacturer’s website.

- Visit local stores with certifications to ensure authenticity.

Online Marketplaces and Platforms

In addition to physical stores, several online platforms offer certified items. It’s crucial, however, to verify the source to avoid counterfeit or incompatible options.

- Look for sellers with high ratings and verified authenticity guarantees.

- Review product descriptions carefully to ensure they match your requirements.

Troubleshooting Using the Diagram

When issues arise during operation, a visual reference can be an essential tool for identifying the source of the problem. By studying the layout of components, you can effectively trace the system’s functionality and pinpoint potential malfunctions.

To start resolving issues, follow a systematic approach:

- Identify the affected area by checking for unusual noises, vibrations, or reduced performance.

- Refer to the visual guide, focusing on the section that corresponds to the malfunctioning part.

- Compare the component’s appearance and connections to ensure nothing is out of place or damaged.

- Check the sequence of interconnected elements to trace where the issue might have originated.

By carefully analyzing these details, you can resolve most common problems effectively and keep the equipment running smoothly.

Assembly Instructions for DIY Repairs

When it comes to maintaining and repairing your equipment, having a clear guide for reassembly is essential. Whether you’re dealing with simple components or more complex systems, following a structured process can help ensure everything is fitted together correctly.

Before starting the assembly, make sure all necessary tools are on hand and all parts are accounted for. Keep the workspace organized to avoid losing any small items during the process. Below is a step-by-step guide to assist with reassembly.

- Prepare the workspace: Clear any clutter from the area to have space for the task. Gather all tools, such as wrenches, screwdrivers, and any other required equipment.

- Sort the components: Lay out all pieces in the order they will be assembled. This helps in visualizing the steps and ensures nothing is missing.

- Follow the sequence: Start with the base or primary structure and work your way towards smaller components. Tighten bolts and screws gradually to avoid any misalignments.

- Check alignment: As each piece is attached, check that everything is properly aligned and secured. Mis

Comparing Models: Husqvarna 350BT vs Others

When selecting a tool for outdoor tasks, it’s important to weigh the performance, features, and efficiency of different models. Each product offers unique characteristics suited for various environments, and comparing these differences allows you to choose the most suitable option for your specific needs. Understanding the strengths and potential limitations of each choice helps make an informed decision when considering alternatives.

Some alternatives prioritize higher power output, while others focus on being more lightweight and maneuverable. Various models also differ in fuel efficiency, noise levels, and user comfort, making them preferable in different working conditions. By evaluating these factors, one can better understand which option is ideal for extended use or more demanding tasks.