In any complex mechanical system, a thorough understanding of individual elements and their arrangement is crucial for effective maintenance and operation. Each component plays a vital role, contributing to the overall functionality and efficiency of the mechanism. By examining these intricate relationships, one can identify potential issues and ensure optimal performance.

Visual representations of these elements allow for easier comprehension, making it possible to grasp the intricacies of how they interact with one another. Such illustrations serve as essential references for technicians and engineers alike, facilitating troubleshooting and repairs. They highlight the significance of each part while providing insights into the assembly and disassembly processes.

Exploring the various aspects of these mechanical assemblies not only enhances knowledge but also promotes a proactive approach to maintenance. Understanding the specifics of each element enables professionals to anticipate problems before they escalate, ensuring smooth operation and longevity of the system. By delving into the details, one can uncover valuable information that ultimately contributes to improved reliability and performance.

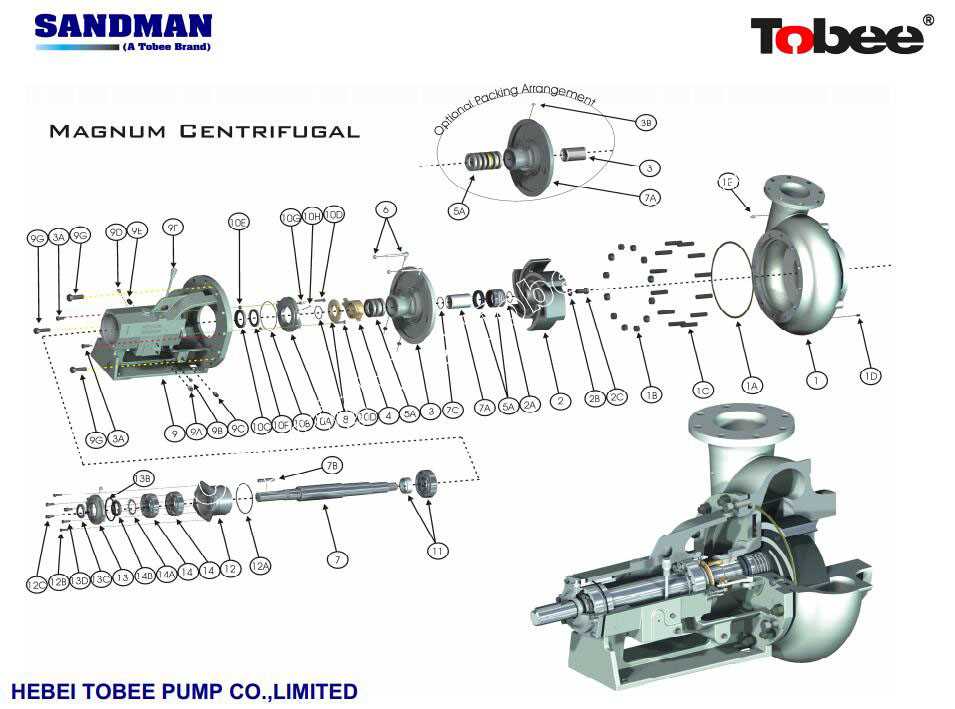

Overview of Sf60110-1 Pump

This section provides a comprehensive examination of a specific model designed for fluid movement and management. Known for its efficiency and reliability, this apparatus is commonly employed in various industrial applications. Its construction integrates advanced engineering techniques, ensuring optimal performance under diverse conditions.

The device features a robust design that allows it to handle a wide range of substances, making it suitable for both light and heavy-duty tasks. The innovative mechanisms within this model enable smooth operation, reducing wear and tear while extending its lifespan. Additionally, its user-friendly interface facilitates easy maintenance and operation, contributing to its popularity in the market.

Moreover, the unit is equipped with multiple components that work synergistically to achieve desired outcomes. Understanding the function and arrangement of these elements is crucial for efficient utilization and troubleshooting. Users can benefit from detailed schematics and manuals that outline the operational capabilities and maintenance procedures, ensuring that the equipment remains in top condition.

In summary, this model exemplifies a well-engineered solution for fluid dynamics, combining durability, efficiency, and ease of use. Its widespread adoption in various sectors underscores its importance as a reliable choice for professionals seeking quality performance in their operations.

