When maintaining and repairing agricultural machinery, having a clear visual representation of the various elements is crucial. This guide focuses on providing an insightful overview of the intricate assembly of components that make up a specific model of heavy-duty machinery. By examining these essential parts, operators can ensure optimal performance and longevity.

Utilizing a comprehensive illustration not only aids in identifying each segment but also enhances the efficiency of repair and maintenance processes. With the right knowledge, users can effectively troubleshoot issues, replace worn-out pieces, and maintain their equipment in top-notch condition.

In this article, we will delve into the details of a renowned model, highlighting its unique features and components. This exploration will empower owners and technicians alike to navigate through their machinery with confidence and precision.

Overview of John Deere 717A

This section provides a comprehensive look at a specific model known for its reliability and efficiency in various agricultural tasks. Designed with user needs in mind, this equipment serves as a valuable asset for both small and large-scale farming operations.

Key Features

- Robust construction for durability

- Efficient performance in diverse conditions

- User-friendly interface for operators

- Versatile applications in farming and landscaping

Applications

- Field preparation and tilling

- Soil cultivation and planting

- Maintenance of gardens and lawns

- Transporting materials across various terrains

Understanding the functionalities and design elements of this machinery can help users maximize productivity and ensure longevity in their operations.

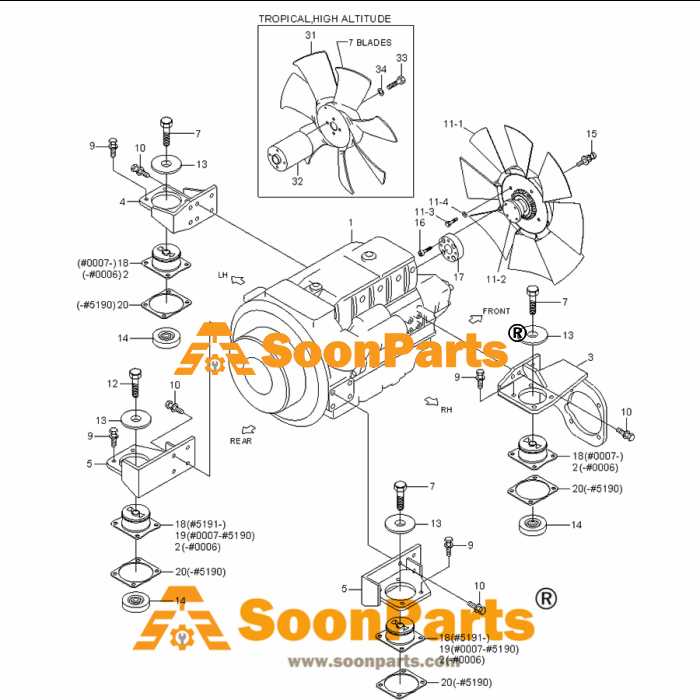

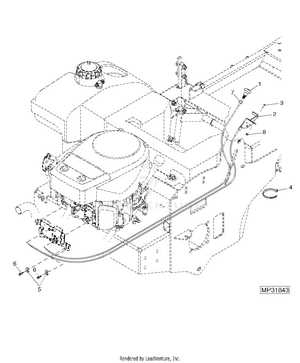

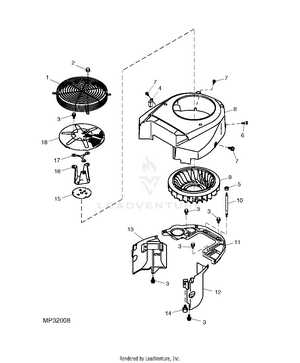

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations provide a clear understanding of how various elements fit together, enabling users to identify, locate, and replace necessary items efficiently.

Enhancing Understanding

- Facilitates quick identification of components.

- Clarifies the assembly and disassembly process.

- Reduces the likelihood of errors during repairs.

Streamlining Maintenance

- Enables efficient inventory management of replacements.

- Simplifies troubleshooting by highlighting potential issues.

- Increases overall productivity in repair tasks.

Overall, these visual guides are indispensable tools for anyone involved in the upkeep of complex machinery, ensuring that operations run smoothly and efficiently.

Key Components of the 717A

This section focuses on the essential elements that contribute to the functionality and efficiency of the machinery. Understanding these components is crucial for maintaining optimal performance and ensuring longevity.

Powertrain System

The powertrain system serves as the heart of the machine, transmitting power from the engine to the wheels. It comprises various elements, including the transmission, drive shafts, and differentials. Each component plays a vital role in facilitating smooth operation and effective torque distribution.

