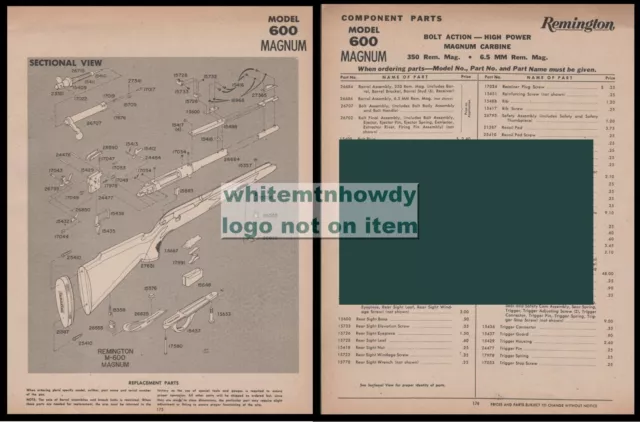

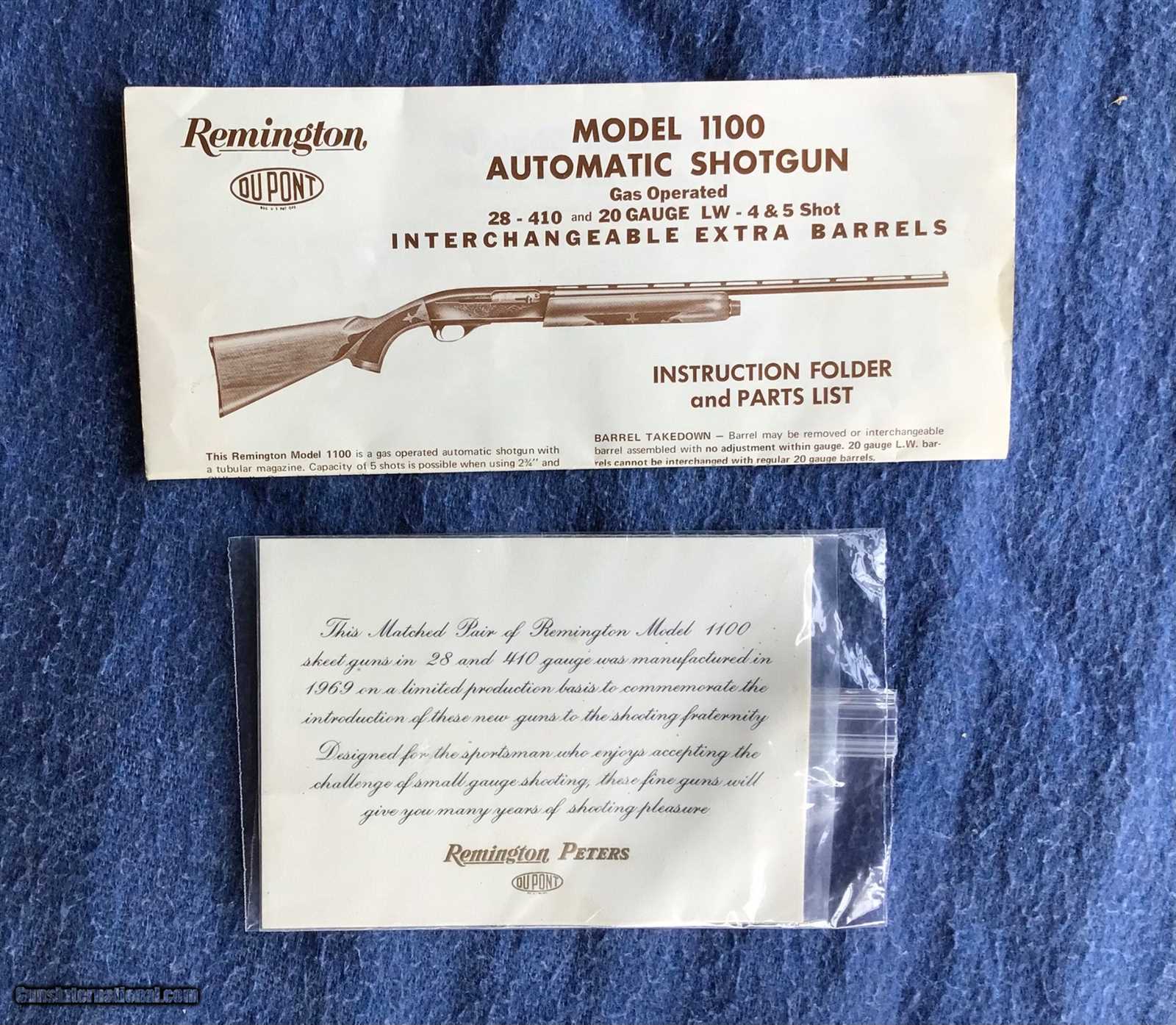

Exploring the intricacies of a time-honored mechanism offers a deeper understanding of its unique construction and operational principles. This guide delves into the detailed inner workings of a classic design, emphasizing the layout and function of each element within its assembly. Such knowledge proves invaluable for enthusiasts, collectors, and those aiming to maintain this piece of history.

The focus lies on a model known for its balance of precision and durability, presenting a design that has remained relevant through generations. By examining each element, from the primary operating components to the smaller connectors and fasteners, one can appreciate the engineering that has gone into creating a balanced and reliable structure.

Understanding the arrangement and interaction of individual elements not only aids in restoration and upkeep but also

