For those who rely on robust all-terrain vehicles for work or recreation, having a clear understanding of the internal mechanisms and essential elements of these machines is crucial. This knowledge not only improves maintenance but also ensures long-lasting performance in a variety of demanding conditions.

Knowing how various elements interact within an off-road vehicle can help you identify any potential issues quickly and address them efficiently. Whether it’s the engine, transmission, or other mechanical systems, being familiar with their layout and function can significantly enhance the vehicle’s reliability and overall usability.

Regular inspection and accurate identification of critical components are key to preventing breakdowns and ensuring smooth operation. This section will provide an overview of the essential mechanisms you should focus on to maintain top-notch performance and extend the life of your vehicle.

Vehicle Model Overview

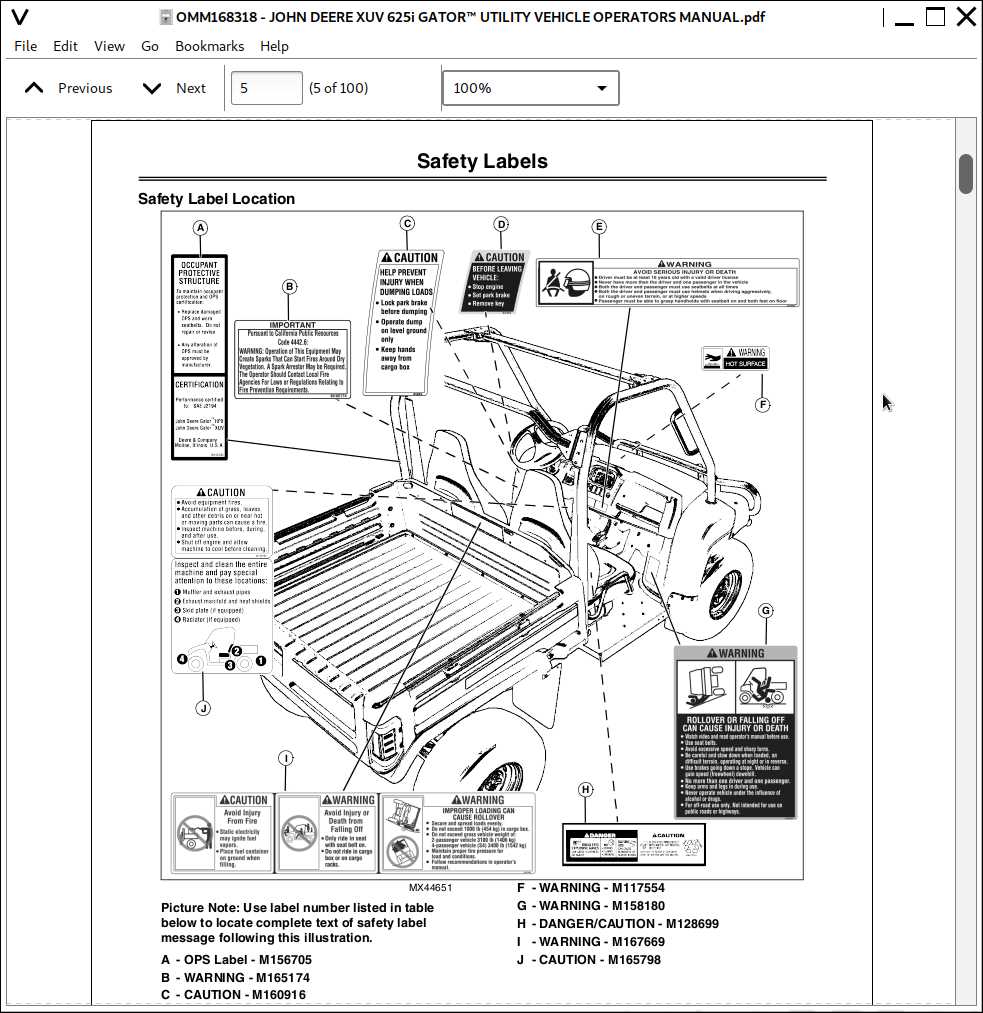

This utility vehicle is known for its exceptional durability and versatility, designed to handle both demanding tasks and off-road adventures. With a focus on functionality and performance, it stands out as a reliable choice for various outdoor activities and work-related tasks.

