Maintaining a pristine lawn requires the right tools and knowledge about their individual elements. Understanding how each component contributes to the overall functionality of your machinery can enhance performance and extend its lifespan. This knowledge is crucial for efficient upkeep and troubleshooting potential issues that may arise during operation.

In this section, we will explore the intricate structure of specific models designed for lawn care. By examining their various sections, users can gain insight into the mechanical relationships and the importance of each piece. This understanding will facilitate informed decisions when it comes to repairs, replacements, or upgrades.

Additionally, visual aids play a significant role in simplifying complex assemblies. Clear representations allow for easier identification of components and their respective roles. This resource aims to equip you with the necessary information to navigate your equipment confidently and ensure that it operates at its best.

Kubota RCK60B23BX Overview

This section provides an insightful look into a specific model designed for lawn care and landscape maintenance. It emphasizes the functionality and efficiency of this tool, highlighting its importance for both residential and commercial users.

The unit is characterized by its robust construction and innovative features that enhance performance. With a focus on user experience, it offers various adjustments and settings to accommodate different terrain types and mowing conditions. The design prioritizes ease of use, ensuring that operators can achieve optimal results with minimal effort.

Additionally, the implementation of high-quality materials contributes to the longevity and durability of the equipment. Regular maintenance is straightforward, allowing users to keep the machine in peak condition over time. This ensures that it remains a reliable choice for maintaining well-groomed lawns and landscapes.

Overall, this model stands out in its category, merging advanced technology with practical design to meet the needs of its users effectively.

Essential Components of Kubota RCK60B23BX

Understanding the fundamental elements of a lawn maintenance attachment is crucial for ensuring optimal performance and longevity. Each component plays a significant role in the overall functionality, contributing to effective operation and ease of use.

Key components include:

- Cutting Deck: The primary element responsible for the precision and quality of the cut. Its design affects the grass height and clipping dispersal.

- Blades: Sharp and durable, these are vital for achieving a clean finish. Regular maintenance ensures they remain effective.

