When maintaining outdoor machinery, having a clear understanding of its components is essential for effective repairs and enhancements. This section delves into the intricate details of essential machinery elements, providing valuable insights into their functions and interconnections.

Visual representations serve as a powerful tool for both seasoned technicians and DIY enthusiasts alike. By exploring these detailed illustrations, users can identify various components, ensuring that they are well-informed when it comes to servicing or upgrading their equipment.

Whether you are troubleshooting an issue or planning a maintenance schedule, comprehending the layout of each piece is crucial. This knowledge not only simplifies the repair process but also enhances the longevity and performance of your outdoor machinery.

Troy-Bilt TB110 Overview

This section provides an insightful look into a popular lawn care machine designed for efficient yard maintenance. Known for its reliability and user-friendly features, this model stands out in the landscaping market, making it a preferred choice among homeowners and gardening enthusiasts alike.

Key Features

Equipped with a powerful motor, this tool ensures robust performance while tackling various outdoor tasks. Its lightweight design allows for easy maneuverability, enabling users to navigate through tight spaces effortlessly. Additionally, the innovative cutting technology promotes a clean and even finish, enhancing the overall appearance of the lawn.

User Experience

Owners appreciate the straightforward operation, which minimizes the learning curve for new users. The ergonomic design contributes to comfort during prolonged use, reducing fatigue. Furthermore, routine maintenance is simplified, making it accessible for individuals to keep their equipment in top condition.

Identifying Key Engine Components

Understanding the essential elements of a motor is crucial for effective maintenance and performance enhancement. Each part plays a specific role, contributing to the overall functionality and efficiency of the machine. Familiarity with these components not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades.

Major constituents include the combustion chamber, where fuel ignites, and the crankshaft, which transforms linear motion into rotational force. Additionally, the intake and exhaust systems regulate airflow, significantly impacting performance. Recognizing these features can streamline the diagnostic process and facilitate better care of the apparatus.

By delving into the intricacies of each segment, users can achieve an ultimate understanding of how their machine operates, leading to enhanced longevity and reliability. Knowing the function of each key piece helps in identifying potential issues before they escalate, ensuring smooth and efficient operation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your outdoor machinery. By following a consistent maintenance routine, you can enhance efficiency and prevent premature wear and tear. Regular attention not only safeguards your investment but also optimizes functionality for a better user experience.

Routine Checks

Conducting frequent inspections is vital. Look for any signs of wear, corrosion, or damage. Pay special attention to vital components such as air filters, fuel systems, and blades. Cleaning these parts regularly can prevent buildup that may hinder performance. Additionally, always ensure that fasteners are tight and secure to avoid operational issues.

Seasonal Care

Adapting your maintenance practices with the changing seasons is crucial. Before winter, make sure to drain any fuel and clean the machinery thoroughly. In spring, check and replace any worn parts to prepare for the active months ahead. Regularly changing fluids and lubricants is also key to maintaining optimal performance throughout the year.

Common Issues with TB110 Engines

Many users encounter various challenges with their small motorized tools. Understanding these common problems can help in timely diagnosis and maintenance, ensuring optimal performance and longevity.

Frequent Problems

- Starting Difficulties: Many users report issues when trying to initiate operation, often due to fuel delivery or spark plug malfunctions.

- Overheating: This can result from insufficient cooling or oil supply, leading to performance drops and potential damage.

- Power Loss: A decline in output can stem from air filter clogs or fuel line blockages.

- Excessive Vibration: This might indicate loose components or unbalanced elements within the system.

Preventive Measures

- Regularly inspect and clean the air and fuel filters.

- Change the oil and check levels frequently to prevent overheating.

- Ensure that all bolts and screws are tightened properly to minimize vibration.

- Keep the unit clean and free from debris to maintain airflow.

