In the realm of machinery, a thorough comprehension of individual elements is essential for optimal functionality and maintenance. Every intricate system relies on a harmonious interplay of its various constituents, each serving a unique purpose. To achieve peak performance, it is vital to grasp the relationships and specifications of these components.

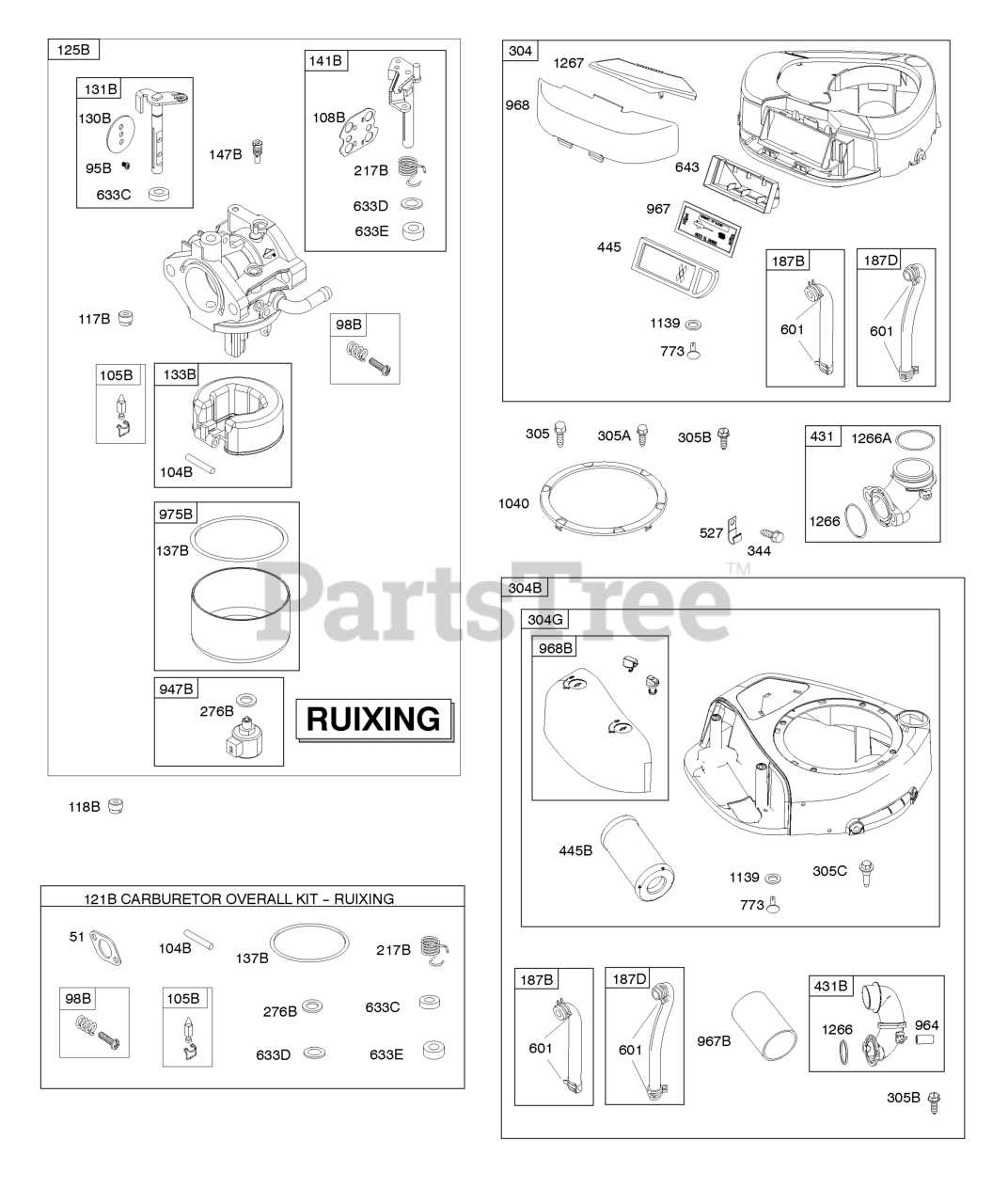

Visual representations play a critical role in this understanding, offering clear insights into the assembly and interaction of different parts. By analyzing these graphical illustrations, one can identify the roles and placements of each element, facilitating effective repairs and enhancements. This process not only aids in troubleshooting but also fosters a deeper appreciation for engineering design.

Furthermore, knowledge of the specific characteristics of each component enables technicians and enthusiasts alike to make informed decisions when sourcing replacements or upgrades. The clarity provided by these visual aids can significantly reduce downtime and improve overall efficiency, making them invaluable tools in the maintenance toolkit.

