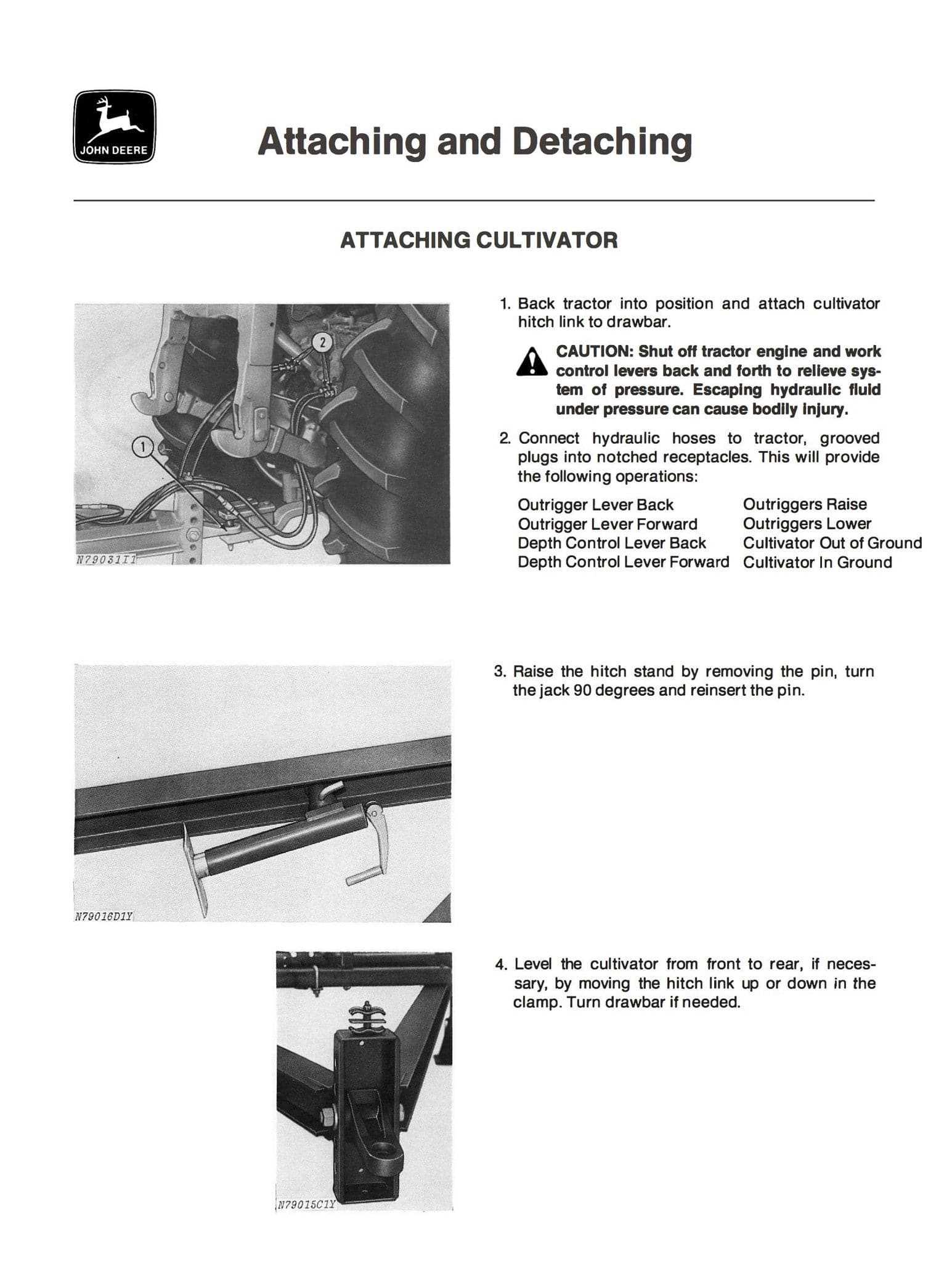

The functionality of modern farming machinery greatly depends on the efficient integration of various components that allow for seamless operation. Among these essential elements, the mechanism that facilitates the connection between implements and tractors plays a crucial role in enhancing productivity. A thorough exploration of this mechanism reveals its intricate design and the significance of each component.

