When it comes to maintaining agricultural machinery, a comprehensive understanding of its components is essential for effective repairs and upgrades. This knowledge empowers operators to identify and address issues promptly, ensuring optimal performance and longevity of their equipment.

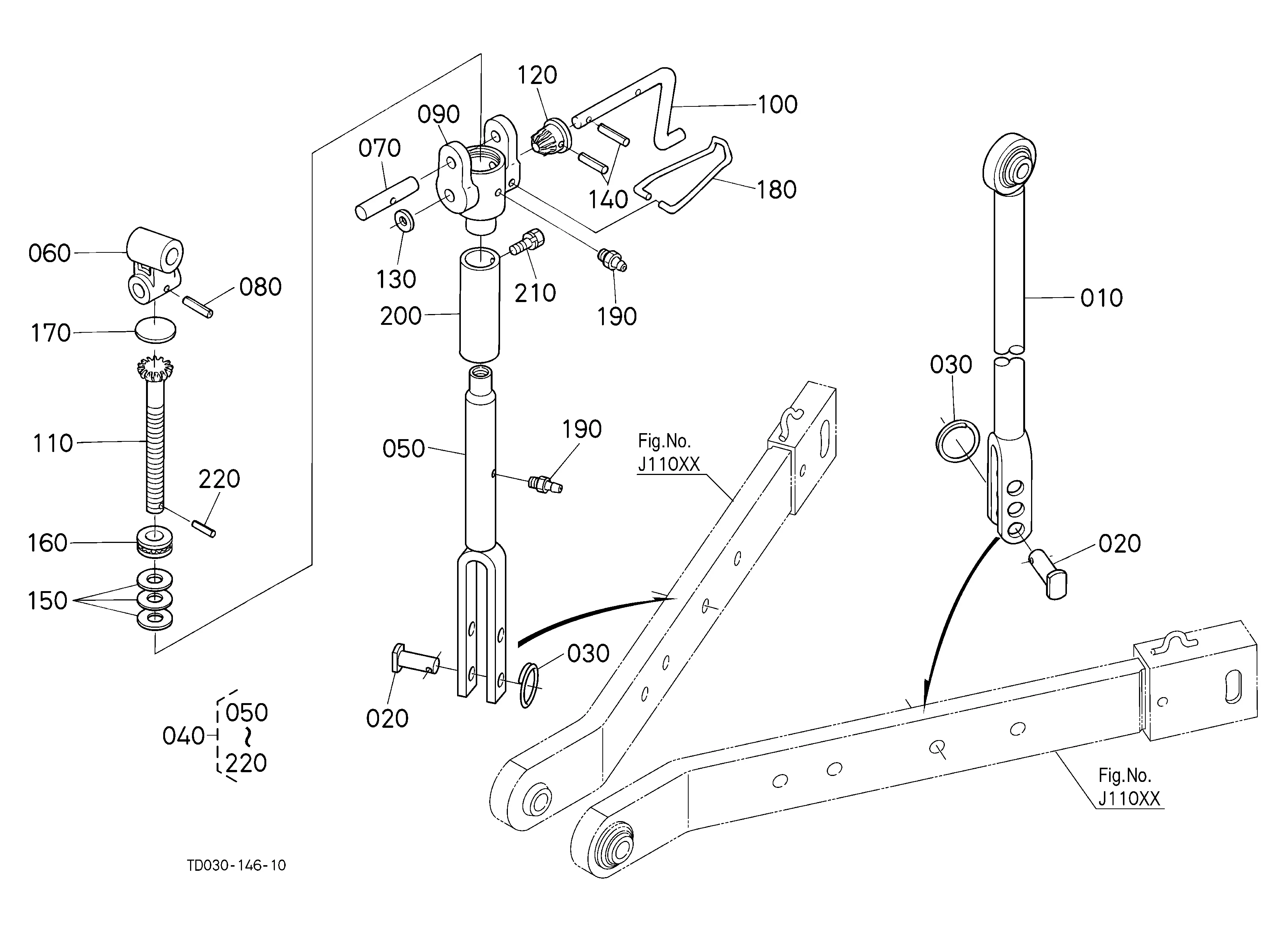

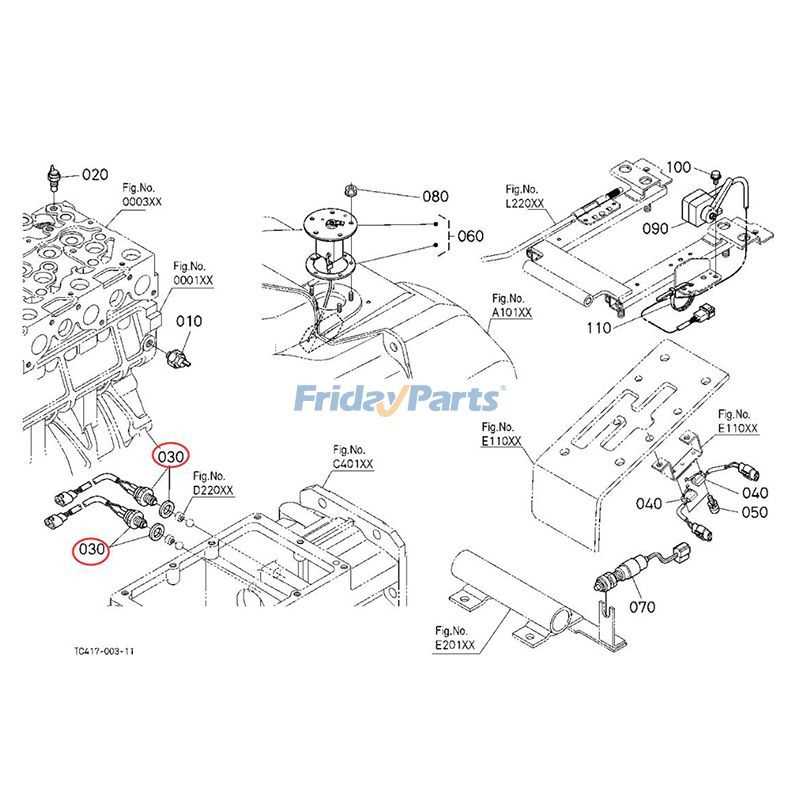