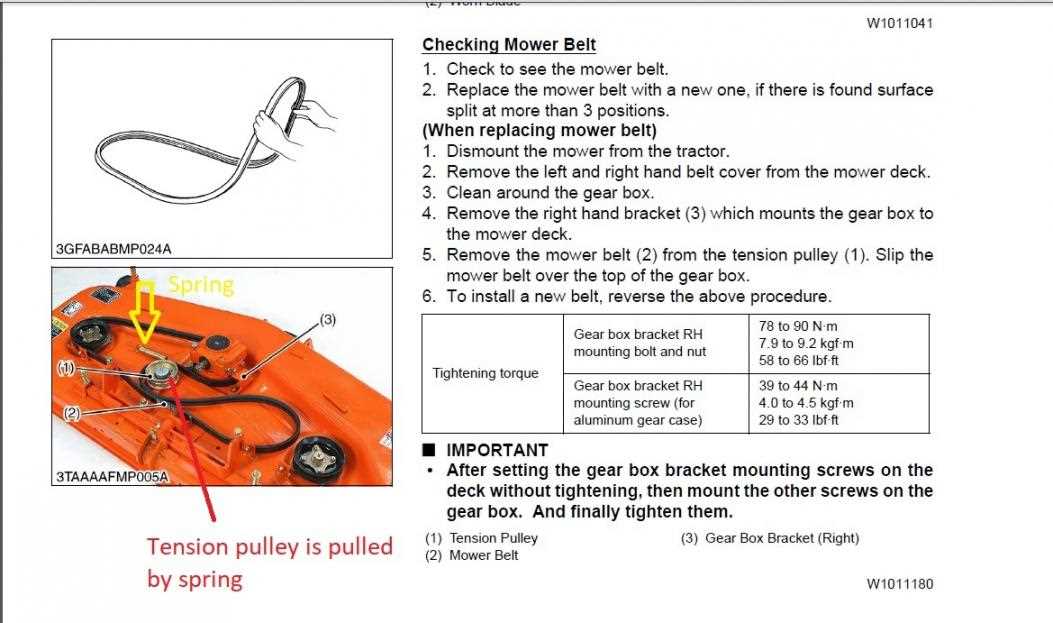

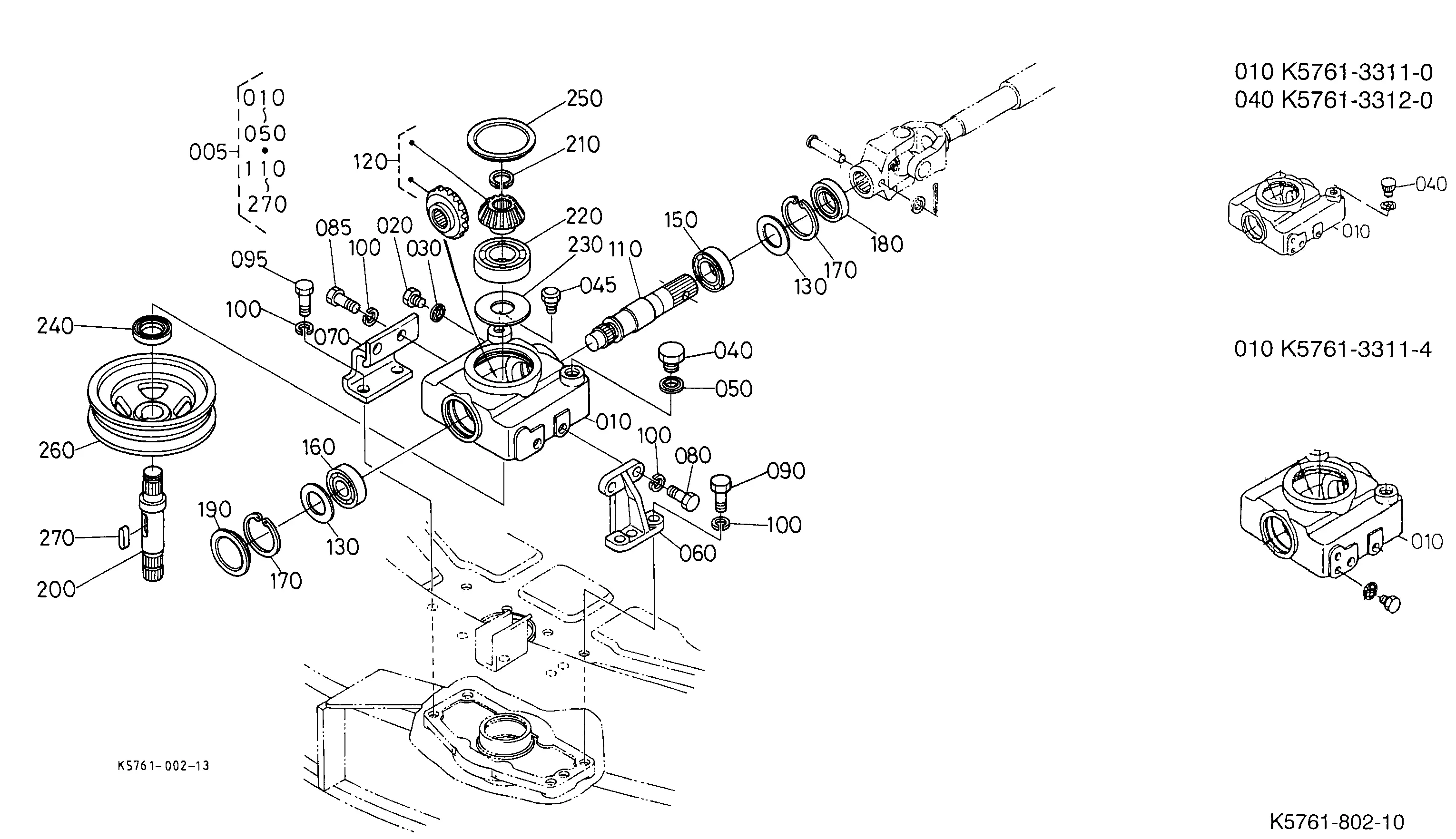

- Drive Mechanism: This includes belts and pulleys that transmit power from the engine to the cutting deck, ensuring smooth operation.

