In the realm of plumbing and construction, a certain tool stands out for its efficiency and durability. This essential equipment is a go-to for professionals and DIY enthusiasts alike, facilitating various tasks with ease. A comprehensive understanding of its structure enhances both maintenance and operational effectiveness.

To optimize the use of this tool, it’s crucial to explore its internal makeup. Each element plays a pivotal role, contributing to the overall functionality. By examining these components, users can ensure their equipment remains in peak condition, allowing for smooth performance during demanding projects.

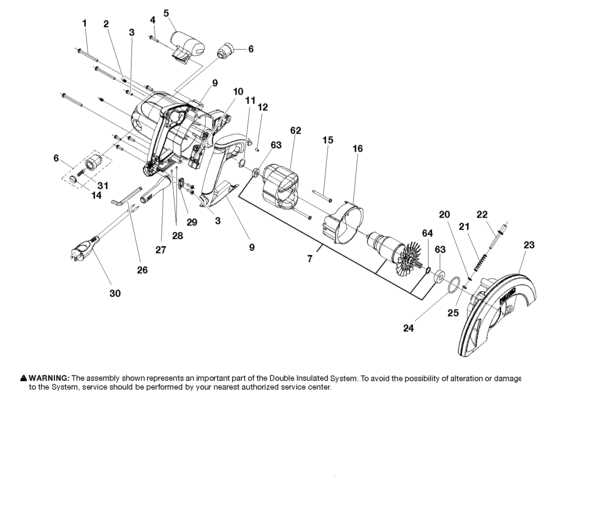

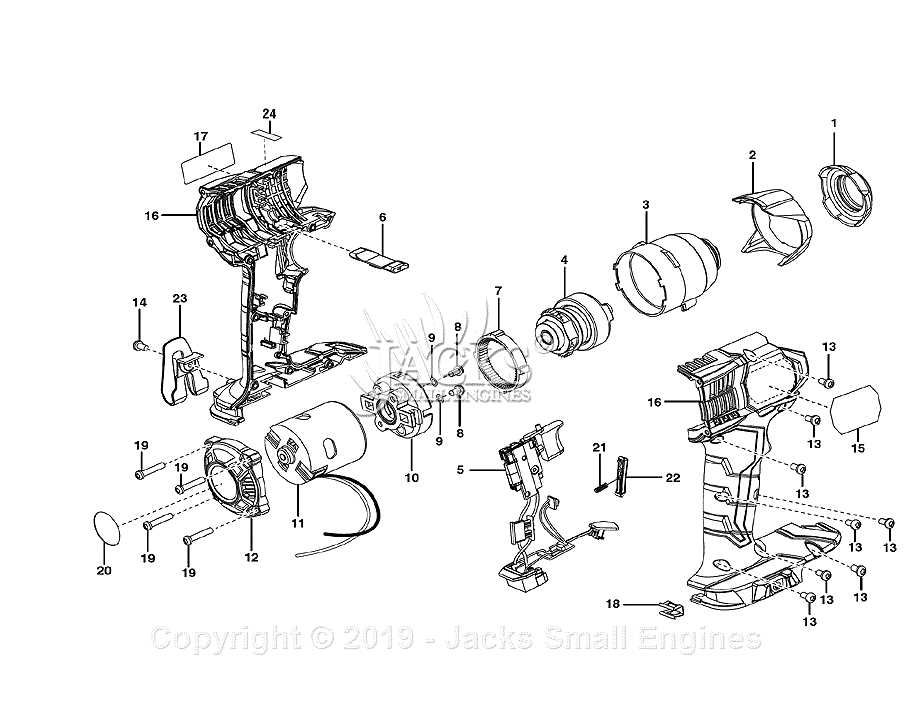

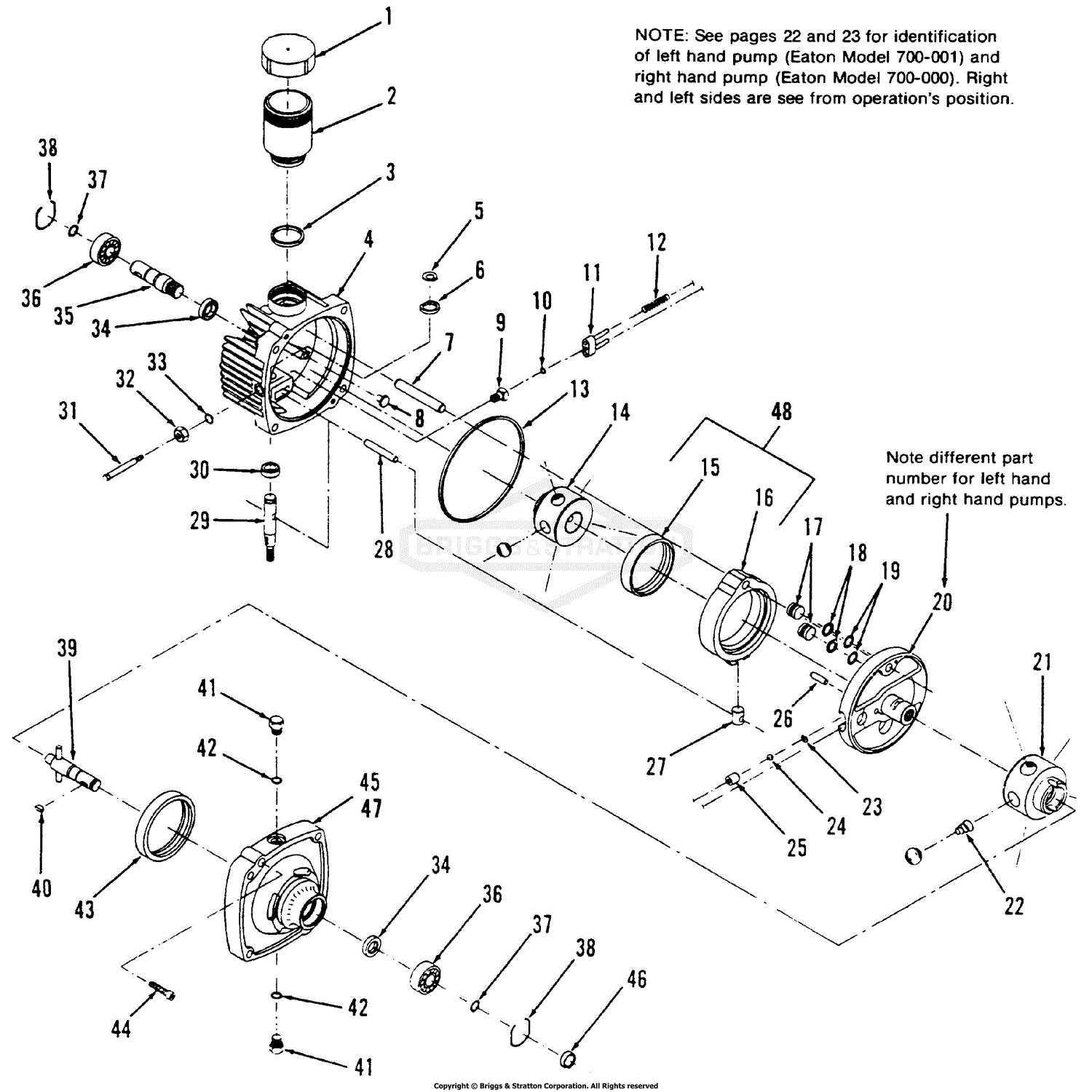

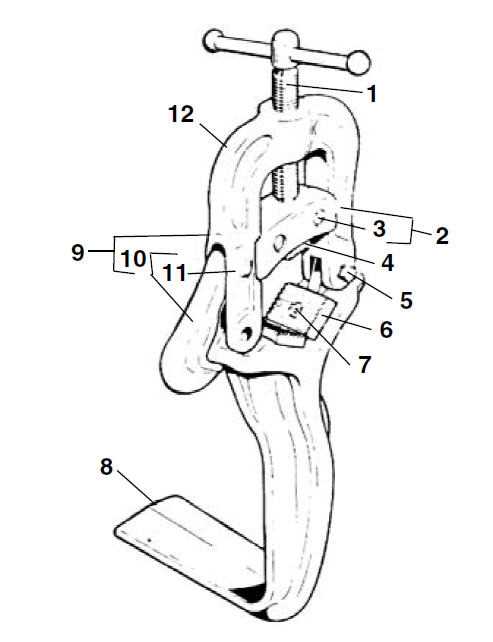

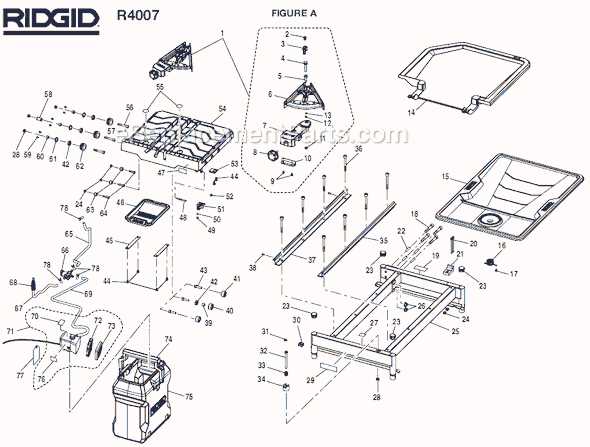

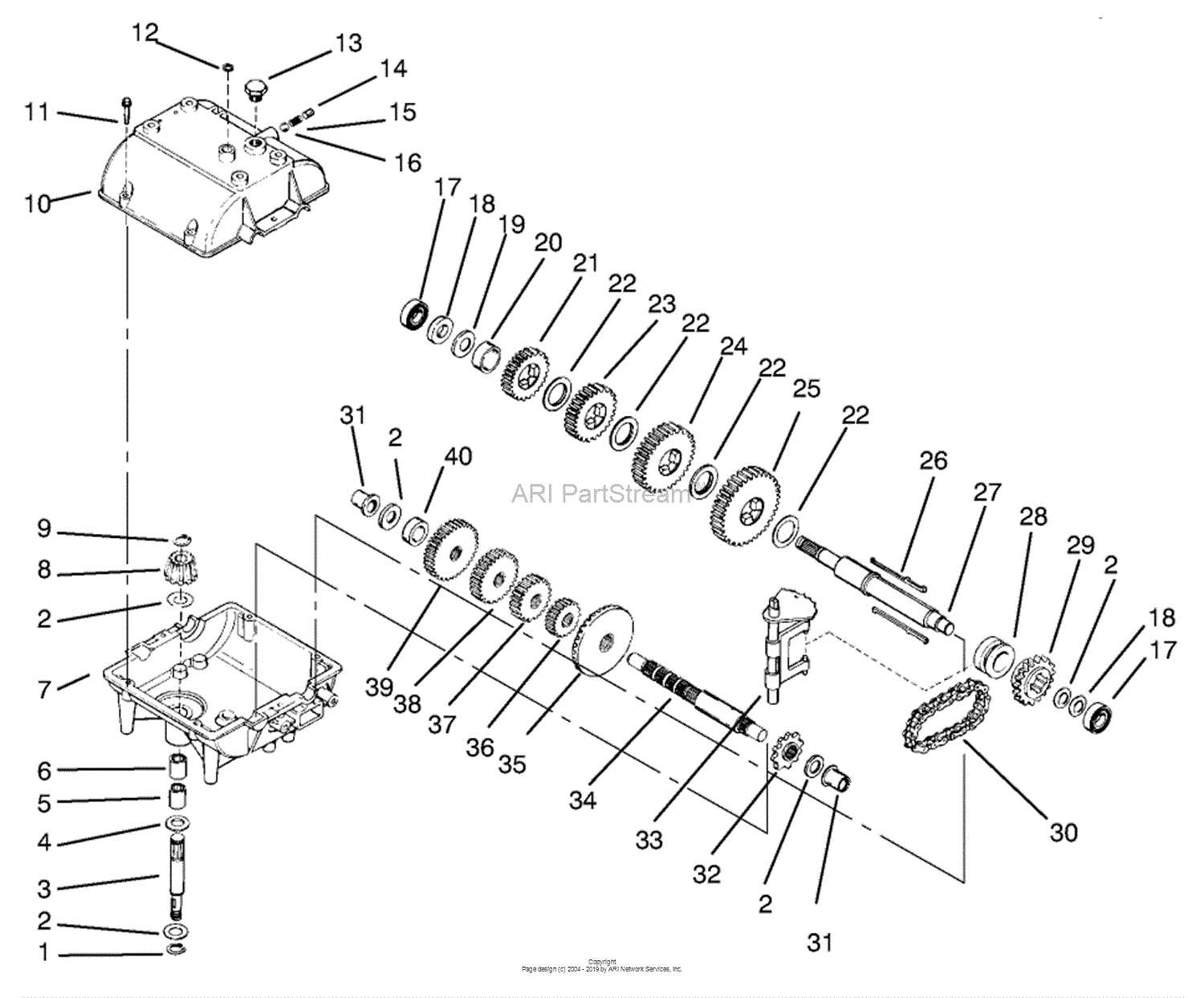

