In the world of farming equipment, having a clear understanding of the various elements that make up machinery is crucial for optimal performance and maintenance. This section delves into the intricate layout of components that contribute to the functionality of specific agricultural tools. By familiarizing oneself with these intricate systems, operators can enhance their efficiency and ensure longevity in their equipment.

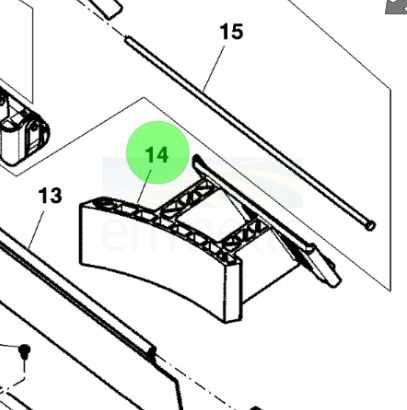

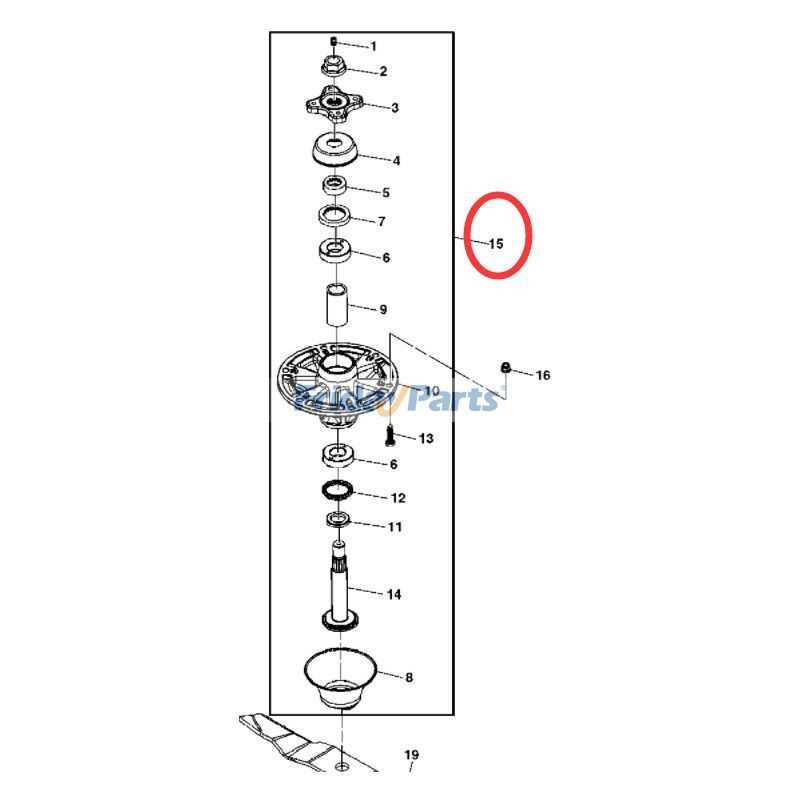

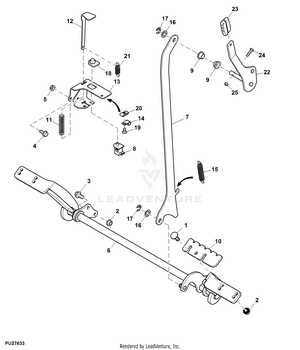

Visual aids play a pivotal role in grasping the relationship between different parts. By examining a detailed schematic, one can easily identify how individual pieces interact, which ultimately facilitates troubleshooting and repairs. This visual representation allows for a comprehensive overview, ensuring that no aspect is overlooked during maintenance procedures.

Moreover, understanding the anatomy of these machines empowers users to make informed decisions when sourcing replacements or upgrades. The availability of precise information not only aids in improving performance but also enhances safety and reliability during operation. Familiarity with the specific configurations can significantly reduce downtime and enhance productivity in agricultural practices.

Overview of John Deere 652R

This section provides a comprehensive look at a specific model in the range of high-performance machinery designed for various agricultural and landscaping tasks. Understanding its features and capabilities can help users make informed decisions regarding their equipment needs.

Key characteristics of this model include:

- Powerful engine options for enhanced performance.

- Robust construction ensuring durability and longevity.

- Advanced technology integration for improved efficiency.

- Versatile attachments that expand functionality for different tasks.

Users benefit from:

- Increased productivity in both commercial and residential applications.

- Ease of operation, reducing the learning curve for new operators.

- Maintenance simplicity, contributing to lower operational costs.

- Excellent maneuverability in tight spaces and varied terrains.

Overall, this equipment is designed to meet the diverse demands of its users, providing reliability and performance that can significantly enhance work efficiency.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining complex machinery. These illustrations serve as valuable resources for technicians and users, providing clarity on assembly and function. By offering a detailed view of individual elements, they simplify the repair and replacement processes.

- Enhanced Understanding: Visual aids allow for easier comprehension of how various components interact within a system.

- Efficient Troubleshooting: Identifying issues becomes straightforward when each element is clearly depicted, helping in quick diagnostics.