To ensure optimal performance, it is vital to familiarize oneself with the various elements involved in this connection system. Each component has its specific function, contributing to the overall efficiency and versatility of agricultural tasks. This knowledge empowers operators to make informed decisions when it comes to maintenance and upgrades, ultimately leading to improved results in the field.

In this guide, we will delve into the various components that make up this connection system, illustrating their roles and interrelationships. By examining these elements in detail, readers will gain a comprehensive understanding of how to effectively utilize and maintain their agricultural machinery, ensuring that every task is executed with precision.

Understanding John Deere 3 Point Hitch

This section explores the mechanics and functionality of a crucial attachment system commonly used in agricultural machinery. By grasping its design and operation, users can enhance their equipment’s versatility and efficiency in various farming tasks.

Key Components

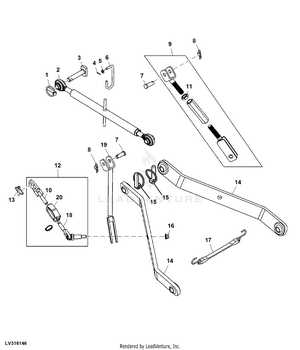

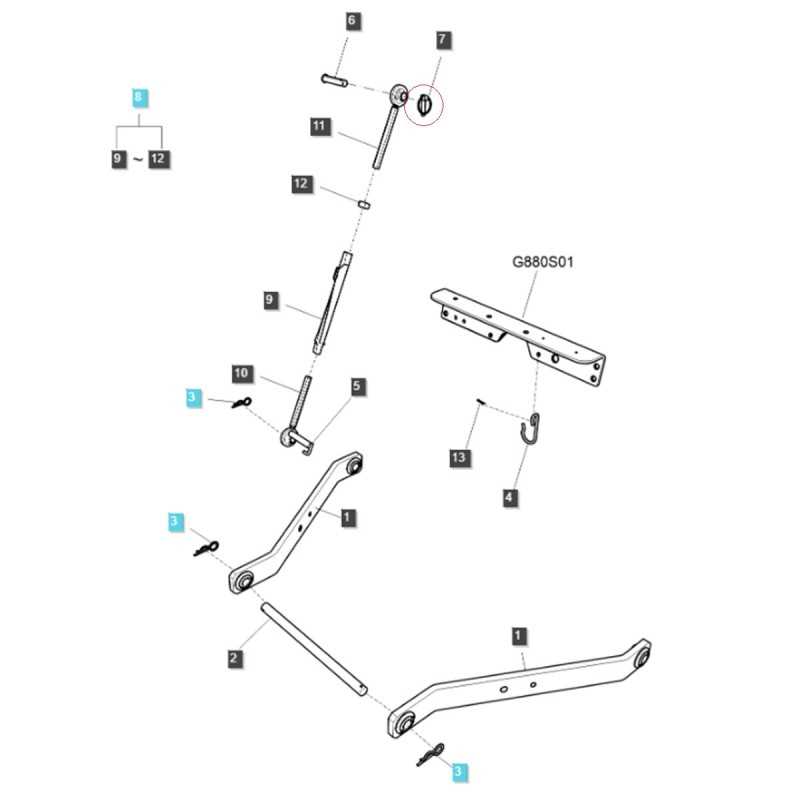

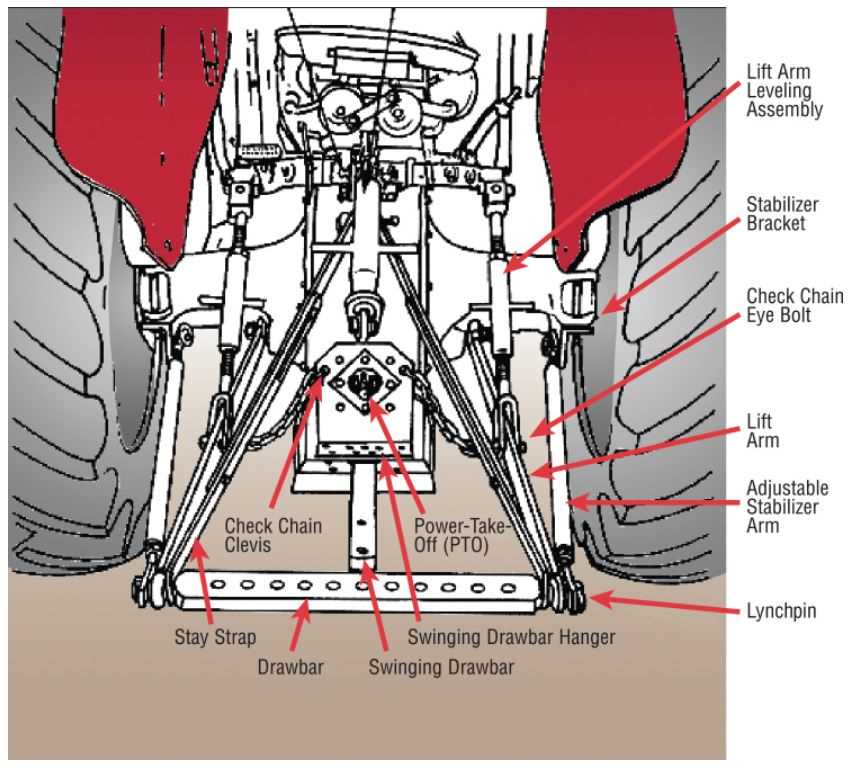

Essential elements of this system include the upper link, lower links, and the lifting mechanism. Each component plays a vital role in ensuring stability and ease of use when connecting implements.

Benefits of the System

Employing this connection method allows for quick implement changes and improved control during operation. It significantly enhances the overall productivity of agricultural activities, making it an ultimate choice for farmers seeking efficiency.

