When it comes to maintaining and servicing various vehicles or heavy machinery, having reliable hydraulic lifting equipment is essential. This specialized apparatus is designed to provide the necessary support and stability during repairs, ensuring both safety and efficiency. To achieve optimal performance, familiarity with the individual components is crucial.

In this section, we will explore the intricacies of the various elements that make up this lifting tool. Each component plays a vital role in the overall functionality, contributing to the apparatus’s ability to elevate substantial weight with ease. By examining these parts, users can enhance their understanding of the equipment, facilitating better maintenance and troubleshooting practices.

Equipped with the right knowledge, users will be empowered to identify potential issues, perform repairs, and ensure that their lifting tool operates smoothly. This guide aims to provide clarity on the assembly and function of each component, enabling enthusiasts and professionals alike to maximize their investment in this essential equipment.

Pittsburgh Floor Jack Overview

This section provides a comprehensive look at a popular lifting tool designed for heavy-duty applications. Renowned for its durability and efficiency, this device plays a crucial role in both professional and DIY settings. Understanding its components and functionality enhances user experience and safety.

Key Features

Notable attributes include a robust construction, excellent lift capacity, and user-friendly operation. Many models offer features such as quick lift technology and a low profile design, allowing for versatility across various vehicles and situations.

Maintenance and Care

Regular upkeep is essential for optimal performance. Checking fluid levels, inspecting seals, and cleaning moving parts are vital practices that ensure longevity and reliability in any environment.

Understanding Floor Jack Components

To effectively utilize any lifting mechanism, it is crucial to have a solid grasp of its fundamental elements. Each component plays a specific role, contributing to the overall functionality and safety of the equipment. By familiarizing yourself with these parts, you can enhance your maintenance practices and ensure optimal performance.

Key Components

- Frame: The sturdy base that supports the entire assembly, providing stability during lifting operations.

- Hydraulic Cylinder: This component generates the lifting force by converting hydraulic fluid pressure into mechanical energy.

- Pump Mechanism: Responsible for creating pressure within the hydraulic system, enabling efficient operation.

- Release Valve: Controls the descent of the lifted load, allowing for safe lowering when needed.

- Wheels: Provide mobility, allowing the apparatus to be easily positioned under the load.

Understanding Functionality

Each of these elements works in concert to facilitate safe and effective lifting. Proper maintenance of each part is essential for ensuring reliability and longevity. Regular checks and timely replacements can prevent unexpected failures and enhance user safety.

In summary, recognizing and understanding the distinct components of this equipment is vital for any user. This knowledge not only aids in the effective operation but also empowers individuals to perform necessary maintenance and repairs confidently.

Importance of Maintenance and Care

Regular upkeep and attention to equipment are crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to inefficiencies, decreased safety, and costly repairs over time. By investing time in routine checks and servicing, users can significantly enhance the reliability and functionality of their tools.

Enhancing Safety

Proper maintenance plays a vital role in safety. Regular inspections can identify wear and tear, preventing potential accidents. Ensuring that all components are functioning correctly reduces the risk of malfunctions during use, safeguarding both the operator and surrounding individuals.

Maximizing Efficiency

Well-maintained tools operate at peak performance, allowing for smoother operation and quicker task completion. Routine care, such as lubrication and cleaning, ensures that every mechanism works harmoniously, ultimately saving time and effort in the long run. Emphasizing maintenance not only prolongs the lifespan of the equipment but also contributes to overall productivity.

Common Issues with Floor Jacks

Hydraulic lifting devices are essential tools for various automotive tasks. However, like any mechanical equipment, they can encounter problems that affect their performance. Understanding these common issues can help users maintain their tools and ensure safe operation.

- Fluid Leaks: One of the most frequent issues is the leaking of hydraulic fluid. This can occur due to worn seals or damaged hoses, leading to decreased lifting capability.

- Difficulty in Lifting: If the device struggles to lift weight, it may indicate a problem with the hydraulic system or insufficient fluid levels.

- Unstable Operation: A device that wobbles or feels unstable when lifting can pose serious safety risks. This may be due to uneven surfaces or faulty components.

- Noisy Operation: Unusual sounds during operation can suggest internal damage or the need for lubrication.

- Slow Descent: A slow release of weight can indicate a malfunctioning release valve, which may require adjustment or replacement.

Regular maintenance and timely repairs can help mitigate these issues, ensuring reliable and safe use of lifting equipment.