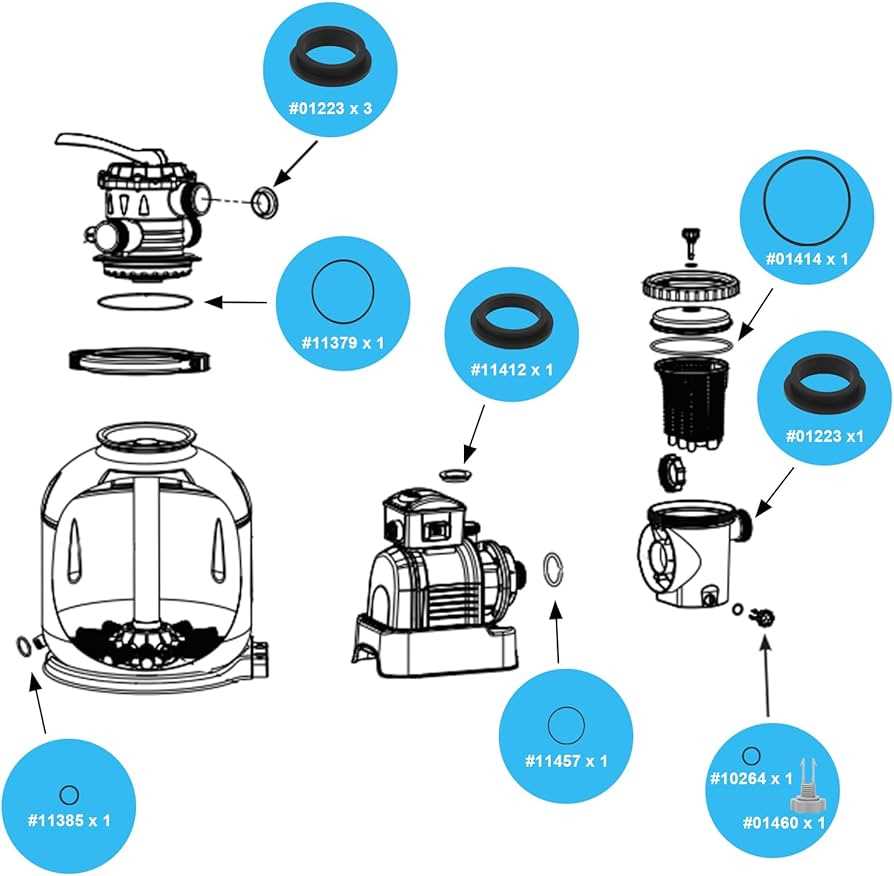

Key Components of the Pump

Understanding the essential elements of any fluid-moving mechanism is crucial for efficient operation and maintenance. Each component plays a specific role in ensuring that the device functions smoothly and effectively. This section will outline the primary elements involved in the system, highlighting their importance and interconnections.

Essential Elements

- Impeller: This rotating element is responsible for transferring energy to the fluid, enabling movement through the system.

- Casing: The outer structure that houses the internal components, providing protection and directing fluid flow.

- Shaft: A central rod that connects the impeller to the motor, transmitting mechanical energy for operation.

- Seals: Components that prevent leaks, ensuring that the fluid remains contained within the system.

- Bearings: Support the rotating shaft, reducing friction and wear during operation.

Supportive Accessories

- Strainers: Prevent debris from entering the system, protecting internal components from damage.

- Valves: Control the flow and pressure within the system, allowing for efficient regulation of the fluid.

- Controllers: Electronic devices that monitor and adjust operation parameters for optimal performance.

Each of these components works synergistically to create a reliable and effective fluid transfer system. Understanding their functions can significantly enhance troubleshooting and maintenance efforts.