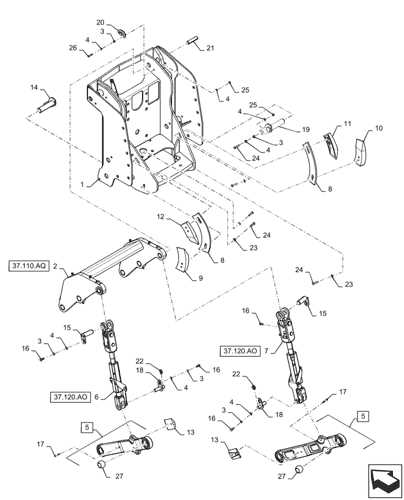

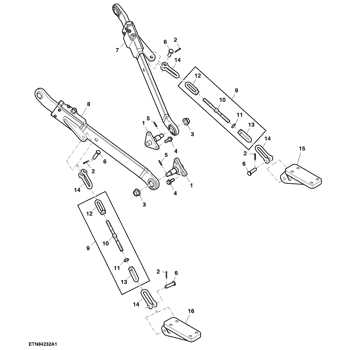

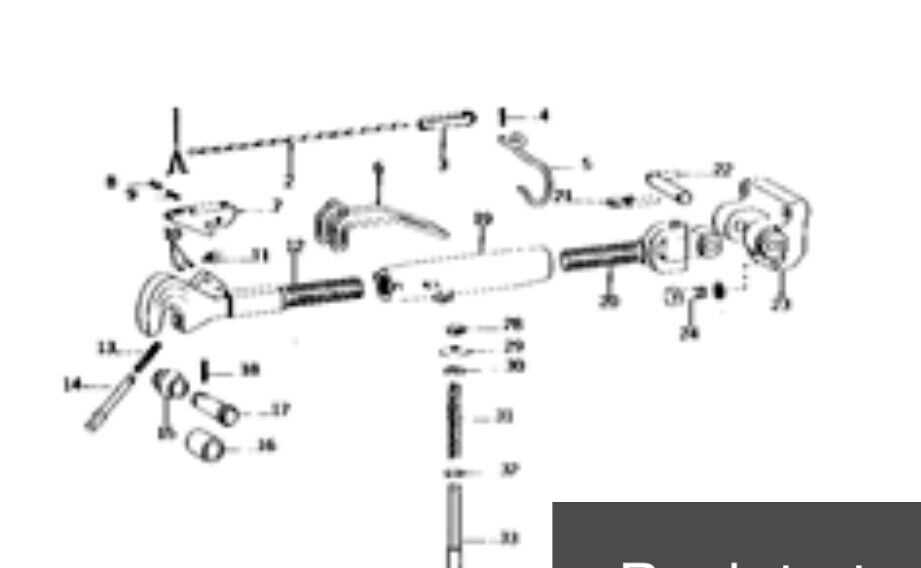

Components of the 3 Point System

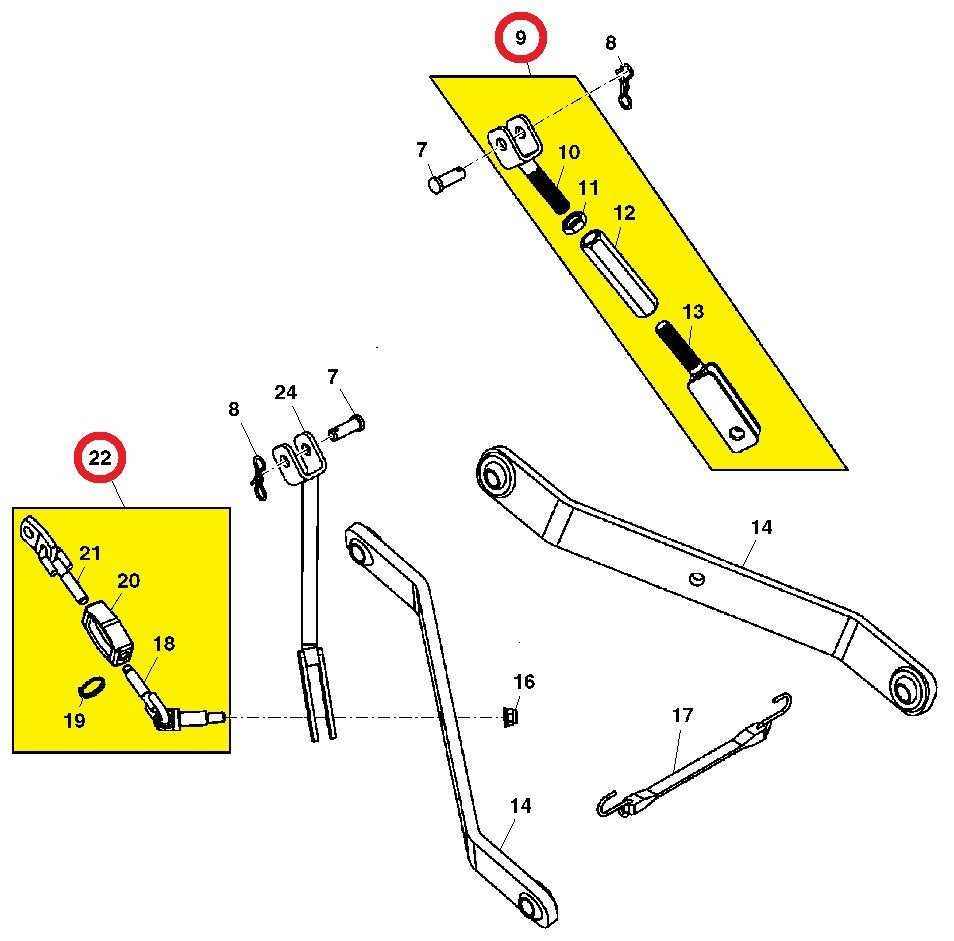

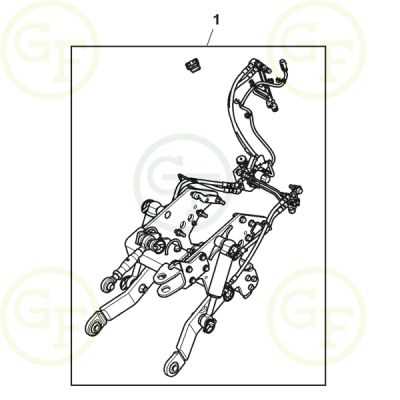

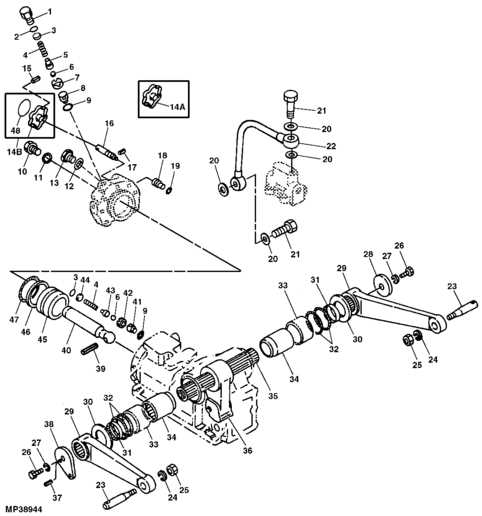

The three-point attachment system is essential for connecting implements to tractors, providing stability and control during operation. This mechanism allows for the efficient transfer of power and ensures precise positioning of various tools used in agricultural tasks.

