The intricate workings of a lawn care machine can often seem daunting, yet grasping the fundamental components is essential for effective maintenance and repair. A detailed exploration of the various elements involved in the propulsion system provides valuable insights into the functionality and longevity of these machines.

By examining the various mechanisms that enable movement, users can enhance their understanding and potentially troubleshoot common issues. This guide aims to offer clarity on how each component interacts, ensuring an ultimate appreciation of the engineering behind these essential tools.

Whether you’re a seasoned technician or a novice enthusiast, knowing the layout of the propulsion assembly can greatly simplify repair tasks. With the right information at hand, tackling mechanical challenges becomes a more manageable and less intimidating endeavor.

Understanding the John Deere D105

This section explores a popular model in the lawn care industry, emphasizing its mechanical components and overall functionality. Recognizing how these systems work together is essential for optimal maintenance and performance.

| Component | Description |

|---|---|

| Engine | Powers the machine and provides necessary torque for operation. |

| Drive System | Facilitates movement across various terrains with ease. |

| Control Mechanism | Allows user to navigate and adjust settings for tailored performance. |

| Chassis | Provides structural integrity and houses other critical components. |

By delving into these elements, one can gain a clearer understanding of this machine’s capabilities and how to maximize its use in various landscaping tasks.

Overview of Transmission Systems

The mechanics behind power transfer in machinery are crucial for optimal performance and efficiency. These systems play a vital role in converting and directing energy, ensuring that the right amount of force reaches various components. Understanding these mechanisms can greatly enhance the operation and maintenance of equipment.

Types of Power Transfer Mechanisms

There are several methods employed to transmit energy, including gear-based, belt-driven, and hydrostatic systems. Each type has its own advantages and applications. For instance, gear systems provide precise control over speed and torque, while belt-driven mechanisms are often simpler and lighter, making them suitable for various tasks.

Importance of Maintenance

Regular upkeep of these systems is essential to prevent wear and ensure longevity. Inspection and timely replacement of components can significantly impact overall functionality. Understanding the signs of wear can help operators address issues before they lead to significant failures, thereby maintaining the efficiency of the entire machinery.