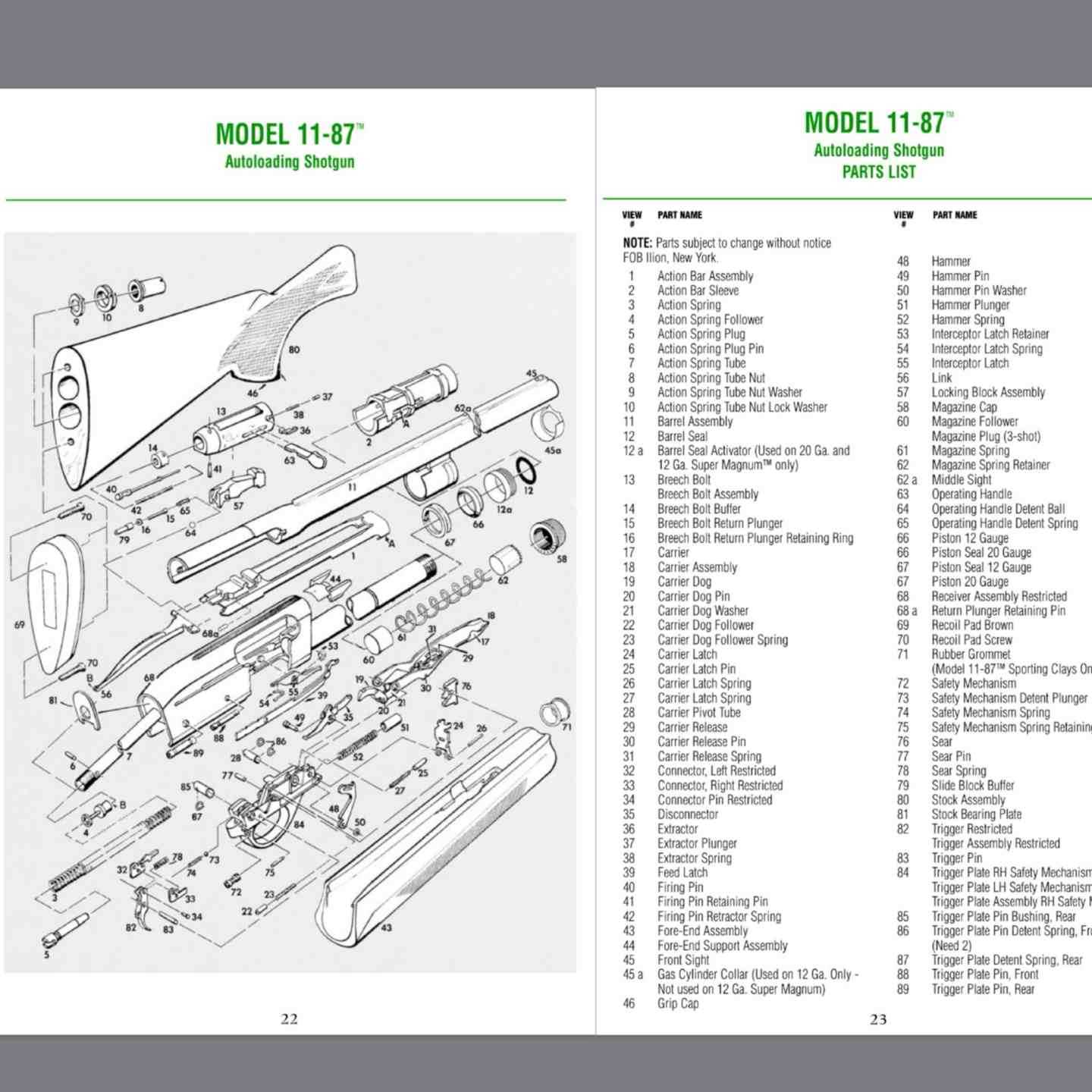

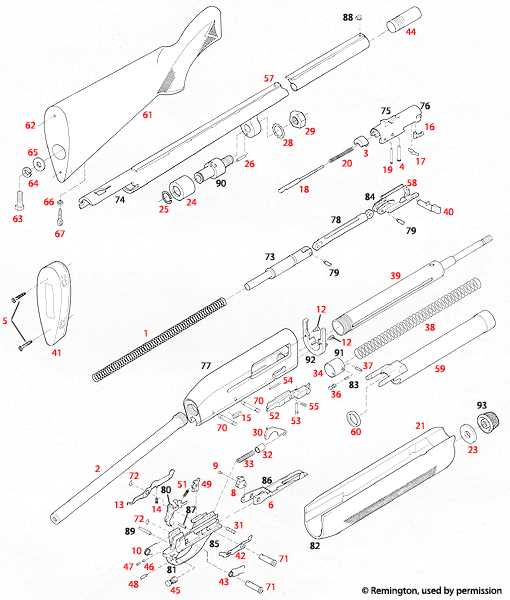

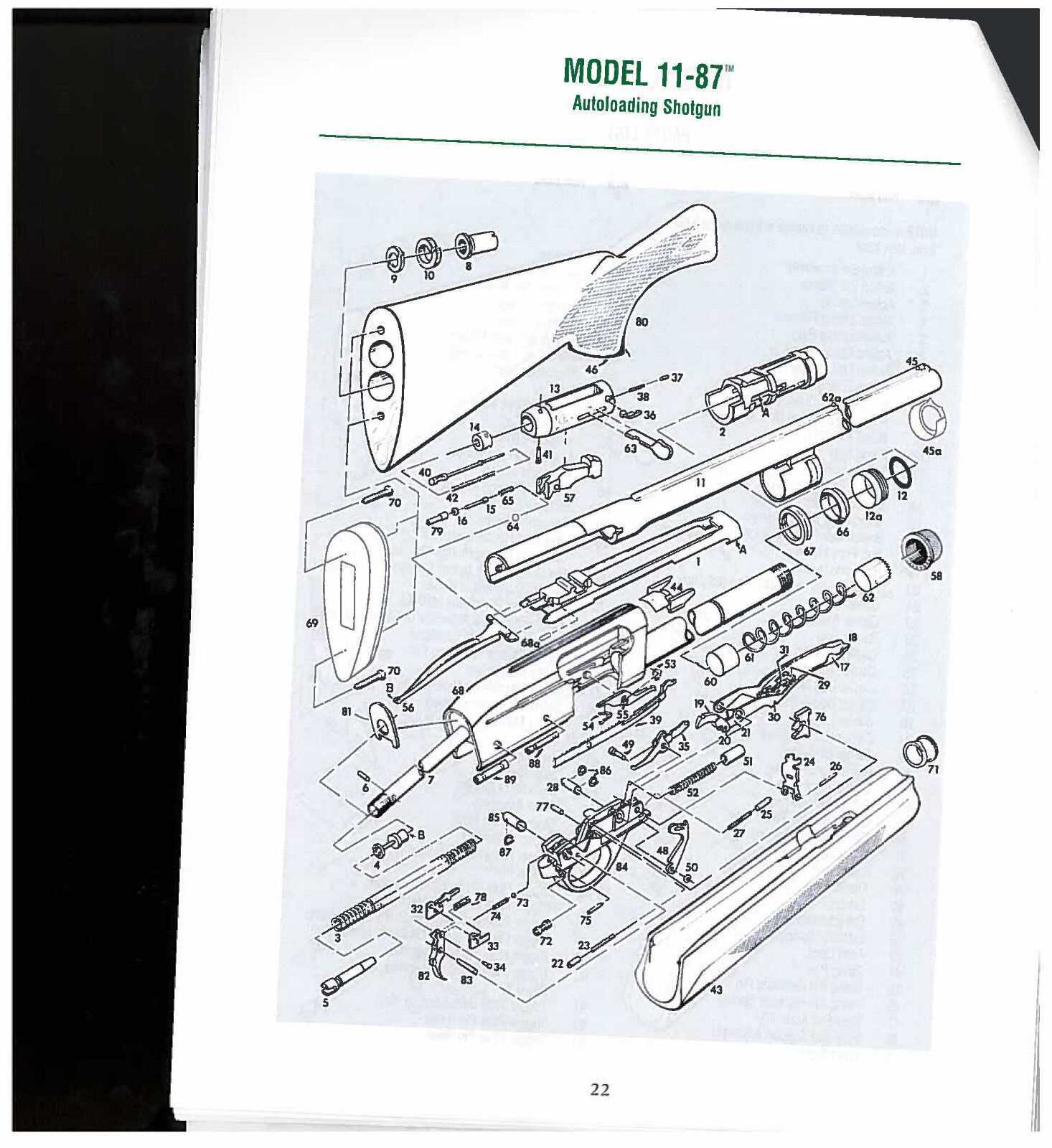

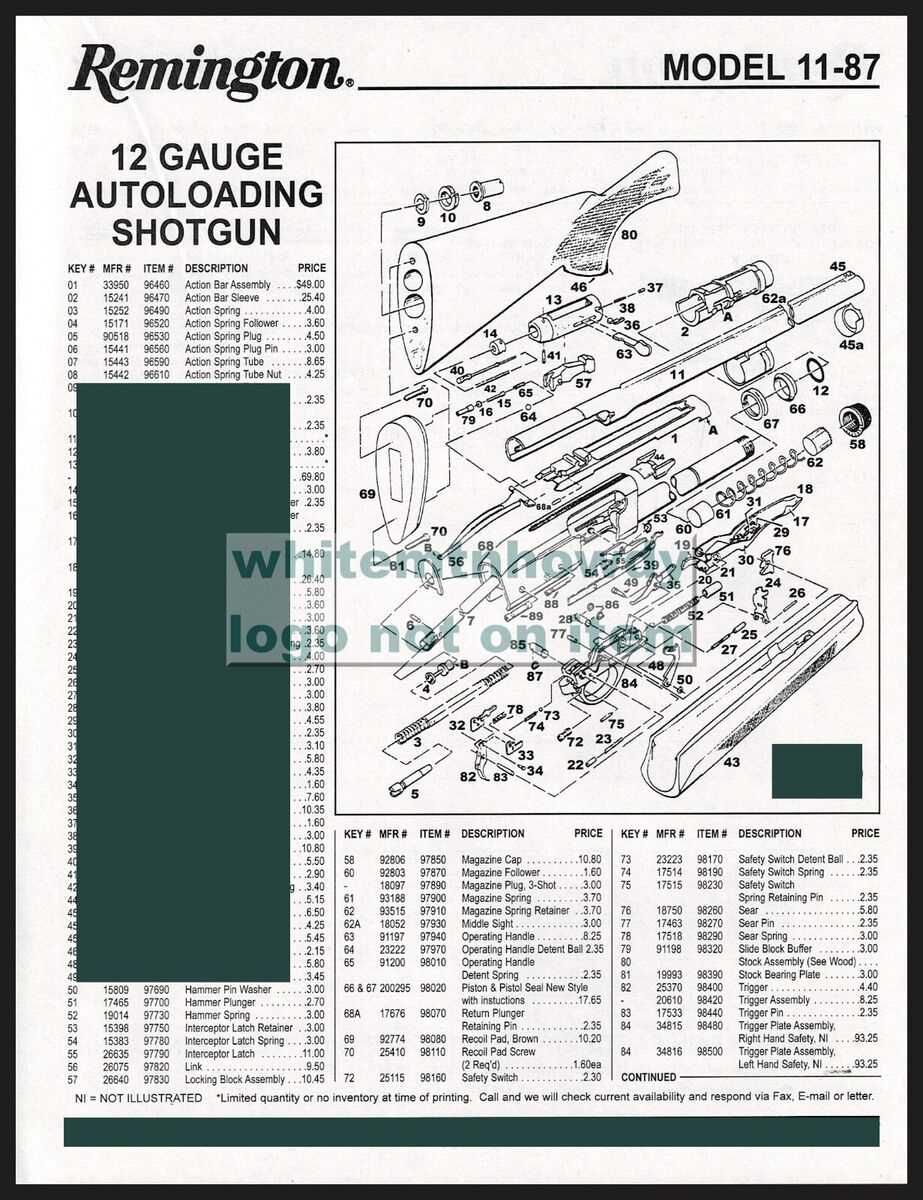

Overview of the Remington 11-48 Components

This section delves into the intricate assembly of a classic autoloading shotgun, highlighting the various mechanisms that contribute to its functionality. By exploring each key element, readers can better understand how these parts interact to provide reliable performance.

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Barrel Assembly | Responsible for guiding the projectile, this element features a smooth interior to ensure accuracy and consistency during discharge. | ||||||||||||

| Trigger Mechanism | A crucial part that controls the release of the firing pin, enabling the ignition of the shell with precise timing. |

