The proper functioning of any machine relies heavily on the interconnectedness of its core elements. Understanding the structure and

Understanding the Components of John Deere L120A

This section will explore the various key elements that make up this well-known riding machine. By familiarizing yourself with these essential mechanisms, you can better understand how they function together to provide reliable performance. Each component is designed to fulfill a specific role, and knowing how these parts work in harmony will help you with maintenance and troubleshooting tasks.

- Engine System: The heart of the machine, responsible for generating the power needed for operation. Its design ensures optimal efficiency and longevity.

- Transmission: A critical element that controls the vehicle’s movement and speed, ensuring smooth transitions between gears.

- Steering and Suspension: Provides stability and maneuverability, allowing the machine to navigate various terrains with ease.

- Cutting Deck: The section responsible for trimming grass, engineered for precision and durability, allowing for an even and professional cut.

- Drive System: Transfers the engine’s power to the wheels, enabling forward and backward movement.

- Control Panel:

Engine Layout and Functionality

The engine structure plays a vital role in ensuring smooth operation and optimal performance. Understanding the overall layout helps in grasping how various components work together to deliver power efficiently. This section highlights the essential elements of the system and their specific roles, providing insight into the arrangement and purpose of each key part.

- Cylinder Configuration: The central part where fuel combustion occurs, converting energy into mechanical motion.

- Crankshaft Mechanism: A rotating shaft that transforms linear piston movement into rotational energy, driving the machine.

- Fuel Delivery System: Ensures precise fuel flow to the combustion chamber, optimizing power output.

- Cooling System: Maintains the temperature within safe limits, preventing overheating during prolonged operation.

- Exhaust Assembly: Channels waste gases away from the engine, improving

Transmission and Drive System Overview

The propulsion and power distribution in this equipment are key to ensuring optimal performance. The ability to transfer energy effectively from the motor to the wheels plays a vital role in maintaining smooth operation and handling. Understanding the mechanisms that allow for controlled speed and movement is essential for both performance and longevity.

Key Components

The driving system consists of several essential elements that work together to provide seamless energy transfer. The primary unit, responsible for torque conversion, regulates the movement, while secondary parts ensure stability and efficient power usage. These components must be in sync to maintain operational efficiency and prevent breakdowns.

Maintenance Considerations

Routine checks and servicing of the driving elements are critical for preventing wear and tear. Lubrication and proper alignment help in extending the lifespan of the equipment, while prompt repairs of any irregularities ensure uninterrupted functionality. Regular care guarantees that the system operates with precision under varying conditions.