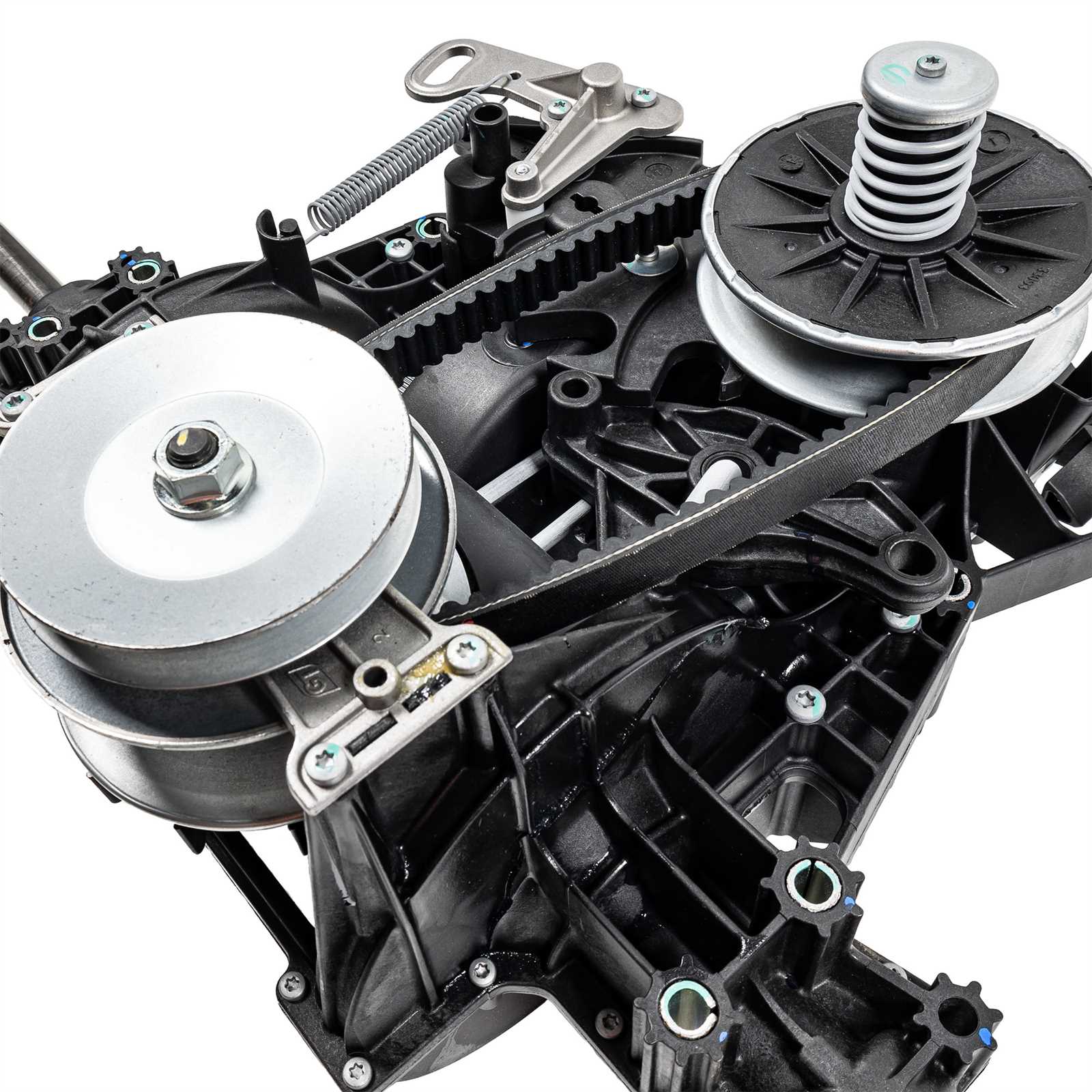

Key Components of D105 Transmission

The intricate machinery behind effective movement relies on several essential elements that work harmoniously together. Understanding these crucial components helps in maintaining optimal functionality and efficiency.

1. Drive Belt: This component is vital for transferring power from the engine to the wheels, ensuring smooth operation.

2. Gear Set: A series of interlocking gears that facilitate speed variation and torque multiplication, allowing for precise control during operation.

3. Pulley System: This system aids in adjusting the tension on the drive belt, enabling seamless transitions between different speeds.

4. Shift Linkage: This mechanism connects the control lever to the gear set, allowing the operator to easily change gears and enhance maneuverability.

5. Fluid Reservoir: Essential for lubrication, this reservoir ensures that all moving parts operate smoothly and reduces wear and tear.

6. Control Mechanism: This element allows the user to manage the various functions effectively, providing a responsive driving experience.

Delving into these fundamental aspects offers insights into maintaining and troubleshooting the machinery, ultimately enhancing its lifespan and performance.

Importance of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. By committing to a routine care schedule, owners can prevent unexpected failures and enhance the overall efficiency of their equipment.

Benefits of Routine Upkeep

Regular service can significantly reduce the likelihood of major breakdowns. Additionally, it helps in maintaining the resale value of the equipment, ensuring that it operates smoothly throughout its lifecycle.

Key Maintenance Tasks

| Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Improves lubrication and reduces wear |

| Filter Replacement | Every 100 hours | Enhances performance and fuel efficiency |

| Belt Inspection | Monthly | Prevents slippage and damage |

| Cleaning | After each use | Prevents buildup and ensures visibility |

Troubleshooting Common Transmission Issues

Identifying and resolving problems related to the gear system in your machinery can significantly enhance its performance and longevity. Understanding the signs of malfunction and following a systematic approach to diagnosis will help you maintain optimal functionality.

Common Symptoms

- Unusual noises during operation

- Difficulty in shifting gears

- Slipping or hesitation while moving

- Fluid leaks underneath the machine

Steps for Diagnosis

- Inspect fluid levels and quality. Ensure the lubricant is at the recommended level and free of contaminants.