At its core, the system consists of several key elements that work together to facilitate seamless interaction between the tractor and the attached equipment. Understanding these components is crucial for optimal performance and maintenance.

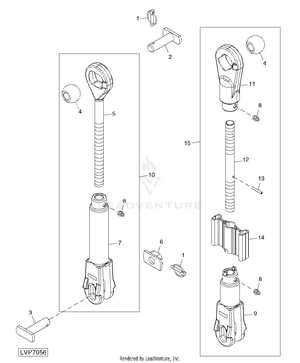

Upper Link: This adjustable element connects the top of the implement to the tractor, allowing for height adjustments and ensuring proper alignment during operation.

Lower Links: These two arms provide lateral stability and support the weight of the implement. They can be adjusted to fit different attachments, enhancing versatility.

Lift Arms: These components are responsible for raising and lowering the implement. They are typically operated by a hydraulic system, enabling smooth and precise movements.

Draft Arms: These are critical for managing the force exerted by the implement during operation. They help in maintaining balance and control, especially in uneven terrain.

Stabilizers: These parts are designed to minimize side-to-side movement of the attached equipment, enhancing stability and ensuring consistent performance.

Each of these components plays a vital role in the overall functionality of the three-point system, contributing to the efficiency and effectiveness of agricultural machinery.

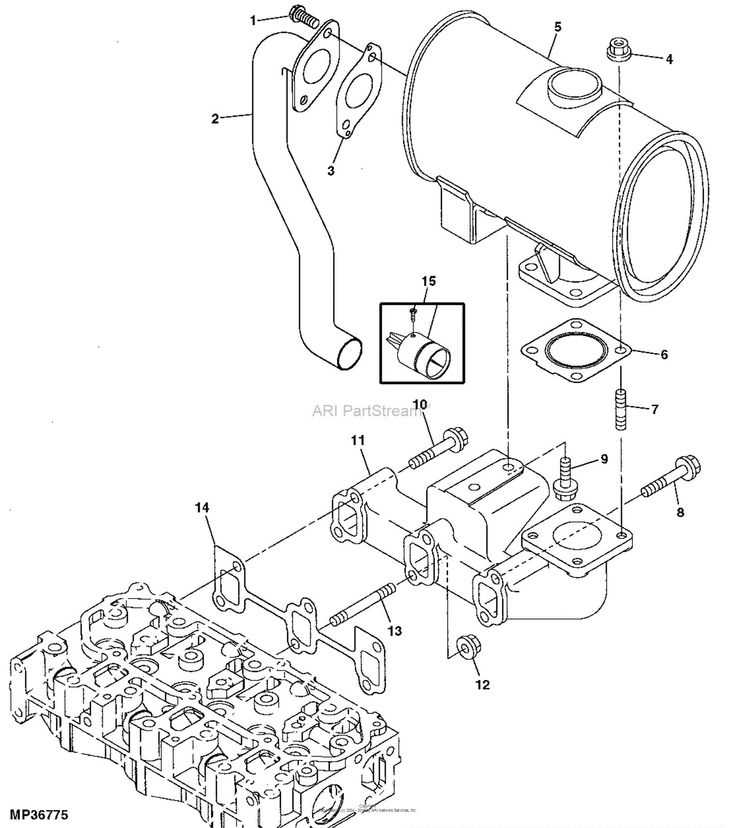

Importance of Hitch Diagrams

Understanding the layout and components of attachment systems is crucial for optimal performance in agricultural machinery. These illustrations serve as a valuable resource for operators, enabling them to identify and comprehend the various elements that facilitate the connection between equipment and tractors. Clear visuals promote effective maintenance, installation, and troubleshooting, ultimately enhancing operational efficiency.

Enhanced Maintenance

Detailed schematics provide insights into the specific elements that require regular upkeep. By referring to these guides, users can systematically check for wear and tear, ensuring that all components function smoothly. This proactive approach not only extends the lifespan of the machinery but also reduces the risk of unexpected breakdowns.

Efficient Troubleshooting

In the event of mechanical issues, having access to precise visuals can significantly expedite the diagnostic process. Operators can quickly pinpoint faulty parts or misalignments, allowing for prompt repairs. This efficiency minimizes downtime, ensuring that agricultural operations continue uninterrupted and maintain productivity.