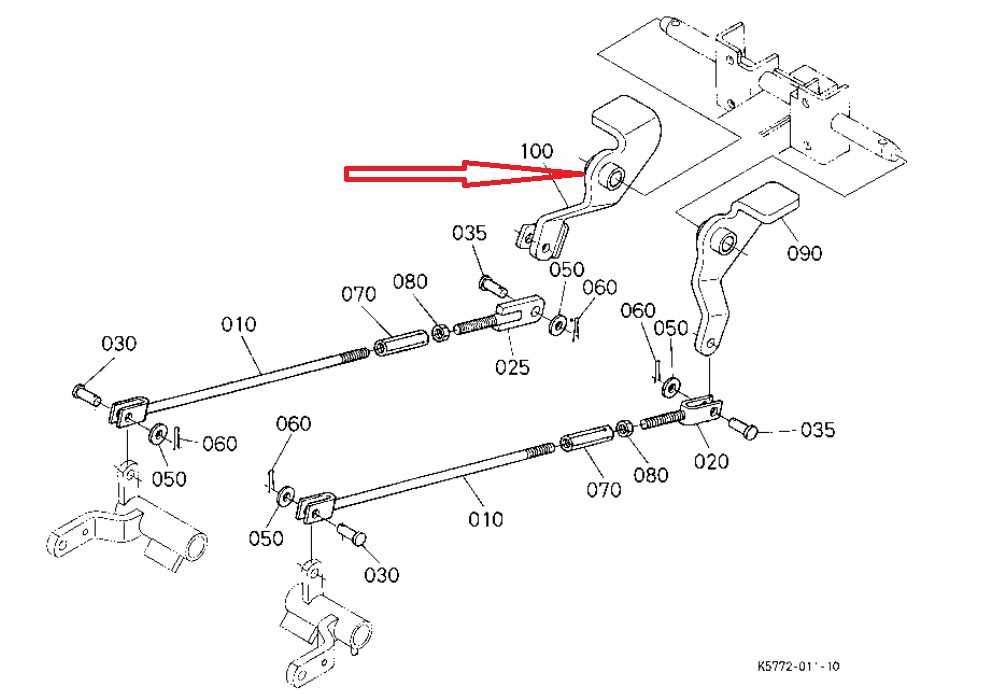

- Height Adjustment System: A critical feature that allows users to customize cutting heights, catering to various lawn types and conditions.

- Chassis: The frame provides stability and support, contributing to the overall durability of the attachment.

By familiarizing yourself with these essential parts, you can better maintain your equipment, enhancing its performance and extending its lifespan.