- Check for visible leaks. Look for any signs of fluid pooling around seals and gaskets.

- Examine the linkage and cables. Ensure they are properly connected and not worn or damaged.

- Test the operation under various conditions. Note any irregularities in response when changing speeds.

By following these guidelines, you can effectively pinpoint issues and take corrective action, ensuring your equipment remains reliable and efficient.

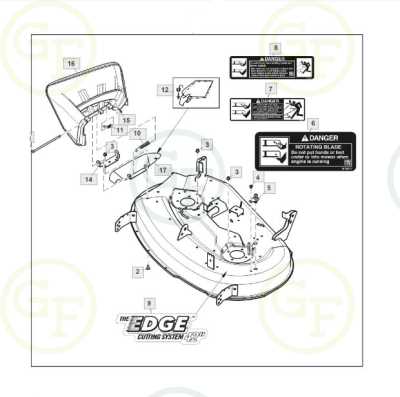

How to Access Transmission Parts

Gaining entry to the internal mechanisms of your mower is essential for effective maintenance and repairs. Understanding the layout and the correct approach will facilitate a smoother process, allowing you to address any issues that may arise. This guide outlines the necessary steps to access the components you need to inspect or replace.

Preparation and Safety

Before beginning, ensure that the mower is parked on a flat surface and powered off. Disconnect the battery to prevent accidental starts. Gather the required tools, including wrenches, screwdrivers, and safety goggles. A clean workspace will help keep track of small components during disassembly.

Accessing the Mechanism

Start by removing any external covers or shields that obstruct access. Typically, this involves unscrewing several fasteners. Once the outer casing is removed, carefully detach additional components, such as belts or pulleys, to reveal the inner workings. Make sure to take notes or pictures during disassembly to assist with reassembly.

Always handle parts with care to avoid damage, and consult your equipment’s manual for specific instructions related to your model. With patience and attention to detail, you’ll be able to successfully reach and evaluate the mechanisms that require your attention.