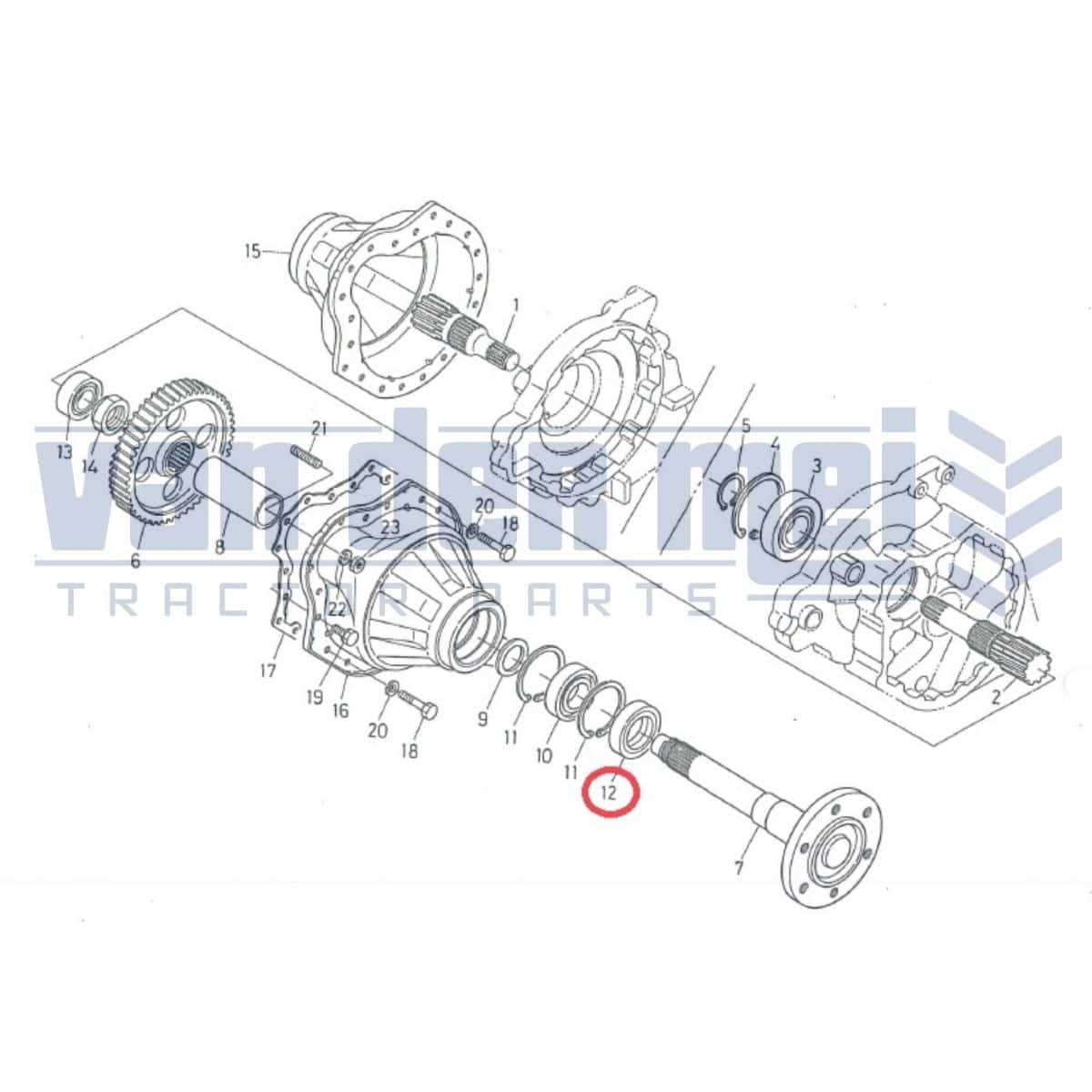

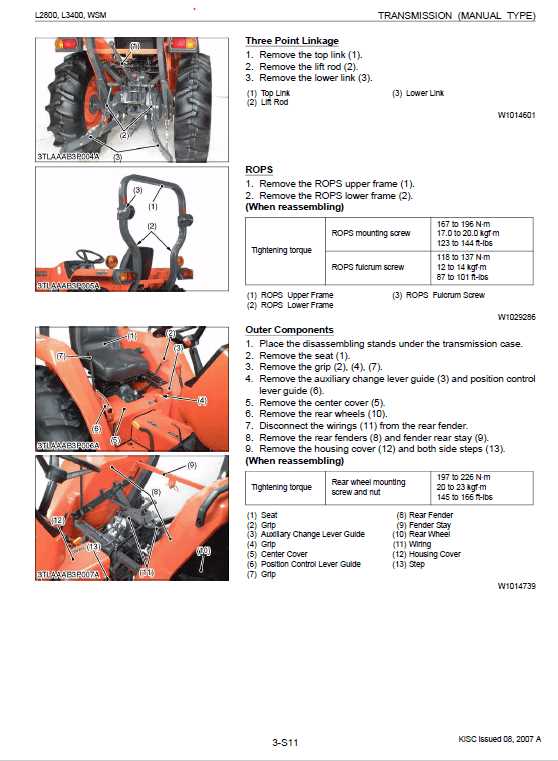

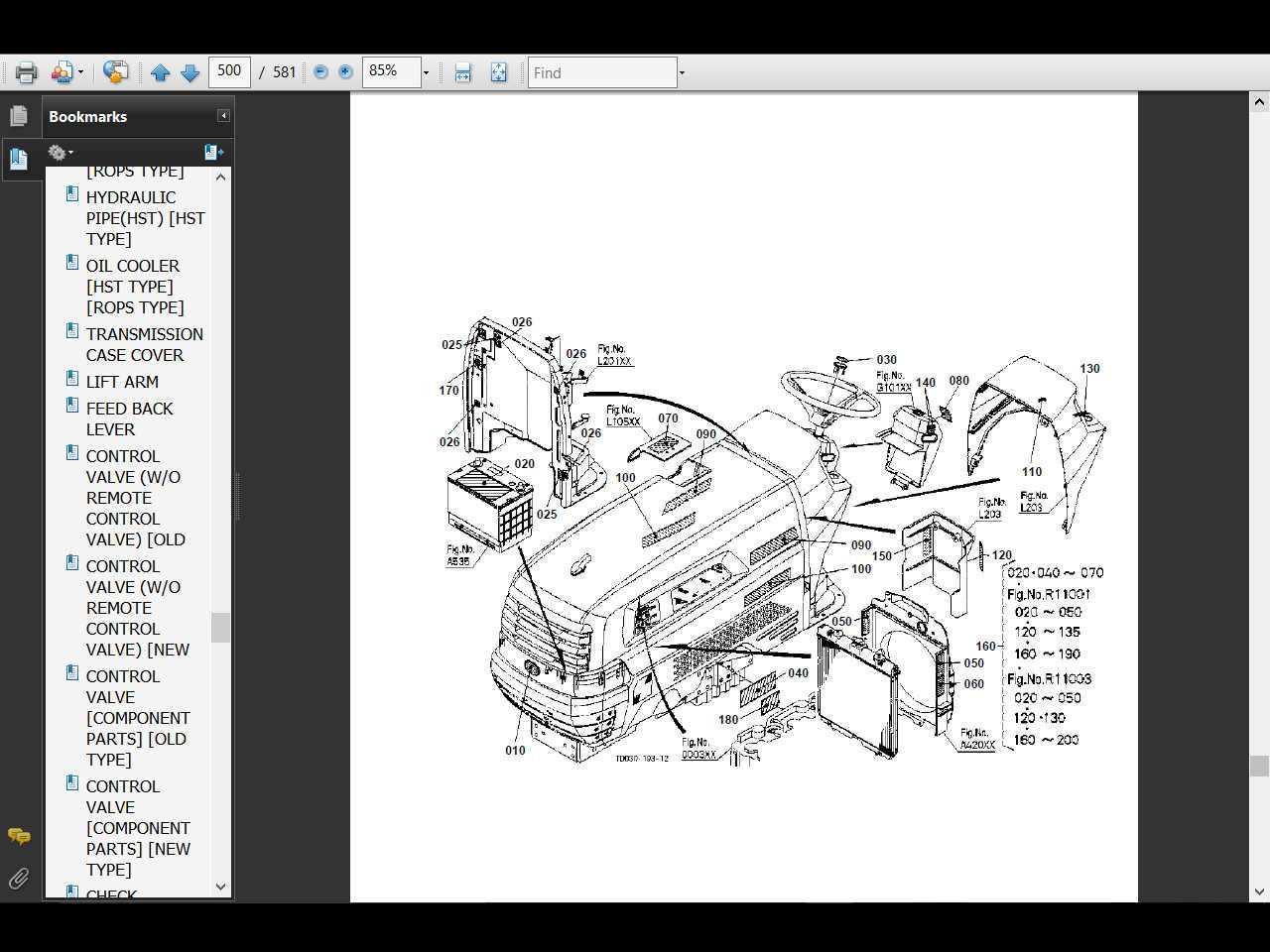

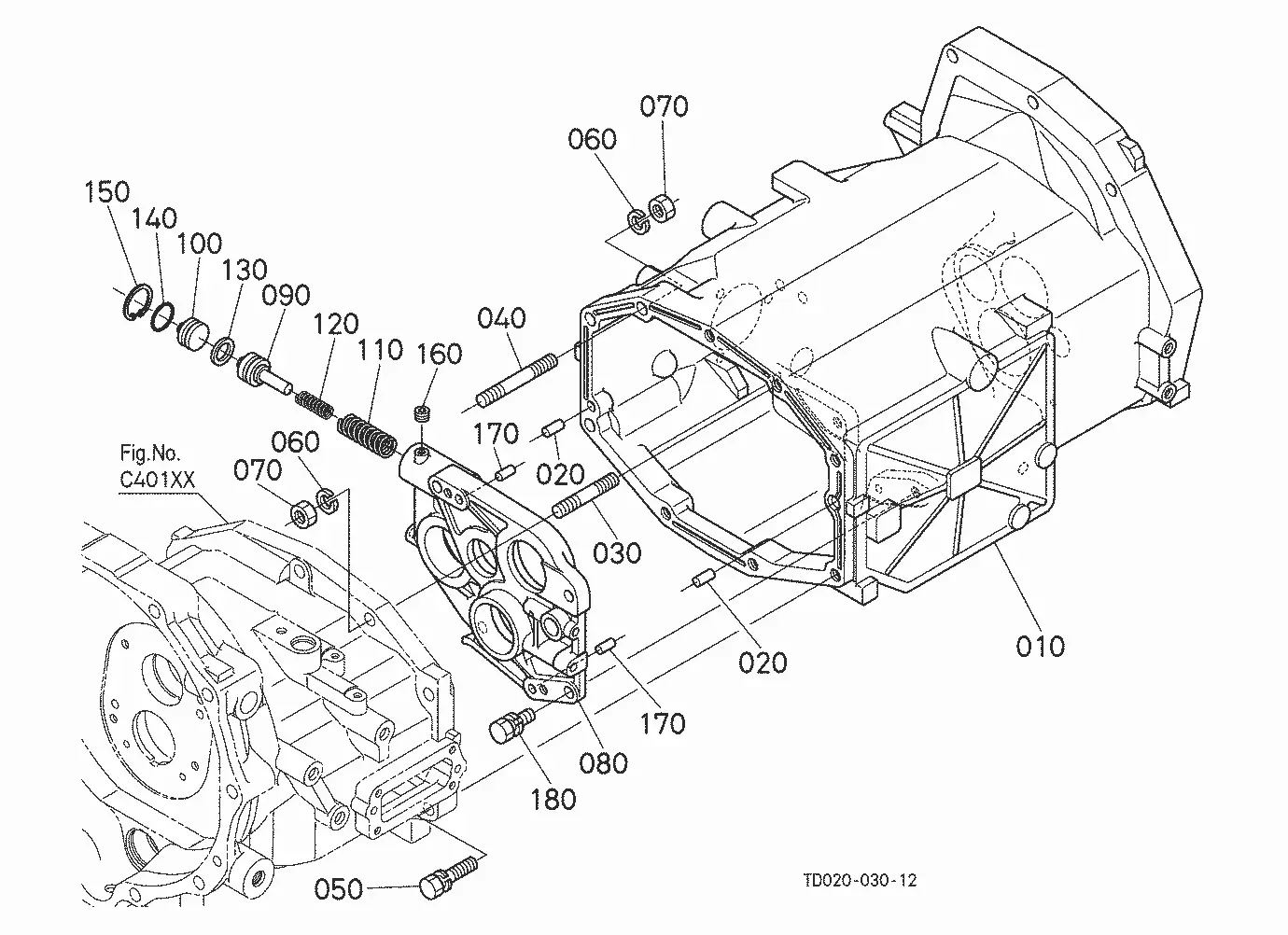

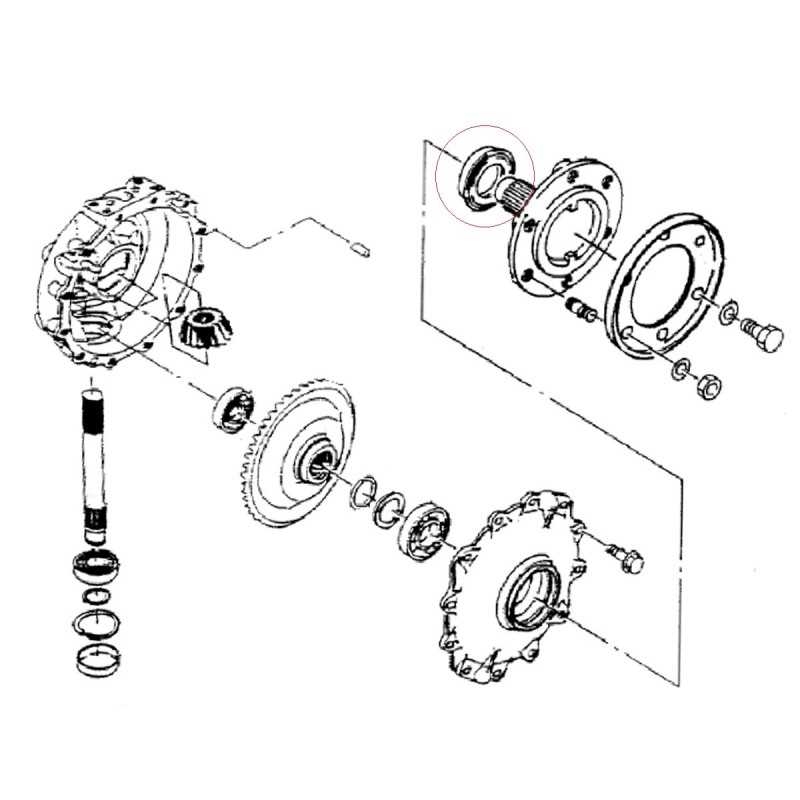

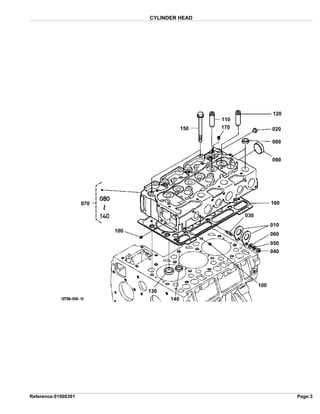

Visual representations of machinery assemblies serve as invaluable tools in this process. They provide clarity on how various elements interact and fit together, which can be crucial for troubleshooting and replacement tasks. By consulting these schematics, users can make informed decisions, minimizing downtime and maximizing productivity.

In this discussion, we will explore the intricacies of component layouts for a specific model of tractor. We will delve into the significance of each part, elucidating their functions and the role they play in the overall operation of the machine. Gaining insight into these relationships is key to mastering the art of machinery maintenance.

Kubota L3130 Parts Diagram: Exploring Your Tractor’s Anatomy

Understanding the intricate components of your agricultural machine is essential for effective maintenance and operation. This section delves into the essential elements that make up the structure of your equipment, allowing for improved functionality and longevity. By familiarizing yourself with each section, you can enhance your troubleshooting skills and ensure optimal performance.

Mechanical Components: The heart of any agricultural machine lies in its mechanical systems. Each segment plays a vital role in the overall operation, from the engine to the transmission. Identifying these components helps in diagnosing issues and facilitating timely repairs.

Hydraulic Systems: These systems are crucial for lifting and moving implements. Understanding their configuration allows operators to troubleshoot fluid leaks and ensure efficient power transfer. Recognizing the various elements involved can significantly improve work efficiency.