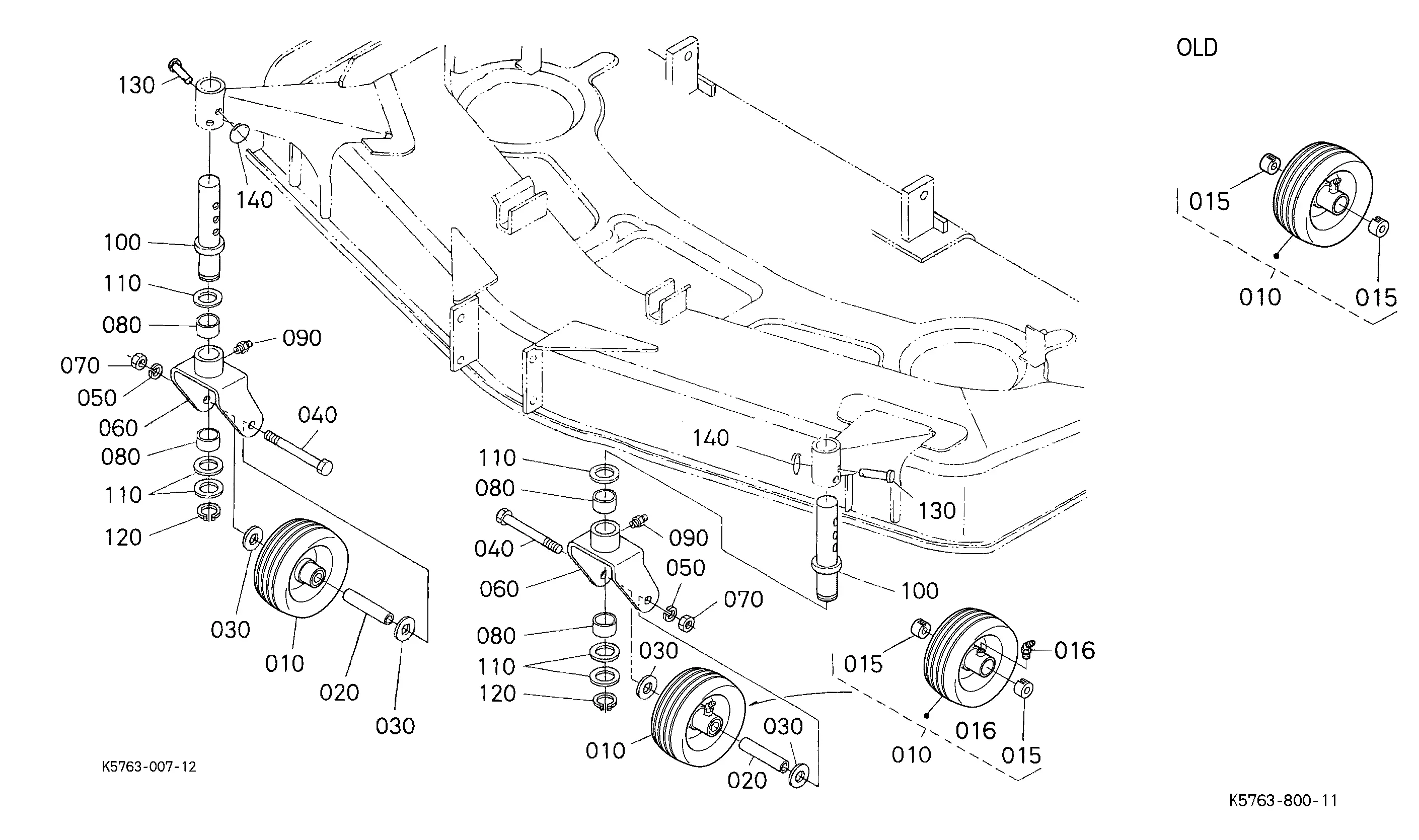

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and enthusiasts alike, allowing for a clearer grasp of how different elements interact within a system. This clarity not only aids in identifying issues but also streamlines the process of ordering replacements when necessary.

Efficient troubleshooting is one of the key advantages of these visual aids. By offering a detailed view of each segment, users can quickly locate the source of a problem, reducing downtime and enhancing productivity. Additionally, these representations facilitate better communication among team members, as they provide a common reference point during discussions and repairs.

Moreover, these illustrations promote knowledge retention. When users engage with visual content, they are more likely to remember the layout and function of each part, leading to improved confidence during maintenance tasks. This aspect is particularly beneficial for those who are new to handling machinery, as it encourages a hands-on learning approach.

Ultimately, having access to these resources fosters a culture of safety and efficiency in operations. Whether for routine checks or extensive repairs, a comprehensive visual guide is an invaluable asset for anyone working with complex equipment.

How to Read Parts Diagrams

Understanding schematics is essential for efficient maintenance and repairs. These visual representations provide a detailed view of components and their relationships within a system. By mastering how to interpret these illustrations, one can effectively identify necessary elements and their functions.

Start by familiarizing yourself with the overall layout. Each section often corresponds to a specific area or function. Look for labels and symbols that indicate the type of component, as these can vary across different systems. Additionally, color coding may help in distinguishing between various elements, making it easier to track connections and placements.

Next, pay attention to the numerical references. These often correlate with a list of items or specifications, allowing for quick identification when sourcing replacements. It’s beneficial to have this reference on hand when inspecting or ordering new pieces.

Lastly, practice is key. The more you engage with these visual guides, the more intuitive reading them will become. With time, you will be able to quickly pinpoint the exact components you need for any repair or upgrade task.

