Maintaining a lawn tractor can often seem daunting, especially when it comes to understanding its intricate workings. Each machine is composed of numerous elements, all working in harmony to ensure optimal performance. Familiarity with these components can empower owners to troubleshoot issues and carry out repairs more effectively.

In this guide, we will delve into the various segments of your mower, highlighting their functions and importance. Whether you’re a seasoned user or a newcomer, grasping the layout of these critical elements can greatly enhance your maintenance routine.

By gaining insight into the configuration of the essential parts, you’ll be better equipped to make informed decisions about upgrades, replacements, or general upkeep. This knowledge not only extends the life of your equipment but also enhances its efficiency, providing a more satisfying mowing experience.

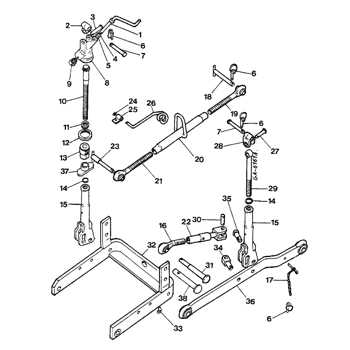

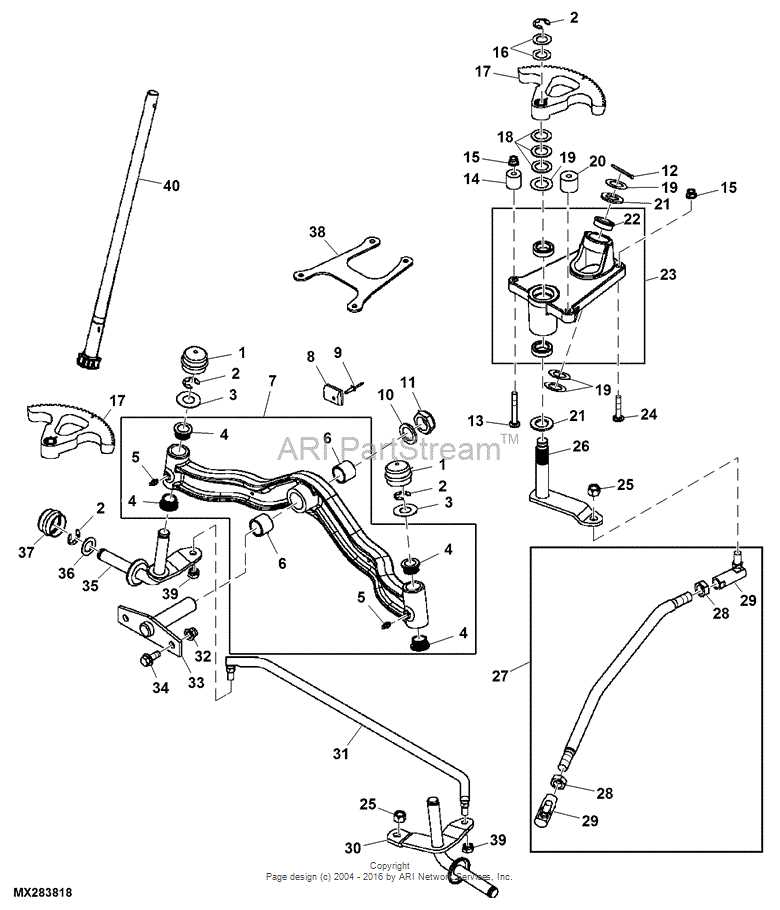

Understanding the GT245 Parts Diagram

Grasping the intricacies of machinery components is essential for efficient maintenance and repair. A visual representation of the elements within a particular model aids users in identifying and locating specific parts, ensuring smooth operation and longevity of the equipment.

Importance of Component Identification

Familiarity with each element enhances both troubleshooting and replacement processes. Recognizing individual parts and their functions allows for:

- Timely repairs and minimized downtime.

- Effective communication with service professionals.

- Improved understanding of machinery operations.

How to Utilize the Visual Representation

To make the most of the visual guide, consider the following steps:

- Study the layout thoroughly to familiarize yourself with the arrangement.

- Refer to the identification numbers and descriptions for clarity.

- Cross-reference with the maintenance manual for detailed information on each part.

By understanding the configuration and roles of components, users can enhance their operational knowledge and ensure their machinery remains in optimal condition.

Key Components of John Deere GT245

This section explores the essential elements that contribute to the functionality and efficiency of a particular model of lawn and garden machinery. Understanding these components is crucial for maintenance and optimal performance.

Engine System

- Powerful engine designed for durability

- Fuel system ensuring efficient combustion

- Cooling mechanisms for temperature regulation

Transmission and Drive

- Automatic transmission for ease of use

- Drive belts that connect the engine to the wheels

- Axles providing stability and control

Benefits of Using Original Parts

Utilizing authentic components for machinery maintenance and repairs offers numerous advantages that can enhance performance and longevity. These elements are specifically designed to work seamlessly with your equipment, ensuring optimal functionality and reliability.

One of the primary benefits of employing genuine components is the assurance of quality. These items are manufactured to meet rigorous standards, providing durability and efficiency that aftermarket alternatives often cannot match. This leads to reduced breakdowns and a more reliable operation.

Moreover, authentic components typically come with a warranty, which adds an extra layer of protection for your investment. In the event of a malfunction, you can rely on support and potential replacements, minimizing downtime and repair costs.

Additionally, using original elements can improve resale value. Prospective buyers often prefer equipment with verified components, knowing they are purchasing a machine that has been maintained with care and precision.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to strict standards, ensuring reliability. |

| Warranty Protection | Offers coverage for defects, reducing financial risk. |

| Enhanced Resale Value | Preferred by buyers, leading to higher resale prices. |

In conclusion, investing in original components is a strategic choice that can lead to improved machinery performance, lower maintenance costs, and greater peace of mind for operators.

