When it comes to maintaining heavy machinery, having a clear understanding of the layout and functionality of its components is essential. This knowledge not only aids in efficient repairs but also enhances overall performance. A comprehensive overview of the individual elements can help operators identify potential issues and streamline their maintenance routines.

In this section, we delve into the intricate details of your machine’s architecture, highlighting the various components and their roles. By visualizing how these elements interact, you can gain valuable insights into the operational mechanics of your equipment. This foundational understanding is crucial for ensuring that your machinery operates smoothly and efficiently.

Whether you’re a seasoned technician or a new operator, grasping the arrangement of these components will empower you to make informed decisions regarding repairs and upgrades. With a focus on clarity and accessibility, this guide aims to provide you with the necessary tools to enhance your maintenance skills and optimize your equipment’s performance.

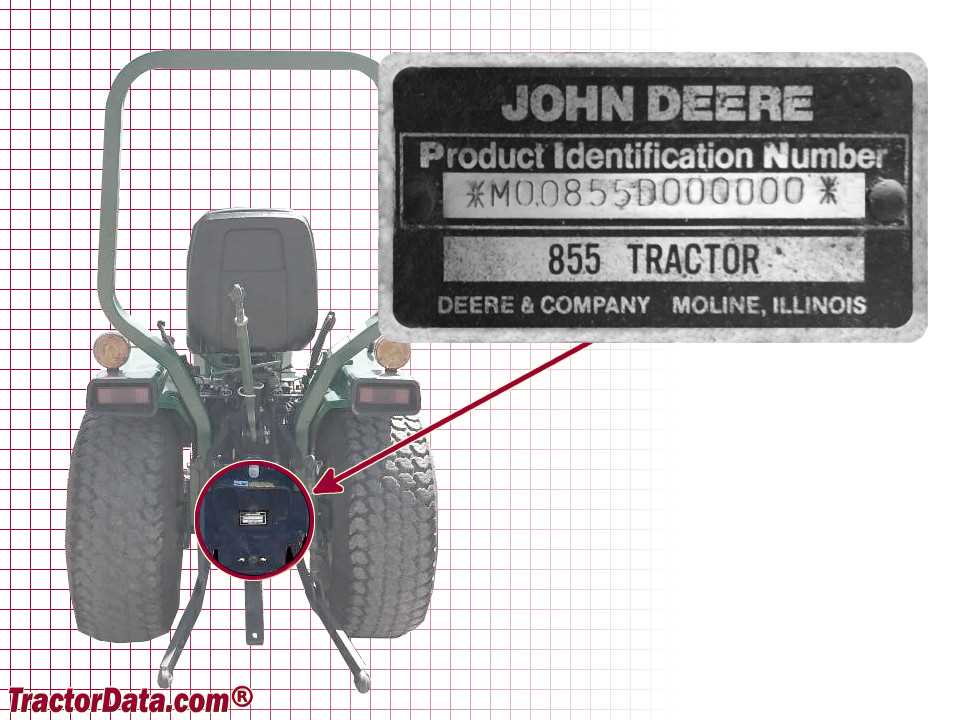

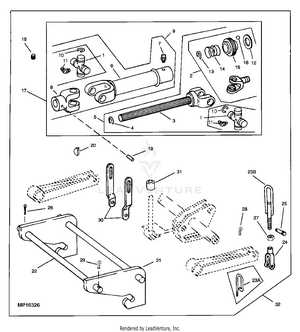

Understanding the John Deere 755 Model

This section delves into the essential characteristics and functionalities of a specific agricultural machine known for its reliability and efficiency. Designed to meet diverse farming needs, it offers a robust performance that supports various tasks in the field.

Power and Efficiency: The machine is equipped with a powerful engine that ensures optimal productivity. Its design facilitates ease of operation, making it suitable for both seasoned operators and newcomers to the agricultural sector.

Versatility: One of the standout features is its adaptability to different attachments, enhancing its usability across various applications. Whether for tilling, mowing, or transporting materials, this model proves to be a valuable asset on any farm.

Maintenance and Support: Regular upkeep is crucial for sustaining performance. Access to a comprehensive support system and quality components contributes to minimizing downtime, ensuring that the machine remains operational throughout the busy seasons.

In summary, this model embodies a blend of power, versatility, and reliability, making it a top choice for farmers seeking to optimize their operations.