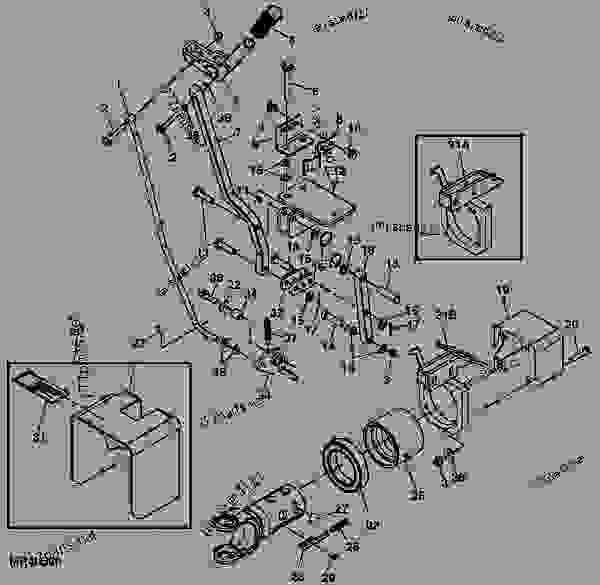

Common Issues with Hitch Parts

When operating agricultural machinery, several frequent challenges can arise related to the connection system. Understanding these issues can help in maintaining efficiency and ensuring safety during usage. This section explores typical problems encountered, their causes, and potential solutions.

1. Misalignment Problems

One of the most common complications is misalignment, which can lead to uneven weight distribution and poor performance. This issue often occurs due to wear and tear or improper attachment techniques.

2. Wear and Tear

Components may experience significant wear over time, affecting their functionality. Regular inspections can help identify worn elements before they lead to serious failures.

| Issue | Causes | Solutions |

|---|---|---|

| Misalignment | Improper attachment, wear | Regular checks, adjustments |

| Excessive Wear | Frequent use, lack of maintenance | Routine inspections, timely replacements |

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of agricultural equipment requires consistent attention and care. By following a set of proactive maintenance practices, operators can significantly extend the lifespan of their machinery and reduce the likelihood of unexpected breakdowns.

Regular checks and timely interventions are key to maintaining functionality. Below are some essential maintenance tips to consider:

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Inspect and Clean Connections | Monthly | Prevents rust and ensures proper function |

| Lubricate Moving Parts | Every 50 hours of use | Reduces friction and wear |

| Check Fluid Levels | Weekly | Maintains optimal performance and cooling |

| Tighten Bolts and Fasteners | Monthly | Ensures structural integrity and safety |

| Replace Worn Components | As needed | Avoids further damage and downtime |

By adhering to these maintenance guidelines, operators can enhance the reliability of their equipment, ensuring that it remains in top condition for many years to come.

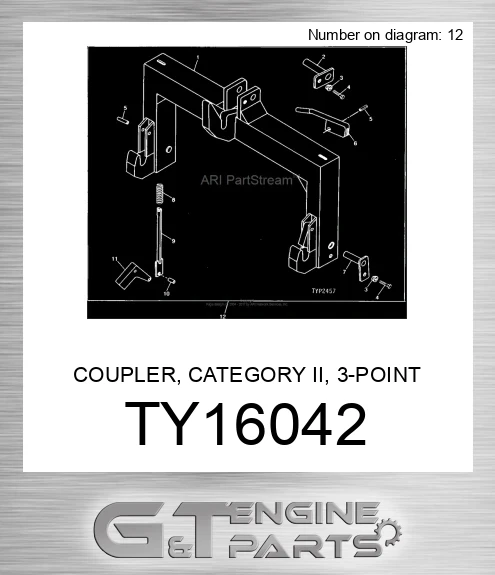

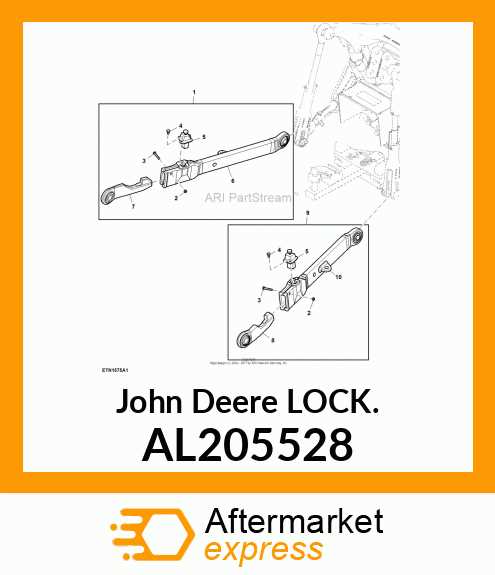

How to Identify Replacement Parts

Finding the right components for your agricultural machinery is essential for maintaining its efficiency and functionality. Knowing how to accurately identify the necessary elements can save time and ensure proper performance. This guide will help you navigate the process of recognizing the components you need for effective repairs or upgrades.