Common Replacement Parts

Maintaining your equipment is essential for optimal performance and longevity. Certain components are more prone to wear and tear due to their frequent use and exposure to various elements. Understanding which items commonly need replacement can help you ensure your machinery runs smoothly.

Here are some frequently replaced components:

- Blades: These cutting edges can dull over time, affecting efficiency.

- Belts: Drive and timing belts are critical for power transmission and may fray or break with regular operation.

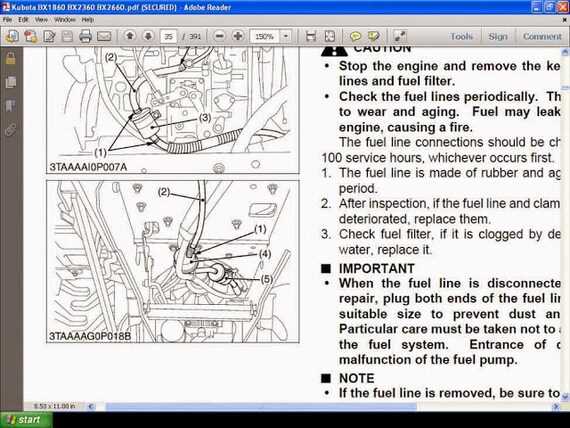

- Filters: Oil, air, and fuel filters should be changed regularly to maintain clean operation and prevent engine damage.

- Spindles: These support the cutting blades and may wear down, leading to reduced performance.

- Tires: Worn or damaged tires can affect traction and stability, necessitating replacement.

Regular inspections can help identify these components early, allowing for timely replacements and minimizing downtime.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your machinery. Implementing a consistent maintenance routine not only prolongs the life of the equipment but also enhances its efficiency, saving time and resources in the long run. Here are some effective strategies to consider.

Regular Inspections

Conducting frequent checks on your equipment allows you to identify wear and tear before it leads to significant issues. Look for signs of damage, leaks, or unusual noises. Keeping a log of these inspections can help track any recurring problems and facilitate timely repairs.

Proper Cleaning and Lubrication

Keeping your machinery clean is crucial for preventing the accumulation of dirt and debris, which can lead to mechanical failure. Regularly clean components and ensure that all moving parts are adequately lubricated. This reduces friction and helps maintain optimal performance levels, ultimately extending the lifespan of your equipment.

Where to Find Parts Diagrams

Locating visual guides for various components can significantly enhance your maintenance and repair efforts. These resources offer detailed illustrations and annotations that simplify the identification of individual elements within machinery, making it easier to ensure everything functions smoothly.

Online Resources

The internet is a treasure trove of information, with numerous websites dedicated to machinery maintenance. Manufacturer sites often provide downloadable manuals, while forums and community groups can offer shared experiences and insights. Utilizing search engines with specific queries can lead you directly to the diagrams you need.

Local Dealers and Distributors

Your nearest equipment dealer or distributor can be invaluable when seeking detailed schematics. Many of these businesses maintain archives of documentation and can assist in locating specific illustrations. Additionally, they can offer expert advice on sourcing the correct components for your needs.

Comparative Analysis with Similar Models

This section aims to provide a comprehensive comparison between various models in the same category, highlighting their similarities and differences. By examining key features, performance metrics, and design elements, users can make informed decisions based on their specific needs and preferences.

| Model | Engine Power | Cutting Width | Weight | Price Range |

|---|---|---|---|---|

| Model A | 23 HP | 60 inches | 450 lbs | $3,000 – $3,500 |

| Model B | 25 HP | 60 inches | 475 lbs | $3,200 – $3,700 |

| Model C | 22 HP | 54 inches | 400 lbs | $2,800 – $3,300 |

In this comparison, it is evident that each model offers unique advantages. For instance, while Model A provides a balance of power and weight, Model B offers slightly higher horsepower, which may be beneficial for more demanding tasks. Meanwhile, Model C presents a lighter option with a narrower cutting width, catering to those with smaller spaces or less intensive mowing needs.