Understanding the intricate assembly of agricultural machinery is crucial for effective maintenance and operation. This section aims to provide a clear representation of the various elements that contribute to the functionality of a specific type of agricultural implement. By breaking down the individual components, users can gain insights into their roles and importance within the overall system.

In the realm of farming tools, each piece serves a distinct purpose, working in harmony to enhance productivity. The visual representation of these components enables operators to identify key areas for inspection, maintenance, or replacement. Recognizing the significance of each segment fosters a deeper appreciation for the technology behind modern farming practices.

Moreover, this analysis not only assists in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades. A thorough understanding of how these elements interact can lead to improved efficiency and longevity of the machinery, ultimately benefiting agricultural operations.

Ensuring that machinery operates at peak performance requires consistent upkeep and care. Regular maintenance is essential for preventing unexpected failures and extending the lifespan of equipment. A well-maintained machine not only functions more efficiently but also promotes safety and reliability in operation.

Benefits of Regular Upkeep

- Enhanced Efficiency: Regular inspections and servicing can significantly improve the performance of the equipment.

- Cost Savings: Preventative maintenance helps avoid costly repairs that may arise from neglect.

- Increased Lifespan: Consistent care leads to a longer operational life for machinery, maximizing investment.

- Improved Safety: Regular maintenance reduces the risk of accidents caused by malfunctioning equipment.

Key Maintenance Practices

- Conduct routine inspections to identify wear and tear early.

- Replace worn components promptly to avoid further damage.

- Keep machinery clean to prevent buildup that can hinder performance.

- Follow manufacturer guidelines for servicing intervals.