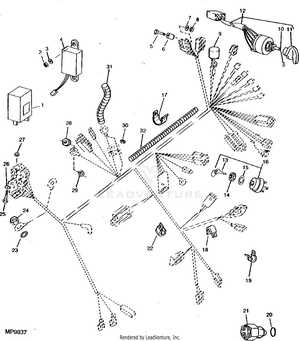

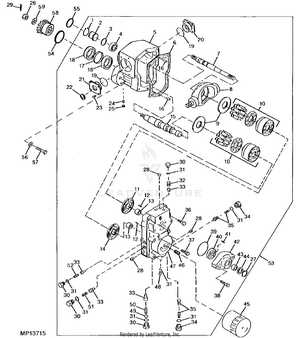

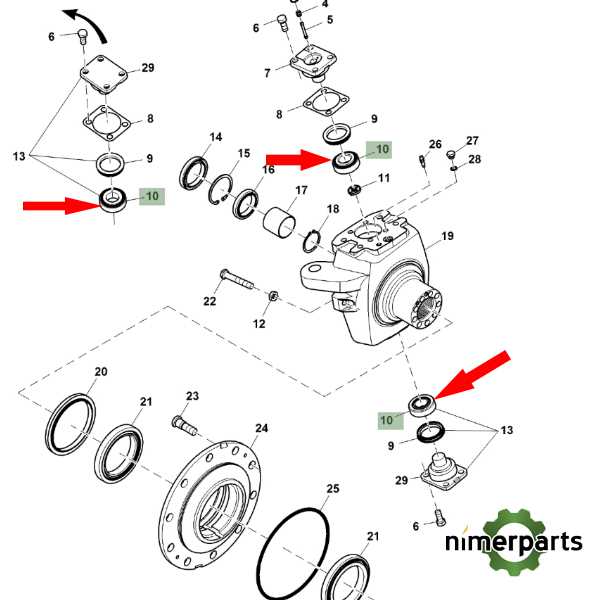

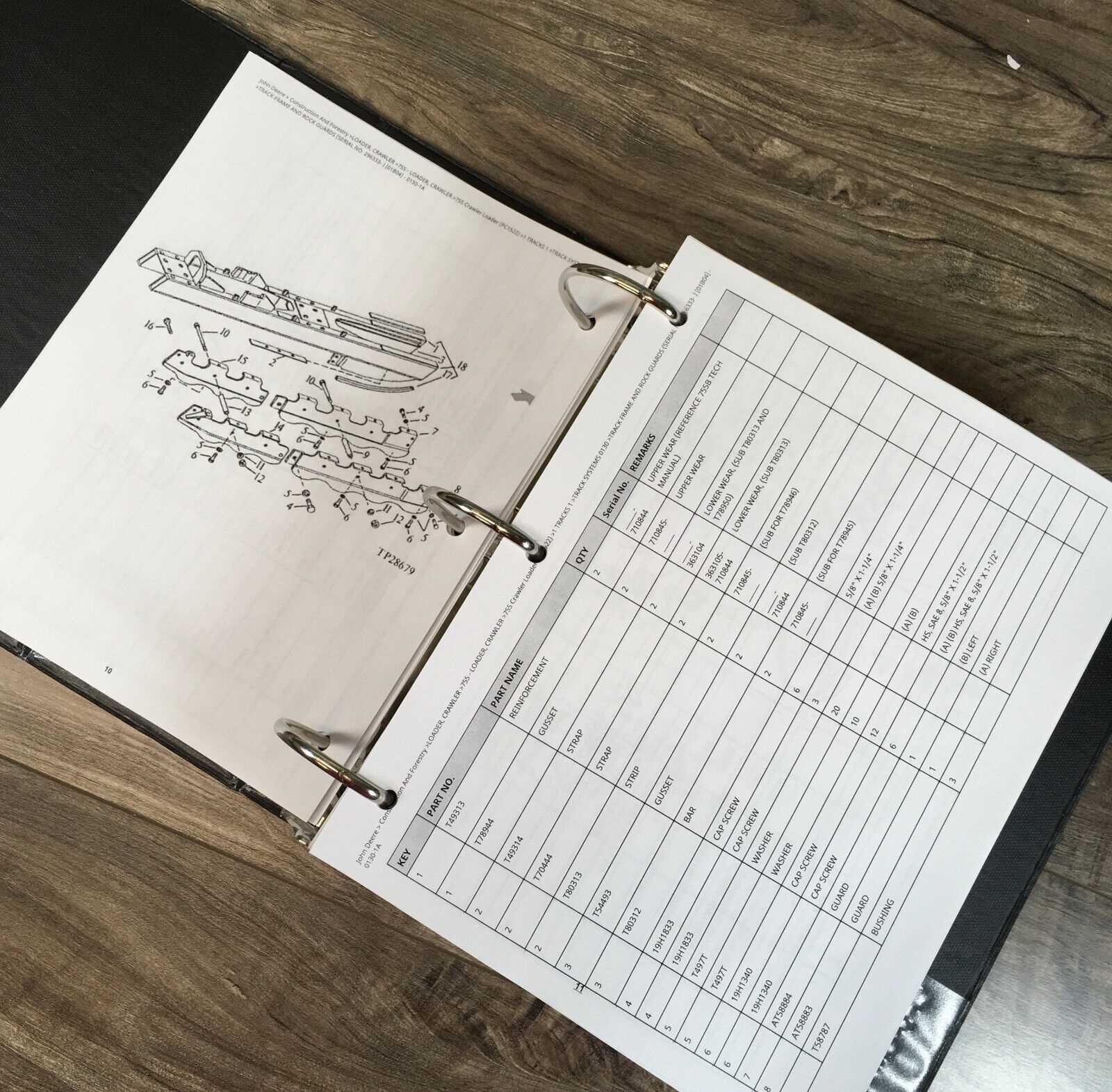

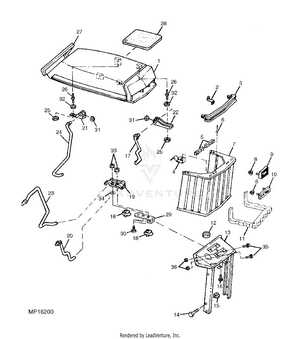

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of individual elements allow users to identify and locate specific components quickly. This understanding not only enhances the efficiency of troubleshooting but also aids in making informed decisions regarding replacements or upgrades.

Benefits of Visual References

- Facilitates quick identification of components

- Enhances communication between technicians

- Reduces the likelihood of errors during assembly or disassembly

- Improves overall efficiency in repair processes

Role in Maintenance Planning

- Helps in creating detailed maintenance schedules

- Assists in tracking wear and tear of individual components

