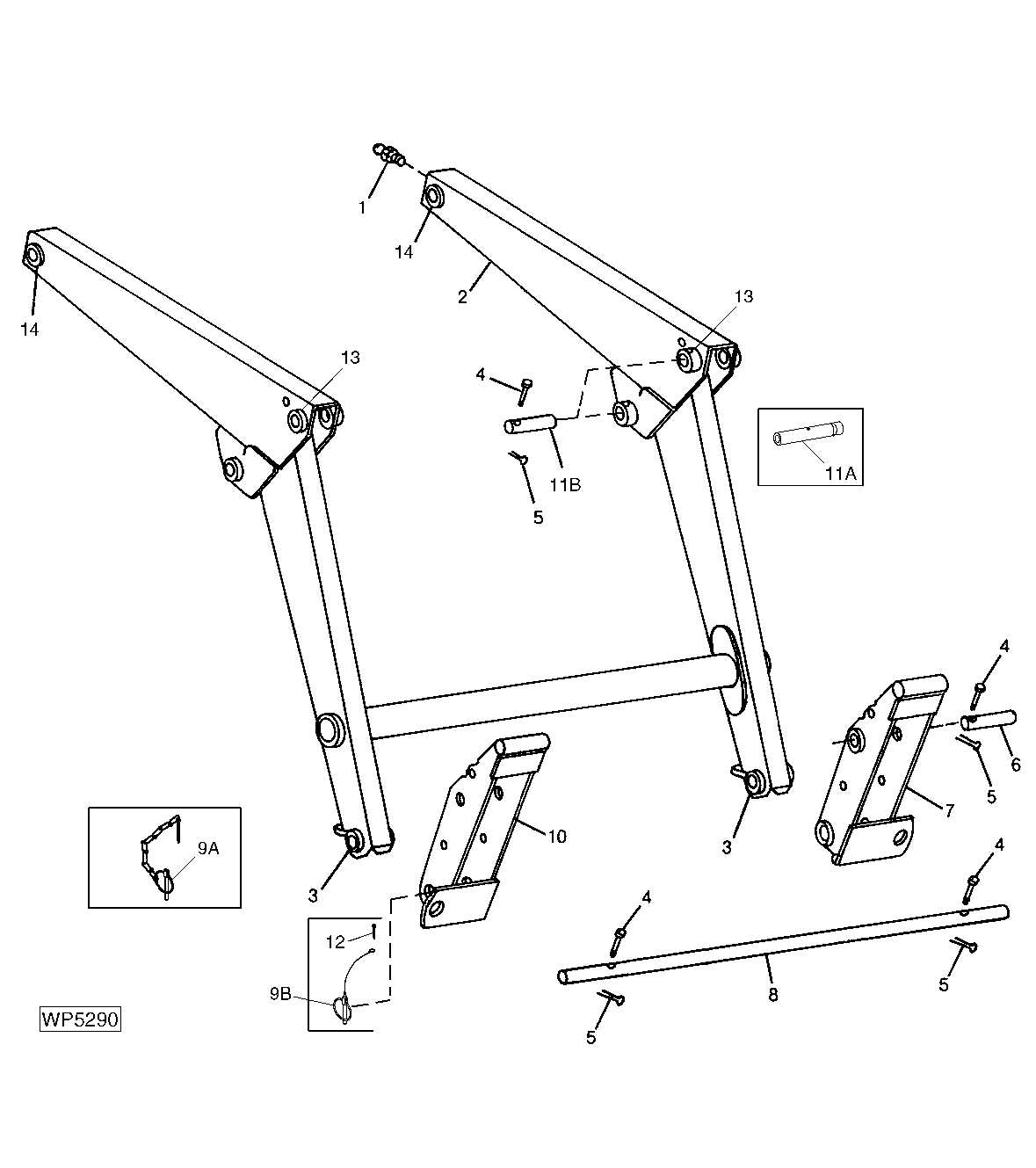

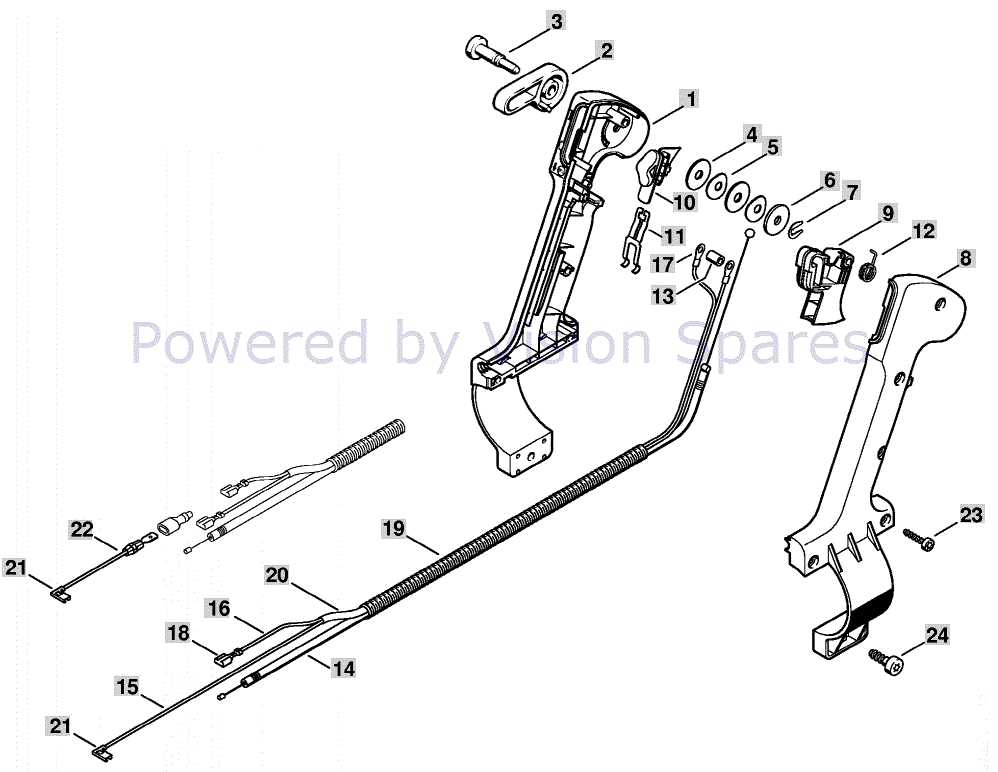

In the realm of agricultural machinery, comprehending the layout of various components is essential for effective maintenance and repair. An organized visual representation aids in identifying individual elements and their interconnections, ensuring that operators can efficiently troubleshoot and optimize performance.

These visual aids serve as invaluable resources for both seasoned professionals and novices, offering clarity in understanding how different sections interact within the larger system. By studying these representations, one can enhance their knowledge of machinery functionality, leading to better upkeep and prolonged lifespan of the equipment.

Moreover, familiarizing oneself with the intricacies of machinery components empowers users to undertake repairs with confidence. This approach not only saves time but also reduces dependency on external services, ultimately fostering a greater sense of independence in managing agricultural tasks.

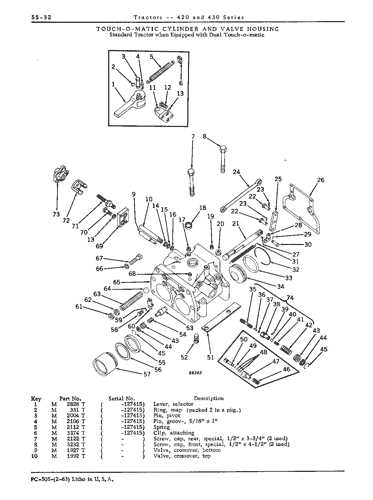

Understanding John Deere 420 Components

Exploring the intricate elements of agricultural machinery reveals the essential components that contribute to their functionality. A comprehensive understanding of these parts not only enhances operational efficiency but also aids in effective maintenance and troubleshooting.