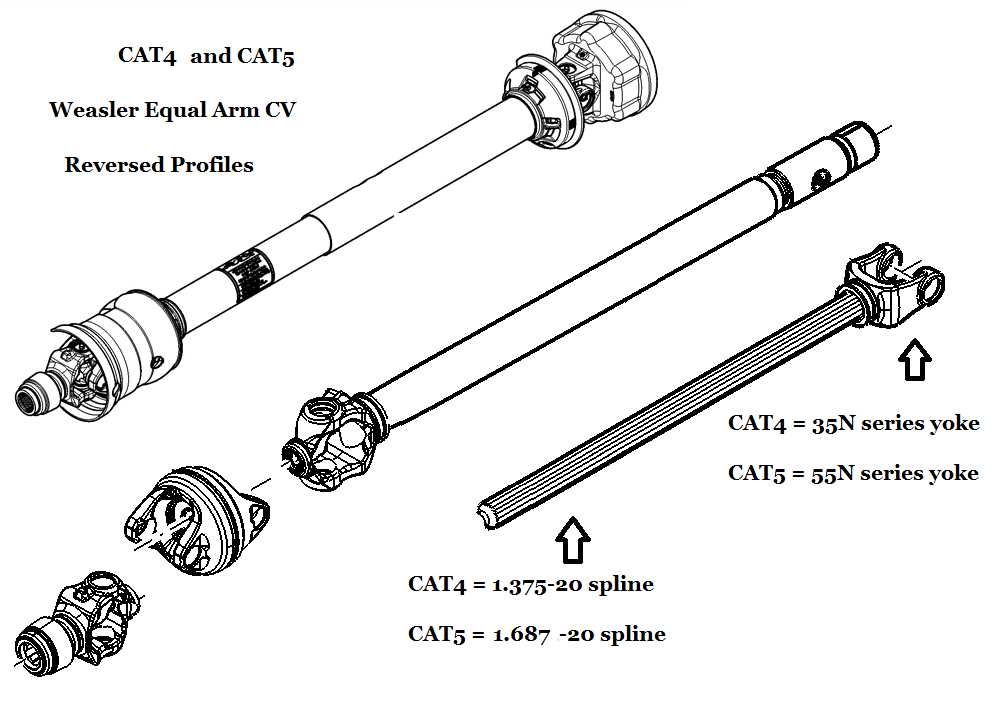

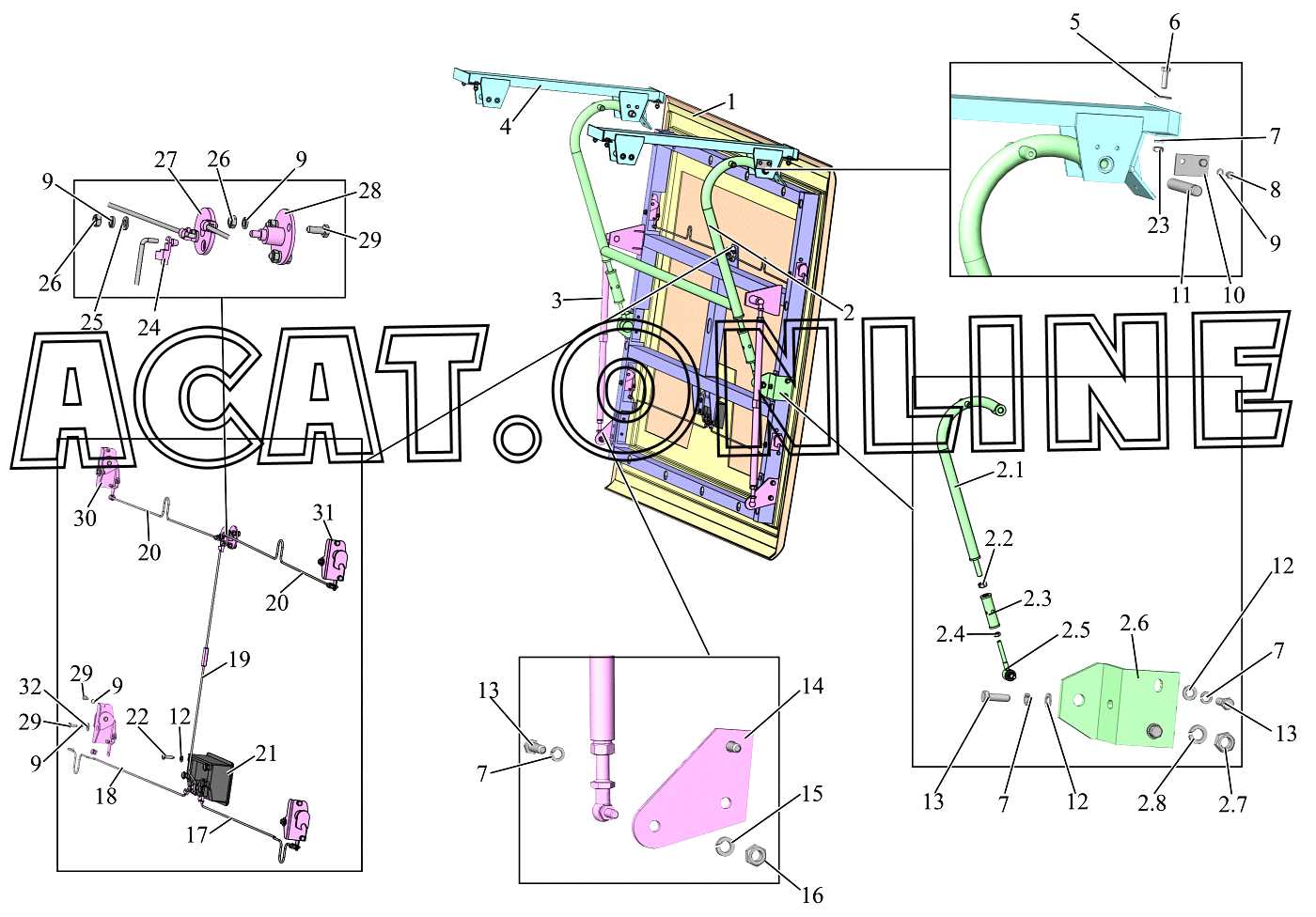

Key Components of the Baler

The efficiency and effectiveness of a hay-making machine depend on its essential elements. Understanding these crucial parts is vital for optimal operation and maintenance, ensuring a smooth workflow during the harvesting season. Each component plays a significant role in the overall functionality and reliability of the machinery.

One of the primary elements includes the mechanism responsible for gathering and compressing the material into manageable units. This feature is critical for maintaining the desired density and shape, allowing for easy transport and storage. Additionally, a robust drive system ensures that all moving parts operate harmoniously, providing the necessary power to handle various types of forage.

Moreover, the cutting mechanism contributes to the overall performance by facilitating the efficient processing of raw materials. The durability and precision of this component directly impact the quality of the final product. Lastly, effective discharge systems are vital for timely unloading, enhancing productivity during operation.

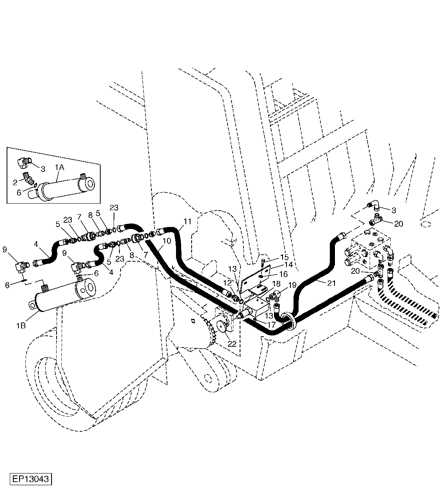

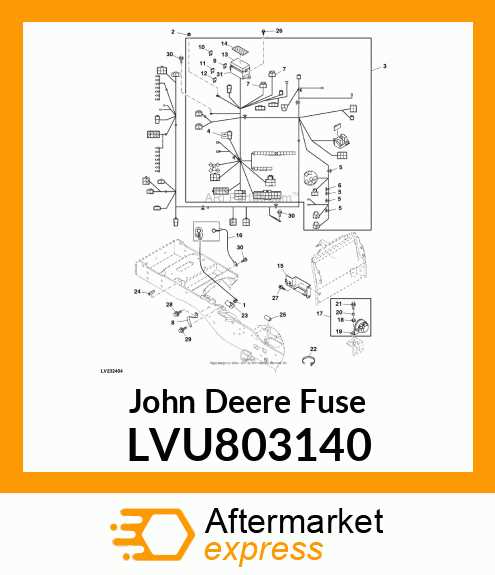

Understanding the Parts Diagram

Grasping the components layout is essential for anyone involved in the maintenance or operation of agricultural machinery. This visual representation serves as a guide, detailing the various elements and their relationships within the equipment. A comprehensive understanding of this illustration can significantly enhance the efficiency of repairs and servicing.

