Understanding how various mechanical elements interact and work together is crucial for ensuring smooth operation and maintenance. This section provides an in-depth look into the key elements and connections that form a functional and efficient system.

Whether you’re performing repairs, replacements, or regular checks, being familiar with the specific configuration of each component can make the task significantly easier. Proper identification helps avoid errors and ensures that every part operates as intended, contributing to overall longevity and performance.

Efficient upkeep relies heavily on recognizing the core mechanical pieces involved. By having a clear picture of these components, you can streamline troubleshooting, maintain optimal function, and reduce downtime. In this guide, you’ll find an organized overview that covers all necessary aspects to help you with any maintenance task.

Comprehensive Overview of the John Deere 2305

In this section, we will explore a versatile and reliable compact machine that has become essential for a wide range of tasks. Known for its efficiency and flexibility, this equipment offers excellent performance across various operations. It is highly valued for its capability to handle different workloads, from routine maintenance to more demanding projects.

Key Features of this model include a robust engine, precise handling, and adaptable attachments, making it suitable for various types of work environments. The ability to switch between functions easily adds to its appeal, ensuring a smooth operation whether in a home garden or a professional setting.

Another noteworthy aspect of this equipment is its durability, which guarantees longevity and minimal need for repairs. This makes it a cost-effective choice for users seeking a dependable solution for their daily tasks.

Key Components of the Compact Tractor

This section will highlight the essential mechanical and functional elements of a compact utility vehicle designed for agricultural tasks. Each component plays a critical role in ensuring the machine operates efficiently and reliably across various applications.

- Engine System: The power source that drives the entire machine, ensuring smooth operation and providing the necessary torque for demanding tasks.

- Transmission: A vital part of the vehicle, allowing seamless gear shifts and ensuring the right speed and power are available when needed.

- Hydraulics: Essential for lifting and operating attachments such as loaders and mowers, this system ensures precise control of external implements.

- Chassis and Frame: The structural backbone of the vehicle, designed to withstand heavy loads and provide stability on different terrains.