Core Elements of Machinery

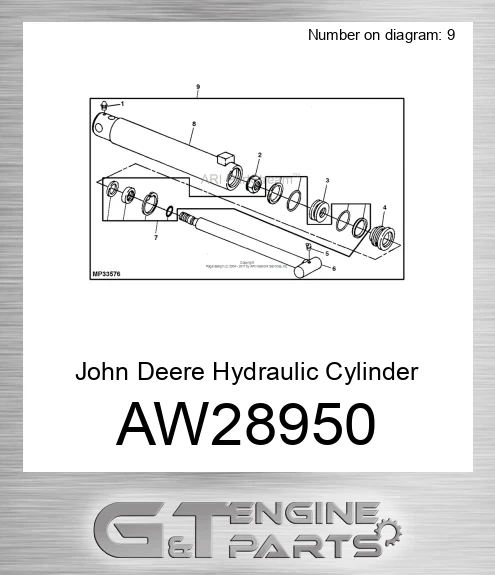

Each machine is composed of various crucial elements, including the powertrain, transmission, and hydraulic systems. The powertrain is responsible for converting fuel into mechanical energy, while the transmission regulates speed and torque. Additionally, hydraulic systems play a vital role in facilitating movement and operating implements.

Maintenance and Troubleshooting

Regular inspection of these components is paramount for ensuring optimal performance. Identifying wear and tear early can prevent costly repairs and downtime. Moreover, understanding the specific functions of each element enables operators to troubleshoot effectively, leading to more informed decisions regarding repairs and replacements.

Key Features of John Deere 420

This section highlights the significant attributes of a well-known agricultural machine, showcasing its advantages and functionalities that enhance performance in various tasks.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that ensures high efficiency and reliability in demanding conditions. |

| Versatile Attachments | Supports a wide range of attachments, allowing for diverse agricultural and landscaping applications. |

| User-Friendly Controls | Designed with intuitive controls, making operation straightforward for users of all experience levels. |

| Durable Build | Constructed with high-quality materials, ensuring longevity and resistance to wear and tear. |

| Excellent Maneuverability | Features compact design that allows for easy navigation in tight spaces and varied terrains. |

Importance of Accurate Parts Diagrams

Precise representations of components play a vital role in maintenance and repair tasks. These illustrations not only facilitate the identification of individual elements but also enhance the efficiency of assembly and disassembly processes. When technicians and operators have access to clear visuals, they can minimize errors and improve overall productivity.

Enhanced Understanding

Clear visual aids contribute significantly to the comprehension of complex machinery. When users can see how each element interacts within the system, they are better equipped to diagnose issues and perform necessary interventions. This understanding leads to fewer mistakes and faster resolutions.

Efficient Maintenance

Having accurate representations simplifies the maintenance process. Technicians can quickly locate specific components, leading to a more streamlined workflow. This efficiency not only saves time but also reduces costs associated with prolonged downtimes.

| Benefit | Description |

|---|---|

| Improved Accuracy | Reduces risk of mistakes in repairs and installations. |

| Time Savings | Facilitates quicker diagnostics and solutions. |

| Cost Efficiency | Lowers expenses by minimizing unnecessary replacements. |

| Enhanced Training | Serves as a valuable resource for educating new personnel. |

Where to Find John Deere 420 Parts

Locating components for your agricultural machinery can be a straightforward process when you know where to look. Various sources offer a range of options, ensuring you can find the necessary items for maintenance or repair tasks. From online marketplaces to local suppliers, there are multiple avenues to explore for acquiring high-quality replacements.

One of the most convenient methods is to utilize the internet. Numerous e-commerce platforms specialize in equipment accessories, providing extensive catalogs that can be searched by model or part number. Additionally, manufacturer websites often have dedicated sections where you can find original replacements directly from the source.

If you prefer a hands-on approach, visiting local equipment dealers is another effective option. Many dealers have knowledgeable staff who can assist in identifying the correct components you need. Furthermore, salvage yards can be a treasure trove for finding used items at reduced prices, which can be particularly beneficial for older models.

Don’t overlook community forums and online groups dedicated to machinery enthusiasts. These platforms can provide valuable insights and recommendations on where to find specific items, as well as tips from other users who have faced similar challenges. Engaging with fellow owners can enhance your search and help you uncover hard-to-find components.