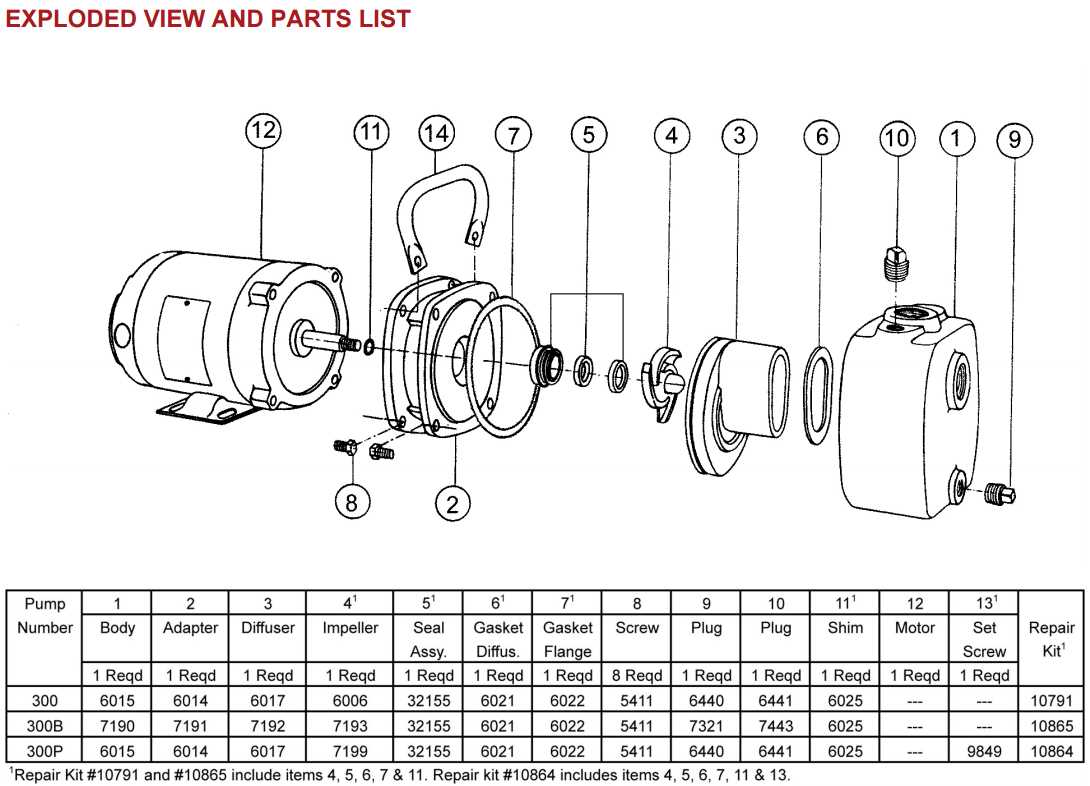

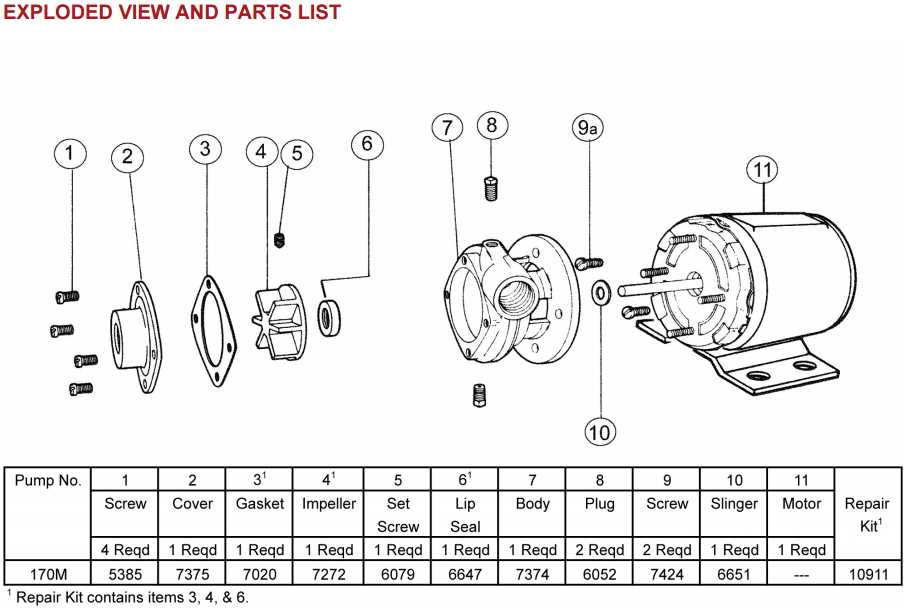

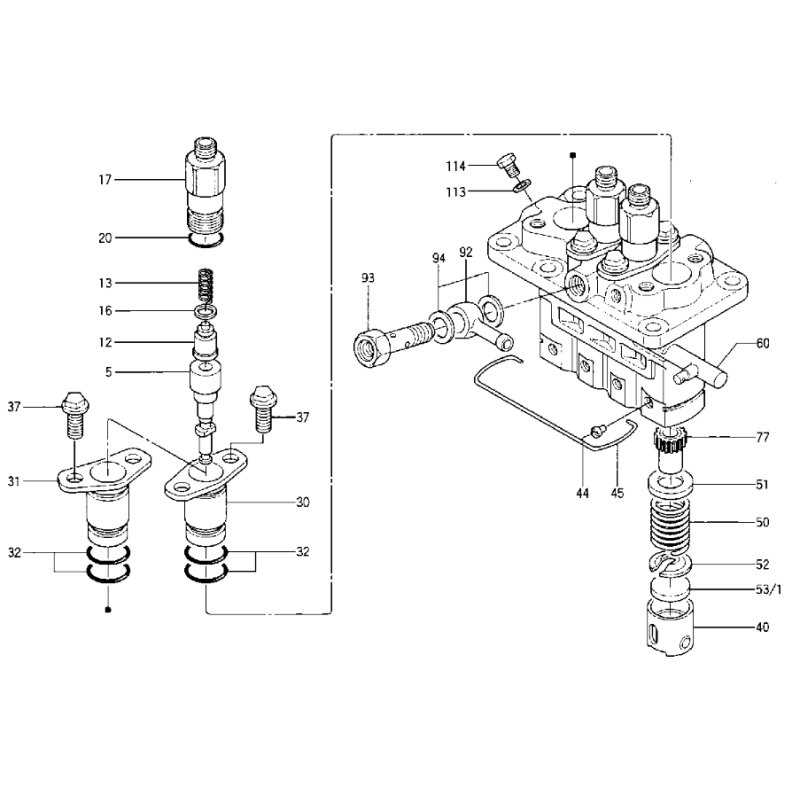

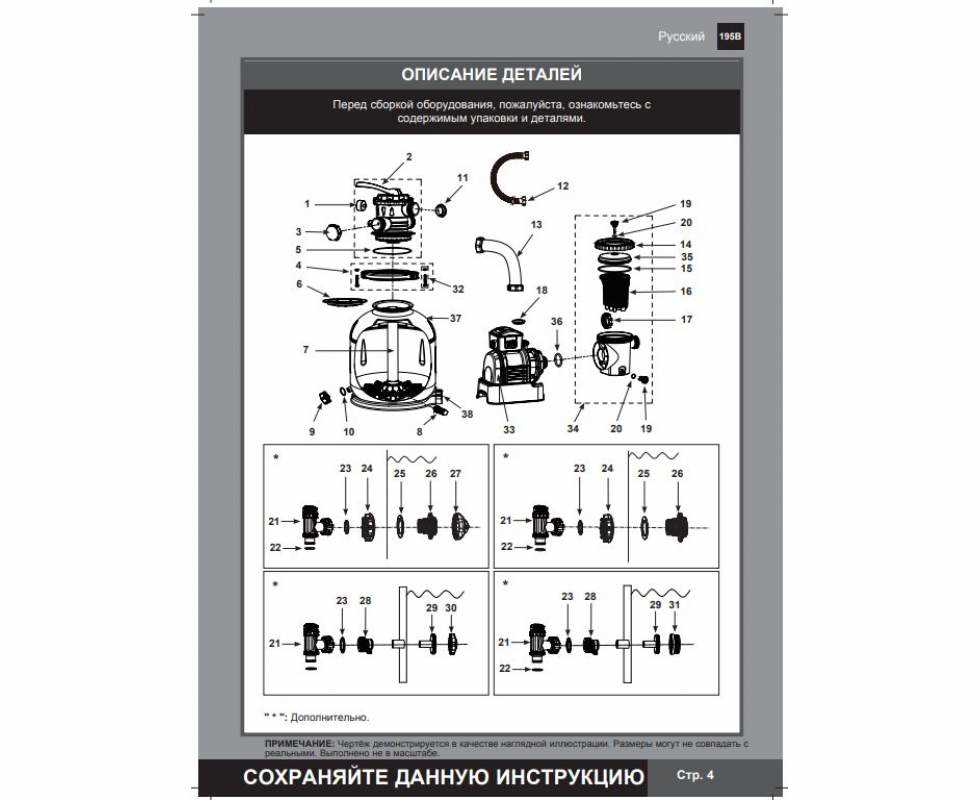

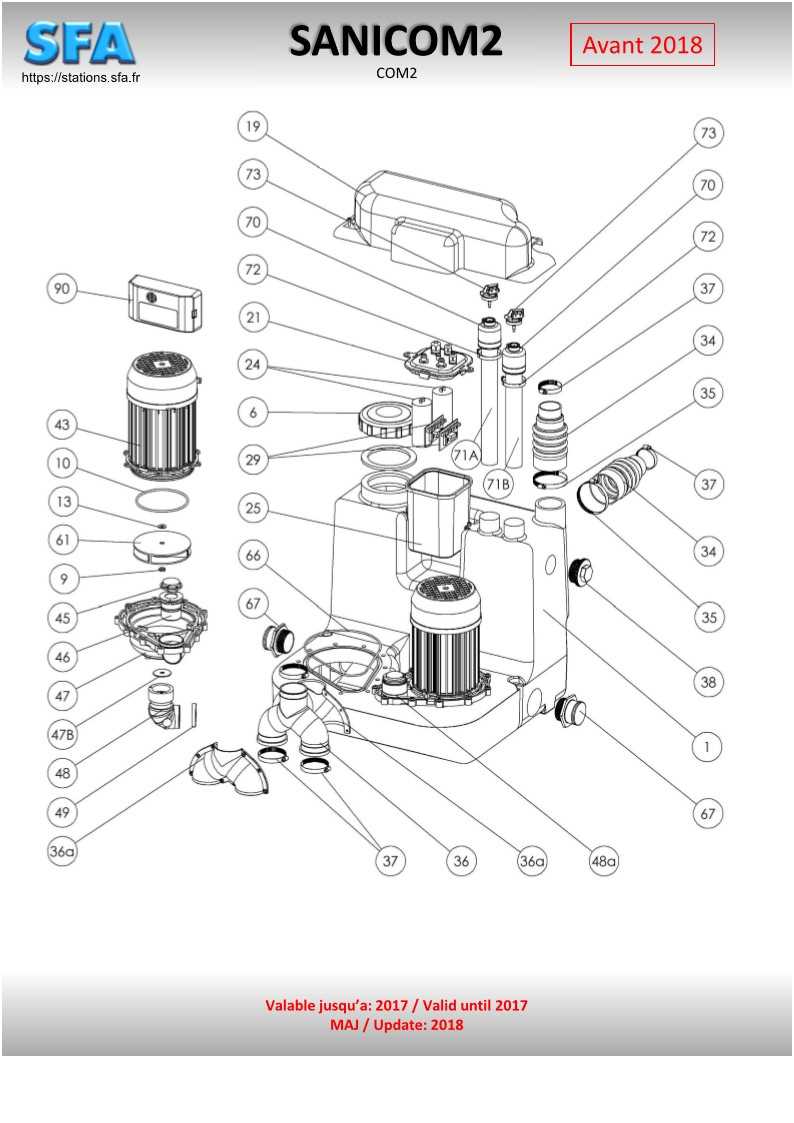

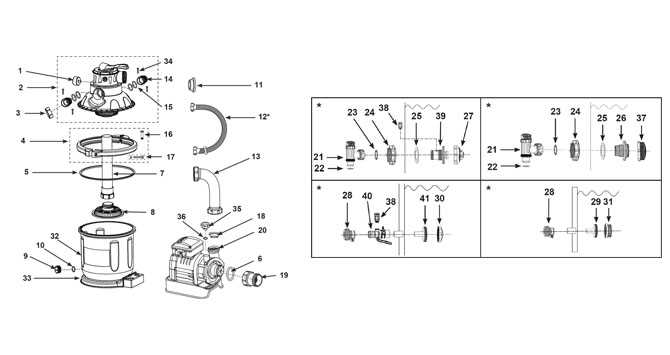

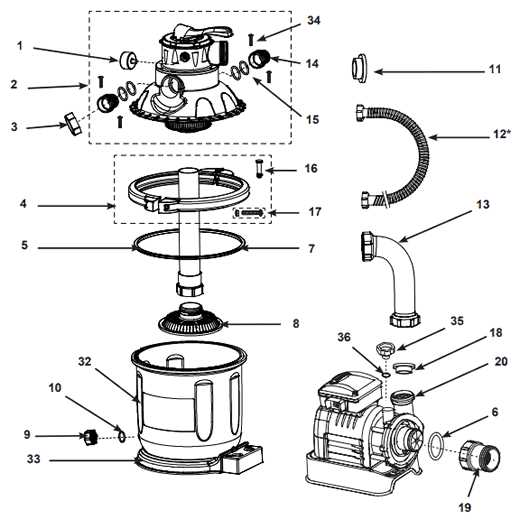

Understanding the Parts Diagram

Grasping the layout of a mechanical system is essential for efficient maintenance and troubleshooting. A visual representation provides clarity on the individual components and their interrelationships, helping users identify specific areas of interest. This knowledge is crucial for effective repairs and optimal performance.

Each segment of the visual representation serves a purpose, highlighting various elements that contribute to the overall function. By examining these sections, one can quickly ascertain the role of each piece within the assembly. Familiarity with these details allows for more informed decisions during servicing.