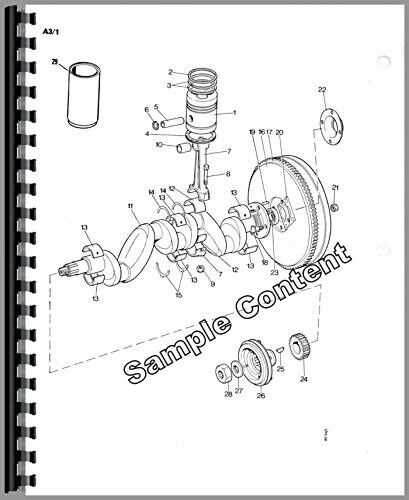

- Cylinder block

- Pistons and connecting rods

- Crankshaft

- Camshaft and timing mechanisms

- Valves and valve springs

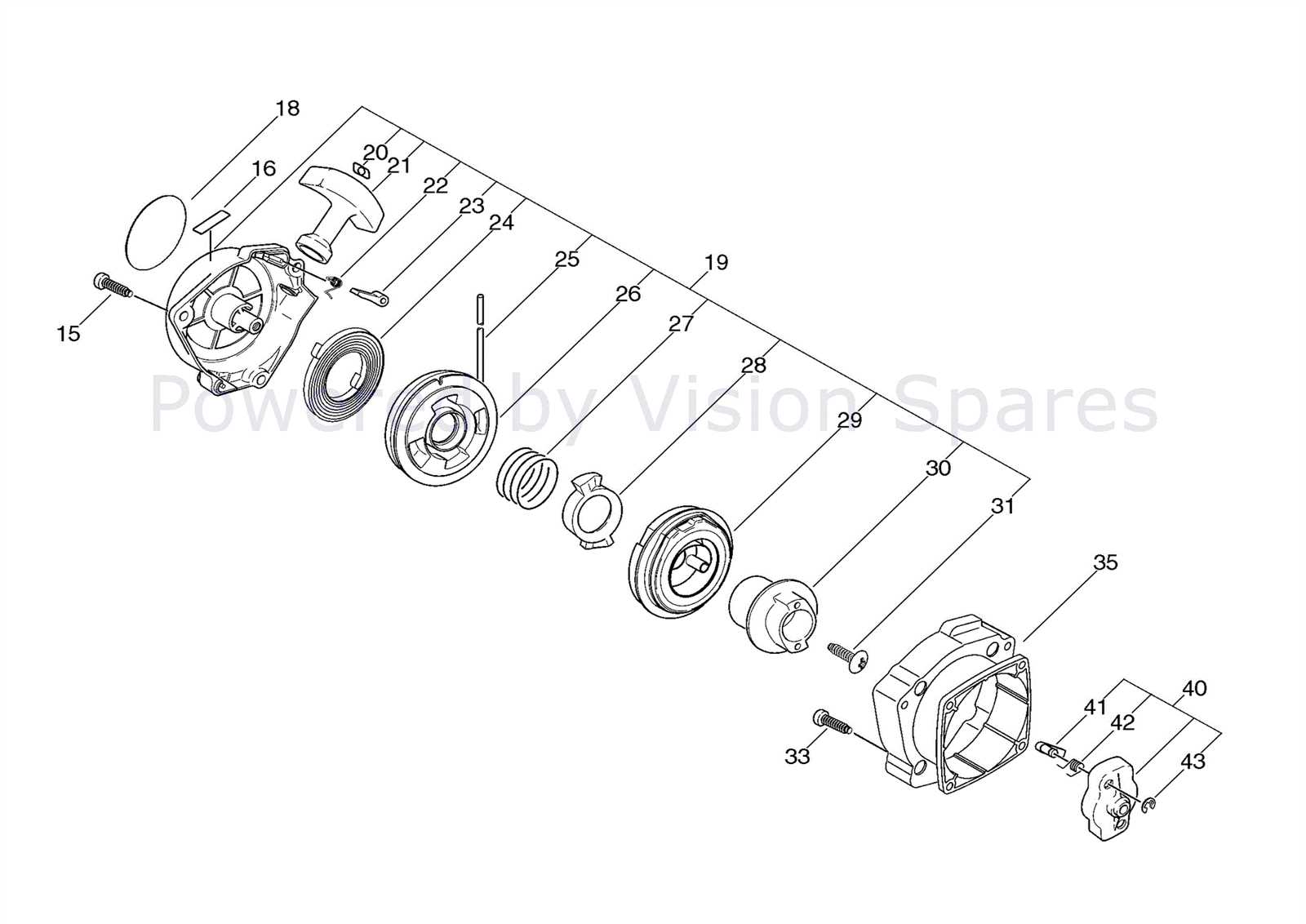

Detailed Breakdown of Engine Components

The engine is composed of various interconnected elements, each playing a critical role in its overall functionality. Understanding how these components fit together and contribute to the engine’s operation is essential for maintenance and troubleshooting.

Main Components

Supporting Systems

In addition to the main parts, several supporting systems ensure the engine runs smoothly and efficiently. These include:

- Cooling system

- Lubrication system

- Fuel delivery mechanisms

- Exhaust system

Each of these systems works in harmony, ensuring the engine remains reliable under various conditions. A deeper understanding of how they interact is vital for keeping the machinery in peak performance.

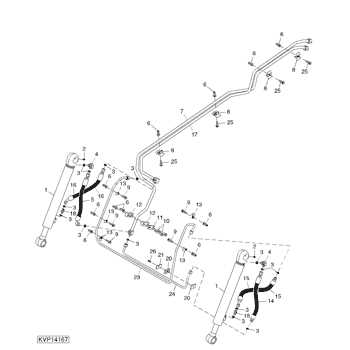

Hydraulic System Structure and Functions

The hydraulic system is a vital component in modern machinery, responsible for delivering power through fluid dynamics. By using pressurized liquid, the system efficiently transfers energy to various mechanical parts, enabling smooth and controlled movements. Understanding how this system operates helps ensure proper maintenance and optimal performance.

Components of the Hydraulic System

A typical hydraulic system consists of key elements such as a pump, valves, actuators, and hoses. The pump generates the necessary pressure, while valves control the flow and direction of the liquid. Actuators convert the hydraulic energy into mechanical motion, driving the movement of different mechanisms.

Main Functions of the Hydraulic System

The primary role of the hydraulic system is to transmit power efficiently. Pressurized fluid ensures smooth operation of machinery, while precise control of flow allows for accurate adjustments in speed and force. Regular inspection and maintenance are crucial to avoid breakdowns and maintain consistent functionality.

