The intricate world of cooling apparatus offers a fascinating glimpse into the components that ensure optimal performance and efficiency. Each element plays a crucial role in the overall functionality, contributing to the seamless operation of the entire system.

By exploring the various segments of these devices, one can uncover the relationships between parts and how they work in unison. This knowledge not only enhances maintenance practices but also empowers users to make informed decisions regarding repairs and upgrades.

In this guide, we will delve into the essential features and configurations of these mechanical systems, providing a comprehensive overview that serves both enthusiasts and professionals alike. Understanding these elements is the ultimate key to mastering the intricacies of cooling technology.

Understanding Mastercool Parts Diagrams

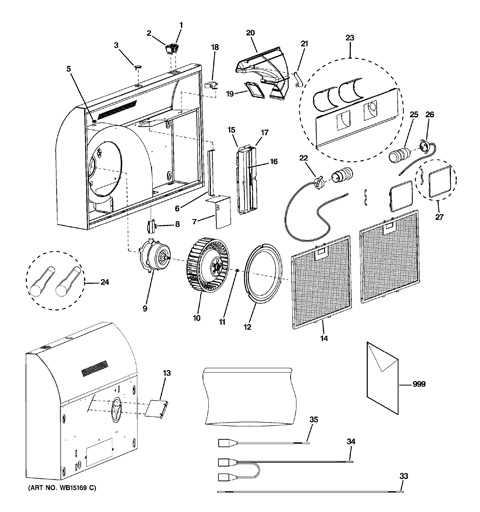

Comprehending the visual representations of components within a system is essential for effective maintenance and repair. These illustrations serve as crucial tools, enabling users to identify various elements and their interconnections. By interpreting these visual guides, individuals can better navigate the complexities of equipment, facilitating troubleshooting and enhancing overall performance.

Each illustration typically showcases the arrangement and function of individual elements, providing a clear reference for assembly or disassembly. This clarity helps users pinpoint specific areas that may require attention, ensuring efficient repair processes. Furthermore, understanding these visuals contributes to a deeper knowledge of the entire mechanism, empowering users to address issues more effectively.

Familiarity with these graphical resources also aids in sourcing replacements and understanding compatibility, which is vital for maintaining optimal functionality. By becoming adept at reading these illustrations, users can take proactive steps to extend the lifespan of their equipment and ensure reliable operation over time.

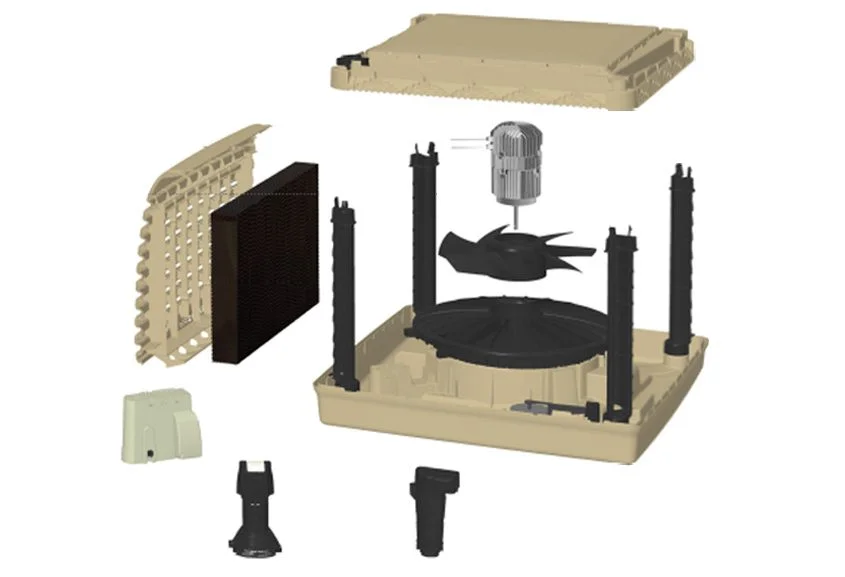

Key Components of Mastercool Units

This section highlights essential elements found in advanced cooling systems, focusing on their functionality and importance in overall performance.

- Compressor: The heart of the unit, responsible for circulating refrigerant and maintaining pressure.

- Condenser: Essential for dissipating heat, transforming gas back into a liquid state.

