In the world of outdoor maintenance, machines designed for intense cleaning play a crucial role. Their ability to tackle tough stains and grime makes them invaluable for homeowners and professionals alike. A comprehensive understanding of these machines not only enhances their functionality but also extends their lifespan.

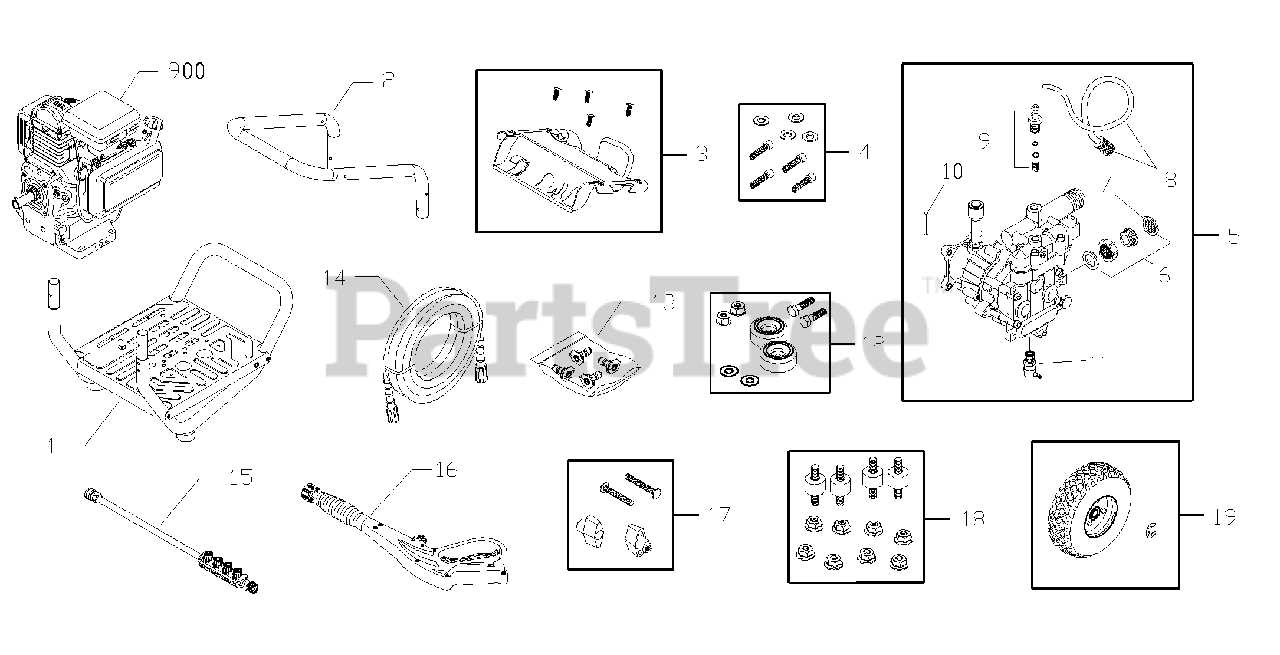

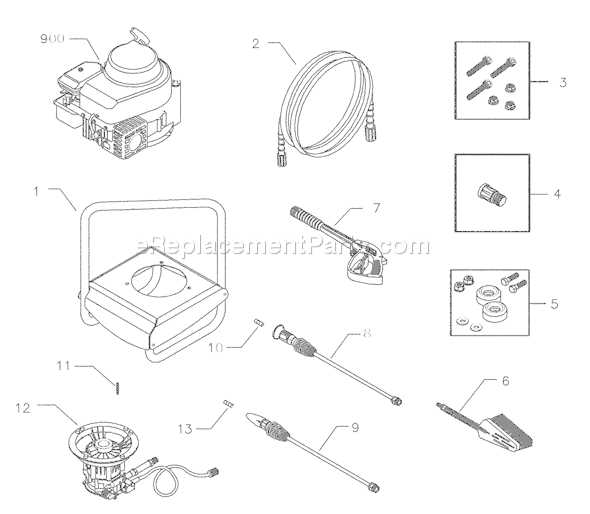

Every device comprises various elements, each serving a specific purpose. Recognizing how these components interact can significantly improve the effectiveness of the cleaning process. This knowledge empowers users to make informed decisions about maintenance and repairs, ensuring optimal performance when tackling challenging tasks.

