Maintaining a lawn care machine involves more than just routine cleaning and fueling; it requires a thorough understanding of its intricate parts. By familiarizing yourself with each component, you can enhance both performance and longevity. This knowledge allows users to tackle repairs with confidence, ensuring the machinery operates at peak efficiency.

Identifying individual elements is crucial for anyone seeking to optimize their equipment. Whether you’re dealing with the cutting deck, engine, or drive system, recognizing how these pieces interact can lead to smarter maintenance practices. Moreover, understanding the configuration aids in troubleshooting and enhances your ability to perform effective repairs.

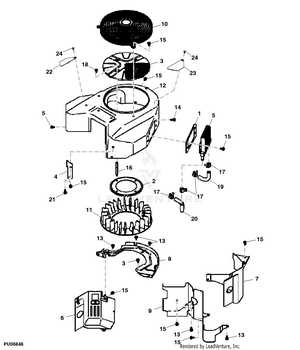

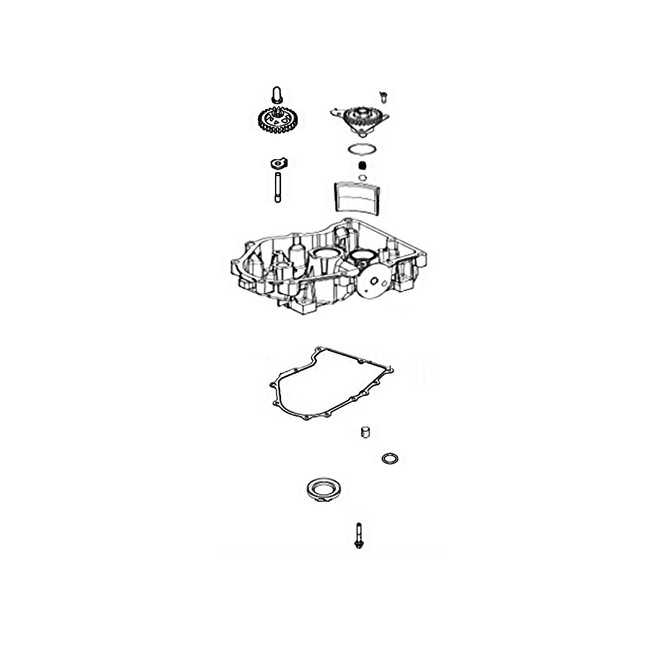

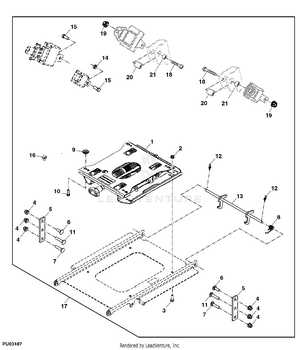

For enthusiasts and professionals alike, a visual representation of the machine’s architecture serves as a valuable resource. Such illustrations break down the layout into manageable sections, facilitating a clearer grasp of where each part fits within the overall system. This organized view not only simplifies the repair process but also empowers users to take proactive measures in equipment upkeep.

Understanding John Deere Z925A Components

Exploring the intricate elements of this mowing machine reveals a complex interplay of various systems that contribute to its functionality. Each component plays a vital role in ensuring optimal performance, efficiency, and durability, catering to the diverse needs of landscaping and lawn maintenance.

Key Functional Elements

At the heart of the system are the engine and transmission, which work together to deliver power and control. The engine serves as the powerhouse, while the transmission allows for seamless movement across different terrains. Additionally, the cutting deck is designed to provide precision and consistency in trimming grass, ensuring an even finish.

Maintenance and Repair Insights

Understanding the significance of regular maintenance for these components is essential for longevity. Regular checks on belts, filters, and blades help prevent breakdowns and enhance overall performance. Familiarity with these essential elements not only aids in troubleshooting but also empowers operators to carry out effective repairs when necessary.

Importance of Accurate Parts Diagrams

Detailed schematics play a crucial role in the maintenance and repair of machinery. They serve as essential tools for technicians and owners alike, facilitating a deeper understanding of how components interact within a system. Accurate representations ensure that individuals can effectively identify, source, and replace any necessary elements, ultimately enhancing the longevity and functionality of equipment.

Benefits of Precise Illustrations

- Efficient Repairs: Clear visuals help streamline the repair process by allowing for quicker identification of issues.

- Reduced Errors: Having a well-defined reference minimizes the chances of using incorrect components during replacements.

- Time Savings: Familiarity with the layout leads to faster troubleshooting and reduced downtime.

Enhanced User Understanding

- Visual aids assist users in grasping complex systems more easily.

- They empower individuals to perform routine maintenance confidently.

- Accurate visuals foster better communication between users and service professionals.

In summary, investing in reliable schematics is vital for anyone involved in the upkeep of machinery, ensuring smoother operations and effective maintenance practices.

