The complex machinery used in construction and excavation tasks requires a thorough understanding of its internal systems. Each machine is made up of various interconnected elements that work together to perform specific functions. Familiarizing yourself with the layout and organization of these components is essential for both maintenance and repair.

When it comes to heavy machinery, the design and placement of mechanical elements play a crucial role in ensuring efficiency and reliability. Knowing how these individual units fit and operate within the whole system can make a significant difference in diagnosing issues and performing upkeep.

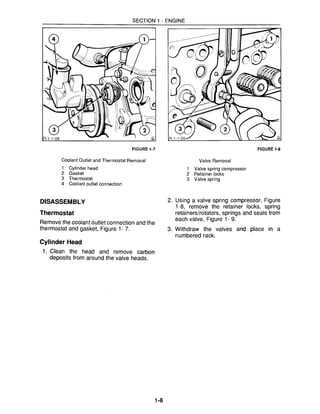

Identifying key mechanical components within the equipment’s framework is crucial for ensuring smooth operation. By carefully examining how each piece is aligned, you can achieve a clearer understanding of its purpose and function, making it easier to address any potential malfunctions.

Essential Components Overview

The mechanical system consists of numerous interconnected elements that ensure efficient operation and smooth functionality. Understanding the key structural and operational units is crucial for effective maintenance and troubleshooting.

Hydraulic Mechanism

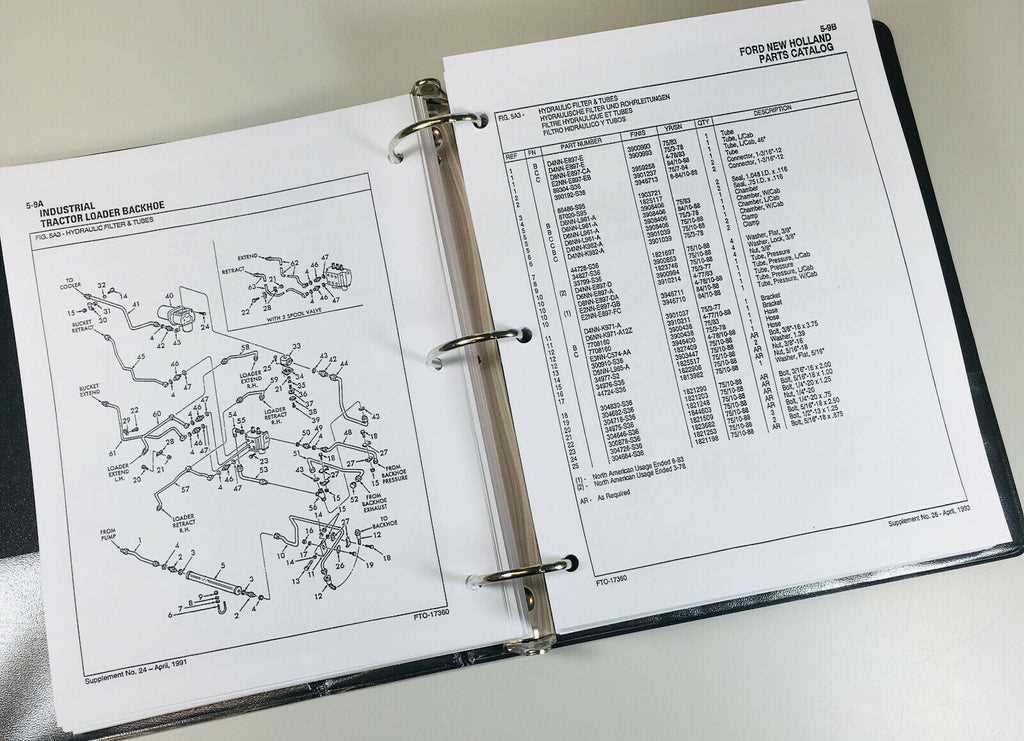

The hydraulic mechanism plays a vital role in enabling various functions. It powers movements through pressurized fluid, ensuring precision and control during operation. Regular maintenance of this system is essential to avoid performance issues.

Structural Framework

The overall design is supported by a durable framework that provides stability and strength. This structure ensures balance and allows for the seamless integration of various working components, maximizing operational efficiency.