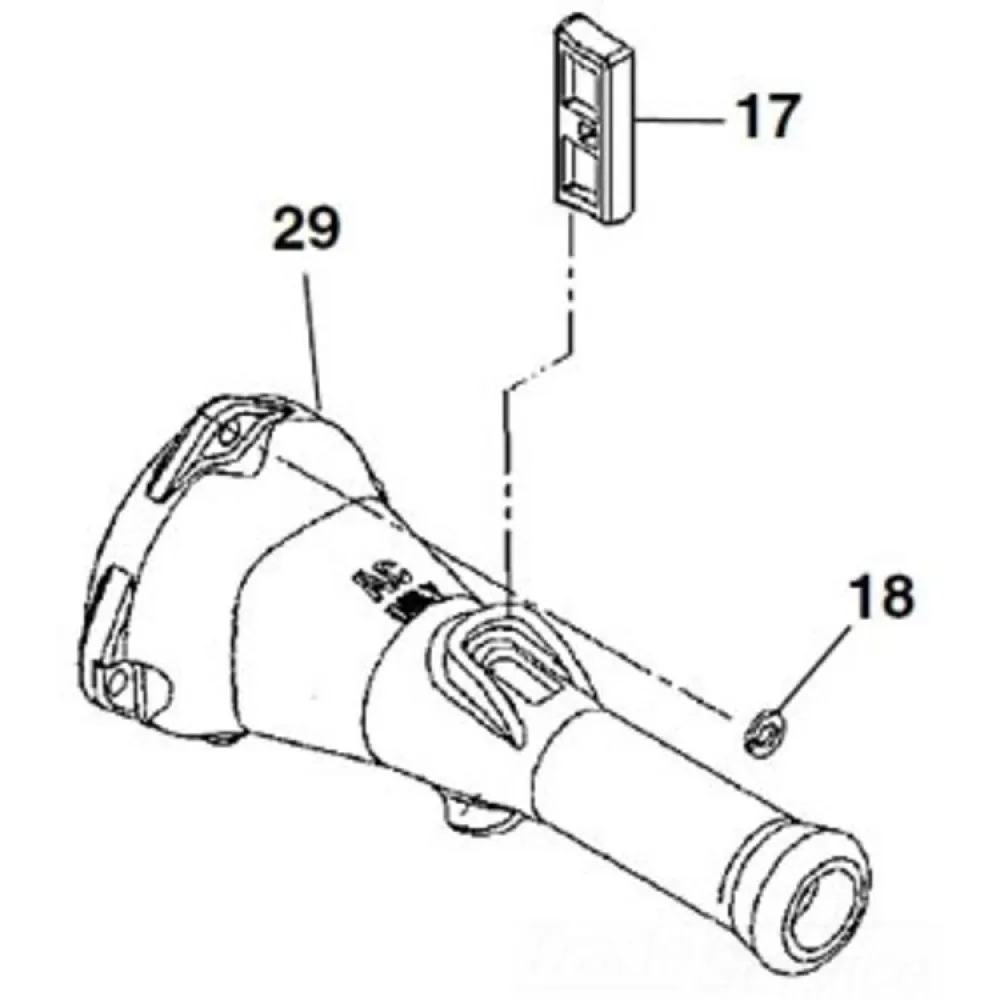

In this section, we will delve into a visual representation that illustrates the intricate arrangement of each part. This guide aims to provide the ultimate resource for anyone seeking to familiarize themselves with the inner workings of this indispensable device.

