When it comes to maintaining your cutting tool, a comprehensive grasp of its individual components is essential. Knowing how each piece works together can significantly enhance your operational efficiency and longevity of the machine. This knowledge not only helps in troubleshooting issues but also empowers users to perform necessary repairs and replacements with confidence.

In this section, we will explore the intricate layout of the various elements that constitute your chainsaw. By delving into the specific functions of each component, users can develop a clearer picture of how to optimize performance and ensure smooth operation. Understanding the assembly will also aid in identifying wear and tear, allowing for timely interventions.

Equipped with this insight, enthusiasts and professionals alike can navigate the complexities of their equipment more effectively. Whether you are a seasoned user or a newcomer to the world of cutting tools, familiarizing yourself with the essential parts will undoubtedly enhance your experience and mastery of the device.

Understanding the Stihl MS 251C Parts

In order to effectively maintain and troubleshoot a specific model of a chainsaw, it is crucial to have a comprehensive understanding of its components. Each element plays a vital role in the overall functionality, ensuring optimal performance during operation. Familiarity with these elements can greatly enhance the user experience and prolong the lifespan of the tool.

Here are some key components to consider:

- Engine Assembly: This is the heart of the machine, providing the necessary power for cutting.

- Guide Bar: Essential for directing the chain during operation, ensuring precision and control.

- Chain: The cutting mechanism, designed to effectively slice through various materials.

- Fuel System: Comprising the tank and lines, this system is responsible for delivering the energy required for operation.

- Ignition System: This includes the spark plug and ignition coil, crucial for starting the engine.

- Air Filter: Prevents debris from entering the engine, maintaining efficiency and performance.

Understanding how these components interact is essential for effective troubleshooting and maintenance. Regular inspections can help identify wear and tear, ensuring that each part functions optimally.

For optimal performance, users should consider the following maintenance tips:

- Regularly check and replace the air filter to prevent engine damage.

- Keep the chain sharp and well-lubricated for efficient cutting.

- Inspect fuel lines for leaks or blockages that could affect performance.

- Ensure the ignition system is functioning correctly for reliable starting.

By gaining insight into these crucial components, users can enhance their experience and ensure that their chainsaw remains in peak condition.