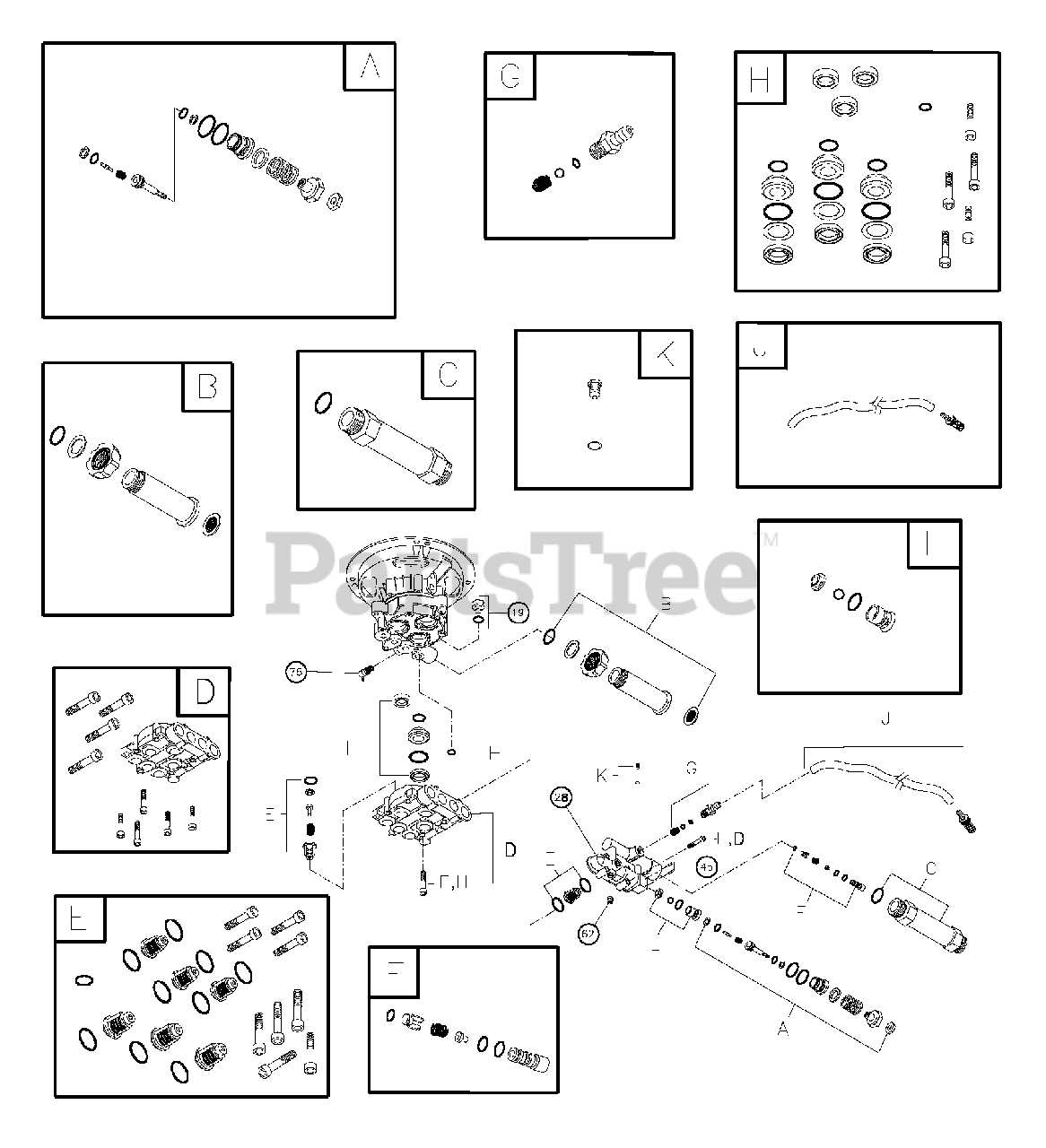

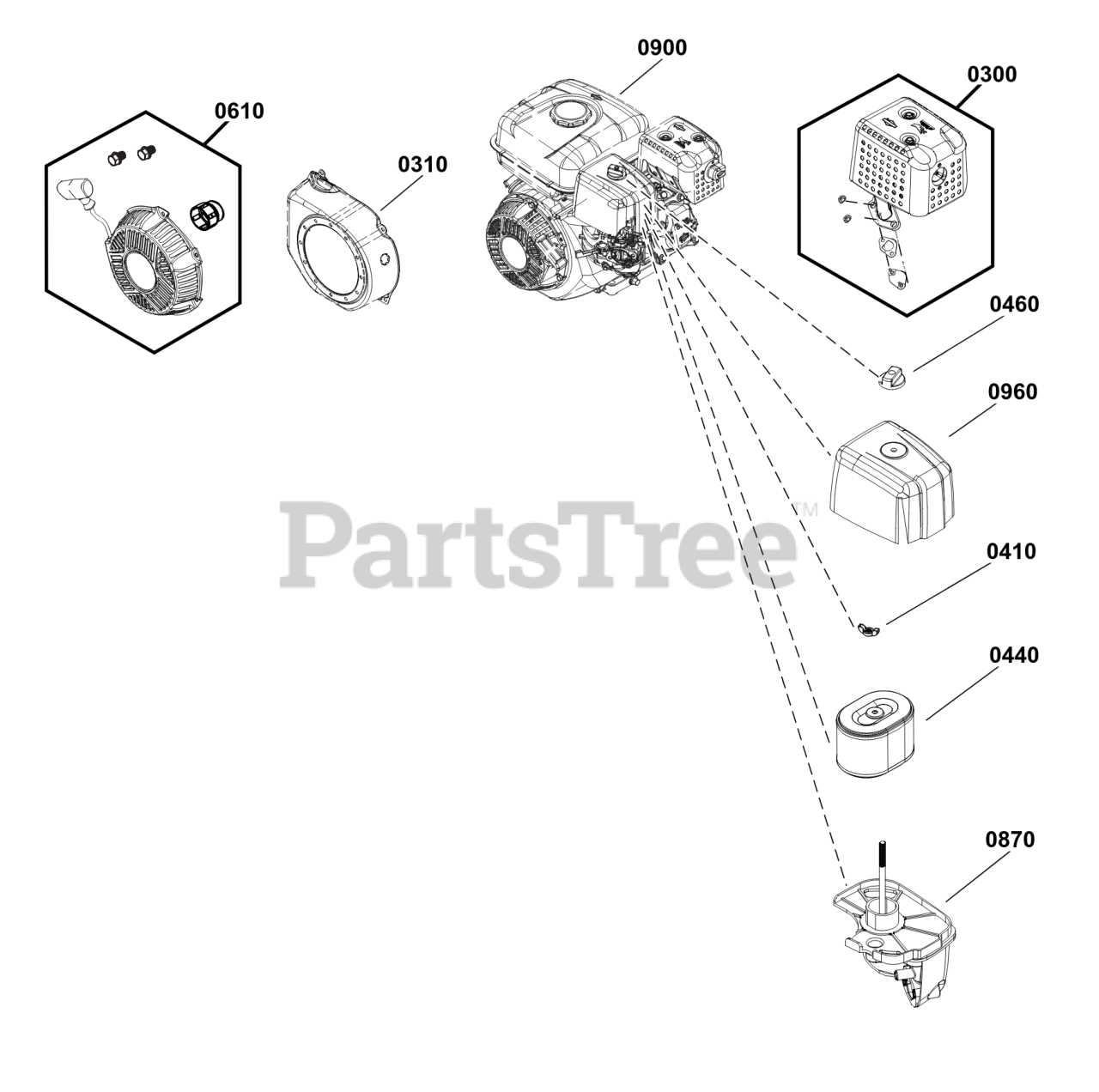

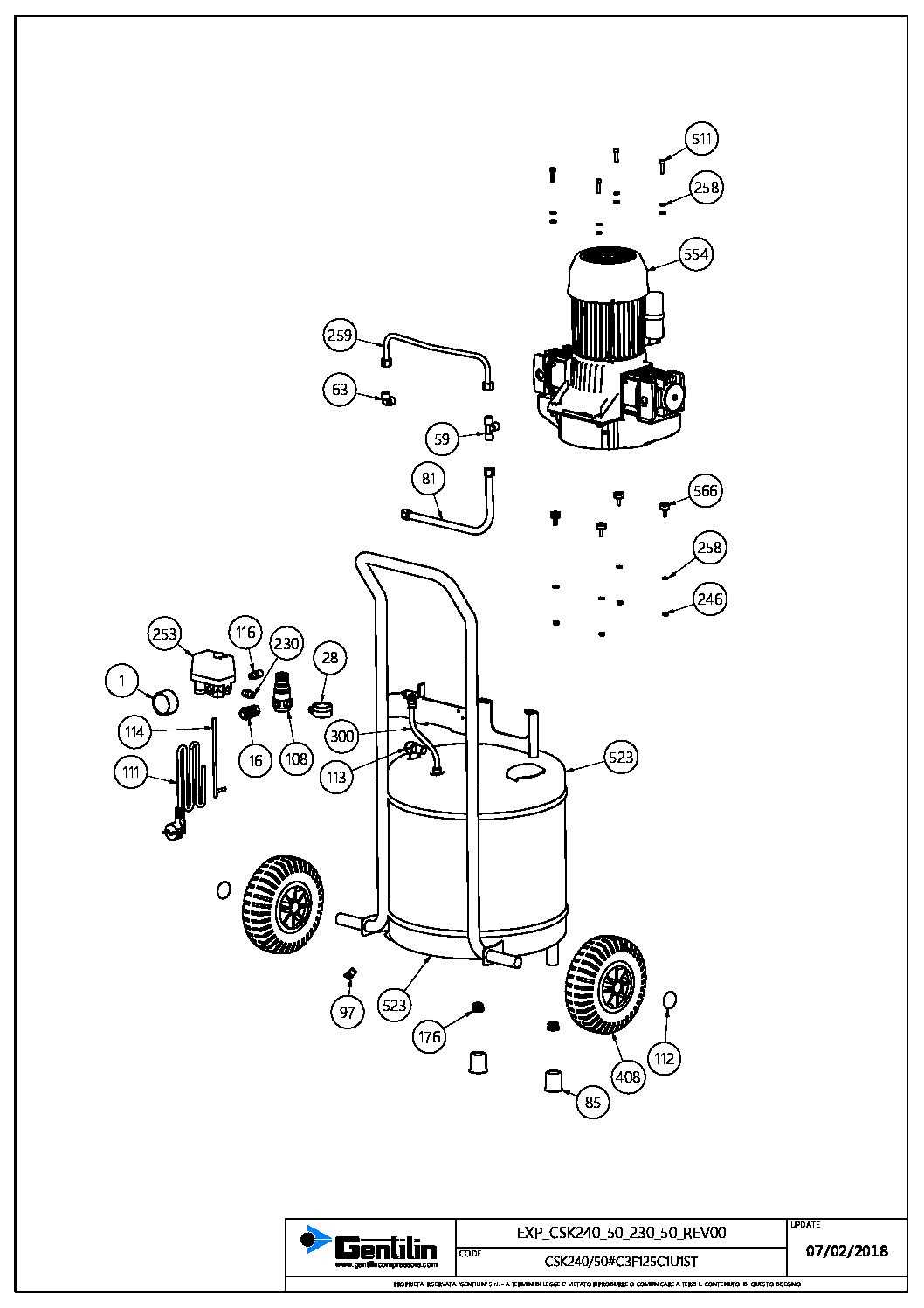

Furthermore, visual aids detailing the arrangement and function of each component can be instrumental. Such illustrations facilitate a deeper grasp of the system’s mechanics, allowing users to troubleshoot issues more efficiently. By gaining insights into the inner workings, operators can enhance their cleaning strategy and achieve superior results.

Understanding Brute Pressure Washers

This section aims to provide insights into a specific type of cleaning equipment designed for high-performance tasks. Such devices are widely utilized for their efficiency in tackling tough grime and dirt. Understanding the fundamental components and their functions can enhance the user experience and improve maintenance practices.