- Evaporator: Facilitates the absorption of heat from the environment, allowing for cooling.

- Expansion Valve: Regulates the flow of refrigerant, controlling temperature and pressure.

Understanding these critical components is vital for optimizing efficiency and ensuring long-lasting operation.

How to Read the Diagram Effectively

Understanding a visual representation of components can significantly enhance your ability to troubleshoot and assemble machinery. By familiarizing yourself with the layout and symbols used, you can streamline your work process and avoid common mistakes. This section provides essential tips for navigating these illustrations with confidence.

Familiarize Yourself with the Symbols

Every illustration features specific icons and markings that indicate various elements. Take the time to learn these symbols, as they often convey critical information about functionality and compatibility. For instance, arrows may indicate flow direction, while different shapes can represent various types of components. Recognizing these indicators will improve your comprehension and efficiency.

Follow the Flow

When examining the layout, focus on the flow of connections. Visualizing how parts interact with one another will help you understand the overall system better. Pay attention to sequences and relationships; this can be particularly useful when diagnosing issues or planning repairs. A clear grasp of the interconnectedness of components will allow for a more systematic approach to any task at hand.

By mastering these techniques, you will enhance your proficiency in interpreting technical illustrations, ultimately making your projects smoother and more efficient.

Common Issues and Solutions

In any mechanical system, various challenges can arise that may affect performance and efficiency. Understanding these issues and knowing how to address them can significantly enhance longevity and functionality. Below are some frequent problems encountered, along with their corresponding solutions.

Common Challenges

| Issue | Description |

|---|---|

| Overheating | Excessive temperatures can lead to operational failures and reduced lifespan. |

| Leakage | Fluid leaks can cause drops in performance and efficiency, leading to costly repairs. |

| Noisy Operation | Unusual sounds during operation may indicate internal wear or misalignment. |

Solutions

| Issue | Recommended Solution |

|---|---|

| Overheating | Ensure proper ventilation and regularly check coolant levels. |

| Leakage | Inspect seals and gaskets, replacing any that are damaged. |

| Noisy Operation | Examine components for wear and realign or replace parts as needed. |

Tools Needed for Maintenance

Proper upkeep requires the use of a variety of equipment to ensure that all components are functioning efficiently. Selecting the right instruments can streamline the process, making it more effective and reducing the risk of damage or wear. It is important to have a comprehensive set of tools on hand to address various tasks, from simple adjustments to more involved repairs.

| Tool | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wrench Set | Used for loosening and tightening connections | ||||||||||

| Screwdriver Set | Essential for fastening or removing screws | ||||||||||

| Pressure Gauge | Helps to monitor system performance and pressure levels | ||||||||||