Understand Your Machinery

Before diving into replacement options, familiarize yourself with the specifications and layout of your equipment. Review the owner’s manual, as it typically includes vital information about the various assemblies and their designated elements. Additionally, take note of any identification numbers or labels on the machine that can aid in locating suitable replacements.

Consult Resources and Experts

Utilize online resources, such as manufacturer websites or forums dedicated to machinery enthusiasts. These platforms often provide valuable insights and recommendations from experienced users. Moreover, don’t hesitate to reach out to professionals who can offer advice or direct you to the correct suppliers for your needed components. This collaborative approach can enhance your understanding and ensure you select the best options for your specific requirements.

Benefits of Using Original Components

Utilizing authentic components for agricultural machinery offers numerous advantages that can significantly enhance operational efficiency and longevity. Original equipment not only ensures compatibility but also supports optimal performance, which is crucial for maintaining productivity in the field.

Reliability is one of the primary benefits of using genuine components. These parts are designed specifically for the machinery, resulting in a perfect fit and reducing the risk of malfunctions. When you invest in original pieces, you are more likely to experience fewer breakdowns, leading to less downtime and increased productivity.

Furthermore, quality assurance is a vital aspect of original components. Manufacturers typically subject these parts to rigorous testing, ensuring they meet high standards of durability and performance. This level of scrutiny guarantees that you are using materials that can withstand the demands of heavy-duty agricultural tasks.

Another important benefit is warranty protection. Many manufacturers offer warranties on their original components, which provides peace of mind. If any issues arise, you can address them without incurring additional costs, unlike with non-genuine parts, which may void warranties and lead to costly repairs.

In addition, using authentic components can enhance resale value. Prospective buyers often look for machinery that has been maintained with original parts, as this indicates a commitment to quality and reliability. Maintaining the integrity of your equipment can thus prove beneficial in the long run.

Ultimately, investing in original components is a smart choice for anyone looking to maximize the performance and lifespan of their agricultural equipment. By prioritizing authenticity, you ensure that your machinery operates at its best, providing you with the efficiency and reliability needed to succeed in your endeavors.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining machinery, choosing the right components can significantly impact performance and longevity. Two main categories of replacements exist: those produced by the original manufacturer and those made by third parties. Each option has its advantages and drawbacks that warrant careful consideration.

Quality and Reliability

Original components often guarantee compatibility and durability, whereas third-party options may vary in quality. It’s crucial to evaluate the source and manufacturing standards of alternatives.

Cost Considerations

While original components tend to be pricier, aftermarket alternatives can provide savings. However, lower costs may sometimes correlate with shorter lifespans or performance issues.

| Criteria | OEM | Aftermarket |

|---|---|---|

| Quality | High and consistent | Variable |

| Cost | Higher | Lower |

| Compatibility | Guaranteed | Not always assured |

| Availability | Limited to original outlets | Widely available |

Resources for Further Learning

Expanding your knowledge about agricultural machinery components can greatly enhance your understanding and maintenance skills. Numerous resources are available to provide insights, technical guidance, and community support for those looking to delve deeper into this subject. Whether you’re a beginner or an experienced operator, the following options can help you explore various aspects of machinery attachments and their functionalities.

Online Courses and Tutorials

Many educational platforms offer comprehensive courses focused on agricultural machinery. These courses typically cover everything from basic operation to advanced maintenance techniques.

Community Forums and Support Groups

Engaging with community forums can be invaluable. These platforms allow enthusiasts and professionals to share experiences, troubleshooting tips, and best practices.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Structured learning on machinery operation and maintenance. | Coursera |

| Community Forums | Discussion boards for sharing knowledge and experiences. | Agriculture.com Community |

| Manufacturer Resources | Official guides and manuals for specific machinery. | Manufacturer Website |