Key Components

The functionality of this cleaning apparatus relies on several critical elements. Each component plays a vital role in ensuring effective operation:

- Motor: Powers the machine, enabling it to generate the necessary force for cleaning.

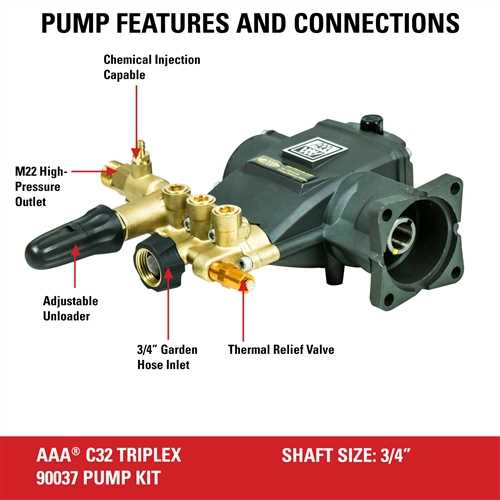

- Pump: Responsible for drawing in and expelling water at high pressure.

- Nozzle: Directs the flow of water, allowing for various spray patterns depending on the task.

- Hose: Connects the device to the water source, facilitating fluid movement.

- Frame: Provides structural support, housing all components securely.

Maintenance Tips

To prolong the life of your equipment, consider these essential maintenance practices:

- Regularly check and clean the filter to prevent clogs.

- Inspect hoses for wear and tear, replacing them as necessary.

- Ensure that all connections are tight to avoid leaks.

- Store the unit in a dry place to prevent damage from moisture.

By understanding these elements and maintenance tips, users can maximize the effectiveness of their cleaning devices while ensuring longevity and reliability.

Key Components of Pressure Washers

Understanding the essential elements that contribute to the effective operation of cleaning machines can enhance both maintenance and performance. Each component plays a pivotal role in ensuring optimal functionality and longevity, making it crucial to familiarize oneself with their purposes and interconnections.

Motor and Pump

The motor serves as the heart of the unit, providing the necessary power to initiate the cleaning process. Coupled with the motor, the pump is responsible for converting that power into water pressure. Together, they create the force needed to tackle stubborn dirt and grime on various surfaces.

Hoses and Nozzles

Flexible hoses allow for ease of movement and access to hard-to-reach areas, while specialized nozzles can adjust the spray pattern and intensity. This versatility enables users to customize their cleaning approach, making the tasks more efficient and effective.

Functionality of Each Part Explained

This section provides an overview of the various components and their specific roles in ensuring efficient operation. Understanding these elements enhances your ability to maintain and troubleshoot the equipment effectively.

- Motor: Powers the entire system, converting electrical energy into mechanical force.

- Pump: Creates the necessary fluid pressure, essential for effective cleaning.

- Nozzle: Directs and adjusts the flow, allowing for various spray patterns and intensities.

- Hose: Transports the liquid from the pump to the nozzle, designed to withstand high pressures.

- Trigger: Controls the flow of the liquid, providing ease of use and safety.

- Chassis: Supports all components, ensuring stability and durability during operation.

Each of these elements works synergistically to achieve the ultimate performance, making it vital to understand their individual functions.

Common Issues with Brute Parts

In the realm of high-performance cleaning equipment, various components can experience wear and tear over time. Understanding the frequent challenges associated with these elements is crucial for maintaining optimal functionality and ensuring longevity. Below are some typical problems users may encounter.

Frequent Problems

Several common issues can arise that impact the efficiency of the machinery. These include:

| Issue | Description |

|---|---|

| Leaks | Often caused by worn seals or damaged connections, leaks can significantly reduce effectiveness. |

| Clogs | Debris buildup in hoses or filters can lead to decreased flow and performance issues. |

| Noise | Unusual sounds may indicate internal damage or loose components, requiring immediate attention. |

| Starting Problems | Difficulty in ignition can be a sign of fuel issues or electrical failures. |

Maintenance Tips

Regular upkeep can mitigate many of these concerns. Check connections, clean filters, and replace worn-out components promptly to ensure seamless operation. Keeping an eye on these aspects will extend the life of your equipment and enhance performance.