- Guides users in selecting appropriate replacements

- Supports training initiatives for new technicians

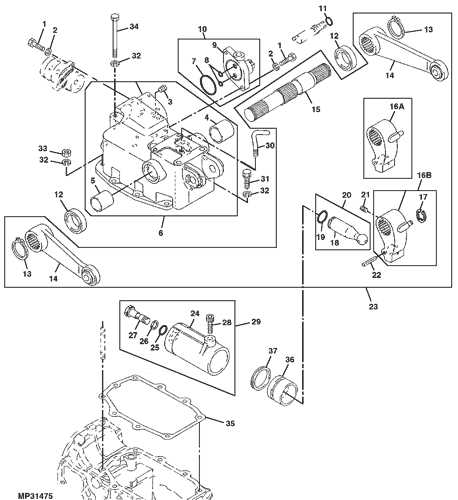

Key Components of the John Deere 755

The efficient operation of any agricultural machinery relies on several crucial elements that work in harmony. Understanding these essential components is vital for effective maintenance and troubleshooting. This section delves into the fundamental parts that contribute to the functionality and performance of this specific model.

| Component | Description |

|---|---|

| Engine | Powers the machinery and provides the necessary force for operation. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

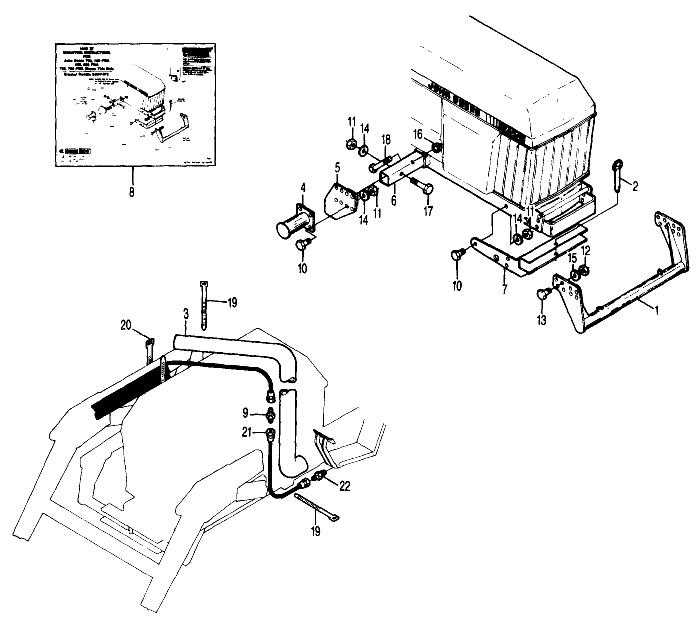

| Hydraulic System | Facilitates lifting and controlling implements, enhancing versatility. |