Understanding Ridgid 700 Components

Grasping the intricacies of a machine’s elements is crucial for effective maintenance and operation. Each component plays a vital role, ensuring that the entire system functions harmoniously. By familiarizing oneself with these individual pieces, one can troubleshoot issues and optimize performance.

Core Elements: The foundation of any robust apparatus includes essential mechanisms that drive its functionality. These key parts work together seamlessly, contributing to the overall efficiency and reliability of the device.

Interchangeable Parts: Many components can be replaced or upgraded, allowing for greater versatility and enhanced performance. Understanding which elements can be interchanged can lead to improved outcomes and longevity of the equipment.

Maintenance Insights: Regular inspection of each segment is imperative. Identifying wear and tear can prevent larger malfunctions, saving time and resources. Knowledge of the structure and function of each part aids in timely interventions.

Assembly and Disassembly: Mastery of how components fit together is essential for both repairs and upgrades. Knowing the correct order of assembly can streamline the process and reduce the risk of damaging any parts during handling.

In summary, a thorough comprehension of the various elements within this machine not only enhances operational effectiveness but also empowers users to engage confidently with their equipment.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding assembly, maintenance, and repair processes. They provide a clear overview of individual elements, ensuring users can identify and locate specific items quickly. This clarity enhances efficiency and minimizes the risk of errors during servicing.

Facilitating Efficient Repairs

Utilizing detailed illustrations allows technicians to quickly reference necessary elements, which significantly reduces downtime. By having access to accurate visual information, they can streamline their workflow and enhance productivity.

Enhancing Understanding

These visual aids not only assist in practical applications but also improve overall comprehension of how various components interact. Users can delve into the mechanics of an assembly, leading to a deeper appreciation of the system’s functionality.

| Benefits | Description |

|---|---|

| Quick Reference | Immediate identification of components for repairs. |

| Error Reduction | Minimizes mistakes during assembly and maintenance. |

| Time Efficiency | Speeds up the repair process through clear visuals. |

| Increased Knowledge | Improves understanding of system functions and interactions. |

Common Issues with Ridgid 700

Many users encounter several recurring challenges when operating this particular tool. These problems can range from minor inconveniences to significant operational failures, affecting efficiency and performance. Understanding these issues is crucial for maintaining optimal functionality and prolonging the tool’s lifespan.

One frequent concern involves overheating during prolonged use, which can lead to decreased performance and potential damage. Regular maintenance and proper cooling techniques can help mitigate this risk.

Another common issue is the wear and tear of certain components, which may require timely replacement to ensure smooth operation. Familiarity with the assembly and associated parts is essential for effective troubleshooting.

Finally, inconsistent performance may arise from improper calibration or alignment, necessitating adjustments to achieve the best results. Addressing these issues proactively can enhance the overall user experience.

How to Access Parts Diagram

Understanding the various components of your equipment is essential for effective maintenance and repair. To streamline this process, obtaining a visual reference can greatly enhance your ability to identify each element and its functionality. This section will guide you on how to efficiently locate and access these valuable resources.

Online Resources

The internet is a powerful tool for finding technical illustrations. Many manufacturers offer downloadable resources directly on their websites. Start by visiting the official site and navigate to the support or resources section. There, you can often find a searchable archive where you can input your model number and retrieve the necessary visuals.

User Manuals and Documentation

Another effective way to access detailed representations is through user manuals. These documents often contain comprehensive illustrations and descriptions of components. If you have a physical copy, check the index for relevant sections. Alternatively, many manuals are available in PDF format online. A quick search with your model’s name followed by “manual” can lead you to the correct document.

By utilizing these methods, you can enhance your understanding and maintenance capabilities of your equipment, ensuring optimal performance and longevity.

Key Features of Ridgid 700

This model is renowned for its exceptional reliability and versatility, making it an essential tool for professionals and DIY enthusiasts alike. Its robust design ensures durability, while its innovative engineering provides superior performance in various applications.

Powerful Motor: The unit is equipped with a high-performance motor that delivers impressive torque, allowing it to tackle tough tasks with ease. This ensures efficient operation, even under demanding conditions.