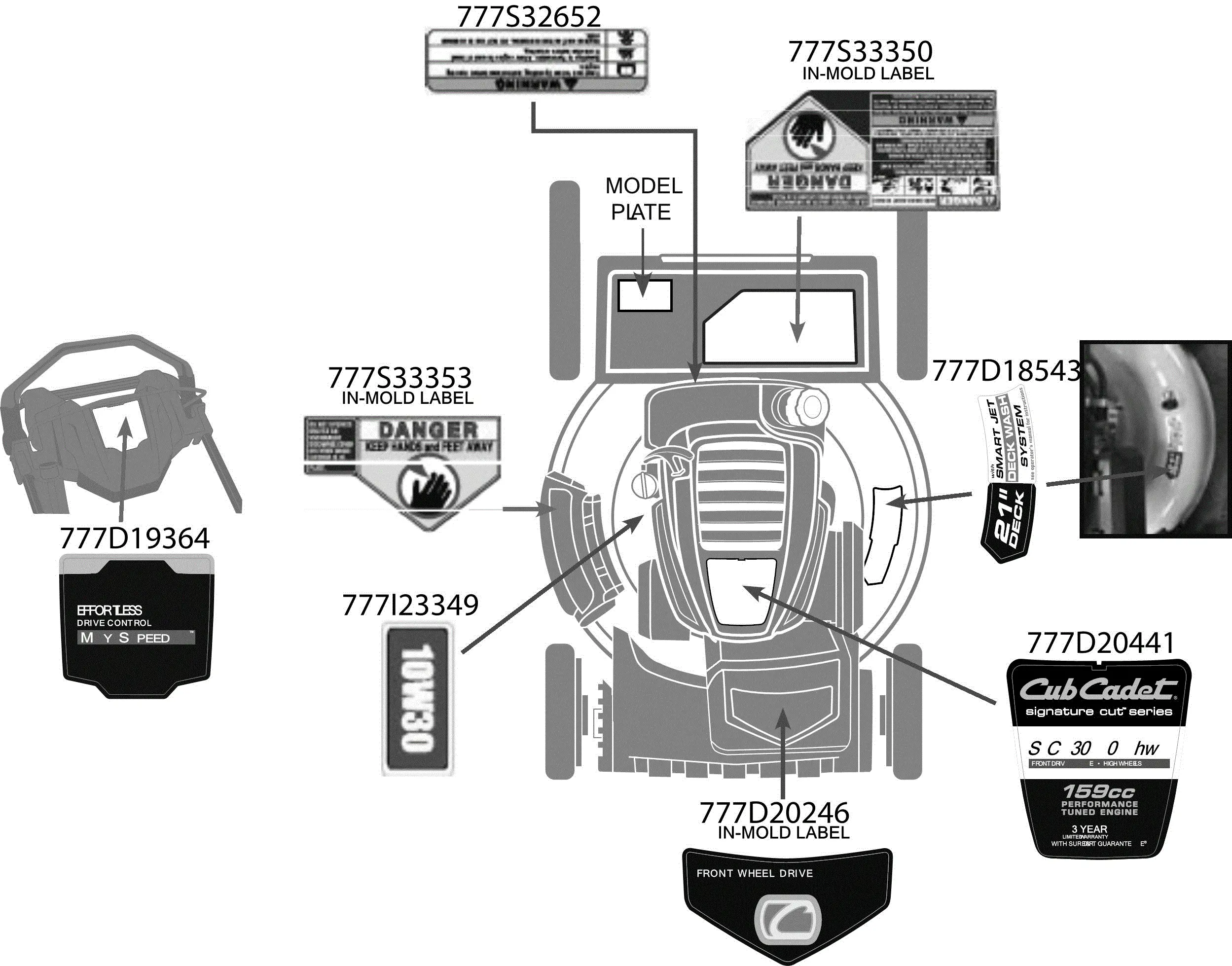

Parts Replacement Guide

This section provides essential guidance for replacing various components in your equipment. Proper maintenance ensures optimal performance and longevity, making it crucial to understand the process of component substitution. Below are steps and considerations to help you effectively replace necessary elements.

- Identify the Component: Before starting, ascertain which item needs replacement. Consult the user manual for guidance.

- Gather Tools: Ensure you have all required tools at hand. Commonly needed tools include:

- Screwdrivers

- Wrenches

- Pliers

- Safety gloves

- Remove Old Component: Carefully detach the faulty item. Take note of how it is installed to aid in the reassembly process.

- Install New Component: Align and secure the new part in place. Follow the manufacturer’s guidelines for proper installation.

- Test Functionality: After installation, test the equipment to ensure everything operates smoothly. Make adjustments if necessary.