| Hose Cutter | Used to trim hoses accurately during maintenance | ||||||||||

| Lubricant | Ensures smooth operation and reduces

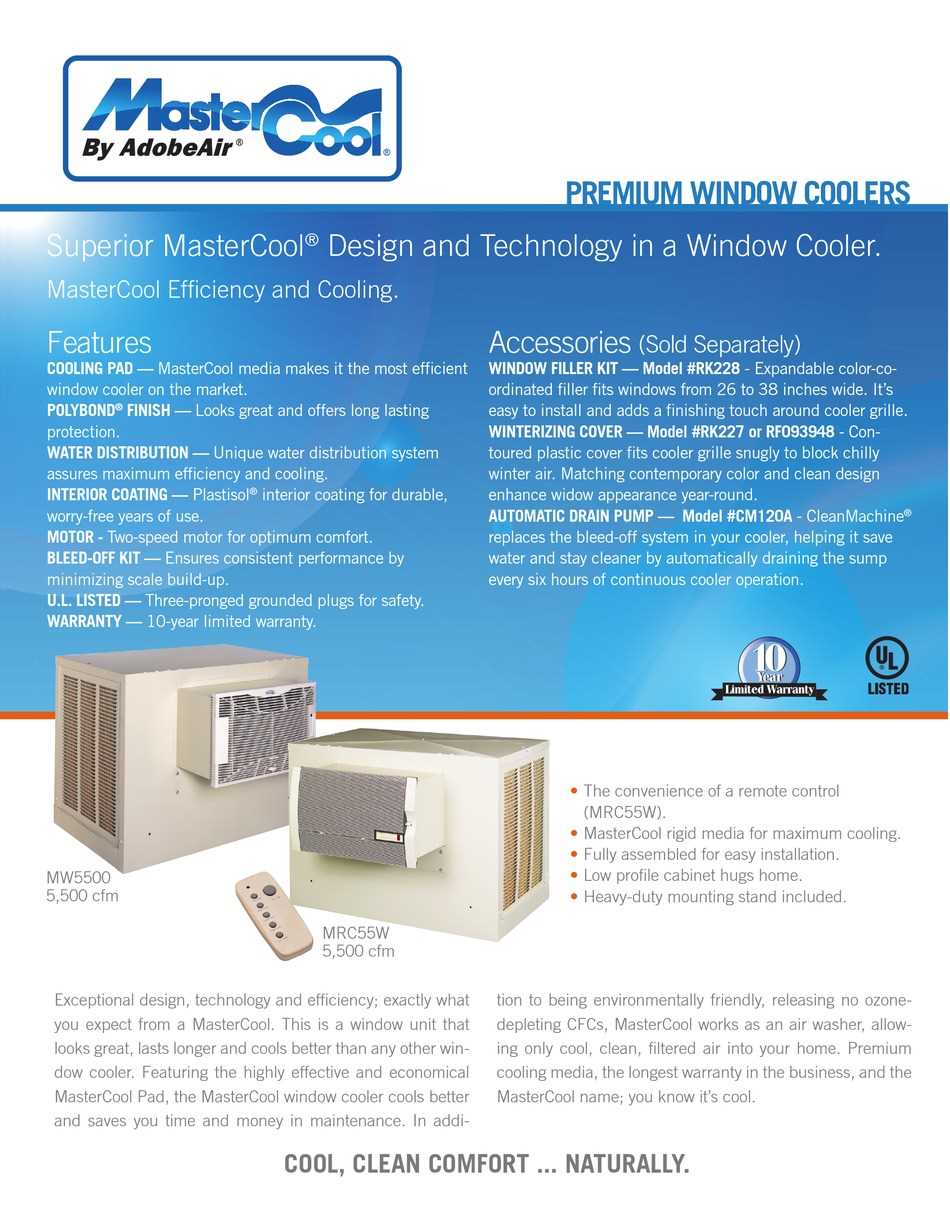

Replacement Parts: What to ConsiderWhen selecting components for repair or maintenance, it’s essential to evaluate several key factors to ensure the longevity and efficiency of your equipment. Choosing the right substitutes can prevent future issues and maintain optimal performance. Compatibility and SpecificationsOne of the primary aspects to examine is compatibility. Ensuring that the new component matches the original specifications is critical to avoid operational issues. Verify measurements, material quality, and design to guarantee a seamless fit and functionality. Durability and QualityAnother important consideration is the durability of the chosen replacement. Opt for high-quality materials that can withstand the operational demands of your system. Reliable components can reduce the need for frequent repairs, saving time and cost in the long term. By carefully selecting your replacements, you can enhance the performance and extend the lifespan of your equipment, ensuring smooth operation for years to come. Importance of Regular ServicingMaintaining equipment in optimal condition requires consistent attention. Regular check-ups ensure that all components are functioning efficiently and prevent unexpected breakdowns. The key is not only to address issues as they arise but also to implement a proactive maintenance plan to extend the lifespan of the system. Benefits of Consistent Maintenance

Steps for Effective Maintenance

Where to Find Diagrams Online

When you’re in need of detailed technical illustrations, the internet provides a wealth of resources. Many websites specialize in offering comprehensive visual guides for various equipment, helping users identify components and understand their placement. To assist with locating these resources, we’ve outlined some useful online platforms below that cater to diverse needs:

Using these sources, you can easily find the information you’re looking for, ensuring smooth maintenance or repairs. Tips for DIY Repairs and UpgradesUndertaking repairs and enhancements yourself can be a cost-effective and rewarding experience. It allows you to understand your equipment better and make necessary adjustments as issues arise. With the right approach, you can resolve common problems and even improve the performance of your setup without professional assistance. Essential Tools and MaterialsBefore starting any repair or modification, ensure you have the necessary equipment. Commonly required items include screwdrivers, pliers, wrenches, and a multimeter for testing electrical connections. It’s also important to have replacement components on hand, such as fuses, connectors, or seals.

Common Issues and SolutionsMany challenges can be |