Understanding the intricate layout of machinery is crucial for maintaining optimal performance. This section delves into the various elements that comprise a specific model of outdoor power tools, offering insights into their arrangement and functionality. By familiarizing oneself with these components, users can enhance their maintenance practices and ensure longevity.

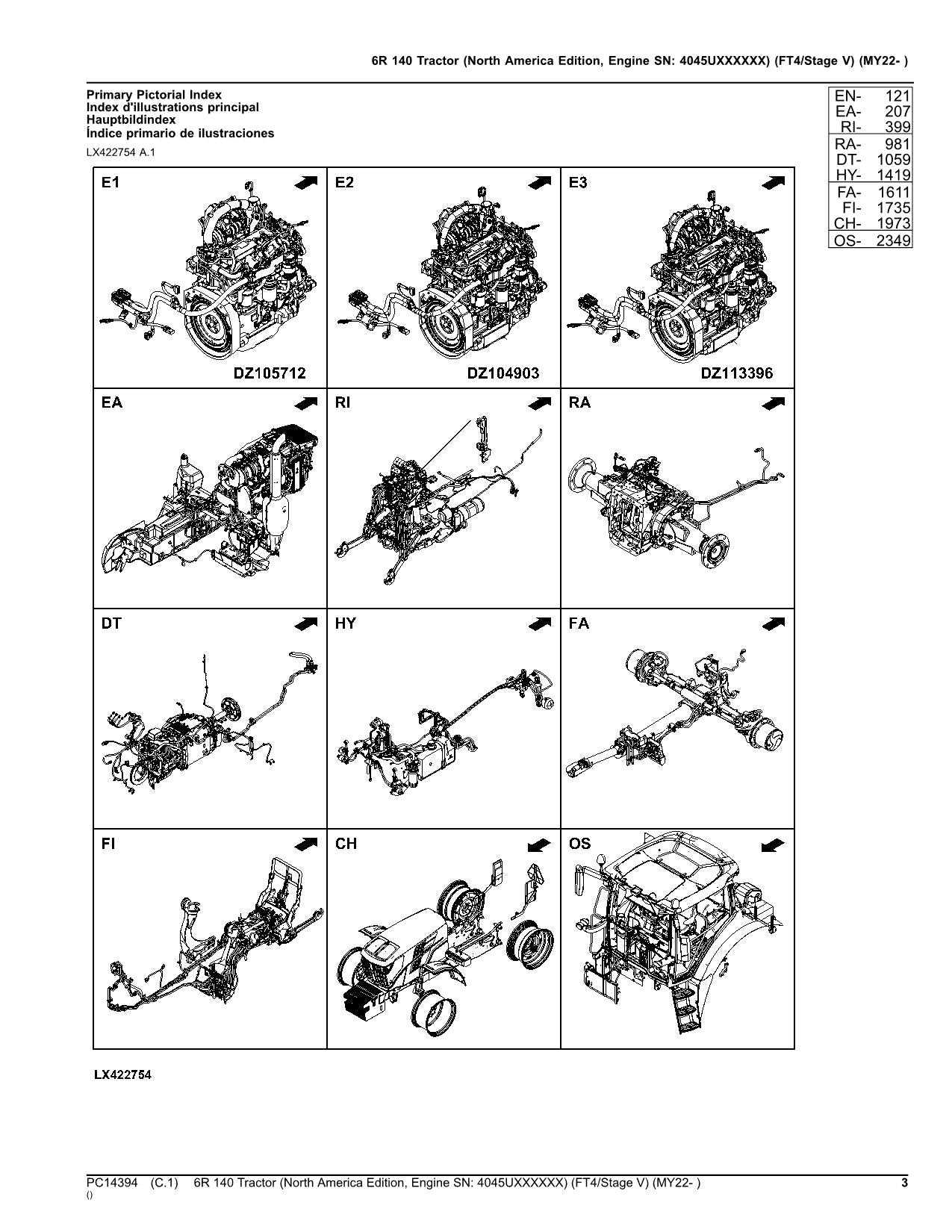

Visual representations play a significant role in grasping the relationships between different pieces. A comprehensive illustration allows operators to quickly identify parts, facilitating easier repairs and replacements. Such resources are invaluable for both seasoned professionals and enthusiasts alike, as they simplify complex processes and promote effective troubleshooting.

Furthermore, recognizing how each segment contributes to the overall operation can empower users to take proactive steps in equipment care. By gaining knowledge about the assembly and disassembly of these essential items, individuals can confidently tackle issues, leading to improved efficiency and satisfaction in their outdoor endeavors.

Overview of John Deere 140

This section provides a comprehensive look at a notable model within the agricultural machinery sector, highlighting its design, functionality, and applications. Renowned for reliability and performance, this machine has garnered a loyal following among enthusiasts and professionals alike.

Key Features: This model is equipped with an array of advanced features that enhance its usability. With a robust engine and efficient transmission system, it ensures smooth operation across various terrains. Its ergonomic design also prioritizes user comfort, making prolonged use less strenuous.

Applications: Ideal for a multitude of tasks, this equipment is particularly favored for lawn care, landscaping, and small farming operations. Its versatility allows users to tackle diverse jobs, ranging from simple mowing to more complex agricultural tasks.

Understanding the specifications and components of this model is crucial for maximizing its potential. By familiarizing oneself with its inner workings, operators can ensure optimal performance and longevity, contributing to more productive outcomes in their respective endeavors.