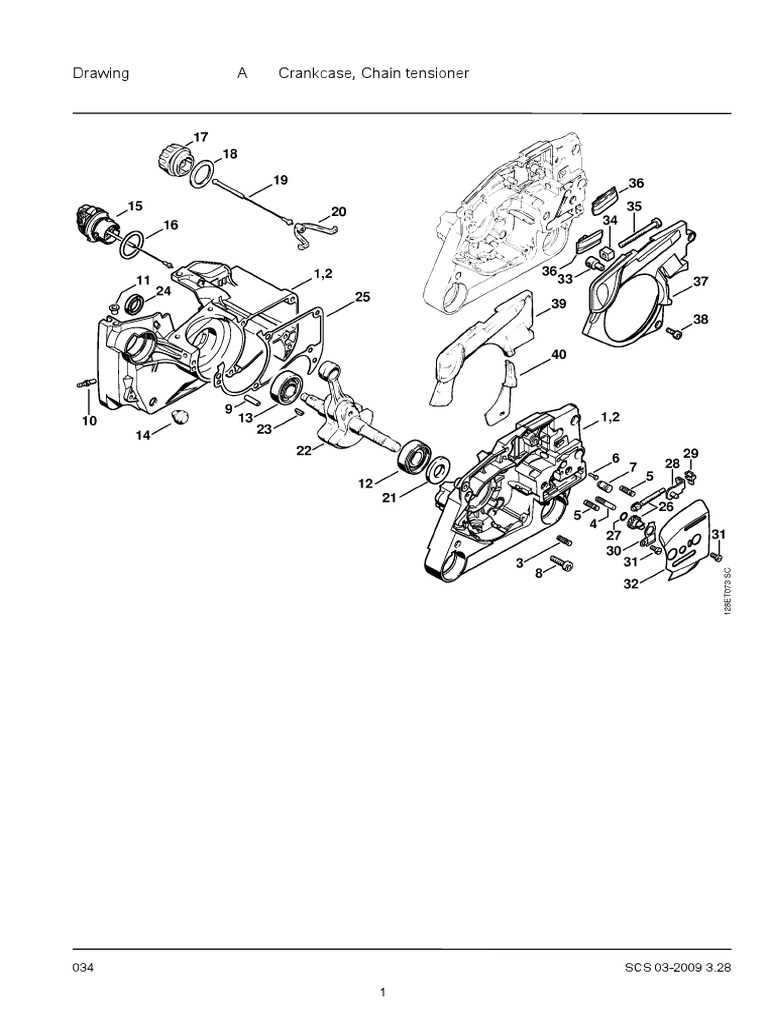

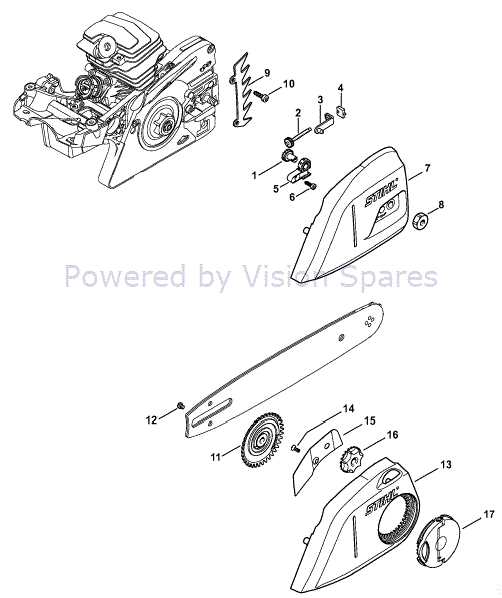

Key Components of Stihl MS 251C

Understanding the essential elements of a chainsaw is crucial for effective maintenance and operation. Each part plays a significant role in the overall functionality, ensuring the tool operates efficiently and safely. Here, we will explore the primary components that contribute to the performance of this particular model.

Major Parts Overview

- Engine: The heart of the machine, providing the necessary power for cutting tasks.

- Guide Bar: The long, flat piece that guides the chain and aids in precise cutting.

- Chain: The cutting element that rotates around the guide bar to perform the cutting action.

- Air Filter: Prevents debris from entering the engine, ensuring optimal performance.

- Fuel System: Comprises the fuel tank, lines, and filter, delivering the energy required for operation.