| Component | Description |

|---|---|

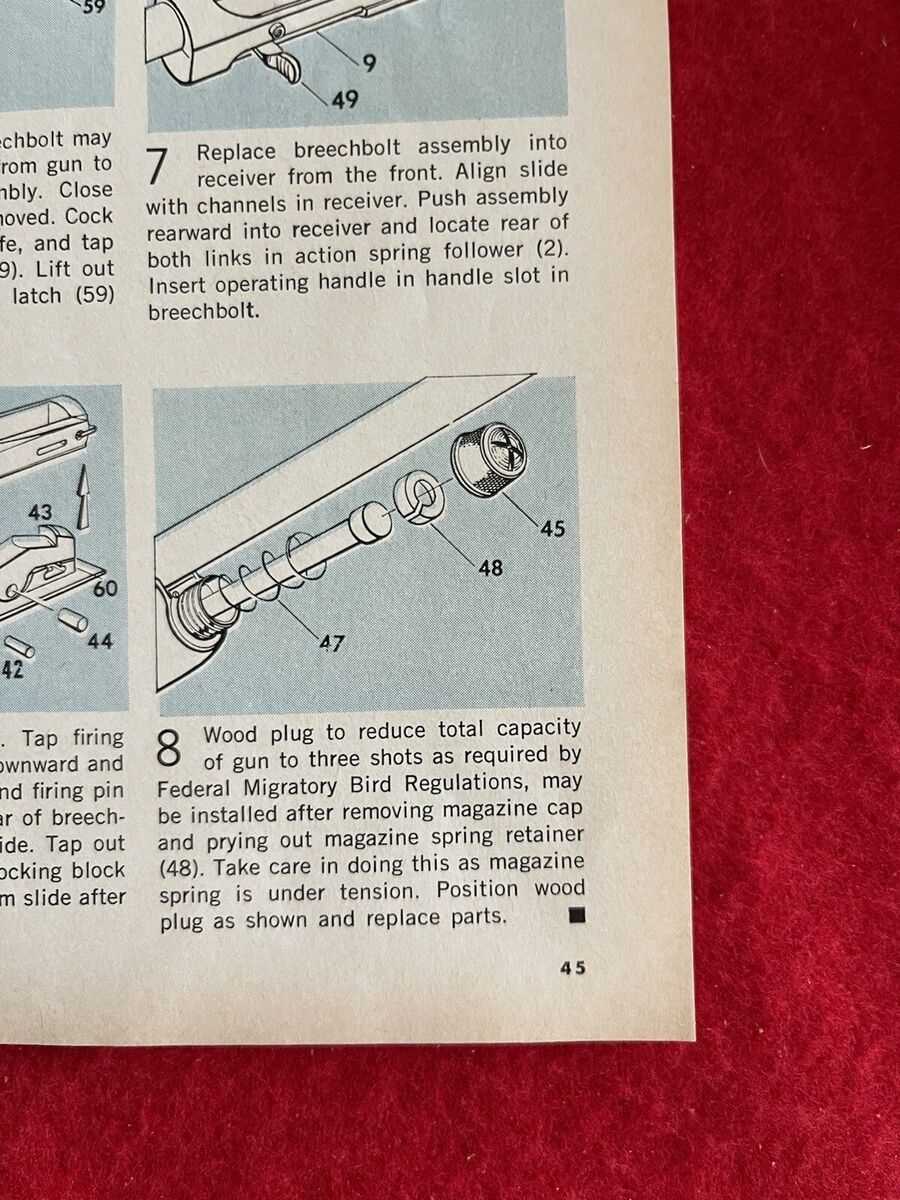

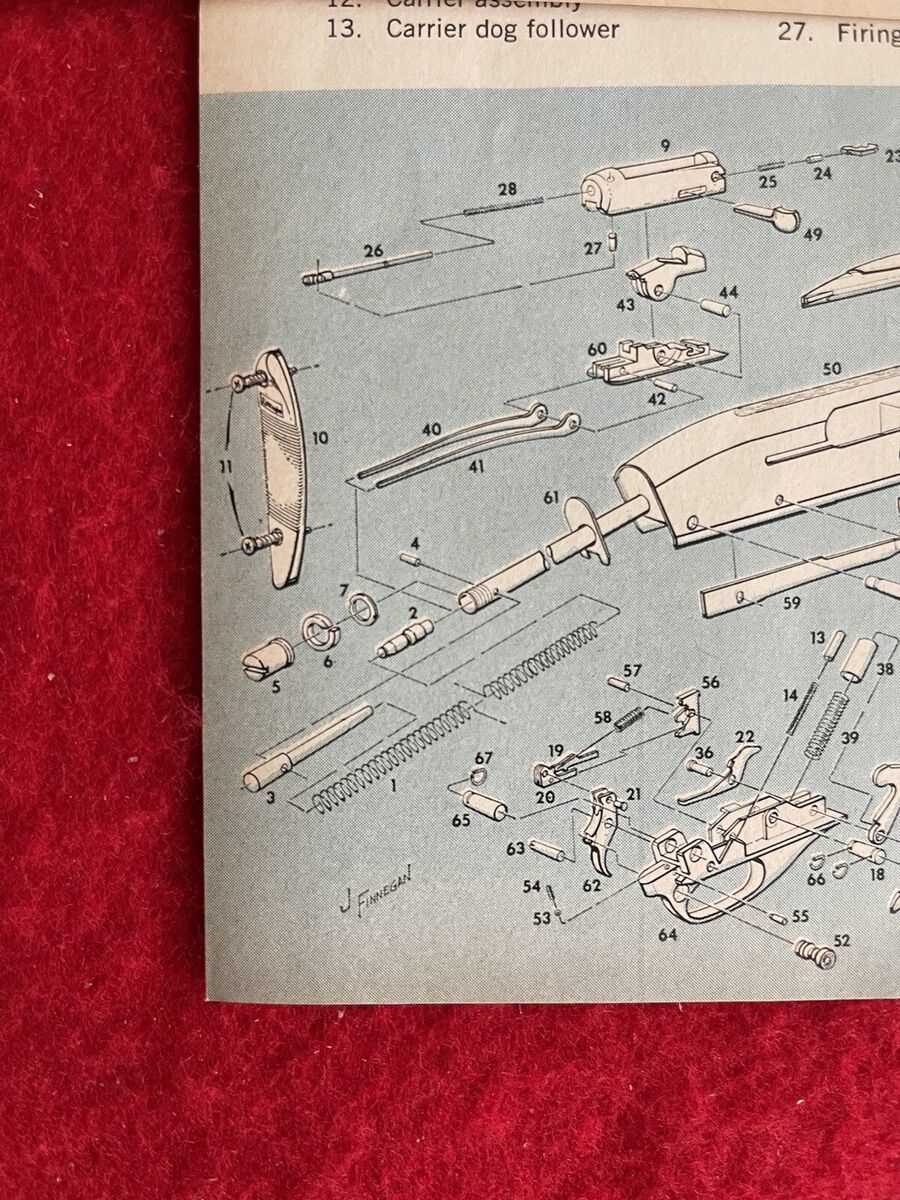

| Tube | Holds the cartridges in place and feeds them into the chamber. |

| Follower | Moves upward as cartridges are fed into the action, ensuring smooth operation. |

| Spring | Provides the necessary tension to push the cartridges upward toward the chamber. |

| Cap | Secures the assembly and prevents cartridges from falling out. |

| Guide | Assists in the smooth movement of the follower within the tube. |

Each of these components must be regularly inspected for wear and functionality to ensure reliable performance. Proper assembly and disassembly techniques are crucial for maintaining the efficiency of the entire mechanism.