Common Issues with John Deere 420

Operating machinery often comes with its own set of challenges. Understanding typical problems can help owners maintain their equipment effectively and minimize downtime. This section outlines frequent issues encountered by users of a specific model, providing insights into potential causes and solutions.

One prevalent concern involves engine performance. Users may notice a decrease in power or difficulty starting the machine, which can stem from fuel delivery issues or air filter blockages. Regular maintenance checks are crucial to ensure optimal functionality.

Another common problem relates to the hydraulic system. Users may experience leaks or reduced lifting capacity, which could indicate worn seals or a malfunctioning pump. Addressing these issues promptly is essential to prevent further damage and ensure efficient operation.

Additionally, the electrical system can pose challenges, such as faulty wiring or issues with the ignition system. Regular inspections and timely repairs can prevent more significant electrical failures that could hinder overall performance.

Lastly, wear and tear on tires or tracks is a typical concern that can affect traction and stability. Monitoring tire pressure and tread condition will help maintain safety and efficiency during operation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. By adopting a few key practices, you can minimize wear and tear while maximizing productivity.

1. Regular Inspections: Conduct frequent checks on all components to identify potential issues before they escalate. Look for signs of wear, leaks, or unusual noises that may indicate a need for immediate attention.

2. Cleanliness is Key: Keep your equipment clean by removing dirt, debris, and residues. A clean machine operates more efficiently and is less prone to corrosion and damage.

3. Lubrication: Regularly lubricate moving parts to reduce friction and prevent premature wear. Ensure that you use the correct type of lubricant as specified by the manufacturer.

4. Follow a Maintenance Schedule: Adhere to a detailed maintenance schedule that outlines when specific tasks should be completed. This will help you stay organized and ensure no essential tasks are overlooked.

5. Use Quality Components: When replacement parts are needed, choose high-quality components that meet or exceed manufacturer specifications. This will ensure compatibility and enhance overall performance.

6. Monitor Fluid Levels: Regularly check and maintain proper fluid levels in all systems, including hydraulic, oil, and coolant. Low fluid levels can lead to overheating and severe damage.

7. Store Properly: When not in use, store your machinery in a dry and sheltered area to protect it from the elements. This simple step can prevent rust and other weather-related damage.

By implementing these maintenance tips, you can significantly increase the longevity of your machinery, ensuring it remains reliable and efficient for years to come.

Upgrading Your John Deere 420

Enhancing the functionality and efficiency of your agricultural machine can significantly improve your productivity. Whether you seek to increase power, improve handling, or enhance comfort, there are numerous modifications available. This section explores several key upgrades that can elevate your equipment’s performance and extend its lifespan.

Performance Enhancements

- Engine Tuning: Consider adjusting the engine settings to boost horsepower and torque.

- Exhaust System Upgrade: A high-performance exhaust can improve airflow, leading to better engine efficiency.

- Transmission Modifications: Upgrading gears or implementing a different transmission type can enhance speed and responsiveness.

Comfort and Usability Improvements

- Cab Upgrades: Adding a more comfortable seat and better climate control can make long hours in the field more enjoyable.

- Attachment Compatibility: Invest in versatile attachments to increase the machine’s functionality for various tasks.

- Lighting Enhancements: Installing brighter LED lights will improve visibility during nighttime operations.

By implementing these upgrades, you can transform your machine into a more powerful and comfortable tool, ready to tackle any challenge on your farm.

Compatibility of Aftermarket Parts

When it comes to enhancing the functionality and longevity of machinery, the integration of third-party components can often provide significant advantages. However, understanding the compatibility of these alternative options is crucial for ensuring optimal performance and preventing potential issues.

Evaluating Compatibility

Before selecting aftermarket components, it’s essential to evaluate their compatibility with the existing system. Not all substitutes are created equal; variations in design, material quality, and specifications can affect how well they integrate with original equipment. Thorough research and consultations with experts can aid in making informed decisions.

Benefits of Aftermarket Solutions

Opting for third-party solutions can offer several benefits, including cost savings and access to innovative features not available in original items. Many aftermarket suppliers provide warranties and customer support, enhancing confidence in their products. Nevertheless, ensuring that these alternatives meet or exceed the standards set by the original manufacturer is key to a successful upgrade.