By following these steps, you can successfully replace components and maintain the efficiency of your machinery. Regular checks and timely replacements are key to preventing larger issues in the future.

Where to Buy Replacement Parts

Finding high-quality components for your outdoor equipment can be crucial for maintaining optimal performance. Whether you’re looking for specific items or general supplies, knowing where to source these materials is essential for effective repairs and upgrades.

Authorized Dealers

One of the most reliable options is to visit authorized dealers. These outlets typically offer genuine components that are designed to fit perfectly and work seamlessly with your machine. Additionally, knowledgeable staff can assist you in identifying the right items for your specific model.

Online Retailers

The internet provides a plethora of options for purchasing necessary components. Websites dedicated to outdoor equipment often feature comprehensive catalogs, making it easy to search for and compare various items. Always check reviews and ratings to ensure the seller’s credibility, and look for warranty information to safeguard your investment.

Understanding Engine Performance Metrics

Evaluating the capabilities of a mechanical unit involves several key indicators that reflect its efficiency, power output, and overall functionality. These metrics provide insights into how well the machine operates under various conditions and can guide users in optimizing performance and maintenance.

Key Performance Indicators

Performance indicators can vary widely, but the most critical aspects typically include torque, horsepower, and fuel efficiency. By understanding these elements, users can assess how their machinery meets specific tasks and requirements.

Table of Metrics

| Metric | Description |

|---|---|

| Torque | Measures rotational force, crucial for tasks requiring strength. |

| Horsepower | Indicates the power output, influencing speed and workload capacity. |

| Fuel Efficiency | Reflects the fuel consumption relative to performance, affecting operational costs. |

