The intricate assembly of a compact tractor encompasses a variety of elements, each designed to enhance functionality and performance. Grasping the layout and interrelationships of these components is essential for effective maintenance and repairs. Such knowledge empowers operators to ensure their machinery operates smoothly and efficiently.

In this section, we will explore the various sections of a typical compact tractor, delving into how each component contributes to the overall performance. Recognizing these elements is crucial for both novice and seasoned users, as it aids in troubleshooting and replacement processes.

By familiarizing oneself with the specifics of each component, operators can make informed decisions regarding upgrades or repairs. This understanding not only facilitates better upkeep but also enhances the longevity of the machinery, ultimately leading to a more productive experience.

This section aims to provide a comprehensive understanding of a specific compact utility vehicle known for its versatility and efficiency in various agricultural tasks. Highlighting its features, capabilities, and common applications will help readers appreciate the machine’s value in modern farming practices.

Key Features and Specifications

- Compact size suitable for tight spaces and maneuverability

- Powerful engine providing optimal performance for various tasks

- Wide range of compatible implements for enhanced functionality

- Ergonomic design ensuring operator comfort during prolonged use

Common Applications

- Landscaping and lawn maintenance

- Snow removal during winter months

- Gardening and tilling for soil preparation

- Transporting materials around the farm or property

Key Features and Specifications

This section delves into the essential characteristics and technical details of a specific compact utility vehicle designed for various agricultural tasks. Understanding these features aids in evaluating its performance, efficiency, and suitability for diverse applications.

The following points outline the significant attributes:

- Engine Type: Equipped with a reliable engine that delivers optimal power and torque for demanding tasks.

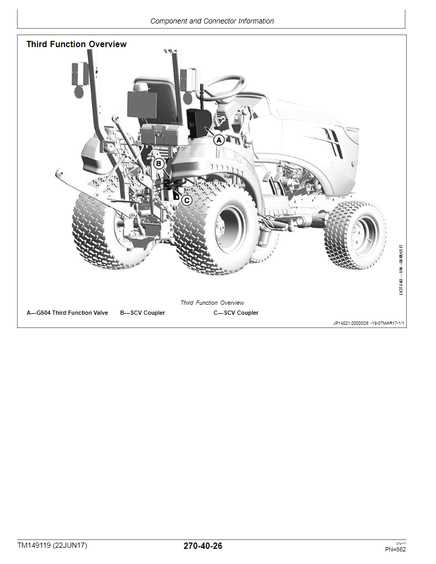

- Hydraulic System: Features an efficient hydraulic system designed to enhance lifting capacity and implement versatility.

- Transmission: Offers a smooth transmission system that ensures ease of operation and adaptability to different terrains.

- Weight Class: Falls within a specific weight category, providing stability and traction for various attachments.

- Dimensions: Compact design allows for maneuverability in tight spaces while maintaining functionality.

These specifications contribute to the overall effectiveness of the vehicle, making it a valuable asset for users seeking reliability and performance in their operations.