Electrical Systems: The electrical architecture is integral to the functionality of your equipment. It powers essential features and ensures seamless operation. Familiarizing yourself with the wiring and electrical components can aid in addressing potential faults swiftly.

Attachments and Implements: Knowing the different attachments enhances versatility in operations. Each accessory is designed for specific tasks, and understanding their connection points ensures proper usage and maintenance. This knowledge empowers you to adapt your machine to various agricultural needs.

By exploring these various systems and their components, you gain a comprehensive understanding of your machine’s anatomy. This not only aids in maintenance but also enhances your operational capabilities in the field.

Understanding the Basics of Kubota L3130 Parts

Gaining insight into the components of agricultural machinery is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance, contributing to the overall efficiency of the equipment. Familiarity with these elements not only aids in troubleshooting but also enhances the longevity of the machine.

Key Components and Their Functions

The primary elements of any tractor include the engine, transmission, and hydraulic system. The engine serves as the powerhouse, converting fuel into mechanical energy. The transmission facilitates the transfer of this energy to the wheels, enabling movement. Meanwhile, the hydraulic system is vital for powering attachments and enhancing operational versatility.

Maintenance and Replacement

Regular upkeep is critical to the reliability of agricultural equipment. Routine checks on fluid levels, filters, and belts can prevent costly breakdowns. When components wear out, timely replacement is necessary to maintain functionality. Understanding the specific roles of each part aids in identifying when replacements are needed.

In conclusion, a thorough comprehension of the machinery’s components is indispensable for any operator. This knowledge ensures effective maintenance, efficient operation, and maximizes the lifespan of the equipment.

Locating and Identifying Key Components

Understanding the essential elements of machinery is crucial for efficient operation and maintenance. Identifying and locating these components can streamline repairs and enhance performance. This section provides insights into effectively recognizing the main parts of your equipment.

Visual Identification Techniques

One of the most effective methods for recognizing components is through visual inspection. Start by familiarizing yourself with the overall layout of the machine. Pay attention to the shape, size, and positioning of different parts. Utilize reference manuals or online resources that offer labeled images, which can help you match the physical attributes of the components.

Utilizing Labels and Markings

Many key components feature labels or markings that can assist in identification. Look for serial numbers, model identifiers, or manufacturer logos, as these can provide valuable information about the specific parts. Additionally, consulting a technical guide can further clarify the functions and importance of each element, aiding in both maintenance and troubleshooting.

Interpreting the Symbols and Labels on the Diagram

Understanding the various symbols and labels within a technical representation is crucial for effective maintenance and repair. These graphical elements provide essential information about the components, their functions, and interconnections, enabling users to navigate the intricate details with ease.

Common Symbols Explained

Each symbol is designed to convey specific meanings, often standardized across different machinery. Familiarizing yourself with these signs is the first step toward mastering the technical representation.

| Symbol | Meaning |

|---|---|

| ⚙️ | Gear or mechanical component |

| Adjustment point or tool required | |

| Power source or battery |

Understanding Labels

Labels often accompany symbols, providing additional context such as part numbers, specifications, or operational instructions. Careful attention to these details can prevent misunderstandings and ensure the correct procedures are followed.

Common Maintenance Tips Derived from the Diagram

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Understanding the various components and their functions can aid in identifying potential issues before they escalate. Here are some key maintenance practices inspired by the visual representation of essential parts.

Routine Checks

Performing frequent inspections can help in early detection of wear and tear. Key areas to focus on include:

| Component | Maintenance Action | Frequency |

|---|---|---|

| Oil Filter | Replace or clean | Every 100 hours |

| Air Filter | Inspect and clean | Every 50 hours |

| Battery | Check connections | Monthly |

| Belts and Hoses | Inspect for wear | Every 100 hours |

Fluid Levels

Maintaining proper fluid levels is crucial for the efficient operation of equipment. Regularly checking and replenishing fluids will prevent overheating and component failure. Key fluids to monitor include:

- Engine Oil

- Coolant

- Hydraulic Fluid

How to Use the Parts Diagram for Troubleshooting

Utilizing a visual representation of components can significantly enhance the troubleshooting process for machinery. This tool provides a clear view of each element, aiding in identifying potential issues and their respective locations. By following a systematic approach, operators can efficiently diagnose problems and implement solutions.