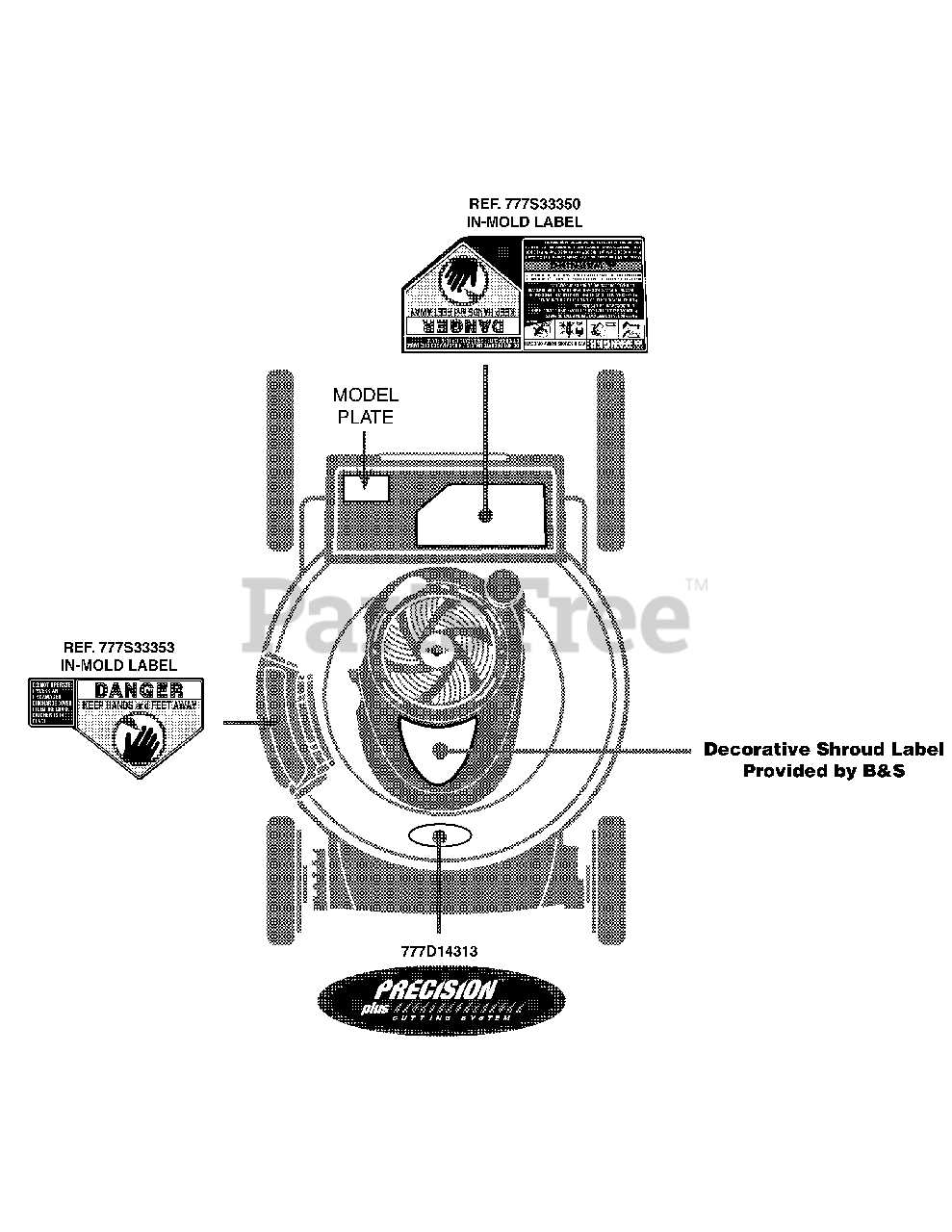

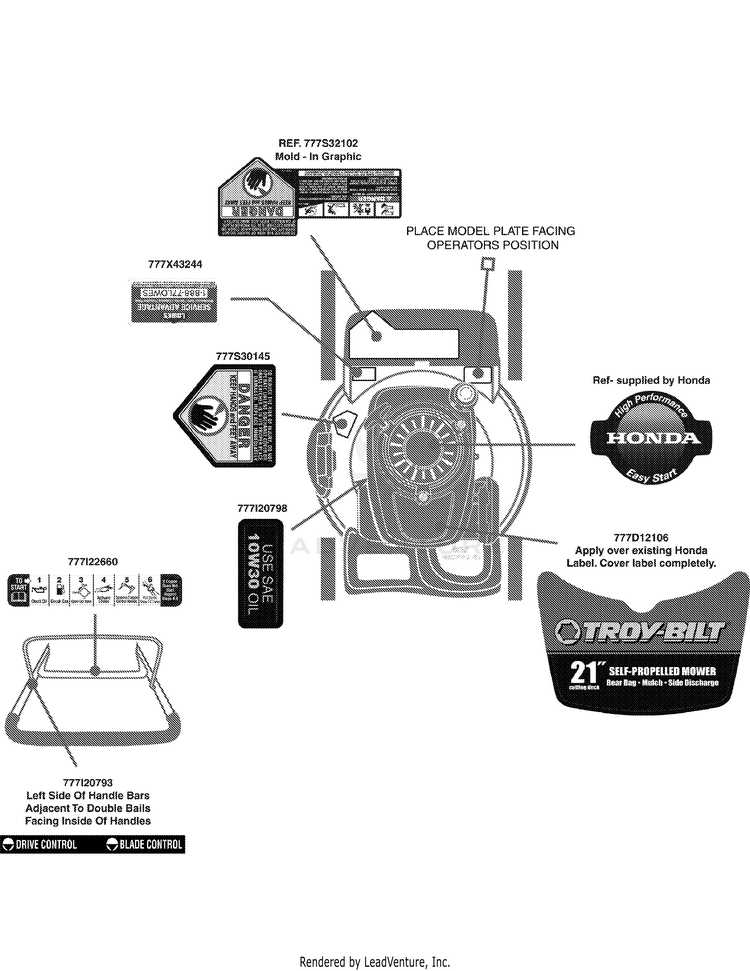

Diagrams for DIY Repairs

When tackling home maintenance projects, visual aids can significantly enhance understanding and execution. Clear illustrations not only clarify complex structures but also guide enthusiasts in identifying components and their functions, ensuring more effective repairs and modifications.

Importance of Visual Aids

Utilizing schematics during repair tasks allows for better planning and precision. These resources help to pinpoint issues quickly and offer step-by-step guidance, reducing the likelihood of mistakes and facilitating smoother workflows.

Finding Quality Resources

Many online platforms provide high-quality visuals for various models. Exploring these sources can uncover valuable information, making the DIY process more accessible and enjoyable for everyone, regardless of experience level.