Hydraulic System Key Elements

The hydraulic system is crucial for efficient operation, as it controls the movement and functionality of various components. Understanding the main parts of this system ensures better maintenance and troubleshooting, leading to smoother operations.

Pumps

Pumps generate the necessary fluid pressure to power the system. They are designed to provide consistent force to ensure reliable performance under different conditions. Regular checks and maintenance are vital for optimal functionality.

Cylinders and Valves

Cylinders convert hydraulic pressure into mechanical force, enabling movement. Valves, on the other hand, regulate the flow and pressure of the fluid, ensuring precise control over the system’s operations.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pumps | Generate fluid pressure | ||||||||||||||||||||

| Cylinders | Convert pressure into motion | ||||||||||||||||||||

| Valves | Control fluid flow and pressure |

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pistons | Convert fuel energy into mechanical motion by moving within the cylinders. | ||||||||

| Cylinder Block | Houses the cylinders and other vital components, providing structural integrity to the engine. | ||||||||

| Crankshaft | Transforms the pistons’ linear motion into rotational energy to drive the machine. | ||||||||

| Valves | Regulate the intake of air and fuel and the release of exhaust gases. | ||||||||

| Component | Description |

|---|---|

| Batteries | Provide power to start the engine and operate electrical components. |

| Wires | Conduct electricity between various parts of the system. |

| Fuses | Protect the circuit from overloads and short circuits. |

| Switches | Control the flow of electricity to different components. |

Steering and Suspension Components

The steering and suspension system plays a crucial role in maintaining stability and control during operation. This section outlines the various elements that contribute to the effective functioning of these systems, ensuring optimal performance and safety.

- Steering Mechanism: This includes components that allow precise control of direction, ensuring smooth navigation.

- Hydraulic Cylinders: Essential for providing the necessary force for steering adjustments.

- Linkages: These connect the steering wheel to the wheels, facilitating communication between the operator and the vehicle.

In addition to steering, the suspension system is vital for absorbing shocks and providing a comfortable ride. Key components include:

- Shock Absorbers: Help in minimizing vibrations and maintaining traction on uneven surfaces.

- Springs: Support the vehicle’s weight and aid in maintaining proper ground clearance.

- Control Arms: Connect the chassis to the wheel assemblies, allowing for vertical movement.

Understanding these components is essential for effective maintenance and troubleshooting, ultimately enhancing the longevity and reliability of the vehicle.

Brake System Diagram

The braking mechanism is a critical component of any machinery, ensuring safety and control during operation. Understanding its layout and functionality is essential for effective maintenance and troubleshooting. This section provides an overview of the various elements involved in the braking system, facilitating a comprehensive understanding of its design and operation.

Key Components

- Brake Pedal: Initiates the braking process.

- Master Cylinder: Converts pedal pressure into hydraulic force.

- Brake Lines: Transmit hydraulic fluid to the brake assemblies.

- Brake Shoes: Create friction against the drum to slow down the machine.

- Wheel Cylinders: Actuate the brake shoes when hydraulic pressure is applied.

System Operation

- Upon pressing the brake pedal, the master cylinder generates hydraulic pressure.

- This pressure travels through the brake lines to the wheel cylinders.

- The wheel cylinders push the brake shoes against the drum, creating friction.

- This friction slows down or stops the machinery.

- Releasing the pedal allows the system to reset, returning to its original state.

Maintenance and Replacement Guidelines

Regular upkeep and timely component substitution are essential for optimal performance and longevity of machinery. Adhering to a systematic maintenance routine ensures the equipment operates efficiently while minimizing the risk of unexpected breakdowns. Understanding the crucial elements that require attention can significantly enhance the machine’s functionality and reliability.

Routine Maintenance Tasks

Performing routine inspections is vital. Regularly check fluid levels, including hydraulic oil, coolant, and engine oil, to ensure they are within recommended limits. Cleaning filters and air intakes prevents blockages and supports smooth operation. Additionally, inspecting hoses and connections for wear can help identify potential issues before they escalate.

Component Replacement Strategies

When components show signs of deterioration, timely replacement is necessary. Identifying parts that exhibit wear or malfunction early on can prevent further damage. Ensure to refer to the equipment’s manual for specifications regarding compatible replacements. Using original or high-quality aftermarket parts is recommended to maintain performance standards.