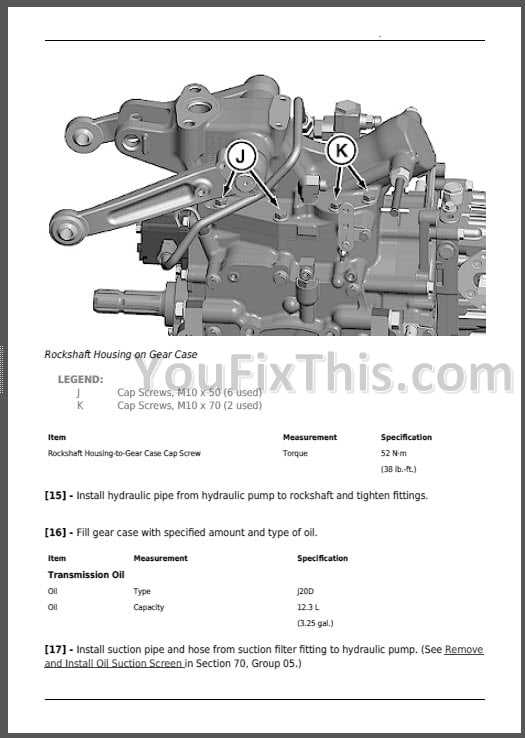

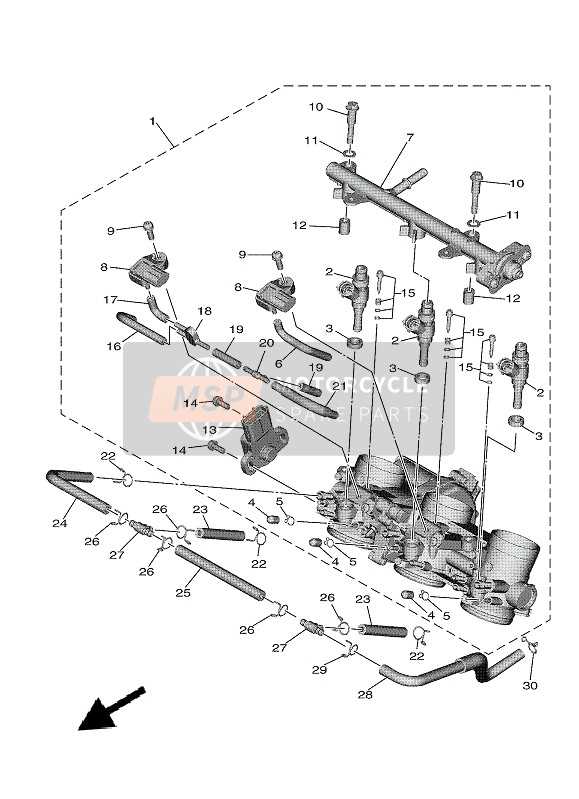

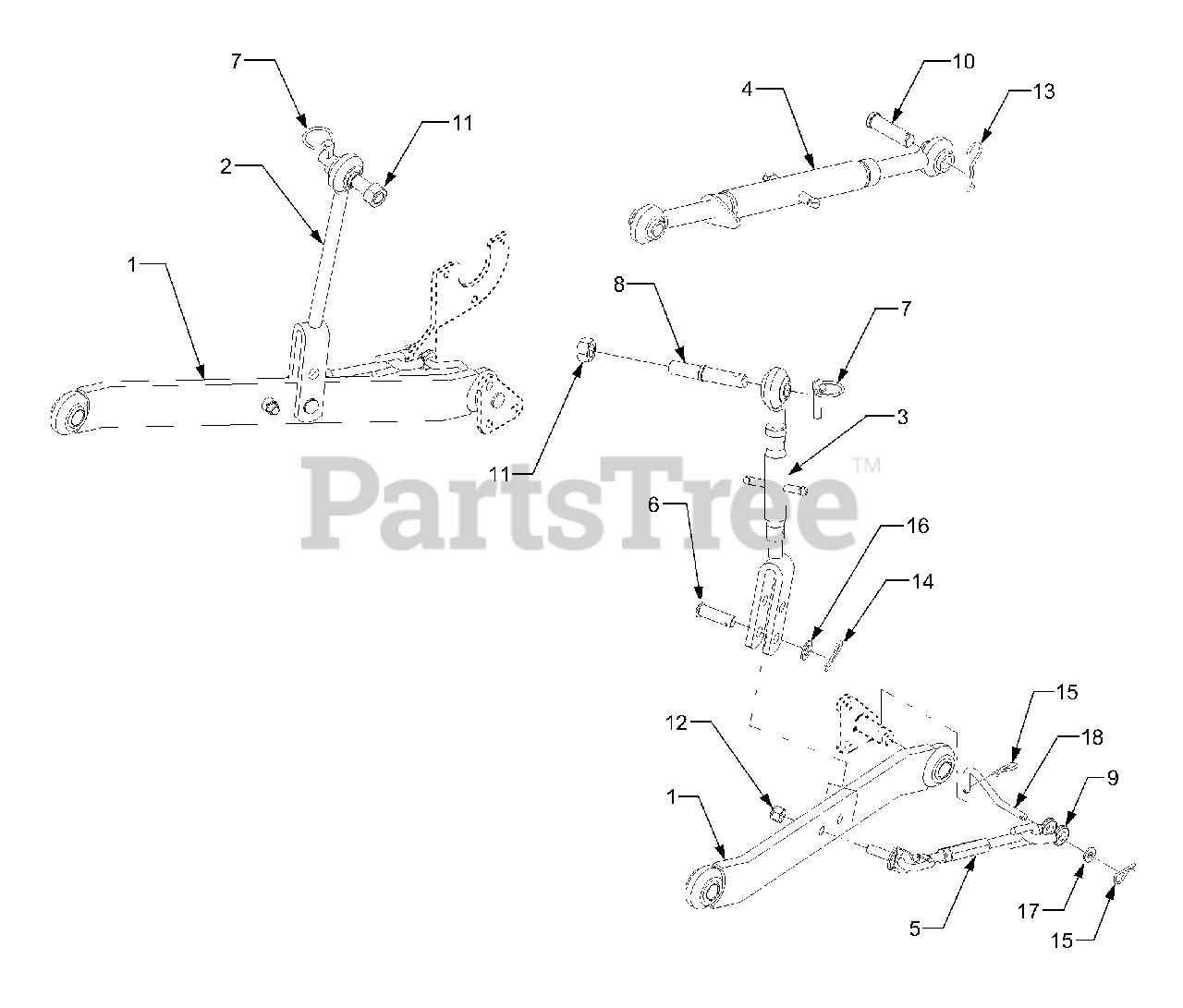

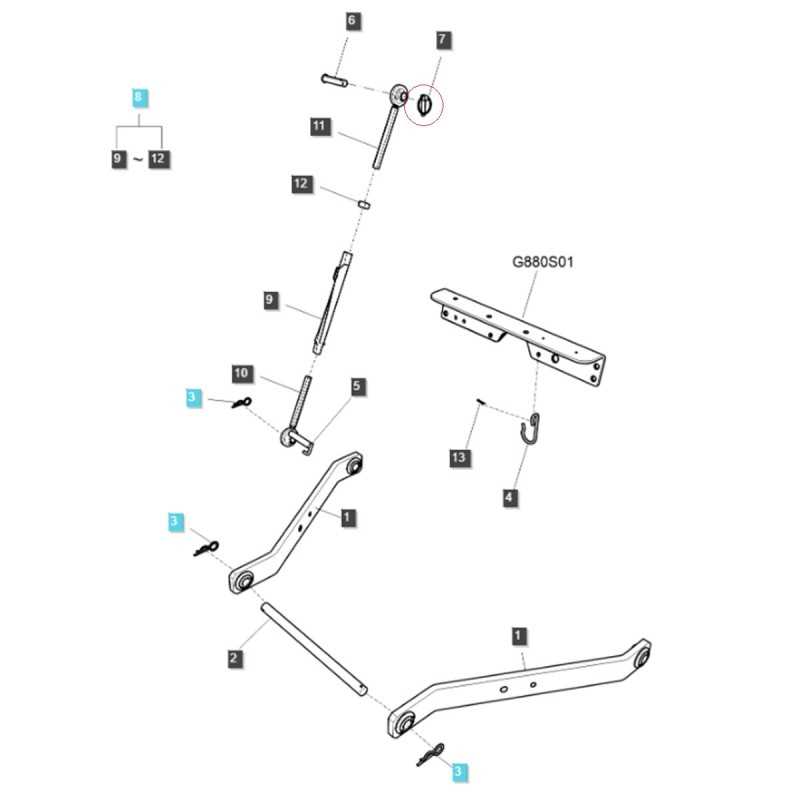

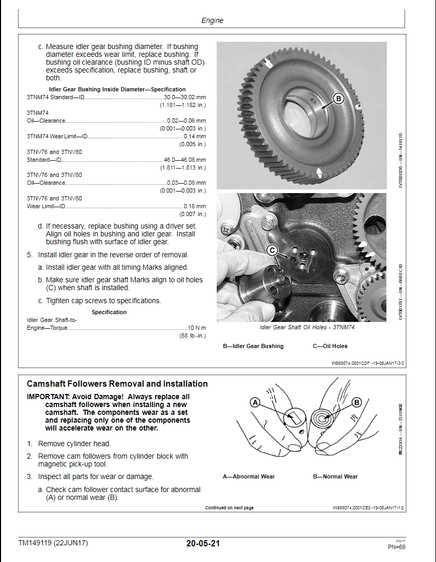

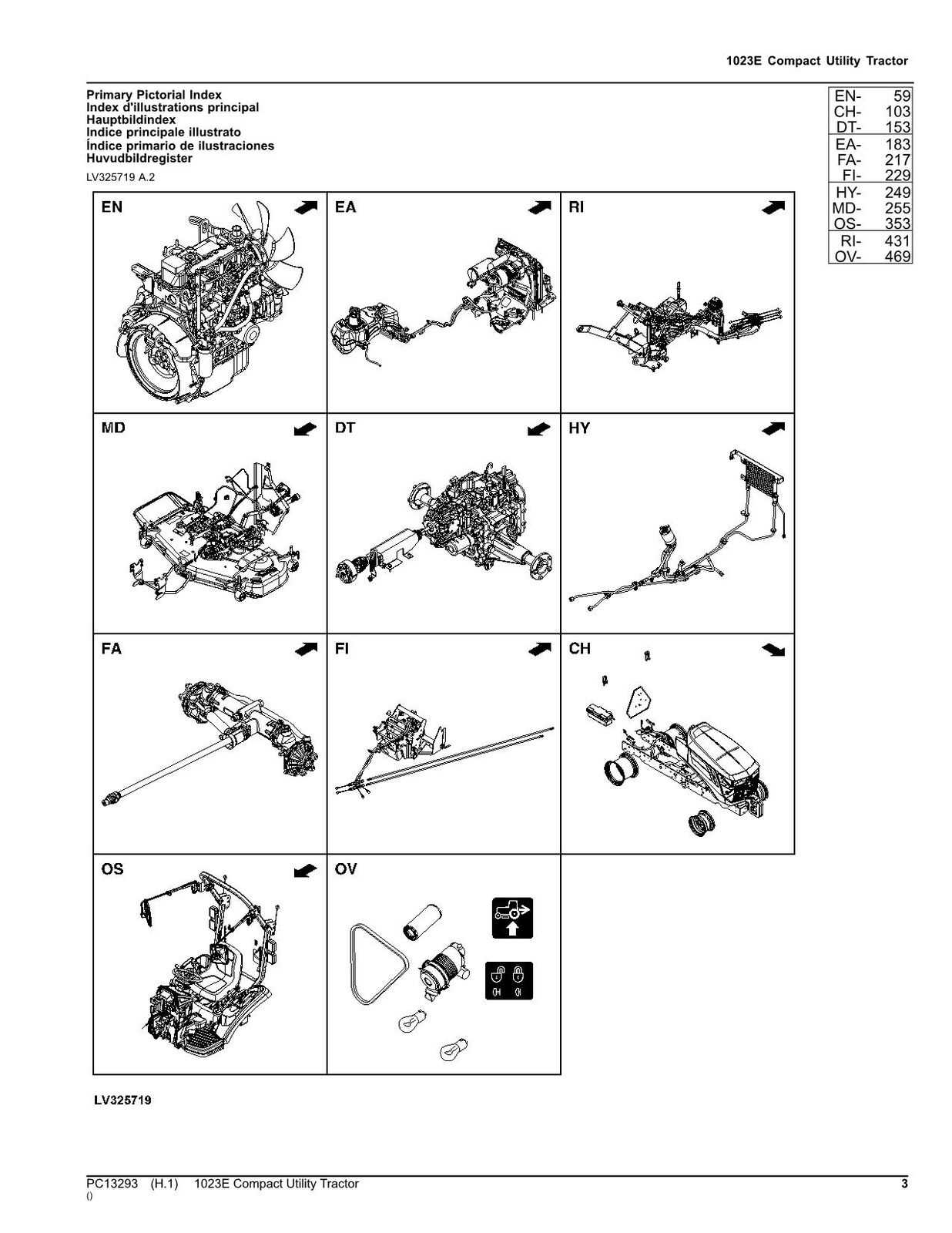

Understanding the Parts Diagram

The visual representation of components and their relationships within a specific machine offers valuable insights for maintenance and repair. This illustration serves as a roadmap, guiding users in identifying each element’s role and connection to the overall system. A thorough comprehension of this layout enhances troubleshooting efforts and streamlines the replacement process.

Key Elements of the Visual Representation

Each component within the illustration is typically labeled, providing clarity on its function. Color coding or distinct symbols may also be utilized to differentiate between various sections, making it easier for individuals to locate specific items quickly. Understanding these identifiers is crucial for effective maintenance.

Utilizing the Illustration for Maintenance

Familiarity with the schematic can significantly aid in performing routine checks and repairs. By referencing this visual guide, users can ensure they address all necessary elements without overlooking critical areas. Proper utilization of this resource not only extends the lifespan of the equipment but also enhances operational efficiency.

Essential Components of the Tractor

Understanding the crucial elements that comprise a modern agricultural machine is vital for optimal performance and maintenance. These fundamental parts work together harmoniously to ensure efficient operation, enabling users to tackle various tasks on the farm. From the engine to the transmission, each component plays a significant role in the overall functionality of the vehicle.