Firstly, it is important to recognize that each segment depicted has a specific role in the overall functionality of the machine. By identifying these sections, operators can better comprehend how different parts interact and contribute to the performance of the equipment.

Moreover, familiarizing oneself with the layout can assist in troubleshooting issues that may arise during operation. Knowing where each component is located allows for quicker diagnostics and resolutions, minimizing downtime during critical harvesting periods.

Common Issues and Solutions

When working with agricultural machinery, various challenges may arise that can hinder efficiency and productivity. Understanding these common problems and their solutions is crucial for maintaining optimal performance.

- Poor Compression:

This issue can result in inadequate bundling, often due to improper adjustments or worn components.

- Check and adjust the tension settings.

- Inspect and replace any damaged or worn belts.

- Jamming:

Frequent blockages can disrupt operation, typically caused by foreign objects or material buildup.

- Clear any debris from the machine regularly.

- Ensure that the material being processed is within recommended specifications.

- Excessive Wear:

Components may experience rapid deterioration, impacting overall functionality and lifespan.

- Conduct regular inspections and maintenance checks.

- Utilize high-quality lubricants to reduce friction.

- Electrical Failures:

Issues with electrical systems can lead to operational interruptions and may stem from faulty wiring or connections.

- Inspect wiring for damage and replace as needed.

- Check fuses and electrical connections for reliability.

Replacement Parts Availability

Access to high-quality components is crucial for maintaining the efficiency and longevity of agricultural machinery. A well-stocked inventory of substitutes ensures that operators can quickly find the necessary elements to keep their equipment functioning smoothly. Understanding the options available can significantly enhance operational readiness and reduce downtime.

Sources for Quality Components

Various suppliers specialize in providing reliable replacements for agricultural machinery. These vendors often offer a wide selection of products, ensuring compatibility with different models and variations. It is advisable to choose suppliers with a strong reputation for quality and customer service to ensure satisfaction with each purchase.

Considerations for Ordering

When seeking replacements, it is essential to consider factors such as delivery times and return policies. Ensuring prompt delivery can help minimize disruptions in daily operations. Additionally, understanding the return process can provide peace of mind when ordering components, allowing for adjustments if necessary.

How to Identify Worn Parts

Recognizing signs of wear and tear in machinery components is crucial for maintaining optimal performance and preventing breakdowns. By understanding the common indicators of deterioration, operators can ensure their equipment operates efficiently and extends its lifespan.

Common Signs of Wear

- Visual Inspection: Look for cracks, chips, or discoloration on the surfaces of components.

- Unusual Noises: Listen for grinding, squeaking, or rattling sounds that may indicate malfunctioning elements.

- Inconsistent Performance: Notice any irregularities in operation, such as reduced efficiency or failure to function as expected.

Steps for Assessing Condition

- Conduct regular visual checks to spot early signs of damage.

- Use appropriate tools to measure dimensions and tolerances, ensuring they align with manufacturer specifications.

- Replace any component that fails to meet performance standards to avoid further issues.

Tools Required for Repairs

To ensure efficient maintenance and restoration of agricultural machinery, having the right equipment is essential. This section outlines the necessary implements that facilitate effective troubleshooting and repairs. Proper tools not only enhance productivity but also promote safety during the repair process.

Essential Hand Tools

Basic hand tools are fundamental for carrying out most repair tasks. These tools are versatile and can be used for a variety of maintenance activities.

| Tool | Description |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts. |

| Screwdrivers | Essential for assembling and disassembling components. |

| Pliers | Handy for gripping and manipulating small objects. |

Power Tools and Equipment

In addition to hand tools, certain power tools can significantly speed up repair tasks, especially for larger or more complex machinery.

| Tool | Description |

|---|---|

| Impact Wrench | Ideal for loosening stubborn bolts quickly. |

| Drill | Useful for creating holes and driving screws efficiently. |

| Angle Grinder | Perfect for cutting and grinding metal components. |

Tips for Efficient Operation

To ensure optimal functionality of your agricultural machinery, it’s crucial to implement effective practices during operation. Proper techniques not only enhance productivity but also prolong the lifespan of the equipment.

Regular Maintenance

Performing routine upkeep is essential. This includes:

- Inspecting belts and chains for wear.

- Cleaning debris from components to prevent overheating.

- Lubricating moving parts to reduce friction.

Optimal Settings

Adjusting settings according to the specific tasks can significantly impact performance. Consider the following:

- Set the correct tension on the compression mechanism.

- Adjust the speed based on material type and moisture levels.

- Regularly calibrate sensors for accurate operation.