Identifying Components

Start by familiarizing yourself with the various sections illustrated in the visual guide. Focus on each part’s label and placement, which will help you recognize where problems may arise. This knowledge is crucial for effective troubleshooting.

Locating Issues

Once you have an understanding of the layout, examine the specific area where you suspect a malfunction. Cross-reference the visual guide with your observations to pinpoint discrepancies. This targeted approach allows for quicker resolutions, minimizing downtime and enhancing productivity.

Exploring Online Resources for Kubota L3130 Parts

In today’s digital age, finding reliable sources for tractor components has become more accessible than ever. Whether you’re looking for specific machine parts or general maintenance guides, online platforms offer a wealth of information. These resources cater to a range of needs, from purchasing individual elements to finding detailed schematics that assist in proper assembly and repairs.

Benefits of Online Platforms

Utilizing internet-based tools allows for convenient comparison shopping and ensures that you can source high-quality replacements or upgrades with ease. Additionally, these platforms often provide user reviews and ratings, which can help guide your purchasing decisions. Many websites also include detailed instructional content that enhances the user experience and supports efficient machine upkeep.

Types of Resources Available

There are several types of online resources you can explore for machinery components. From official vendor sites offering OEM (Original Equipment Manufacturer) options to third-party sellers that specialize in aftermarket options, the choices are abundant. Websites often include catalogs, exploded views, and maintenance tips to aid in troubleshooting and repairs.

| Website Type | Features | Benefits |

|---|---|---|

| Official Manufacturer Sites | OEM components, warranty information | High reliability, quality assurance |

| Third-Party Sellers | Aftermarket options, competitive prices | Cost-effective, wide range of products |

| Online Marketplaces | Variety of sellers, user reviews | Convenient comparison, diverse selections |

Enhancing Performance with Proper Parts Understanding

Maximizing the efficiency of any machinery requires a deep comprehension of its components and how they function together. Proper knowledge of individual elements allows for better maintenance, smoother operations, and longer-lasting performance. When each piece of equipment is understood in its role, users can ensure that the system runs optimally, avoiding unnecessary wear and tear.

Maintenance and repair become more straightforward when the relationship between the various components is clear. By focusing on the key parts, you can achieve greater precision in troubleshooting, allowing for quicker identification of issues. This proactive approach helps in preventing malfunctions and can significantly boost the overall productivity of the machine.

Future-proofing Your Kubota L3130: Parts Replacement Strategy

Ensuring the longevity of your agricultural machinery requires a proactive approach to maintaining and updating its key components. To avoid unexpected downtime and expensive repairs, it’s important to establish a clear strategy for the timely replacement of essential elements. Regular assessments, coupled with careful planning, will help keep your equipment in optimal working condition for years to come.

A well-executed replacement strategy can minimize the risk of operational disruptions. Here are some key steps to consider:

- Identify Wear-Prone Components: Regularly inspect all high-stress areas to detect early signs of wear or fatigue.

- Establish a Maintenance Schedule: Create a maintenance calendar that outlines when parts need to be replaced based on usage and wear rates.

- Prioritize Critical Components: Focus on the most essential parts, such as transmission systems and hydraulic components, to avoid costly breakdowns.

- Use High-Quality Replacements: Always opt for durable and reliable components to ensure long-term performance and reduce the frequency of replacements.

- Stock Commonly Used Items: Keep essential parts on hand to minimize downtime in case of an emergency replacement.

By following these guidelines, you can protect your equipment from future failures and enhance its operational efficiency over time.