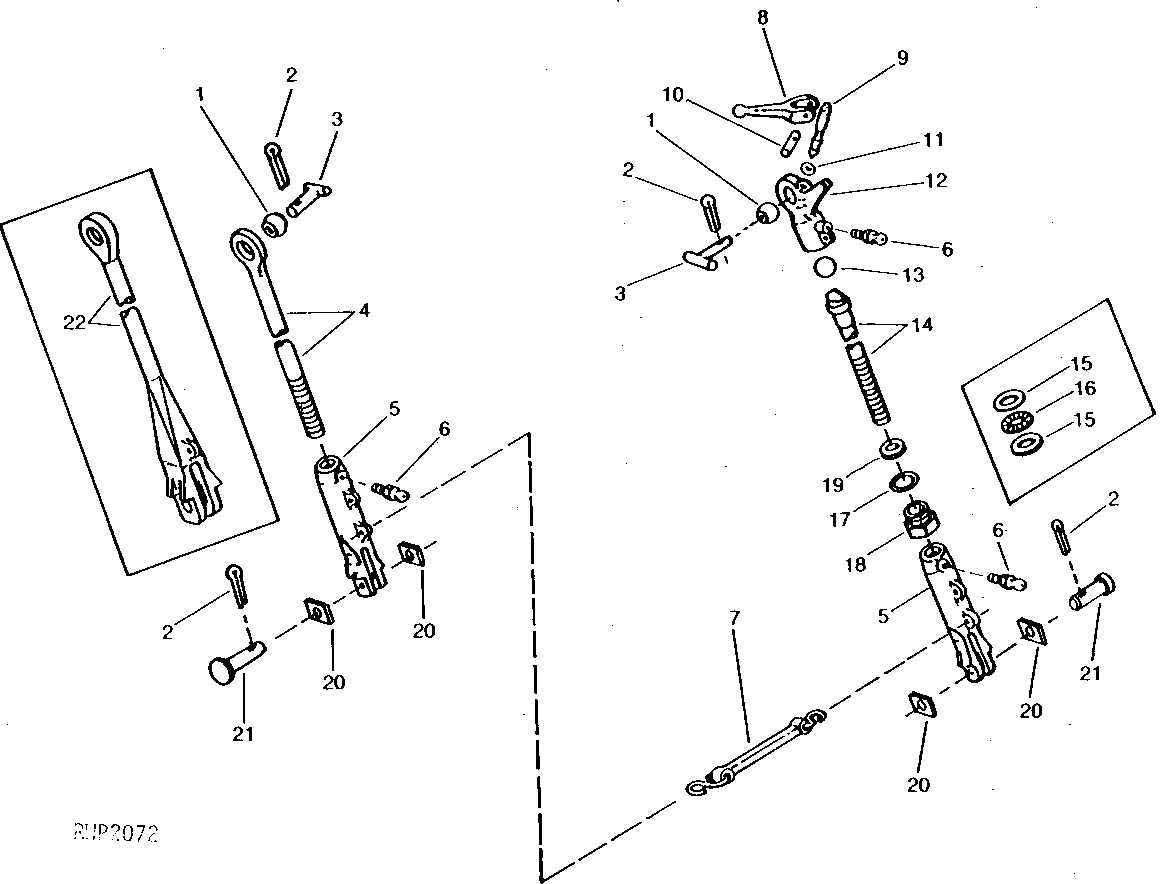

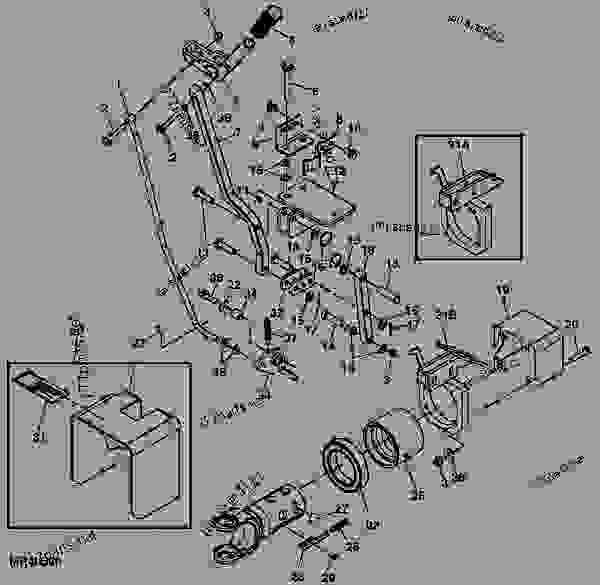

Transmission Parts and Their Roles

The transmission system plays a critical role in ensuring smooth operation by transmitting power from the engine to the wheels. Each component within the system has a specific function that contributes to the overall efficiency and performance of the machine. Understanding how these elements work together can help maintain functionality and prevent issues.