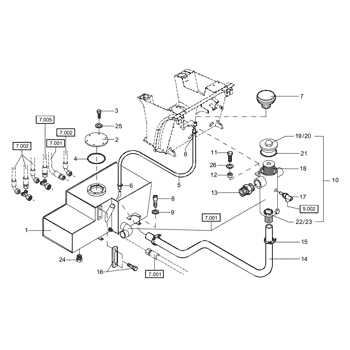

Hydraulic Mechanism

The hydraulic mechanism enhances the machine’s versatility by enabling various attachments and implements. This system consists of hydraulic pumps, cylinders, and hoses that work together to provide the necessary force for lifting and moving heavy loads. Regular maintenance of this system is essential for ensuring reliability and efficiency.

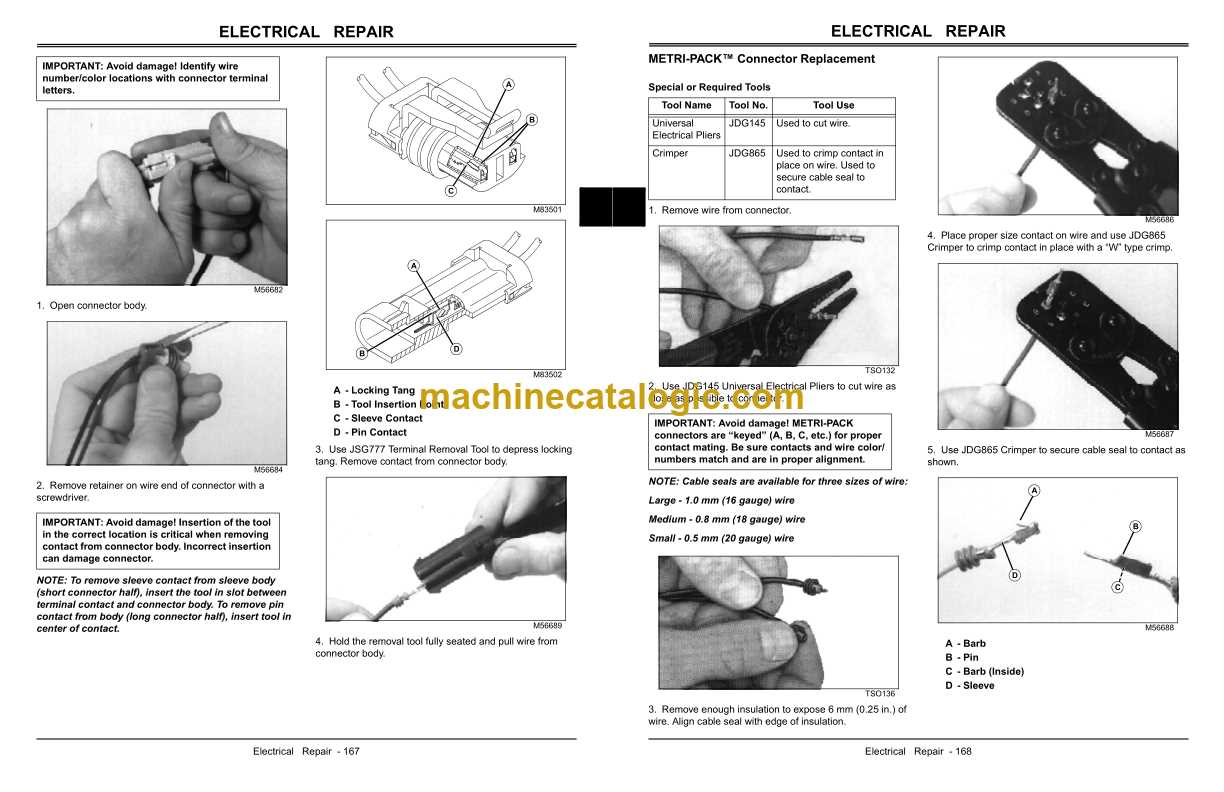

How to Access Parts Diagrams

Accessing technical illustrations for machinery components is essential for maintenance and repair tasks. These visual aids help users understand the layout and relationships between various elements, ensuring efficient troubleshooting and replacement. Here are several effective methods to obtain these valuable resources.

- Manufacturer’s Website: Most equipment manufacturers provide online access to their technical illustrations. Look for a dedicated section for support or resources.

- Authorized Dealers: Contacting a local dealer can yield printed or digital versions of necessary schematics. They often have direct access to official materials.