Understanding the 31C707 Components

Grasping the intricacies of essential elements in a mechanical assembly is crucial for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and reliability of the system. Familiarity with these parts enhances troubleshooting and improves performance.

Key Elements

- Frame: Provides structural support.

- Motor: Drives movement and operation.

- Control Unit: Manages the functioning of other elements.

- Connectors: Ensure seamless electrical communication.

Functionality Overview

- The frame serves as the backbone, holding everything together.

- The motor converts energy into mechanical force.

- The control unit interprets user inputs and coordinates actions.

- Connectors facilitate the necessary electrical connections.

Understanding these components provides insight into how each interacts to achieve ultimate efficiency and reliability.

Importance of Parts Diagrams

Understanding the intricacies of mechanical assemblies is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity on the composition and arrangement of various components. They enable technicians to identify each piece’s function and relationship within the whole system, facilitating informed decision-making during troubleshooting and reassembly.

Enhanced Communication

Visual aids enhance communication among team members, ensuring that everyone is on the same page regarding the assembly’s structure. When discussing repairs or upgrades, these illustrations eliminate ambiguity, allowing for precise references to specific components. This clarity minimizes errors and fosters collaboration, ultimately leading to more efficient workflows.

Streamlined Repair Processes

Having a visual guide at hand can significantly streamline the repair process. Technicians can quickly locate and assess parts that need attention, reducing the time spent searching for information. Moreover, it allows for a systematic approach to disassembly and reassembly, ensuring that no crucial elements are overlooked. In complex systems, such resources become invaluable for maintaining operational integrity.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and assembly. This process allows you to identify various elements and their relationships, facilitating repairs or upgrades with greater ease.

To navigate these visual guides successfully, consider the following steps:

- Familiarize Yourself with Symbols:

- Learn common icons and representations used in the illustration.

- Refer to a legend if available, which clarifies what each symbol means.

- Identify Key Sections:

- Locate main assemblies that form the core of the system.

- Break down complex units into their individual components for better comprehension.

- Trace Connections:

- Follow lines or arrows that indicate how parts are connected.

- Understand how movement or energy flows between different sections.

- Note Reference Numbers:

- Check for numerical identifiers that correspond to a list or table.

- Use these references to find specifications or replacement details.

- Consult Additional Resources:

- Look for manuals or online guides that provide context and detailed instructions.

- Engage with community forums or experts for insights and troubleshooting tips.

By mastering these techniques, you’ll enhance your ability to interpret these visual resources, leading to more efficient and effective outcomes in your projects.

Common Issues with 31C707 Parts

Understanding the frequent challenges associated with specific components is essential for effective maintenance and troubleshooting. These issues can lead to inefficiencies and increased operational costs if not addressed promptly.

Typical Problems

- Wear and tear leading to decreased performance.

- Misalignment causing operational failures.

- Corrosion from environmental factors.

- Inadequate lubrication resulting in friction issues.

Signs of Trouble

- Unusual noises during operation.

- Unexpected vibrations.

- Reduced efficiency in function.

- Frequent error messages or system alerts.

Maintenance Tips for 31C707

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By adhering to a structured maintenance routine, you can prevent issues before they arise and enhance efficiency. Here are some key strategies to implement.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace the oil to maintain engine health and reduce wear. |

| Filter Check | Every 25 hours | Inspect and clean or replace air and fuel filters as needed. |

| Belt Inspection | Monthly | Check for wear and tension, replacing if necessary. |

| Spark Plug Replacement | Every 100 hours | Replace to ensure efficient combustion and smooth operation. |

By following these guidelines, you can ensure your equipment remains in prime condition, reducing downtime and enhancing productivity.