Main Components

Key elements include gears, shafts, and bearings, all of which collaborate to manage power flow. Gears adjust speed and torque, while shafts transfer energy between different sections of the transmission system. Bearings ensure smooth movement and reduce friction during operation.

Supporting Elements

In addition to the core components, smaller mechanisms such as seals and gaskets provide essential support. These elements prevent leaks and contamination, helping to prolong the life of the entire system.

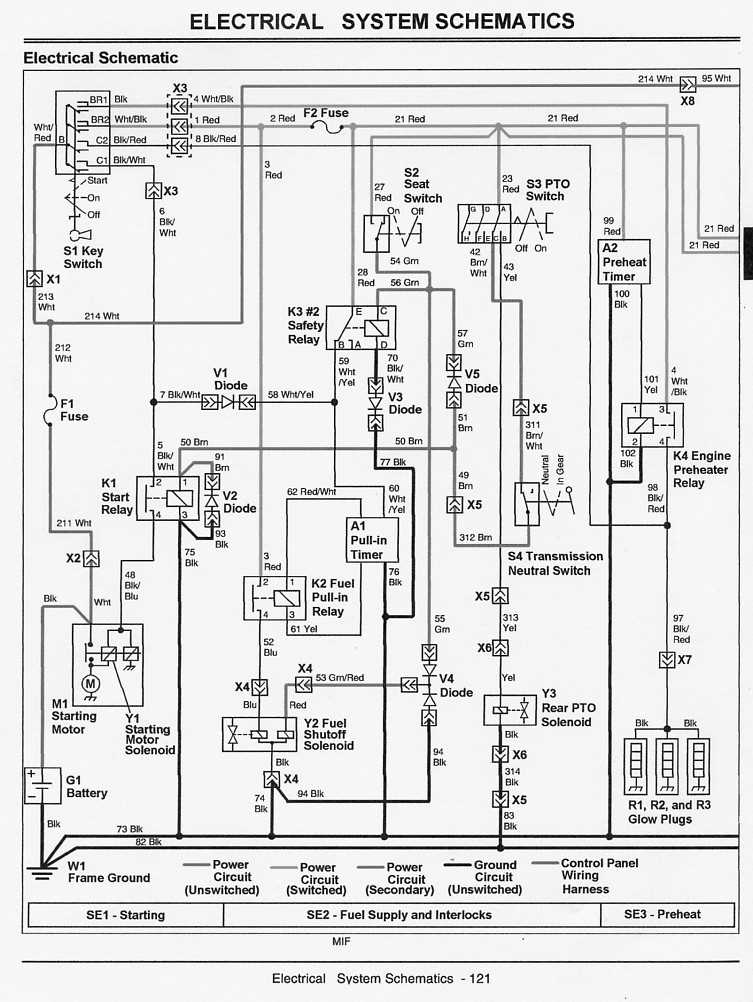

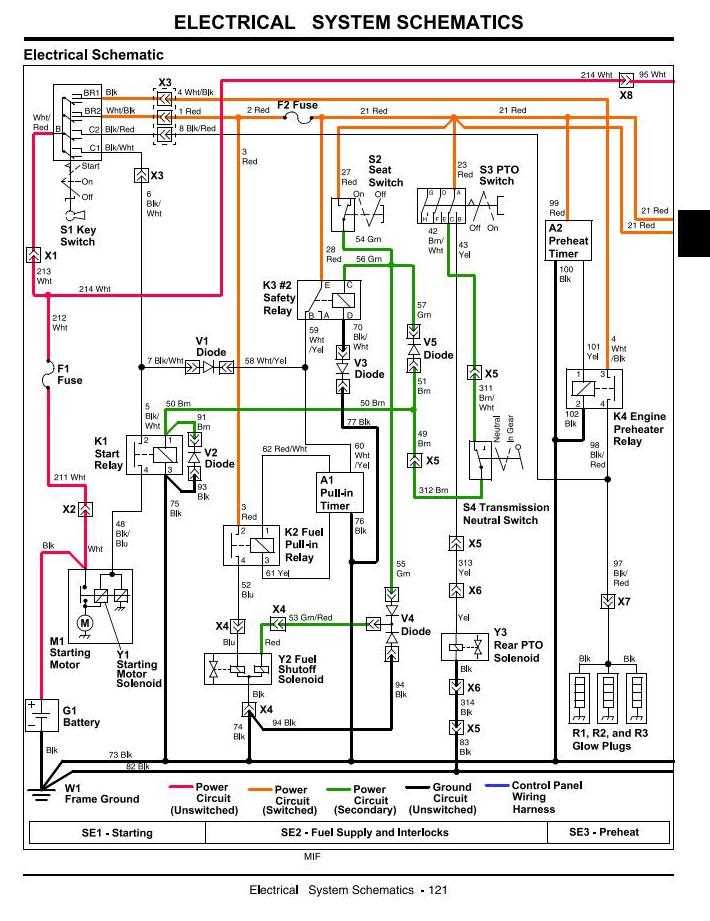

Electrical System Overview for the 2305 Model

The electrical system in compact utility vehicles plays a crucial role in ensuring optimal performance and functionality. This network is designed to provide power to various components, facilitating operation and enhancing user experience. Understanding the intricacies of this system is essential for effective maintenance and troubleshooting.

Key Components

This model features several integral components that contribute to the overall efficiency of the electrical network. Each part is designed to work harmoniously with the others, ensuring reliable operation and minimal downtime.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting and powering the vehicle. |

| Alternator | Generates electricity to recharge the battery and power electrical systems. |

| Starter Motor | Engages the engine to initiate combustion and vehicle operation. |

| Wiring Harness | Facilitates the connection between electrical components, ensuring efficient power distribution. |

Troubleshooting Common Issues

Recognizing common electrical problems is vital for effective resolution. Regular inspections and understanding the functions of each component can significantly reduce the risk of malfunctions.

Steering Mechanism and Its Maintenance

The steering system is a crucial component that ensures precise control and maneuverability of the vehicle. Proper functioning of this mechanism is essential for achieving optimal performance and safety. Regular maintenance helps in identifying potential issues early and ensures longevity.

To maintain the steering system effectively, consider the following key aspects:

- Regular Inspections: Routinely check for wear and tear, as well as any loose or damaged components.

- Fluid Levels: Ensure that steering fluid is at the recommended levels and replace it as necessary to maintain hydraulic efficiency.