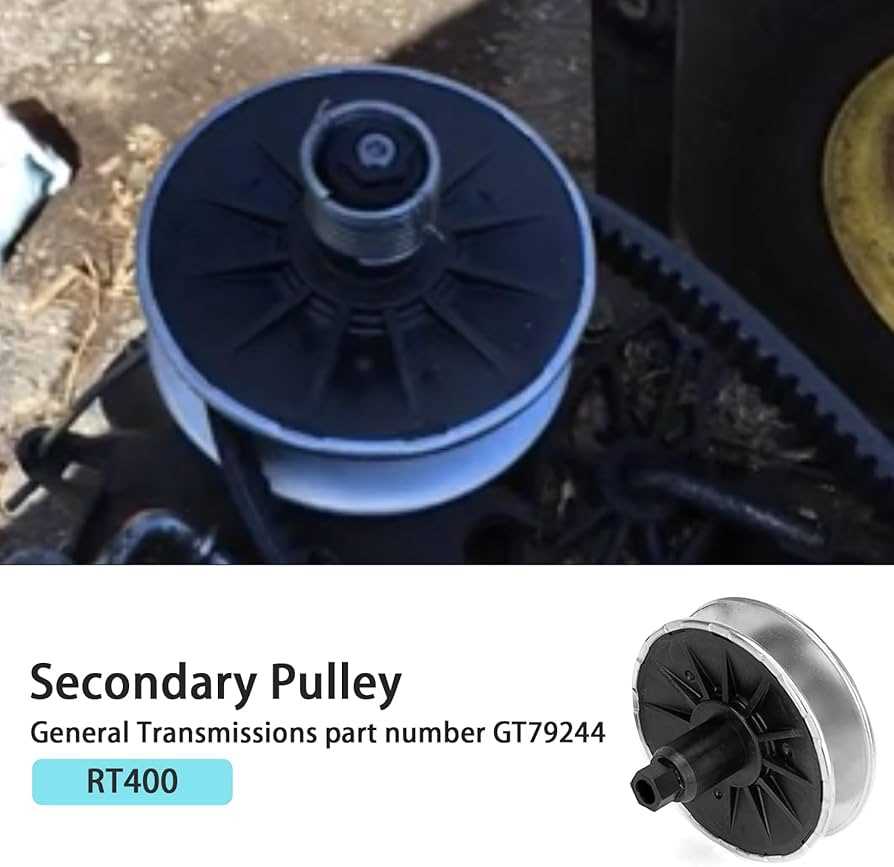

Replacement Parts for Optimal Performance

Ensuring your equipment operates at peak efficiency often hinges on the quality of components utilized. Selecting high-grade replacements can enhance functionality and prolong the lifespan of machinery, making maintenance a critical aspect of ownership.

Benefits of Quality Components

- Enhanced Durability: Premium replacements are designed to withstand rigorous use, reducing the frequency of repairs.

- Improved Efficiency: Well-made components can significantly boost operational efficiency, leading to better performance.

- Cost Savings: Investing in quality can prevent costly breakdowns, saving money in the long run.

Key Considerations When Choosing Components

- Compatibility: Ensure that the replacements fit your specific model to avoid issues during installation.

- Manufacturer Reputation: Opt for trusted brands known for their reliability and customer support.

- Warranty Options: Look for parts that come with a warranty, providing peace of mind and assurance of quality.

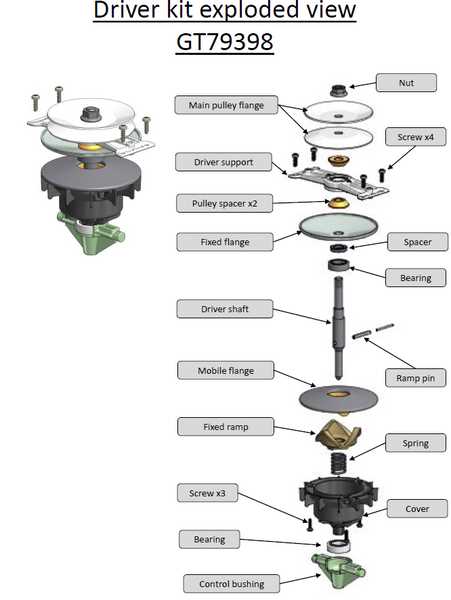

Visual Guide to Transmission Diagram

This section aims to provide a comprehensive visual representation of the internal mechanisms that drive performance. Understanding the layout and interconnections of various components can greatly enhance troubleshooting and maintenance efforts.

Illustrations serve as invaluable tools for both novices and experienced individuals alike, allowing for quick reference and clarity. By examining these visual aids, one can gain insights into how each element interacts within the system.

Additionally, exploring the schematic can reveal critical points of wear and potential failure, empowering users to make informed decisions about repairs or replacements. This understanding ultimately contributes to more efficient operation and longevity of the machinery.

In summary, familiarizing oneself with these representations is essential for effective management and optimization of equipment functionality.

Resources for Parts and Repairs

Finding the right components and support for your equipment can significantly enhance its performance and longevity. Access to reliable resources ensures that you can maintain your machinery efficiently and resolve any issues that may arise during operation. This section will guide you through various avenues to obtain necessary items and services.

Online marketplaces offer a vast selection of components, often at competitive prices. Websites specializing in machinery supplies allow users to search for specific items, ensuring quick access to what you need. Additionally, many retailers provide user reviews that can help you make informed decisions based on others’ experiences.

Local dealers and repair shops are invaluable for hands-on assistance. They often have trained staff who can provide expert advice and might even offer installation services. Building a relationship with your local provider can lead to personalized support and quicker turnaround times for repairs.

Online forums and communities are excellent resources for knowledge sharing. Engaging with fellow enthusiasts can yield practical tips and troubleshooting advice, often specific to your model. Many members are eager to share their experiences, which can help you avoid common pitfalls and ensure successful repairs.

Lastly, manufacturer websites frequently have a wealth of information, including manuals and service guides. These documents can serve as a comprehensive reference for maintenance and repair procedures, providing detailed insights into the workings of your equipment.