| Chassis | Serves as the base structure, supporting various components and ensuring stability. |

| Electrical System | Controls ignition, lighting, and other electrical functions essential for operation. |

Identifying Common Replacement Parts

When it comes to maintaining equipment, recognizing frequently needed components is essential for ensuring optimal performance. Knowing which items are most likely to require replacement can save time and effort during repairs. This section provides insight into some of the commonly replaced elements that operators should be aware of.

Essential Components to Monitor

Regular inspections can help identify wear and tear on crucial elements. Among these are items related to the engine, transmission, and hydraulic systems. Understanding their functions and potential issues can lead to timely replacements, reducing downtime.

Replacement Component Overview

| Component | Description | Symptoms of Wear |

|---|---|---|

| Filters | Ensure clean fluid circulation | Reduced efficiency, unusual noises |

| Batteries | Provide electrical power | Difficult starting, dim lights |

| Belts | Transfer motion between parts | Squeaking sounds, visible cracks |

| Seals | Prevent fluid leaks | Fluid stains, reduced pressure |

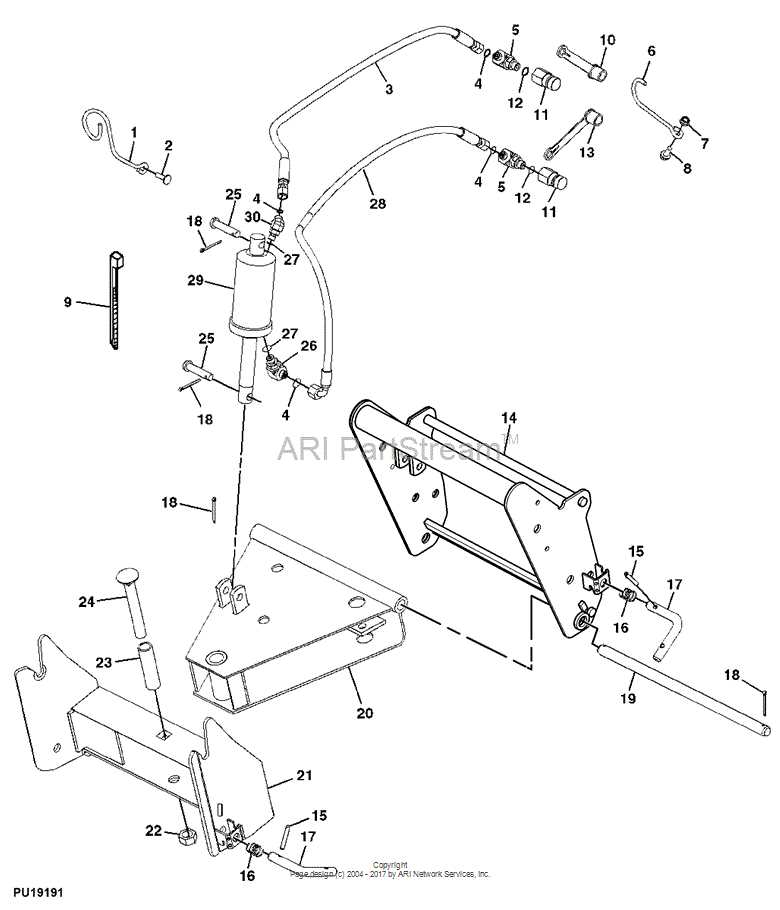

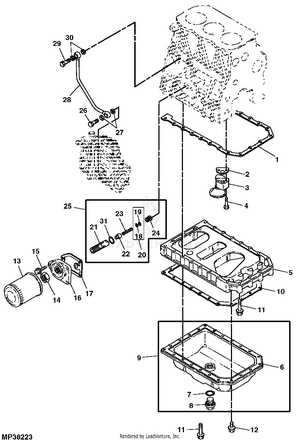

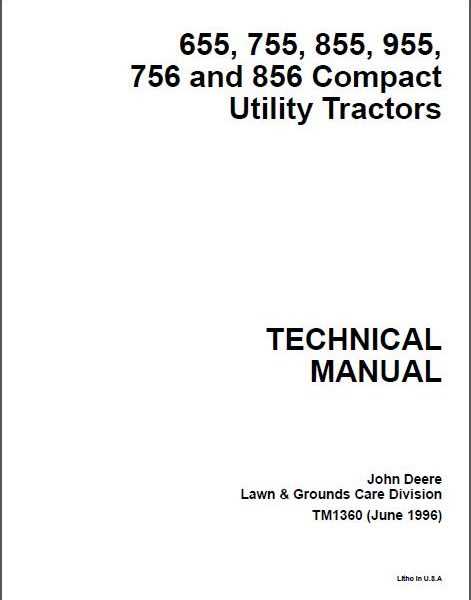

How to Read Parts Diagrams

Understanding schematic representations is crucial for anyone involved in maintenance or repair tasks. These illustrations provide detailed visual guides that help identify components and their interrelationships within a system. Familiarity with these visuals allows users to efficiently locate items, facilitating effective troubleshooting and replacement procedures.

To begin interpreting these visuals, start by familiarizing yourself with the symbols and annotations used throughout. Each representation often includes a legend that explains the various icons and their meanings. This key is essential for correctly identifying the elements depicted in the illustration.

Next, pay attention to the layout and organization of the schematic. Components are typically arranged logically, often in the order they are connected or assembled. Observing this arrangement can provide insight into the assembly process and help in understanding how different parts interact with one another.

Lastly, take note of any reference numbers or codes associated with each component. These identifiers are critical for sourcing replacements or conducting further research. By following these steps, one can effectively navigate and utilize schematic representations to enhance repair and maintenance efforts.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your equipment. Regular attention to details ensures optimal performance and prevents premature wear. Implementing a systematic approach to maintenance not only maximizes efficiency but also minimizes the risk of unexpected failures. Below are key strategies to help you maintain your machinery effectively.

Regular Inspections