How to Read Parts Diagrams

Understanding the layout of components within a mechanical system is essential for maintenance and repair tasks. These visual representations provide an organized way to identify each element, its placement, and how it interacts with others. Mastering the ability to interpret these illustrations can significantly enhance your troubleshooting and assembly skills.

Key Elements of Illustrations

When examining these visual guides, several key aspects should be noted:

| Element | Description |

|---|---|

| Labels | Identify specific components and often include part numbers for easy reference. |

| Connections | Show how various elements are linked, indicating the flow of functionality. |

| Legend | A guide explaining symbols and notations used within the illustration. |

| Scale | Indicates the size of the components relative to each other, essential for fitting parts accurately. |

Steps to Effectively Analyze Illustrations

Follow these steps to enhance your comprehension:

- Start by familiarizing yourself with the legend to understand the symbols used.

- Identify all labeled components and note their corresponding numbers.

- Observe how elements connect and interact with each other to grasp their functions.

- Refer to the scale to ensure accurate fitting when replacing or repairing.

By applying these techniques, you can navigate mechanical illustrations with confidence and improve your repair and maintenance effectiveness.

Common Issues with GT245 Parts

When dealing with garden machinery, several frequent challenges can arise with various components. Understanding these issues can help users maintain optimal performance and longevity of their equipment.

Wear and Tear: Components often experience degradation due to prolonged usage. This can lead to reduced efficiency and may necessitate timely replacements to prevent further damage.

Electrical Failures: Electrical systems are particularly susceptible to malfunctions. Corrosion and poor connections can hinder functionality, leading to issues such as starting problems or intermittent failures.

Fuel System Issues: Fuel delivery can be compromised by clogged filters or faulty injectors. Regular maintenance is crucial to ensure smooth operation and prevent potential breakdowns.

Hydraulic Problems: Hydraulic systems can develop leaks or pressure issues over time. Identifying and rectifying these problems promptly is essential to maintain the machine’s performance and prevent costly repairs.

Blade Dullness: The cutting blades can become dull or damaged, impacting the effectiveness of the equipment. Regular sharpening and timely replacement are vital for achieving the best results during operation.

Addressing these common concerns can significantly enhance the functionality and lifespan of your equipment, ensuring it operates at peak efficiency for years to come.

Where to Find Replacement Parts

Finding suitable components for your equipment is crucial for maintaining its performance and longevity. There are various avenues to explore, each offering unique benefits and accessibility to the necessary items.

Online Retailers

Many websites specialize in providing a wide array of components. Major online marketplaces often have detailed catalogs, enabling users to easily search by model or type. Additionally, consider visiting dedicated platforms that focus on agricultural machinery for more tailored options.

Local Dealers

Reaching out to local distributors can be advantageous as they typically stock popular items and can provide expert advice. Establishing a relationship with these vendors may also yield insights into new arrivals and exclusive deals.

Regardless of the route chosen, ensure to verify compatibility and quality to guarantee the best performance for your machinery.

Maintenance Tips for GT245 Owners

Proper upkeep is essential for enhancing the longevity and performance of your equipment. Regular attention to various components not only ensures optimal functionality but also prevents unexpected issues. Following a systematic approach to maintenance can save time and resources in the long run.

Start with routine inspections of the engine, checking for any signs of wear or leaks. Regularly changing the oil and filters will help maintain efficiency and reduce wear on critical parts. Additionally, keep the air filter clean to ensure proper airflow, which is vital for peak performance.

Examine the cutting blades frequently, sharpening or replacing them as necessary to achieve a clean cut. Tire pressure should also be monitored, as it affects both performance and fuel consumption. Lastly, don’t forget to clean the machine after each use to prevent debris build-up that could lead to further complications.

Aftermarket vs. OEM Parts: A Comparison

In the realm of machinery maintenance, the choice between alternative and original components often arises. Each category presents unique advantages and considerations that can significantly impact performance, longevity, and overall satisfaction.

Quality and Reliability

Original Equipment Manufacturer components are typically crafted to stringent specifications, ensuring compatibility and reliability. In contrast, alternative components can vary in quality, offering both economical options and potential risks in performance.

Cost and Accessibility

While OEM options often come with a higher price tag, they guarantee a certain level of excellence. On the other hand, alternative solutions may be more affordable and widely available, appealing to budget-conscious consumers seeking immediate replacements.

Resources for GT245 Parts Support

For individuals seeking assistance with their outdoor equipment, a wealth of resources is available to ensure efficient maintenance and repairs. Whether you’re a seasoned technician or a novice owner, access to reliable information and quality components is crucial for optimal performance and longevity of your machinery.

Online forums and community groups can provide invaluable insights. Here, users share experiences, troubleshoot common issues, and offer recommendations for reliable suppliers. Additionally, manufacturer websites often host a range of manuals and guides that detail maintenance practices, helping you understand the intricacies of your equipment.

Local dealerships serve as another excellent option for sourcing specific components. Knowledgeable staff can assist in identifying necessary items and may offer special orders for hard-to-find parts. Furthermore, many dealerships provide warranty options, giving peace of mind with your purchases.

Don’t overlook third-party retailers, as they frequently carry a wide selection of alternatives at competitive prices. Always ensure that these sources are reputable to guarantee the quality of the components.

Lastly, video tutorials on platforms like YouTube can be particularly beneficial, providing step-by-step instructions for repairs and maintenance tasks. These visual guides can enhance your understanding and confidence in handling equipment issues effectively.