- Service Manuals: Purchasing or downloading service manuals that accompany your equipment can provide comprehensive diagrams along with detailed instructions.

- Online Forums: Joining community forums or discussion groups related to your machinery can lead to shared resources. Experienced users often upload or link to useful visuals.

- Parts Catalogs: Look for catalogs that specialize in parts. These often contain detailed illustrations along with part numbers and descriptions.

By utilizing these resources, you can ensure that you have the correct visuals at your fingertips for any repair or maintenance project.

Common Issues with 717A Parts

When it comes to machinery components, various challenges can arise that may impact performance and longevity. Understanding these issues is essential for maintenance and troubleshooting. Below are some frequently encountered problems that users may face.

Frequent Challenges

- Wear and Tear: Components often experience degradation due to regular usage, which can lead to inefficiencies.

- Corrosion: Exposure to moisture can cause rust and deterioration, especially in metallic parts.

- Misalignment: Improper installation or adjustment can result in components not functioning as intended.

- Blockages: Debris can accumulate in moving parts, hindering their operation.

Preventive Measures

- Regular Inspections: Frequent checks can help identify issues before they escalate.

- Proper Lubrication: Ensuring components are adequately lubricated can reduce friction and wear.

- Timely Replacements: Substituting worn parts promptly can prevent further damage.

- Correct Installation: Following guidelines for setup ensures optimal functionality and alignment.

Replacement Parts and Availability

When maintaining heavy machinery, ensuring the availability of essential components is crucial for optimal performance. Knowing where to find quality replacements can significantly affect operational efficiency and longevity of the equipment.

Sources for Components

Various avenues exist for acquiring necessary items:

- Authorized dealers: These vendors often carry genuine products and can provide expert advice.

- Aftermarket suppliers: Many offer competitive prices and a wide range of compatible items.

- Online marketplaces: Websites can facilitate easy access to multiple sellers, allowing for price comparisons.

- Local repair shops: These establishments may stock popular items and can offer installation services.

Considerations for Selection

When choosing replacement items, keep the following factors in mind:

- Quality: Ensure that the components meet or exceed industry standards.

- Compatibility: Verify that the parts are designed for your specific model to avoid performance issues.

- Warranty: Check for any guarantees that may cover defects or failures.

- Cost: Compare prices among different sources to find the best value without sacrificing quality.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of machinery involves a series of proactive measures. Regular upkeep not only enhances performance but also extends the lifespan of equipment. Adopting a systematic approach to maintenance can prevent costly repairs and downtime, promoting efficient operation.

1. Regular Inspections: Conduct thorough inspections at scheduled intervals. Look for signs of wear and tear, leaks, or unusual noises. Early detection of issues can save time and resources.

2. Fluid Checks: Monitor and maintain fluid levels, including oil, coolant, and hydraulic fluids. Clean and replace fluids as necessary to ensure optimal performance and prevent overheating.

3. Clean Components: Keep all components clean and free from debris. Accumulated dirt can cause parts to wear out more quickly and impede functionality. Regular cleaning helps maintain efficiency.

4. Replace Worn Parts: Address any damaged or worn components promptly. Using original or high-quality replacements ensures compatibility and reliability.

5. Proper Storage: When not in use, store machinery in a dry, sheltered area. Protecting equipment from harsh weather conditions helps prevent rust and corrosion, which can significantly reduce lifespan.

6. Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for maintenance schedules and practices. These guidelines are designed to optimize performance and longevity.

By implementing these maintenance strategies, operators can enhance the reliability and durability of their machinery, ensuring it remains in excellent condition for years to come.

Understanding OEM vs Aftermarket Parts

When maintaining or repairing machinery, the choice between original components and those produced by third-party manufacturers is crucial. This decision can significantly affect performance, longevity, and overall reliability. Each option has its own set of advantages and potential drawbacks that users must consider.

Original Equipment Manufacturer (OEM) Components

OEM components are produced by the original manufacturer of the equipment. These parts are designed to meet the exact specifications and standards set by the manufacturer, ensuring compatibility and quality. Choosing OEM often means enhanced reliability, as these components undergo rigorous testing and quality control. However, they may come with a higher price tag.

Aftermarket Components

On the other hand, aftermarket components are made by independent companies. These parts can offer significant cost savings and may even surpass the original in terms of performance. However, the quality can vary greatly, making it essential for users to conduct thorough research and choose reputable brands. Understanding the trade-offs between cost and quality is vital for making an informed choice.