Frequent assessments of your machinery are crucial. Check for signs of wear and tear, fluid leaks, and loose components. Early detection of issues allows for timely repairs, which can save both time and money in the long run.

Routine Cleaning

Keeping your equipment clean is vital. Dirt and debris can lead to overheating and other mechanical problems. Regularly remove buildup from filters, cooling systems, and moving parts to ensure smooth operation and prevent blockages.

Sourcing Authentic Replacement Parts

Finding the right components for machinery ensures longevity and reliable performance. It’s important to prioritize quality and compatibility when selecting substitutes to maintain optimal functioning. This section outlines how to identify trusted sources and key factors to consider when looking for genuine elements.

- Manufacturer Approval: Always verify that the supplier is recognized by the original equipment manufacturer. This guarantees that the replacements meet the required specifications.

- Supplier Reputation: Research the track record of vendors. Reviews and ratings from other customers can provide valuable insights into product reliability and service.

- Warranty and Support: Opt for distributors who offer warranties on their products. This indicates confidence in the quality of the components and provides security for the buyer.

- Material and Build Quality: Check the materials used in construction. Components made with subpar materials can lead to quicker wear and tear.

In conclusion, sourcing

Comparing Aftermarket Options vs. OEM

When considering replacement components for machinery, it’s essential to evaluate the differences between two main categories: aftermarket alternatives and original manufacturer offerings. Each option has its advantages and potential drawbacks, influencing the decision-making process for users seeking optimal performance and reliability.

Aftermarket options typically provide a cost-effective solution, appealing to those looking to save on expenses without compromising too much on quality. These alternatives are often produced by third-party manufacturers and may offer unique features or enhancements not available in the original versions. However, it’s crucial to research the supplier’s reputation and ensure that their products meet the necessary standards for safety and performance.

On the other hand, OEM offerings are designed and produced by the original equipment manufacturer, ensuring a perfect fit and compatibility with the specific machinery. This can lead to greater reliability and peace of mind for users who prioritize maintaining the integrity of their equipment. Nonetheless, this option often comes at a premium price, which may not be justifiable for all users, especially if they have budget constraints.

Ultimately, the choice between aftermarket and original options hinges on individual needs, budget considerations, and the desired balance between quality and cost. Users should carefully assess their requirements and conduct thorough research to make an informed decision that aligns with their operational goals.