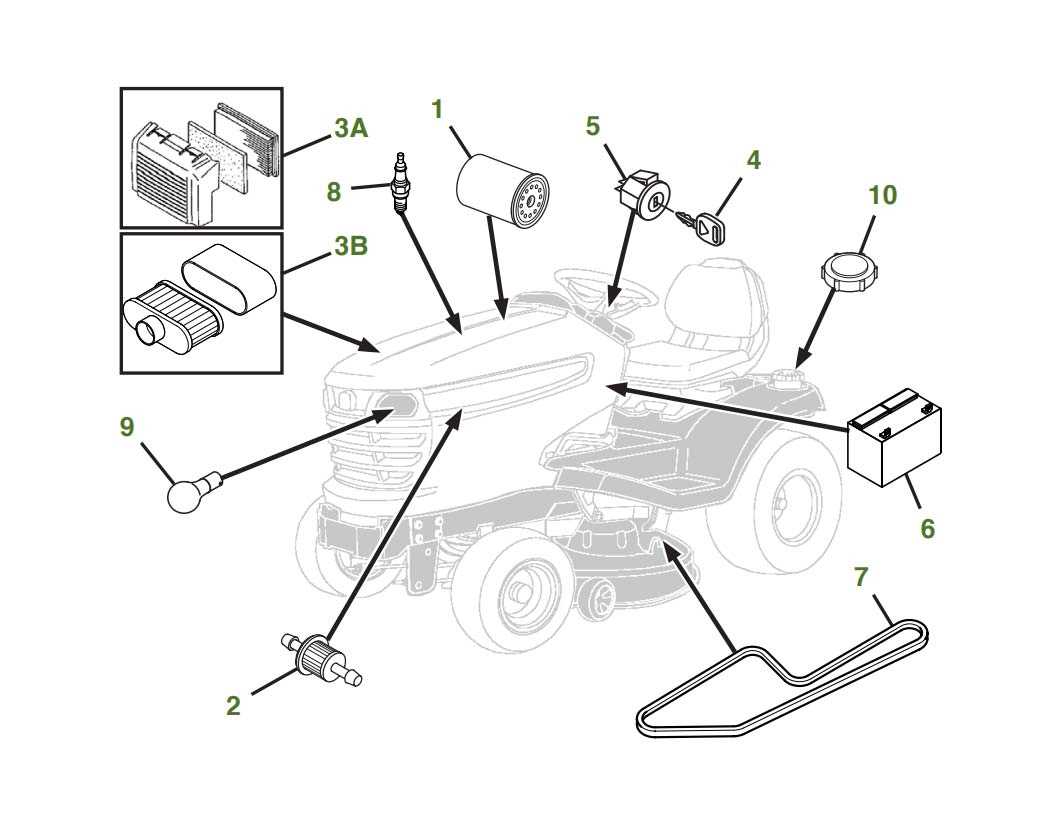

Fuel System and Its Parts

The fuel delivery mechanism is essential for ensuring that the engine receives the necessary energy for efficient operation. This system is responsible for storing, filtering, and supplying the correct amount of liquid energy to the engine for combustion. Understanding its components is key to maintaining overall performance and preventing potential issues.

- Fuel Tank: This container holds the liquid energy source, designed to prevent leaks and ensure safe storage.

- Fuel Pump: Responsible for moving the liquid from the storage container to the engine, ensuring consistent flow under varying conditions.

- Fuel Filter: A critical element that removes impurities and debris, preventing them from reaching sensitive engine parts.

- Fuel Lines: These tubes connect various components, enabling the smooth transfer of liquid energy throughout the system.

- Carburetor: This component mixes the fuel with air in the right proportions before it enters the engine for combustion.

Each part plays a unique role in

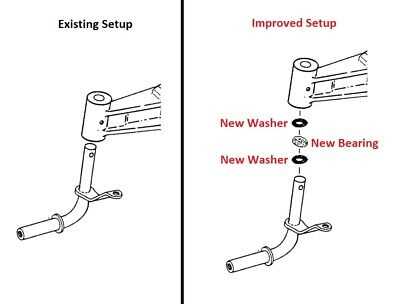

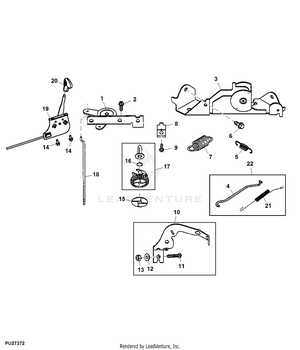

Steering and Control Mechanism

The steering system plays a crucial role in maneuvering the vehicle, providing precise control and stability. Proper functionality ensures smooth direction changes, minimizing effort while maintaining safety. This section will explore the essential components that make the handling efficient and responsive.

Central to this mechanism is the connection between the operator’s controls and the wheel movement. The mechanical linkage is designed to deliver accurate input response, allowing the driver to maintain control even under demanding conditions. Regular maintenance of these components is essential to prevent wear and ensure long-term reliability.

Further, understanding how different elements work together helps identify issues early. The alignment and tension in the system need to be monitored regularly to avoid potential operational failures. By keeping these components in good condition, the vehicle’s steering performance remains optimal.