The model offers impressive features that enhance both comfort and safety. Built with rugged terrain in mind, it incorporates a sturdy frame and efficient suspension, making it suitable for different environments, whether on farms, in forests, or for recreational use.

- Strong and durable construction

- Efficient suspension system

- Reliable engine for heavy-duty use

- Comfortable seating for long rides

- Versatile cargo capacity for various needs

With a focus on ease of maintenance, this vehicle ensures a long lifespan and continuous efficiency. It’s designed to handle heavy loads, making it ideal for those who require a dependable and robust vehicle for multiple purposes.

Main Components of the 625i

The vehicle features an efficient assembly of key elements that work together to ensure smooth functionality and performance. Each crucial part plays a specific role in maintaining optimal operation, contributing to the reliability and durability of the machine. Understanding how these core elements function can help maintain the machine in excellent working condition.

Engine and Transmission

The motor and drivetrain system form the powerhouse, driving the machine forward with consistent force. These two components are designed to work seamlessly, providing the necessary torque and control over different terrains. Proper maintenance of the engine ensures longevity and uninterrupted performance.

Suspension and Steering

The suspension and steering setup provides both stability and maneuverability, allowing for a comfortable ride and precise handling. This configuration is designed to absorb shocks and maintain control even on rough surfaces, ensuring that the vehicle remains responsive and easy to control under various conditions.

Engine Layout and Specifications

The engine design is a crucial aspect of any off-road vehicle, influencing its performance, durability, and efficiency. This section provides a detailed breakdown of the key elements that define the motor’s configuration and technical features, ensuring a better understanding of how it operates in demanding environments.

| Feature | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Configuration | In-line, twin-cylinder design for balanced power delivery and efficiency. | ||||||||||

| Displacement | Fuel-efficient engine displacement optimized for high torque at low RPM. | ||||||||||

| Cooling System | Liquid-cooled mechanism to maintain optimal operating temperatures. | ||||||||||

| Fuel System | Electronic fuel injection for improved fuel atomization and

Transmission Parts and Functions

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring smooth vehicle operation. It is responsible for managing speed and torque, allowing the vehicle to adapt to various terrains and conditions. Understanding the different components involved in this system is essential for maintaining efficient performance. Main ComponentsThe core elements of the transmission system include gears, shafts, and clutches. These components work together to regulate power distribution and ensure optimal operation. Gears of varying sizes adjust the vehicle’s speed, while shafts transmit mechanical force. Clutches engage and disengage power to facilitate smooth transitions between gears. Additional MechanismsSeveral auxiliary mechanisms support the main system, including bearings, seals, and linkages. Bearings reduce friction between moving parts, seals prevent fluid leakage, and linkages connect the system to the control unit, ensuring Chassis and Frame StructureThe foundation of any utility vehicle lies in the robust design of its chassis and frame. This essential framework supports not only the overall weight but also ensures durability and balance during operation. Engineered to withstand various stresses, the structure plays a crucial role in maintaining the vehicle’s stability, even on challenging terrains. Strength and flexibility are key features of the frame, allowing it to handle both high loads and uneven surfaces. The material choice and design are optimized to resist wear and tear, ensuring longevity. Additionally, the modular construction simplifies maintenance and potential upgrades, enhancing the vehicle’s adaptability for different uses. Attention to detail in the alignment and connection of the frame components enhances both safety and performance. Each part is designed to distribute force efficiently, reducing the risk of damage during heavy-duty tasks. This structural integrity is vital for maintaining balance and control, particularly when navigating difficult or unpredictable environments. Electrical System Breakdown