Moreover, recognizing the common terminologies associated with the different sections enhances communication among technicians and engineers. This shared language fosters collaboration, ensuring that everyone involved can discuss issues or solutions effectively. Ultimately, a clear understanding of the layout not only simplifies maintenance tasks but also prolongs the life of the entire system.

In conclusion, a thorough comprehension of the mechanical layout empowers users to tackle challenges confidently. As individuals become more acquainted with the specific functions and placements of each element, they can enhance their technical skills and contribute to the overall efficiency of the machinery.

Common Issues with Pump Components

Understanding the typical problems that can arise with mechanical systems is crucial for ensuring their longevity and efficiency. Components within these systems may experience wear and tear due to various factors, leading to operational inefficiencies or even failures. Identifying and addressing these issues promptly can save time and resources in maintenance and repairs.

Leakage is one of the most frequent issues encountered. Seals and gaskets can degrade over time, resulting in fluid escaping from the system. This not only reduces efficiency but can also cause environmental concerns if the fluid is hazardous. Regular inspections can help catch these issues before they escalate.

Noise is another indicator of underlying problems. Unusual sounds may signify misalignment or damaged bearings. Addressing these issues early can prevent more severe damage and extend the lifespan of the entire assembly.

Vibration can also indicate an imbalance or wear within the components. Excessive vibration not only impacts performance but can lead to premature failure of critical elements. Routine balancing and alignment checks can mitigate these risks.

Corrosion is a common concern, especially in systems exposed to harsh environments. Protective coatings and regular maintenance can help reduce the risk of deterioration and prolong the life of essential components.

Lastly, overheating may occur due to inadequate cooling or blocked flow paths. Monitoring operating temperatures and ensuring proper fluid circulation are vital for preventing thermal damage. Keeping an eye on these common issues will lead to more reliable performance and reduced downtime.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of mechanical devices requires regular upkeep and attention to detail. Proper maintenance not only prolongs the lifespan of the equipment but also enhances performance and reliability. Below are essential practices to consider for optimal operation.

Regular Inspection

- Conduct routine visual checks for signs of wear or damage.

- Inspect seals and gaskets for leaks and degradation.

- Ensure all connections are secure and free from corrosion.

Lubrication and Cleaning

- Apply appropriate lubricants to moving parts to reduce friction.

- Remove debris and contaminants to prevent operational issues.

- Clean filters and screens regularly to maintain airflow and efficiency.

Implementing these practices will help maintain the functionality and extend the operational life of your equipment, ensuring reliable performance for years to come.