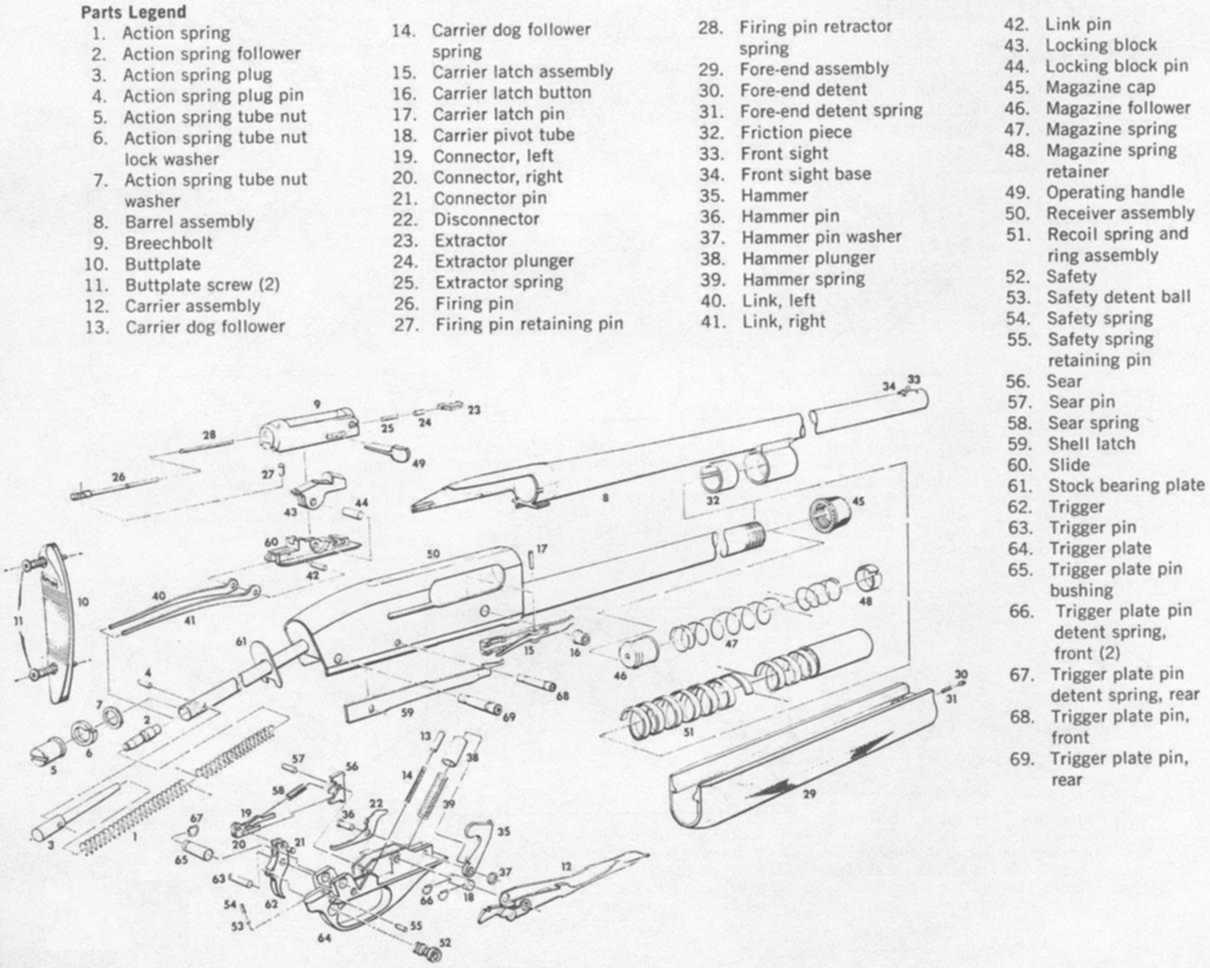

Trigger Group Structure

The mechanism responsible for initiating the firing process is a crucial component within a firearm’s assembly. This system encompasses various elements that work in unison to ensure reliable and safe operation. Understanding its layout and functionality is essential for both maintenance and repair tasks.

- Hammer: This part strikes the firing pin when released, igniting the cartridge.

- Sear: A critical element that holds the hammer in a cocked position until the trigger is pulled.

- Trigger: The component that the shooter engages to release the sear and allow the hammer to fall.

- Disconnector: Prevents the hammer from falling multiple times with a single pull of the trigger.

- Safety Mechanism: Ensures that the firearm cannot be discharged unintentionally.

Each of these components must be properly aligned and functioning to maintain the overall safety and efficiency of the firearm. Regular inspection and cleaning can prevent malfunctions and enhance performance.

Maintenance Tips for Key Parts

Proper upkeep of essential components is crucial for ensuring optimal performance and longevity. Regular attention to specific areas can prevent malfunctions and enhance reliability. Following a few simple guidelines can make a significant difference in the overall condition of your equipment.

Cleaning and Inspection

- Regularly clean moving parts to remove dirt and debris, which can cause wear and hinder functionality.

- Inspect critical areas for signs of wear, rust, or damage, addressing issues promptly to avoid further complications.

- Use a soft brush or cloth to reach tight spaces without causing harm to delicate surfaces.

Lubrication Practices

- Apply appropriate lubricants to all moving elements to reduce friction and ensure smooth operation.

- Be cautious not to over-lubricate, as excess grease can attract dust and lead to buildup.

- Consult manufacturer recommendations for specific lubricants suited for different materials.

Following these maintenance tips will help maintain the efficiency and reliability of key components, extending their lifespan and ensuring optimal performance over time.

Exploring Customization Options

Personalization in firearm design can significantly enhance performance and aesthetics. Enthusiasts often seek to modify their equipment to suit individual preferences, improving ergonomics or functionality. This section delves into various avenues for customization that can elevate a standard model to a more tailored experience.

Enhanced Grip and Control

One of the most impactful changes involves upgrading the grip. Options include ergonomic designs that promote a more natural hold, or textured materials that enhance traction. Such modifications can lead to improved handling and comfort during use, allowing for more precise control in various shooting scenarios.

Optics and Accessories

Integrating modern optics can transform performance, offering improved accuracy and target acquisition. Additionally, accessories like custom forends, sights, and mounts not only enhance utility but also allow users to express personal style. By choosing compatible components, users can create a setup that meets their unique shooting needs.