Importance of Parts Diagrams

Understanding the intricacies of machinery requires clear visual representations. These illustrations serve as invaluable tools for identifying components, facilitating maintenance, and ensuring proper assembly. Their significance extends beyond mere convenience, impacting efficiency and longevity in operations.

Key benefits include:

- Enhanced Clarity: Visual guides eliminate ambiguity, making it easier to locate specific elements within complex systems.

- Streamlined Maintenance: Technicians can quickly reference components, reducing downtime and improving repair accuracy.

- Facilitated Learning: New users can familiarize themselves with equipment more effectively, promoting skill development.

- Efficient Ordering: Clear visuals aid in identifying the exact parts needed for replacement, simplifying the procurement process.

Ultimately, these illustrations play a crucial role in maintaining operational efficiency, ensuring that machinery runs smoothly and reliably over time.

Key Components of the 140 Model

This section delves into the essential elements that define the functionality and efficiency of this particular tractor model. Understanding these components is crucial for maintenance, repair, and optimal operation, ensuring longevity and peak performance in various agricultural tasks.

Core Features

The primary features of this machine encompass its robust engine, transmission system, and hydraulic components, all engineered to work in harmony. Each part plays a significant role in delivering power, speed, and versatility, making it suitable for a variety of farming applications.

Component Overview

| Component | Description |

|---|---|

| Engine | A powerful unit designed for durability and efficiency, providing the necessary horsepower for demanding tasks. |

| Transmission | Ensures smooth gear shifts, optimizing speed and torque for various operational needs. |

| Hydraulics | Facilitates lifting and moving implements with precision, enhancing the tractor’s versatility. |

| Chassis | Offers structural integrity and stability, supporting the machine’s weight and ensuring balance during operation. |

| Steering System | Allows for precise maneuverability, essential for navigating tight spaces in fields. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear overview of various elements, their relationships, and placement within a system. Mastering this skill can enhance your ability to troubleshoot and identify necessary replacements.

Start with the legend: Most visuals include a key or legend that explains symbols and color codes. Familiarizing yourself with these references is essential, as they offer insights into the function of each symbol, making navigation easier.

Follow the flow: Observe the arrangement of components. Typically, the layout follows a logical sequence, guiding you through the assembly or system. By tracing connections from one part to another, you can better understand how everything works together.

Identify groupings: Components are often categorized into sections or groups based on their function. Recognizing these clusters can help you pinpoint which areas require attention or replacement, streamlining your repair process.

Practice and experience play significant roles in enhancing your ability to interpret these visuals. With time, you’ll become more adept at quickly locating the necessary components, making your maintenance tasks more efficient.

Common Issues with John Deere 140

Many owners of this particular model encounter a range of challenges during operation. Understanding these common problems can help in effective maintenance and enhance the overall performance of the machine. Below are some frequently reported issues and their potential solutions.

Engine Problems

- Starting Difficulties: Often attributed to fuel delivery issues or electrical malfunctions. Regular inspection of the battery and fuel lines is recommended.

- Overheating: This can stem from a clogged radiator or low coolant levels. Ensuring proper airflow and regular coolant checks can prevent this issue.

- Unusual Noises: Grinding or knocking sounds may indicate wear in internal components. Routine maintenance is crucial to address these sounds before they escalate.

Transmission Issues

- Shifting Problems: Difficulty in changing gears may result from low fluid levels or worn components. Regular fluid changes can improve shifting performance.

- Slipping Gears: This can be caused by improper adjustment or wear and tear. Regular inspections can help identify early signs of wear.

- Vibration: Excessive vibration during operation may signal imbalance or alignment issues. Checking for loose parts can mitigate this problem.

Finding Replacement Parts Online

In the quest for essential components to restore machinery, navigating online resources can yield fruitful results. The internet offers a vast array of platforms where users can locate and purchase necessary items to ensure their equipment operates smoothly and efficiently.

Utilizing Specialized Websites

Many websites cater specifically to equipment enthusiasts, providing detailed catalogs and search functions. These platforms often feature extensive inventories along with customer reviews that can assist in making informed choices.

Community Forums and Resources

Engaging with online communities dedicated to machinery can also be beneficial. These forums often contain valuable insights, recommendations, and even links to trusted suppliers where one can find the desired components at competitive prices.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan and performance of your equipment. By following systematic practices, you can ensure that your machinery operates efficiently and remains in optimal condition over time.

Routine Inspections

Conduct frequent checks on critical components to identify wear or damage early. Focus on fluid levels, filters, and belts, as these elements are vital for smooth operation. Addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Lubrication

Keep your machinery clean by removing dirt and debris regularly. Proper lubrication of moving parts reduces friction and wear, promoting longevity. Invest in high-quality lubricants that meet manufacturer specifications for the best results.

Expert Resources and Support Channels

Accessing reliable information and assistance is crucial for maintaining machinery efficiency. Numerous resources are available to provide expert guidance, helping users navigate complex issues and enhance their operational knowledge.

Online Forums and Communities

- Specialized discussion boards where enthusiasts and professionals share experiences.

- Social media groups dedicated to equipment maintenance and troubleshooting.

- Websites offering user-generated content, tips, and solutions for common challenges.

Official Support Services

- Manufacturer websites featuring technical documents and product manuals.

- Customer service hotlines for immediate assistance from trained professionals.

- Local dealerships providing parts and repair services with expert advice.