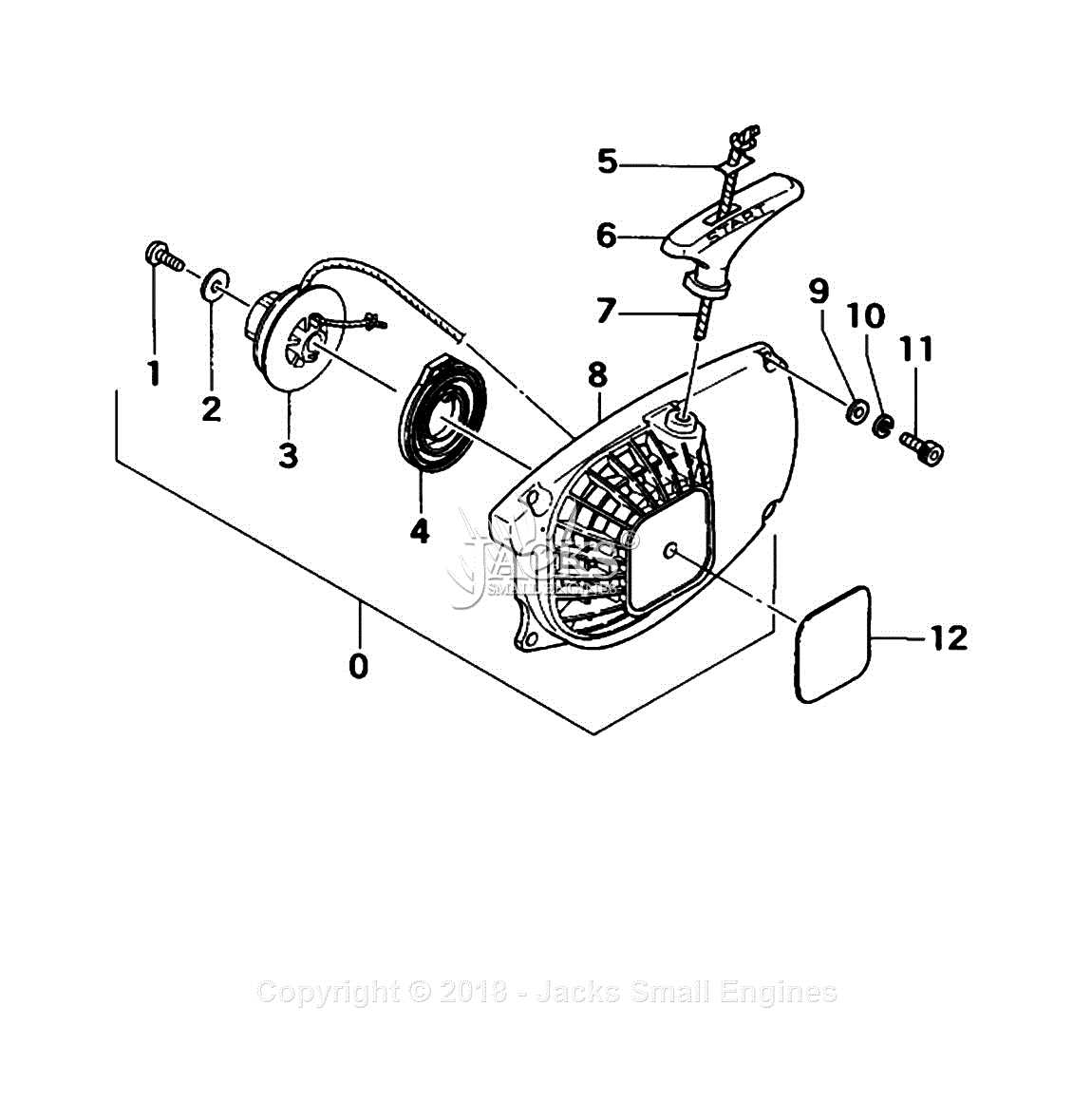

Additional Important Elements

- Starter Mechanism: Facilitates the initial ignition of the engine, allowing for easy starting.

- Clutch: Engages and disengages the chain from the engine, enhancing safety during use.

- Handle: Provides a grip for maneuvering the tool effectively, contributing to user control.

- Oiling System: Ensures proper lubrication of the chain and bar, minimizing wear and tear.

Each of these components works in harmony, allowing for seamless operation and maintenance of the chainsaw. Understanding their functions can greatly enhance user experience and tool longevity.

Importance of Regular Maintenance

Maintaining tools and machinery is crucial for ensuring their longevity and optimal performance. Regular upkeep not only enhances efficiency but also prevents costly repairs and unexpected breakdowns. By prioritizing maintenance, users can enjoy a seamless experience and extend the lifespan of their equipment.

Enhancing Performance

Consistent attention to machinery ensures that all components function harmoniously. When every part is clean and well-lubricated, the overall efficiency is significantly improved, leading to better results during operation. Optimal performance translates to a more enjoyable and effective working experience.

Safety First

Regular maintenance is not only about performance; it is also about safety. Equipment that is not properly cared for can become hazardous, posing risks to the user and those nearby. By keeping machinery in good condition, the likelihood of accidents or malfunctions is greatly reduced, promoting a safer working environment.

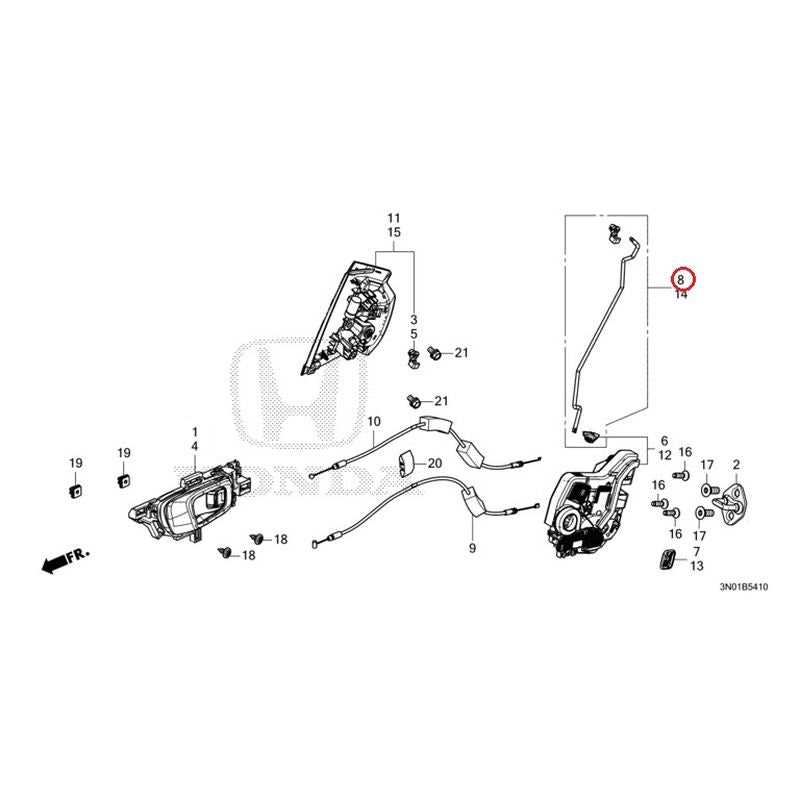

How to Identify Parts Quickly

Recognizing components efficiently is essential for effective maintenance and repair. Familiarity with the equipment’s layout and understanding common terminologies can significantly enhance your ability to locate what you need without confusion.