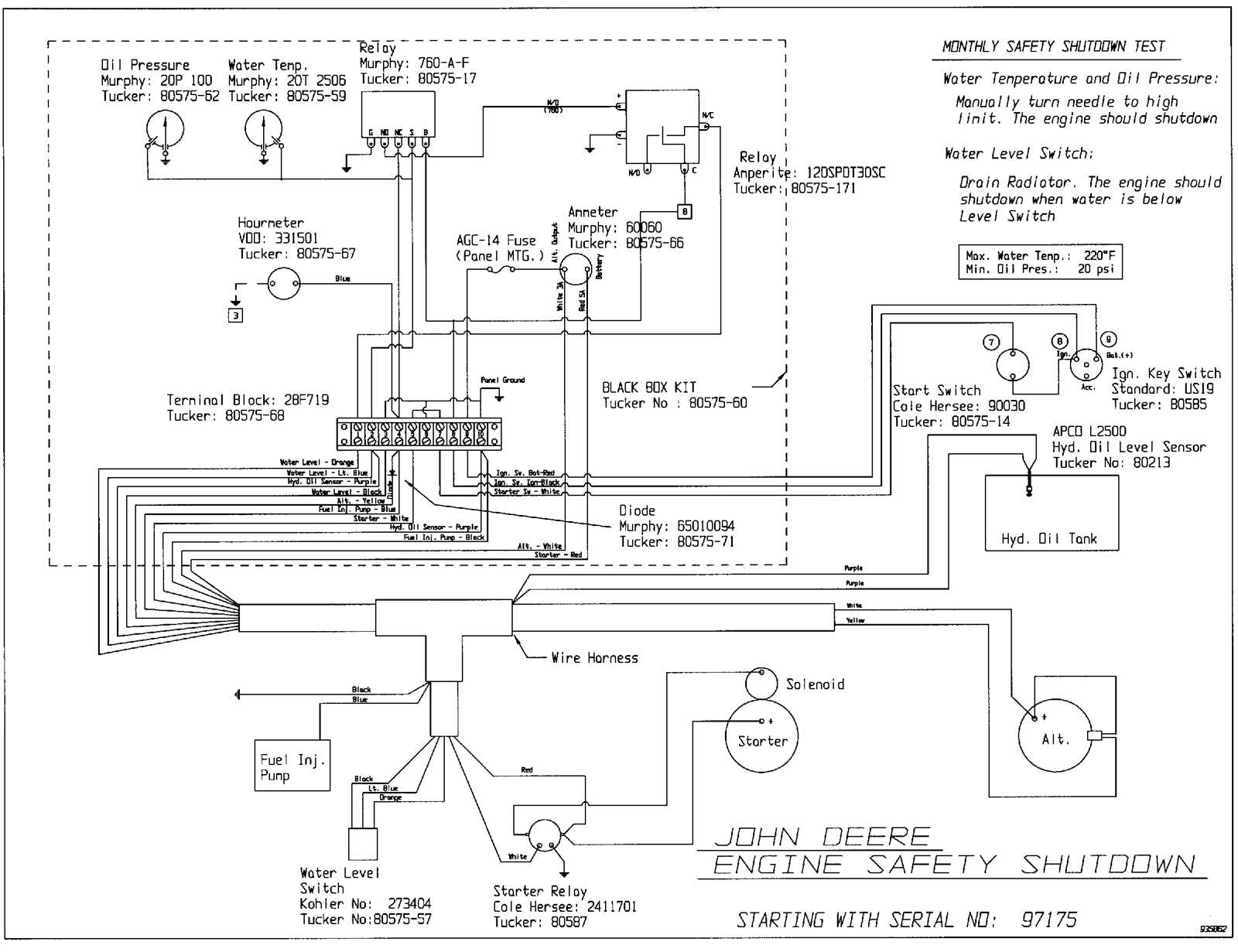

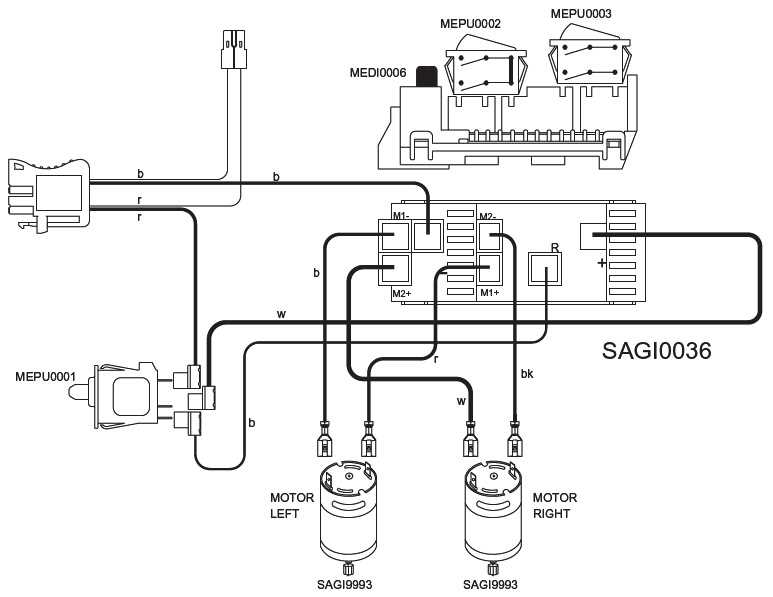

The electrical system of an all-terrain vehicle is a crucial component that ensures its functionality and reliability. This system encompasses various elements that work together to provide power, control, and communication within the vehicle. Understanding the intricacies of this setup can significantly enhance maintenance and troubleshooting efforts. Components OverviewAt the heart of the electrical assembly are the battery, wiring harness, and various connectors. The battery serves as the primary energy source, while the wiring harness facilitates the distribution of electrical current to different systems. Additionally, connectors play a vital role in ensuring secure and reliable connections between components, minimizing the risk of failure. Common Issues and SolutionsIssues within the electrical network can manifest as poor performance or complete failure of the vehicle. Frequent problems include corroded connections, frayed wires, or a depleted battery. Regular inspections and timely replacements of worn-out parts can help mitigate these issues, ensuring the vehicle remains operational and efficient. Utilizing diagnostic tools can also aid in identifying and addressing electrical malfunctions effectively. Suspension and Steering ComponentsThe performance of any utility vehicle greatly depends on its suspension and steering system. These elements work in tandem to provide stability, comfort, and control while navigating various terrains. Understanding the different components involved is crucial for maintaining optimal functionality and enhancing the overall driving experience. Suspension systems are designed to absorb shocks from uneven surfaces, ensuring a smooth ride. They typically include:

On the other hand, the steering mechanism is essential for maneuverability. Key components of the steering assembly consist of:

Regular inspection and maintenance of these systems are necessary to prevent wear and ensure safety. By keeping these components in good condition, users can enjoy enhanced performance and reliability in their vehicle. Brake System Components

The braking system is crucial for ensuring safety and control in various vehicles. It comprises several key elements that work together to provide effective stopping power. Understanding these components is essential for maintenance and repair, enhancing both performance and reliability. Key Elements of the Braking SystemAt the heart of the braking mechanism are the brake pads and rotors, which create the friction necessary to slow down or stop the vehicle. The brake calipers play a vital role in applying pressure to the pads, while the hydraulic system ensures smooth operation by transferring force from the brake pedal. Additional Components

Other significant parts include the master cylinder, which generates the hydraulic pressure, and the brake lines that transport this pressure throughout the system. Regular inspection and maintenance of these components are essential for optimal performance and safety. Maintenance Tips for Key Parts

Regular upkeep of essential components in utility vehicles ensures optimal performance and longevity. By adhering to specific guidelines, users can effectively manage wear and tear, enhance efficiency, and minimize costly repairs. Here are some valuable maintenance practices to consider for critical elements. Engine CareKeeping the engine in peak condition is vital for the overall functionality of the vehicle. Regular oil changes, air filter replacements, and timely inspections of belts and hoses are fundamental to maintaining engine health. Ensure that coolant levels are checked frequently to prevent overheating. Battery MaintenanceA well-maintained battery is crucial for reliable starts and consistent power delivery. Regularly inspect battery terminals for corrosion and clean them as needed. Additionally, ensure that the battery is securely mounted and fully charged, especially before extended periods of inactivity.

|