Maintenance Tips for Longevity

Ensuring the extended life of your cleaning equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs over time.

1. Regular Inspections: Routinely check all components for wear and tear. Look for cracks, leaks, or loose fittings that could affect efficiency.

2. Clean Filters: Keep filters clean to allow optimal airflow and prevent blockages. This helps in maintaining effective operation.

3. Check Fluid Levels: Regularly inspect and replenish necessary fluids, ensuring that your machine operates smoothly and efficiently.

4. Store Properly: When not in use, store your equipment in a dry, sheltered area to protect it from the elements and prevent corrosion.

5. Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and procedures provided in the user manual for best results.

6. Use Quality Accessories: Invest in high-quality attachments and tools, as they can significantly impact performance and durability.

How to Replace Worn Components

Maintaining the efficiency of your cleaning equipment is essential for optimal performance. Over time, various elements may wear out, leading to diminished functionality. This guide outlines the necessary steps to replace these components, ensuring your machine operates at its best.

Identifying Worn Elements

Before you begin the replacement process, it’s crucial to identify which components need attention. Common signs of wear include:

- Leaks or drips from connections

- Reduced cleaning effectiveness

- Unusual noises during operation

- Visible cracks or deterioration on parts

Steps to Replace Components

Follow these steps to successfully replace the worn parts:

- Gather Tools: Ensure you have the necessary tools, such as wrenches, screwdrivers, and replacement components.

- Disconnect Power: Always disconnect the machine from its power source before performing any maintenance.

- Remove Old Parts: Carefully detach the worn components by loosening screws or bolts. Keep track of all fasteners for reassembly.

- Install New Parts: Position the new components correctly and secure them with the previously removed fasteners.

- Reconnect Power: Once all components are replaced, reconnect the power source and perform a test run to ensure everything functions smoothly.

Regularly checking and replacing worn elements will prolong the life of your cleaning device and enhance its effectiveness. Make maintenance a routine part of your care regimen.

Identifying Quality Replacement Parts

When seeking to restore a cleaning device to optimal function, it is essential to recognize components that exemplify durability and efficiency. High-quality substitutes can significantly enhance performance, extending the lifespan of the equipment while ensuring reliable operation.

Characteristics of Superior Components

Look for materials that resist wear and tear, such as reinforced plastics or metals designed for heavy-duty use. Additionally, check for compatibility with your specific model to avoid issues during installation and operation.

Where to Find Reliable Options

Reputable suppliers often provide detailed information about their offerings, including user reviews and performance guarantees. Online marketplaces and specialty retailers are valuable resources for discovering reputable alternatives.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor cleaning equipment, having the right tools is essential. Proper tools not only make the repair process smoother but also ensure that the equipment functions efficiently after maintenance. This section outlines the necessary implements that will aid in effectively tackling common issues.

Essential Hand Tools

A variety of hand tools is crucial for any repair task. Commonly needed items include wrenches, screwdrivers, and pliers. These tools help in loosening or tightening fasteners, as well as disassembling components for thorough inspection. A set of various sizes will allow for flexibility when dealing with different assembly requirements.

Safety Equipment

In addition to hand tools, safety gear is vital to ensure a secure working environment. Protective goggles, gloves, and masks can prevent injuries and exposure to harmful substances. Always prioritize safety to create an effective repair experience while minimizing risks.

Where to Find Diagrams Online

Accessing technical schematics for machinery can significantly ease repair and maintenance tasks. Numerous online resources provide detailed illustrations, helping users identify components and understand assembly. Below are some recommended platforms for locating these invaluable resources.

Popular Websites

- ManualsLib – A vast collection of user manuals and schematics.

- Parts Lookup – Offers searchable databases for various equipment.

- Schematics.com – A dedicated platform for finding technical drawings.

Forums and Community Resources

- Reddit DIY Community – Engage with users who often share helpful links and files.

- YouTube Tutorials – Video guides sometimes include visual aids and links to diagrams.

- HardwareZone Forums – A discussion platform where enthusiasts share resources.

By exploring these sites and communities, users can easily find the necessary illustrations to support their maintenance and repair efforts.