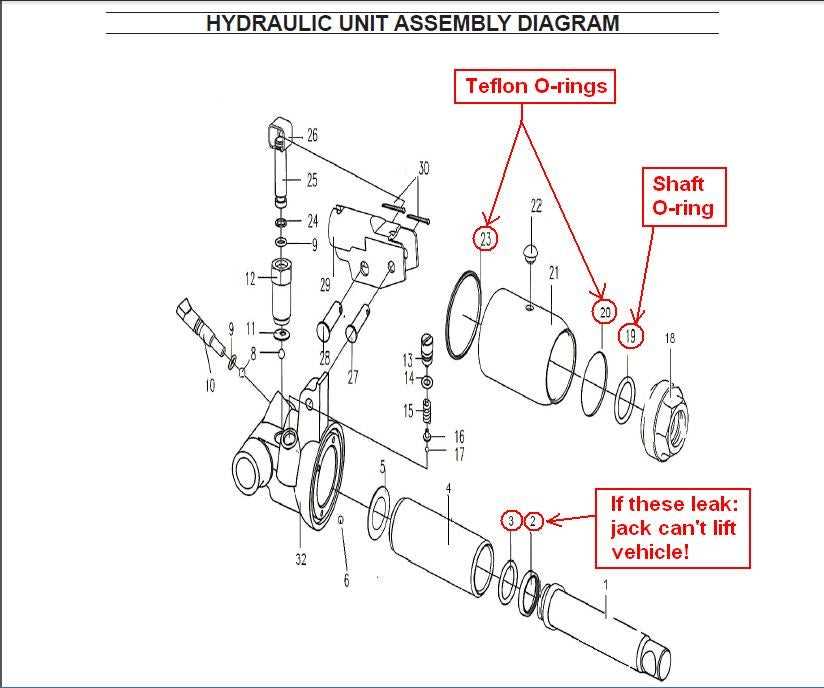

How to Identify Spare Parts

Understanding how to recognize individual components for your equipment is crucial for effective maintenance and repairs. Accurate identification ensures compatibility and functionality, enhancing the overall performance of your device.

Visual Inspection

Begin with a thorough visual examination. Look for identifying markings or numbers that can guide you in locating the correct elements.

Consulting Manuals

User manuals often include valuable information regarding component specifications. Utilize these resources to cross-reference your findings and ensure precise identification.

| Identification Method | Description |

|---|---|

| Visual Inspection | Check for markings and dimensions on the components. |

| User Manuals | Refer to manuals for specifications and diagrams. |

| Online Resources | Explore websites and forums for guidance from other users. |

Step-by-Step Repair Guide

This guide provides a detailed approach to troubleshooting and fixing a common lifting tool. By following these steps, you can ensure your device operates smoothly and efficiently, extending its lifespan and enhancing safety during use.

Identifying Issues

Begin by examining the equipment for any visible signs of wear or damage. Look for leaks, unusual noises, or difficulty in raising and lowering loads. Document any specific issues you encounter, as this will help you during the repair process.

Repair Process

Once you have identified the problems, gather the necessary tools and replacement components. Start by disassembling the mechanism carefully. Ensure safety precautions are in place to prevent accidents. Clean all components to remove dirt and debris. Replace any damaged parts, reassemble the unit, and conduct a thorough test to confirm everything is functioning correctly. Regular maintenance checks will help prevent future issues.

Choosing Quality Replacement Parts

When it comes to maintaining equipment, selecting high-quality components is essential for optimal performance and safety. Reliable alternatives not only enhance the functionality of your tools but also extend their lifespan. Understanding the importance of durability and compatibility can significantly influence your decision-making process.

Evaluating Material and Design

One of the first steps in finding superior alternatives is to assess the materials used in their construction. Robust materials ensure that the components can withstand heavy usage and adverse conditions. Look for options that feature corrosion-resistant finishes or reinforced designs for added strength. Additionally, consider how well the design matches the specifications of your existing equipment; precision engineering can prevent issues down the line.

Researching Brands and Reviews

Not all manufacturers are created equal, so it’s vital to conduct thorough research on brands that produce these essential components. Seek out customer reviews and ratings to gain insights into their reputation. A well-regarded brand often signifies a commitment to quality, ensuring that you invest in items that will not fail when you need them most. Don’t hesitate to consult forums or discussion boards for recommendations and experiences shared by other users.

Safety Tips for Using Floor Jacks

When working with lifting equipment, safety is paramount. Understanding how to properly handle and operate these tools can prevent accidents and ensure a secure environment. Here are essential guidelines to follow for a safe lifting experience.

Preparation and Setup

- Ensure the surface is level and stable before placing the equipment.

- Check the lifting capacity to avoid overloading.

- Inspect the equipment for any signs of damage or wear.

Operation Procedures

- Always use the tool on a solid, non-slip surface.

- Position the lifting mechanism at the correct points specified in the user manual.

- Keep hands and feet clear of the lift area during operation.

- Never work under an unsupported load; always use appropriate safety supports.

- Maintain a clear workspace to avoid tripping hazards.