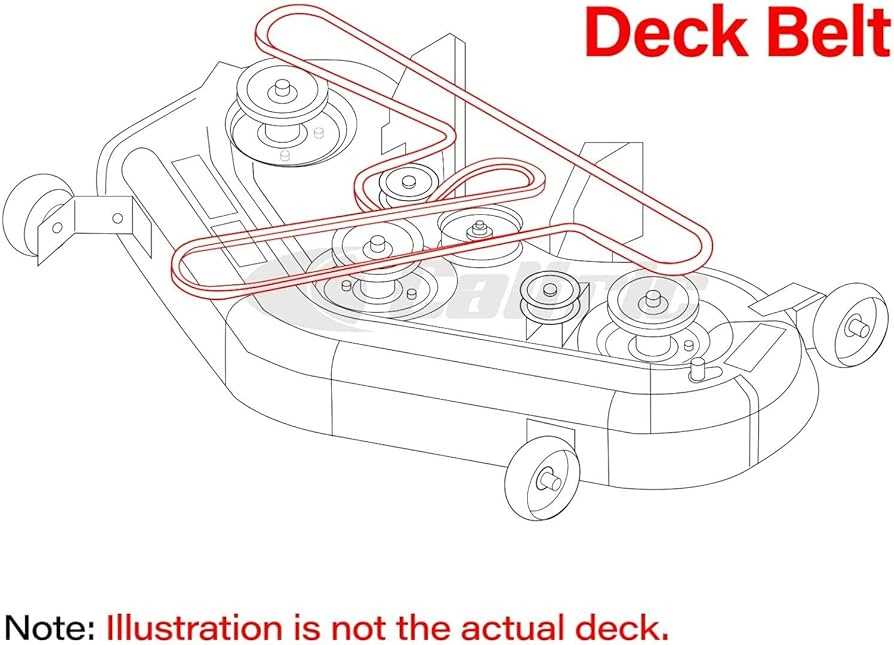

Blades and Deck Assembly

The blades and deck assembly is a crucial component of any lawn maintenance equipment, playing a vital role in ensuring effective grass cutting and overall performance. This assembly not only houses the cutting elements but also integrates with various other parts to create a cohesive system that operates seamlessly. Proper maintenance and understanding of this assembly can greatly enhance the efficiency of the equipment.

Typically, the assembly consists of multiple blades designed to deliver precise cutting action. These blades are often made from durable materials to withstand the rigors of frequent use. Regular inspections are essential to identify any wear or damage that could compromise performance. In addition to the blades, the deck itself serves as the foundation, providing stability and support during operation.

Ensuring that the deck is clean and free of debris is equally important, as this can affect the airflow and cutting efficiency. Moreover, proper alignment of the blades within the assembly can contribute to an even cut and enhance the longevity of the equipment. Overall, understanding the intricacies of the blades and deck assembly can lead to improved maintenance practices and optimal performance of the lawn care machinery.

Electrical Components and Wiring

The functionality of a mowing machine greatly relies on its electrical elements and wiring systems. These components play a crucial role in ensuring efficient operation, safety, and reliability. Understanding the various elements involved can aid in effective troubleshooting and maintenance, ultimately prolonging the life of the equipment.

Key Electrical Elements

Among the fundamental electrical components, the battery serves as the primary power source, providing the necessary voltage to start the engine and operate various systems. Additionally, fuses protect the circuitry from overloads, while switches enable control over different functions. Wiring harnesses are also vital, as they organize and protect electrical connections throughout the machine.

Wiring Configurations and Maintenance

Proper wiring layouts are essential for optimal performance and safety. Regular inspection of connections can prevent issues related to corrosion or wear. Maintenance involves checking for loose wires, frayed insulation, and ensuring all connections are secure. Keeping these elements in good condition will enhance overall functionality and reduce the likelihood of electrical failures.

Maintenance of the Mower’s Hydraulics

Ensuring the proper functioning of the hydraulic system is crucial for the efficiency and longevity of your mowing equipment. Regular upkeep and timely servicing can prevent costly repairs and enhance performance. This section outlines essential maintenance practices to keep the hydraulic components in optimal condition.

Begin by routinely checking hydraulic fluid levels, as insufficient fluid can lead to overheating and reduced efficiency. Use only the manufacturer-recommended fluid for optimal performance. In addition, inspect hoses and connections for signs of wear, leaks, or damage. Any compromised parts should be replaced immediately to avoid further complications.

Another vital aspect of maintenance is flushing the hydraulic system. Over time, contaminants can accumulate, hindering performance. Flushing the system helps eliminate these impurities, ensuring smooth operation. It is also advisable to clean or replace filters as part of this process.

Maintenance Task Frequency Notes Check fluid levels Weekly Ensure levels are within recommended range. Inspect hoses and connections Monthly Look for leaks or signs of wear. Flush hydraulic system Annually Eliminates contaminants and maintains efficiency. Replace filters Annually Use manufacturer-recommended filters. By adhering to these maintenance practices, you can significantly enhance the reliability and performance of your mowing equipment’s hydraulic system, ensuring a smooth and efficient mowing experience.

Replacement Guidelines for Key Parts

When maintaining outdoor equipment, understanding the replacement process for essential components is crucial. Ensuring that the machinery operates efficiently requires timely and appropriate substitutions, which can enhance performance and longevity. Familiarity with the replacement procedures can save time and prevent potential issues in the future.

Identifying Essential Components

Before initiating the replacement process, it is vital to identify the key components that may require attention. This includes evaluating their condition, performance, and any visible signs of wear. Regular inspections can help determine which items need to be replaced, allowing for better planning and more informed decisions.

Replacement Process

Once the necessary components are identified, follow these steps for an effective replacement: first, gather the appropriate tools and new components required for the task. Ensure the equipment is powered off and secured before proceeding. Carefully remove the worn components, taking note of how they are connected. Install the new parts, ensuring they are securely fastened and aligned correctly. Finally, conduct a test to confirm that the machinery is functioning optimally.