- Accurate Repairs: Access to detailed views ensures that the correct replacements are made, minimizing the risk of errors.

- Time Savings: Familiarity with component layouts can significantly reduce the time spent on maintenance tasks.

- Training Resource: These visuals are beneficial for training new personnel, offering a clear reference during instruction.

In summary, detailed representations of machine components are essential for effective maintenance and repair, promoting efficiency and accuracy in handling equipment.

Key Components of the 652R

The efficiency and performance of any machine rely heavily on its essential elements. Understanding these core components allows operators to maintain optimal functionality and ensure longevity. Each part plays a significant role in the overall operation, contributing to both power and precision in various tasks.

Engine and Transmission

The heart of the system lies in the engine, which provides the necessary power for operations. Coupled with a robust transmission, these elements work together to deliver smooth acceleration and effective torque. The synergy between these components is vital for achieving peak performance in demanding environments.

Chassis and Steering System

The chassis serves as the foundation, ensuring stability and durability during operation. Complementing this is the steering system, which allows for precise maneuverability. Together, they enhance control and facilitate smooth navigation, making the machine versatile across various terrains.

Understanding the Diagram Structure

The layout of a schematic representation serves as a vital tool for comprehending the various components and their interrelationships within a mechanical system. By examining these visual aids, users can gain insights into how individual elements interact and contribute to the overall functionality.

Typically, such representations consist of distinct sections that categorize components based on their roles. Each segment is designed to highlight specific parts, making it easier for individuals to navigate and identify the necessary elements for maintenance or repair.

Moreover, understanding the structure can significantly enhance one’s ability to troubleshoot issues, as it provides a clear map of the assembly. Familiarity with the layout empowers users to delve deeper into the mechanics and make informed decisions regarding replacements or upgrades.

Common Issues with 652R Parts

When working with machinery components, various challenges may arise that can affect performance and reliability. Understanding these common problems is crucial for maintaining optimal functionality and preventing costly repairs.

- Wear and Tear: Over time, certain components can degrade due to regular usage. This may lead to diminished efficiency or even failure if not addressed promptly.

- Misalignment: Improper installation or shifting can result in parts not fitting together correctly, causing operational issues and increased wear.

- Corrosion: Exposure to moisture and chemicals can lead to rust and deterioration, especially in metal components.

- Debris Accumulation: Dirt and other foreign materials can accumulate in critical areas, hindering performance and potentially damaging parts.

- Fluid Leaks: Seal failures may lead to fluid leaks, impacting the efficiency and operation of the machinery.

Addressing these issues promptly can significantly enhance the lifespan and effectiveness of the equipment. Regular inspections and maintenance are key to preventing these common pitfalls.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves a consistent maintenance routine that addresses both preventive and corrective measures. Regular care not only enhances performance but also extends the lifespan of various components, reducing the likelihood of costly repairs.

Routine Checks

Implementing a schedule for routine inspections is essential. Key areas to monitor include fluid levels, tire pressure, and belt conditions. Addressing minor issues promptly can prevent them from escalating into major problems.

| Check | Frequency | Notes |

|---|---|---|

| Fluid Levels | Weekly | Ensure all fluids are at recommended levels. |

| Tire Pressure | Monthly | Check for proper inflation and wear. |

| Belt Condition | Monthly | Look for cracks or fraying. |

Storage Practices

Proper storage is crucial when equipment is not in use. Keeping machinery in a sheltered area protects it from harsh weather conditions, while using protective covers can help avoid dust and debris accumulation. Additionally, ensuring that all moving parts are lubricated before storage prevents rust and degradation.

Where to Find Replacement Parts

Locating high-quality components for your equipment can greatly enhance its performance and longevity. Whether you are in need of specific items or general supplies, there are several reliable avenues to explore.

- Authorized Dealers: Visiting certified retailers ensures you receive genuine items designed specifically for your machinery. These dealers often provide expert advice and support.

- Online Marketplaces: Websites such as e-commerce platforms allow you to compare prices and availability. Look for sellers with positive reviews to ensure reliability.

- Specialty Stores: Shops that focus on agricultural or construction equipment often stock a variety of essential items. Their knowledgeable staff can assist in finding the correct components.

- Manufacturer’s Website: Checking the official website of the manufacturer can lead you to authorized sellers and online catalogs, simplifying your search for specific items.

- Local Auctions and Sales: Keep an eye on local listings for auctions or estate sales where equipment and accessories may be sold at discounted prices.

By exploring these resources, you can ensure that your machinery remains in optimal working condition, allowing you to focus on your tasks without interruption.

Comparing with Other Models

This section explores how a specific model stacks up against its counterparts in the same product line. Understanding the differences in features, capabilities, and performance can aid in making informed decisions when selecting equipment for various tasks.

Performance Metrics

When evaluating performance, one model may excel in speed while another offers superior torque. Comparing these metrics helps users identify which machine is better suited for particular applications, whether it be for heavy-duty work or more agile tasks.

Feature Set

Different models often come with unique functionalities designed for specific user needs. While some may prioritize ease of use with advanced technology, others might focus on durability and ruggedness. Analyzing these attributes allows potential buyers to choose equipment that aligns with their operational requirements.