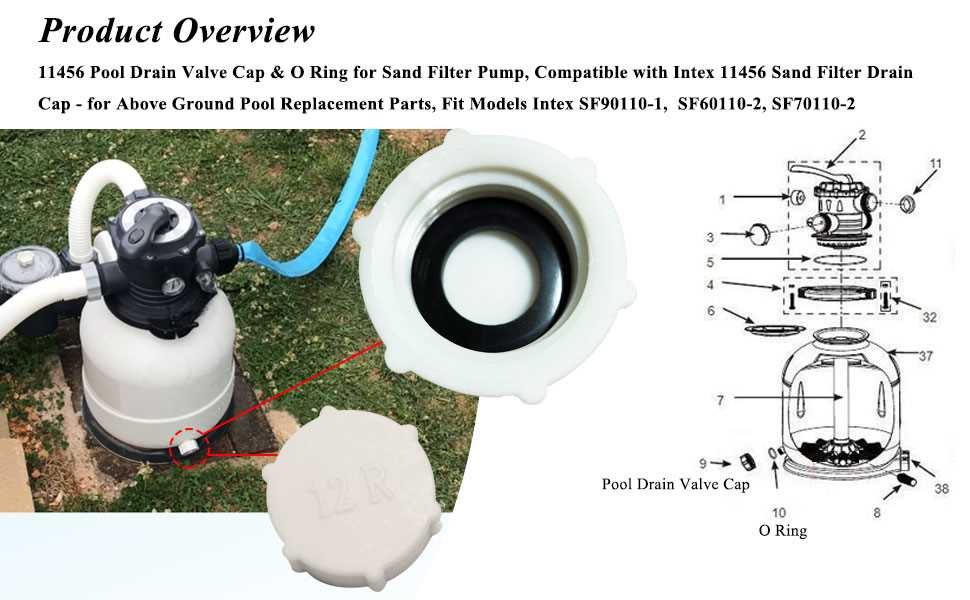

Replacement Parts and Upgrades

Ensuring optimal performance and longevity of any mechanical device often requires timely replacement of worn components and the integration of enhancements. By carefully selecting these elements, users can significantly improve functionality and efficiency, minimizing downtime and maintenance costs. This section delves into the importance of sourcing high-quality substitutes and considering advanced modifications to meet specific operational needs.

Identifying Quality Alternatives

When it comes to sourcing substitutes, it’s crucial to prioritize quality over cost. Genuine components are typically designed to meet the original specifications, ensuring compatibility and reliability. Additionally, aftermarket options can provide value when they are manufactured by reputable suppliers. Always verify that replacements meet industry standards to maintain optimal performance levels.

Upgrading for Enhanced Performance

Incorporating modern technology into existing systems can yield substantial benefits. Performance upgrades may include enhancements such as improved efficiency mechanisms or advanced control systems that allow for better management of operations. Users should assess their specific requirements and consult with experts to determine the most suitable modifications that align with their operational goals.

Installation Guidelines for Sf60110-1

Ensuring proper setup of equipment is crucial for optimal functionality and longevity. Following specific protocols can significantly enhance performance and reduce the likelihood of issues during operation. This section outlines essential instructions for the installation process to facilitate a smooth and efficient setup.

Preparation Steps

Before commencing the installation, it is important to gather all necessary tools and components. Verify that the installation area is clean and free from debris. Additionally, review the manufacturer’s specifications to ensure compatibility with existing systems. Adequate space should be allocated for maintenance and accessibility.

Installation Process

Begin by securely mounting the unit in the designated location, ensuring it is level and stable. Follow the connection instructions closely, paying attention to the orientation of each component. Utilize appropriate fasteners to prevent any vibrations that could lead to wear. Once all connections are made, conduct a thorough inspection for any potential leaks or loose fittings before powering up the system.

Finally, it is advisable to run the unit at low capacity initially to monitor for any irregularities. Gradually increase to full operational levels, keeping an eye on performance indicators. This cautious approach will help identify any installation errors early, ensuring reliable and efficient operation.

Frequently Asked Questions About Pumps

This section aims to address common inquiries regarding the functioning and maintenance of fluid-moving devices. Understanding these essential components can enhance efficiency and prolong their lifespan, making it crucial for users to be informed about various aspects related to their operation.

Common Inquiries

| Question | Answer |

|---|---|

| What are the typical applications for these devices? | They are widely used in industries such as agriculture, construction, and water treatment, serving various purposes from irrigation to fluid transport. |

| How do I determine the right size for my needs? | The appropriate size depends on the flow rate and pressure requirements specific to your application. Consulting a professional can provide valuable guidance. |

| What maintenance practices are essential? | Regular inspection, cleaning, and lubrication of components are vital. It’s also important to check for leaks and wear to ensure optimal performance. |

| How can I troubleshoot issues effectively? | Start by checking for common problems such as clogs, leaks, or unusual noises. Refer to the manufacturer’s guidelines for more detailed troubleshooting steps. |

Operational Tips

To maximize efficiency, always ensure proper installation and adhere to recommended operating conditions. Additionally, staying informed about the latest advancements can help in selecting the most suitable technologies for your requirements.