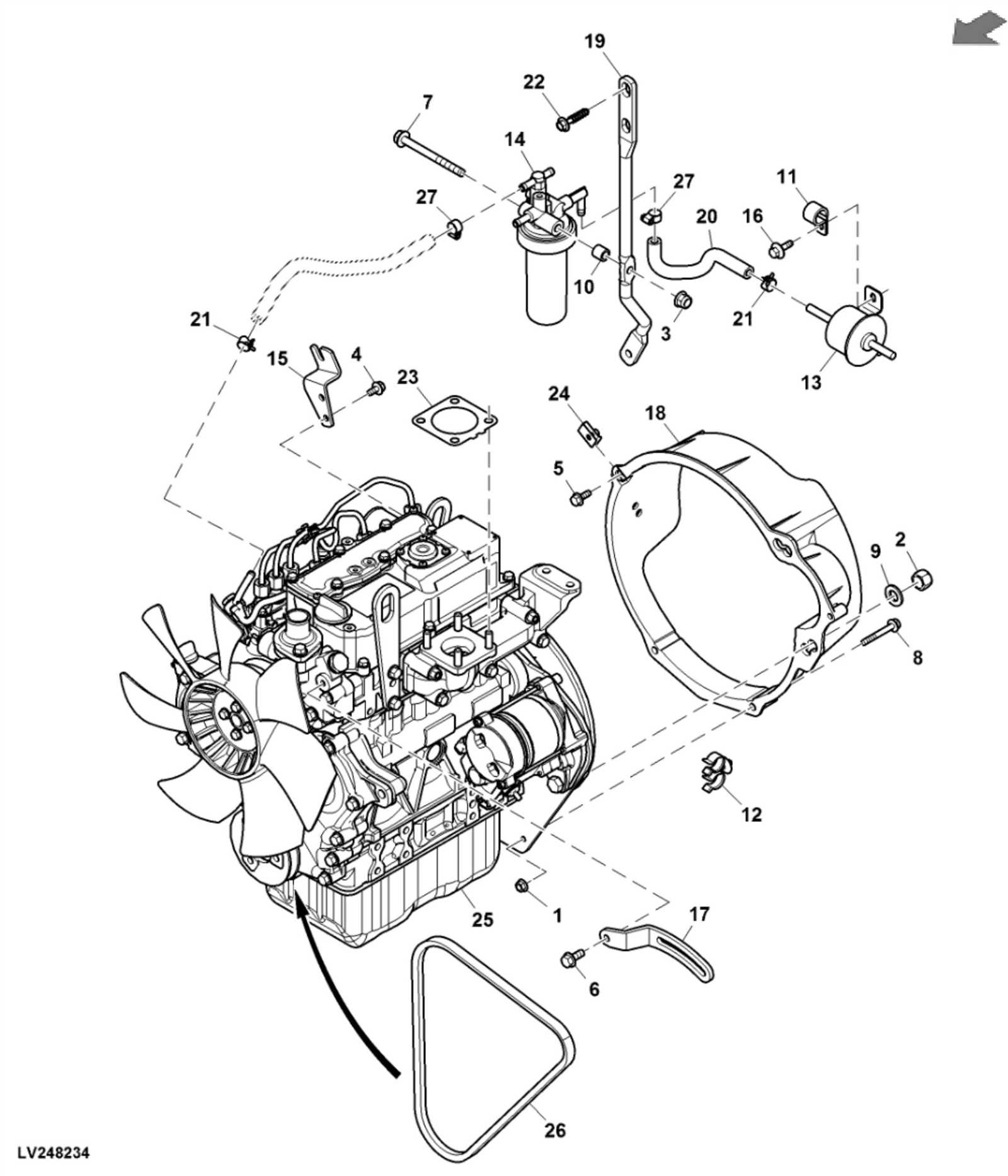

Powertrain and Engine

The powertrain is at the heart of the vehicle, delivering energy from the engine to the wheels. The engine converts fuel into mechanical power, providing the necessary force to move the machine forward. An efficient powertrain design optimizes fuel consumption and enhances performance, making it essential for any agricultural task.

Hydraulic System

The hydraulic system is another critical aspect, responsible for operating various attachments and implements. This system utilizes pressurized fluid to power cylinders, allowing for precise control of tools and equipment. Understanding the hydraulic components is essential for effective maintenance and ensuring that the attachments function correctly.

Maintenance and Replacement Parts

Regular upkeep is essential for ensuring optimal performance and longevity of any machinery. Understanding the various components and their functions can greatly enhance the maintenance process. Here, we will explore the key aspects related to servicing and substituting crucial elements.

When it comes to maintaining equipment, certain elements are particularly vital:

- Engine oil and filters

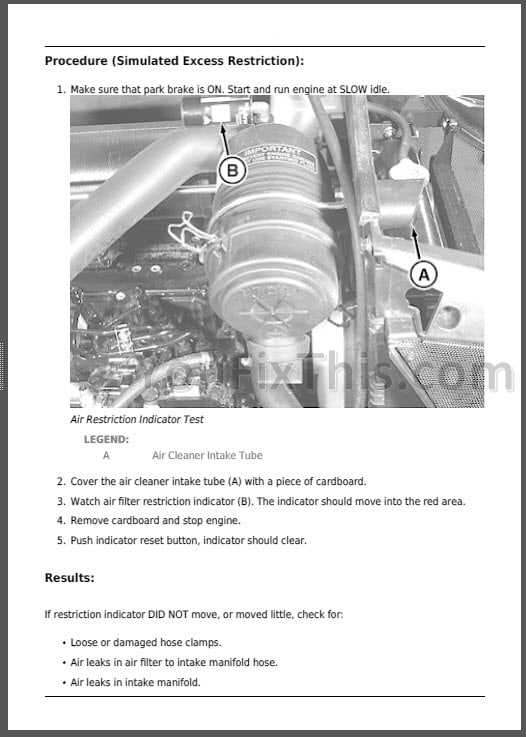

- Air filters

- Fuel filters

- Hydraulic fluids

Using high-quality replacements is paramount. Consider the following options when selecting substitutes:

- OEM (Original Equipment Manufacturer) alternatives ensure compatibility and reliability.