Compact Design: With its lightweight and compact structure, this device is easy to transport and maneuver. This feature is particularly beneficial for work in tight spaces or when mobility is essential.

User-Friendly Controls: The intuitive interface allows for seamless adjustments, ensuring that users can operate the tool efficiently. Ergonomic features enhance comfort during prolonged use, reducing fatigue.

Versatile Applications: This equipment is suitable for a wide range of tasks, from basic home repairs to more complex plumbing projects. Its adaptability makes it a valuable addition to any toolkit.

Enhanced Safety Features: Built-in safety mechanisms provide peace of mind during operation. These features help prevent accidents and ensure that the user can focus on the task at hand.

Replacing Parts: A Step-by-Step Guide

Maintenance and repair are essential for ensuring the longevity of any tool. Understanding the process of component replacement can save time and money while keeping equipment in optimal working condition. This guide will walk you through a systematic approach to replacing elements, ensuring a smooth and efficient experience.

| Step | Action | Tips |

|---|---|---|

| 1 | Identify the Component | Consult the manual to locate the specific piece that needs attention. |

| 2 | Gather Tools | Prepare all necessary tools before starting to minimize downtime. |

| 3 | Disconnect Power | Ensure the device is unplugged to prevent accidents during the process. |

| 4 | Remove the Old Part | Follow the manual’s instructions for safely detaching the malfunctioning item. |

| 5 | Install the New Component | Align and secure the new element as per guidelines to avoid issues. |

| 6 | Reconnect Power | Plug the device back in and ensure everything is functioning correctly. |

| 7 | Test the Equipment | Run a few tests to confirm that the replacement has resolved the issue. |

Following these steps carefully will ensure a successful replacement process. Regular maintenance checks can also help in identifying potential issues early on, prolonging the lifespan of your tools.

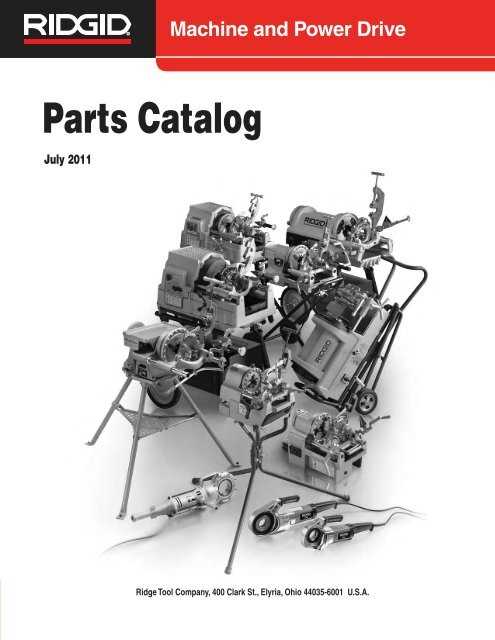

Where to Buy Replacement Parts

Finding quality components for your equipment can enhance performance and longevity. Several reliable sources offer a wide selection, ensuring you can easily locate what you need to keep your tools in top condition.

Online Retailers

- Manufacturer’s Website: Direct purchases often guarantee authenticity.

- Third-Party Retailers: Websites like Amazon and eBay feature various options and competitive pricing.

- Specialized Stores: Look for websites dedicated to tool accessories for specific needs.

Local Supply Stores

- Home Improvement Chains: Major retailers typically stock common components.

- Tool Shops: Local businesses may offer personalized service and expert advice.

- Trade Shows: Attend events to discover new suppliers and unique offerings.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular attention to maintenance not only enhances performance but also prevents costly repairs. By adhering to a few straightforward practices, you can maximize the functionality and durability of your tools.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep surfaces free from dust and debris to prevent wear and tear. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Check for Wear | Inspect components regularly for signs of damage or excessive wear. |

| Proper Storage | Store tools in a dry, clean environment to avoid rust and degradation. |

| Follow Manufacturer Guidelines | Adhere to recommended maintenance schedules to ensure optimal performance. |

Incorporating these simple yet effective strategies into your routine will help maintain the integrity of your tools, ensuring they serve you well for years to come.