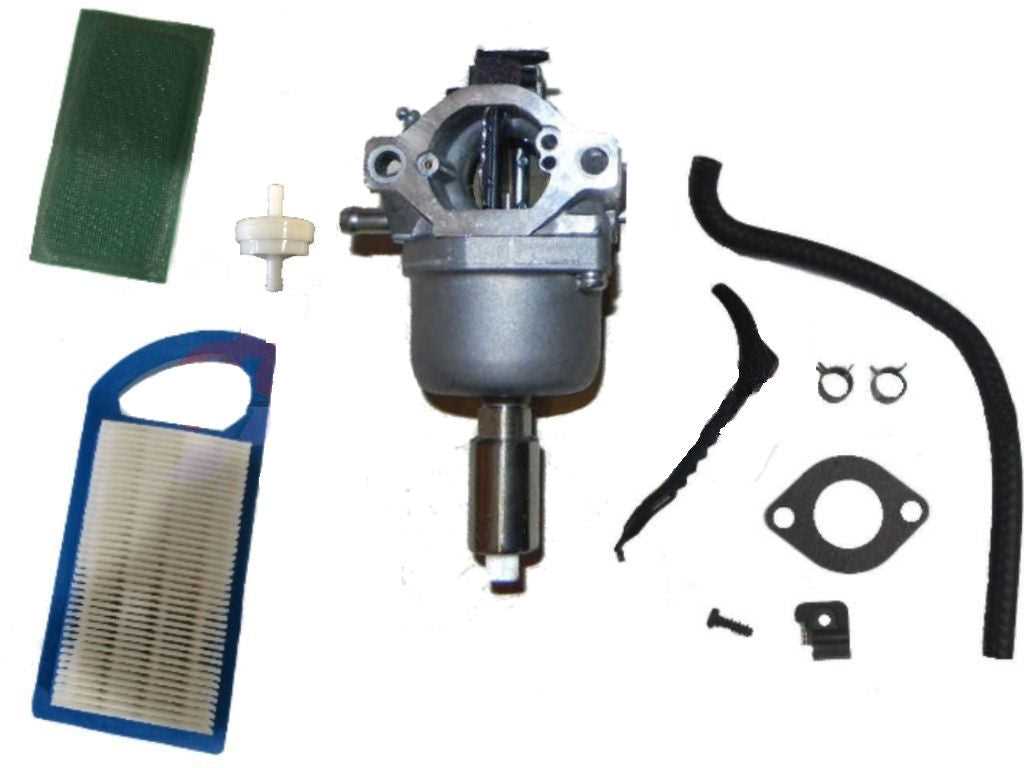

Where to Find Replacement Parts

Finding suitable components for your machinery can be crucial for maintaining efficiency and performance. Various resources are available to help you locate the right items, ensuring your equipment runs smoothly. From online marketplaces to specialized retailers, each option offers unique advantages that cater to different needs.

Online Marketplaces

Many individuals turn to popular e-commerce platforms where a wide range of options is available. Websites like eBay and Amazon often feature listings from various sellers, allowing you to compare prices and conditions easily. Additionally, you may discover user reviews that provide insights into the reliability of specific components.

Specialized Retailers

For those seeking expert advice and quality assurance, specialized stores are an excellent choice. These retailers typically offer a more focused selection and knowledgeable staff who can assist in identifying the exact item you need. It’s beneficial to explore both physical locations and their online counterparts to ensure you find the most suitable replacement.

Comparing 31C707 with Similar Models

When evaluating machinery, understanding the differences and similarities between various models is crucial for making an informed decision. This section will delve into a specific model and its counterparts, focusing on key aspects such as performance, durability, and functionality.

Several alternatives present themselves in the market, each boasting unique features. Below are some critical points of comparison:

- Performance: Many models offer comparable power outputs, but some may excel in specific applications due to enhanced engineering.

- Durability: Materials used in construction can vary significantly. It’s important to assess how these differences affect long-term reliability.

- Functionality: The range of functions and ease of use can greatly influence user experience. Some units may offer advanced features that cater to specific needs.

To further clarify these distinctions, consider the following comparisons:

- Model A: Known for its robust design, it often outperforms in rugged environments.

- Model B: This variant is celebrated for its user-friendly interface, making it an excellent choice for less experienced operators.

- Model C: It features advanced technology that enhances efficiency, though it may come at a higher initial cost.

In summary, assessing these alternatives requires careful consideration of specific needs and contexts. Each model presents distinct advantages that can significantly impact performance and satisfaction.

Upgrades and Modifications Available

Enhancing your equipment can significantly improve its performance and longevity. Various options exist to optimize functionality, aesthetics, and user experience. These enhancements can range from simple replacements to comprehensive overhauls, tailored to meet specific needs.

Performance Enhancements: Upgrading components such as the engine or exhaust system can lead to improved power output and efficiency. Consider high-performance alternatives that offer greater durability and responsiveness.

Aesthetic Modifications: Customizing the look of your machinery can also be rewarding. Adding unique finishes or graphics allows for a personal touch while maintaining functionality.

Technological Integrations: Modernizing with new technology can enhance usability. Features like digital displays or advanced monitoring systems provide valuable insights into performance metrics.

Safety Features: Incorporating additional safety mechanisms ensures not only compliance with regulations but also enhances the overall safety of operation. Upgrading brakes or adding protective gear can make a significant difference.

Overall, exploring available upgrades and modifications can lead to the ultimate enhancement of your equipment, ensuring it meets both your needs and expectations.