Common Issues with Z925A Parts

In the realm of outdoor machinery, certain components often encounter challenges that can impact performance and longevity. Understanding these typical problems can help owners maintain their equipment more effectively.

Worn Blades: One frequent concern is the deterioration of cutting edges, which can lead to uneven mowing and increased effort during operation. Regular inspections and timely replacements are essential.

Hydraulic Leaks: Another issue involves hydraulic systems, where leaks may arise due to damaged hoses or fittings. These leaks can compromise efficiency and require immediate attention to prevent further damage.

Battery Failures: Power issues, particularly with batteries, can also occur. Corrosion and poor connections are common culprits that can leave machinery inoperable. Routine maintenance can mitigate these risks.

Wheel Wear: Finally, tire wear is a prevalent issue that can affect traction and maneuverability. Ensuring proper inflation and alignment can enhance durability and performance.

How to Read Parts Diagrams Effectively

Understanding visual representations of components can significantly enhance your ability to identify and locate necessary items for maintenance or repair tasks. Mastering the art of interpreting these illustrations will ultimately lead to greater efficiency and fewer mistakes.

Begin with the Legend: Always start by examining the legend or key, which provides essential information on symbols and labels used in the illustration. This will help you comprehend the various elements represented.

Identify Sections: Break down the visual into distinct sections. By focusing on one area at a time, you can more easily trace connections and understand the relationship between various components.

Cross-reference with Manuals: Utilize any accompanying manuals or guides. These resources often provide additional context and detailed explanations, enabling you to delve deeper into the specifics of each part.

Take Notes: As you analyze the illustration, jot down notes or highlight key items. This practice reinforces your understanding and serves as a quick reference for future tasks.

Practice Regularly: Familiarity grows with repetition. Regularly studying different visual representations will help you recognize patterns and improve your overall skill in interpreting these valuable resources.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its performance and longevity. Various sources offer a range of options, ensuring you can easily acquire what you need for repairs and maintenance.

Authorized Dealers

Visiting authorized dealers is one of the best ways to secure genuine replacements. These outlets typically have access to the latest inventory and can provide expert advice on compatibility and installation.

Online Retailers

Many online platforms specialize in equipment components, offering convenience and competitive pricing. Be sure to check customer reviews and ratings to ensure you are purchasing from reputable sources.

Maintenance Tips for Z925A Models

Regular upkeep is essential for ensuring the longevity and efficiency of your mowing equipment. By following a structured maintenance routine, you can enhance performance, reduce the risk of breakdowns, and extend the life of your machine. This section outlines key practices that will help keep your mower in top condition.

Routine Maintenance Tasks

- Check the Oil Level: Regularly inspect and change the oil to prevent engine wear.

- Inspect Air Filters: Clean or replace filters as needed to maintain optimal airflow.

- Sharpen Blades: Keeping blades sharp ensures a clean cut and promotes healthy grass.

- Examine Tires: Monitor tire pressure and tread for safe and efficient operation.

- Clean the Undercarriage: Remove grass clippings and debris to prevent buildup and rust.

Seasonal Considerations

- Spring: Perform a thorough inspection and prepare for the mowing season.

- Summer: Regularly check fluid levels and keep an eye on overheating.

- Fall: Prepare for winter storage by cleaning and servicing the equipment.

- Winter: Store in a dry place, and consider using a battery maintainer.

By adhering to these maintenance guidelines, you will ensure your mower remains reliable and performs at its best throughout the seasons.

Upgrades and Customizations Available

Enhancing your mowing equipment can significantly improve its performance and functionality. Various modifications can transform standard models into highly efficient machines tailored to specific needs. From improved cutting systems to additional features, the options are vast and cater to both amateur gardeners and professional landscapers.

Performance Enhancements

One of the primary focuses for upgrades is boosting performance. High-quality blades, enhanced engines, and advanced transmission systems can be incorporated to achieve superior cutting efficiency. Investing in premium components can lead to faster mowing times and a more precise finish.

Comfort and Usability Features

Customizations aimed at comfort and ease of use are also available. Ergonomic seats, upgraded controls, and improved visibility options can make a significant difference during extended use. These enhancements not only increase user satisfaction but also contribute to better overall productivity.

Comparing Z925A with Other Models

This section explores the nuances between a specific model and its counterparts, highlighting differences in design, functionality, and overall performance. By examining these variations, users can make informed decisions based on their specific needs and preferences.

Key Differences

When assessing different machinery, various aspects such as engine power, cutting width, and fuel efficiency come into play. Each model offers unique advantages that cater to different operational requirements.

Performance Comparison

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power (HP) | 25 | 23 | 28 |

| Cutting Width (inches) | 54 | 48 | 60 |

| Fuel Efficiency (mpg) | 3.5 | 3.0 | 4.0 |