- Aftermarket options can provide cost savings, but verify quality and performance reviews.

- Generic components may be appealing for budget-conscious users, yet they often compromise on durability.

Adhering to a maintenance schedule can help prevent unexpected breakdowns. Recommended intervals include:

- Monthly checks on fluid levels

- Biannual replacement of filters

- Annual inspection of belts and hoses

Incorporating these practices will not only enhance functionality but also extend the lifespan of the equipment, ensuring it remains a reliable asset.

Common Issues and Solutions

In the realm of compact machinery, users may encounter various challenges that can impact performance and efficiency. Understanding these typical problems and their respective resolutions is essential for maintaining optimal functionality. This section aims to highlight prevalent concerns and provide effective solutions to ensure smooth operation.

Engine Performance Problems

One frequent issue involves engine performance, which may manifest as difficulty starting or reduced power output. This can often be attributed to fuel quality or filter blockages. Regularly inspecting and replacing fuel filters, along with ensuring high-quality fuel, can significantly enhance engine performance and reliability.

Hydraulic System Malfunctions

Another common challenge is related to the hydraulic system, which may experience leaks or insufficient pressure. Such issues can hinder functionality and lead to operational delays. Checking hydraulic fluid levels and inspecting hoses and connections for wear or damage are crucial steps in identifying and resolving these malfunctions. Timely maintenance can prevent minor issues from escalating into more significant problems.

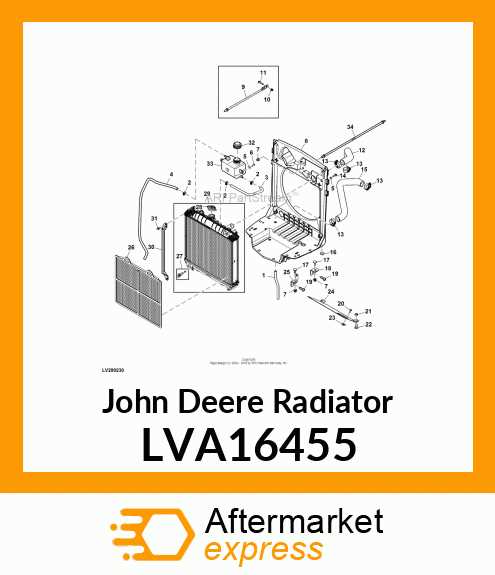

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial. Using high-quality items ensures optimal performance and longevity, providing peace of mind during operation. Counterfeit or substandard alternatives can lead to costly repairs and downtime.

Benefits of Authentic Components

- Enhanced reliability and durability

- Improved performance and efficiency

- Assurance of manufacturer standards and specifications

Where to Find Authentic Components

- Authorized dealers and distributors

- Official manufacturer websites

- Reputable online retailers

- Local repair shops with a good reputation

By prioritizing genuine components, you can ensure that your machinery continues to operate effectively and efficiently. Invest in quality for the best results and the longevity of your equipment.

Aftermarket Options and Considerations

Exploring alternative solutions for machinery maintenance can significantly enhance performance and longevity. These options often provide cost-effective alternatives to original equipment, enabling users to tailor their equipment to specific needs and preferences.

Benefits of Aftermarket Solutions

- Cost Efficiency: Many aftermarket products are available at lower prices compared to OEM counterparts.

- Variety: A broader selection of components allows for customization and personalization of equipment.

- Availability: Aftermarket suppliers may have better stock levels, reducing wait times for essential components.

Considerations When Choosing Aftermarket Components

- Quality: Always check reviews and ratings to ensure reliability and performance.

- Compatibility: Verify that the selected replacements will fit seamlessly with existing machinery.

- Warranty: Assess the warranty and return policies of aftermarket items to protect your investment.