- Alignment Checks: Perform alignment checks periodically to ensure the steering mechanism is functioning correctly and to prevent uneven tire wear.

- Cleaning: Keep the steering assembly clean to prevent dirt and debris from interfering with its operation.

- Professional Servicing: Seek professional help for complex repairs or replacements to avoid further damage.

Implementing these maintenance practices will enhance the reliability of the steering system and contribute to the overall performance of the vehicle.

Understanding the Fuel System Components

The fuel system is a crucial aspect of any machinery, ensuring that the engine operates efficiently and effectively. It comprises various elements that work together to manage the flow of fuel, maintain optimal pressure, and ensure proper combustion. A thorough understanding of these components is essential for troubleshooting and maintenance.

Key Components of the fuel system include the fuel tank, which stores the fuel, and the fuel pump, responsible for transferring the fuel to the engine. The fuel filter plays a vital role in removing impurities, while the fuel injectors deliver the right amount of fuel into the combustion chamber. Each of these elements must function properly to guarantee the overall performance of the machine.

Regular maintenance and inspection of these components can prevent potential issues, ensuring that the engine runs smoothly. Understanding how each part contributes to the fuel system’s functionality is beneficial for operators and technicians alike.

Troubleshooting Common Parts Issues

When dealing with machinery, understanding the common challenges associated with components can significantly enhance maintenance and performance. Identifying and resolving these issues can lead to improved functionality and longevity of the equipment.

Here are some frequent problems and their potential solutions:

- Wear and Tear: Components may exhibit signs of deterioration over time. Regular inspections can help in identifying parts that require replacement.

- Incompatibility: Sometimes, certain components may not fit well with others. Ensure that replacements are compatible with the existing setup.

- Lubrication Issues: Insufficient lubrication can lead to friction and overheating. Regularly check and maintain appropriate lubricant levels.

- Alignment Problems: Misalignment can cause premature wear. Ensure that all parts are properly aligned to avoid unnecessary strain.

By addressing these common issues promptly, operators can maintain optimal performance and reduce downtime.