Utilize Reference Guides

Reference materials are invaluable tools. They often provide visual aids and descriptive labels that clarify each element’s function. Keeping these resources accessible can streamline your identification process.

Focus on Key Features

Pay attention to distinct characteristics, such as size, shape, and color. By noting these details, you can quickly narrow down options and pinpoint the specific item required. Practice makes perfect when it comes to enhancing your recognition skills.

Common Issues and Solutions

When operating power tools, users often encounter a variety of challenges that can hinder performance. Understanding these common problems and their potential remedies can enhance the longevity and efficiency of the equipment. Below are several frequent issues along with practical solutions.

Engine Start Problems

One of the most prevalent difficulties is the engine failing to start. This can stem from multiple factors, including fuel issues, spark plug malfunctions, or air filter blockages. To address this, ensure that the fuel is fresh and mixed correctly. Check the spark plug for signs of wear and replace it if necessary. Additionally, inspect the air filter for debris and clean or replace it as needed.

Power Loss During Operation

Experiencing a reduction in power while in use can be frustrating. Common causes include a dirty air filter, dull cutting equipment, or fuel line issues. To resolve this, regularly clean or replace the air filter, sharpen or replace the cutting elements, and examine the fuel lines for clogs or leaks. Maintaining these components can help restore optimal performance.

Where to Find Replacement Parts

When it comes to maintaining your outdoor power equipment, locating the right components is crucial for ensuring optimal performance. Fortunately, there are various sources available for acquiring high-quality replacements. Below are some options to consider when searching for suitable items.

- Authorized Dealers: Visiting an authorized dealer can provide access to genuine components. These outlets often have knowledgeable staff who can assist with identification and compatibility.

- Online Retailers: Numerous websites specialize in outdoor equipment. These platforms often offer a wide selection and competitive pricing. Make sure to check customer reviews for reliability.

- Local Hardware Stores: Many local hardware stores carry a selection of common items. While their inventory may not be exhaustive, it’s worth checking for immediate needs.

- Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove of used components. Ensure you inspect items thoroughly before purchasing.

- Manufacturer’s Website: The official website often provides an extensive catalog of items available for purchase. It’s a reliable source for finding the exact components you need.

lessCopy code

By exploring these various avenues, you can effectively find the replacements required to keep your equipment running smoothly.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment offers numerous advantages that can significantly enhance performance and longevity. These original elements are designed specifically for your machinery, ensuring optimal compatibility and functionality.

One of the primary benefits of using genuine components is reliability. These parts undergo rigorous testing and quality assurance, which reduces the likelihood of malfunctions and breakdowns. This leads to increased efficiency and consistent operation, allowing users to complete tasks without unexpected interruptions.

Additionally, authentic components often come with warranties that provide peace of mind. In the event of an issue, having the backing of a manufacturer ensures that you receive the necessary support and replacements without incurring extra costs.

Moreover, using original elements can enhance safety. Since these parts meet strict safety standards, they minimize the risk of accidents caused by inferior or incompatible alternatives. This focus on safety not only protects the user but also extends the lifespan of the machinery.

Finally, opting for genuine components can preserve the value of your equipment. Maintaining it with original parts can prevent depreciation and maintain its resale value, making it a wise investment for the future.

Tips for Safe Handling and Usage

When working with power tools, prioritizing safety is crucial to prevent accidents and ensure a smooth operation. Understanding how to handle and operate equipment correctly can significantly reduce risks. Below are essential guidelines to enhance your safety while using machinery.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as gloves, goggles, and hearing protection to shield yourself from potential hazards. |

| Inspect Before Use | Examine the tool for any signs of wear or damage before starting work. This includes checking the chain, bar, and any electrical components. |

| Maintain a Clean Workspace | Ensure the area around you is free of clutter and obstacles. A tidy environment minimizes the risk of trips and falls. |

| Follow Operating Instructions | Always refer to the manufacturer’s guidelines for operating the equipment. Familiarity with the controls and functions is key to safe usage. |

| Keep Others at a Safe Distance | Ensure that bystanders are at least several feet away while you are operating the tool to avoid accidents and injuries. |

| Shut Down When Not in Use | Always turn off and unplug the machine when not in use or when performing maintenance to prevent accidental start-ups. |

Resources for Stihl MS 251C Owners

For those who own a specific model of chainsaw, having access to reliable information and tools is essential for maintenance and effective use. A variety of resources are available to help ensure that your equipment operates smoothly and efficiently.

User Manuals

- Official documentation provides detailed instructions on operation and care.

- Look for downloadable PDFs on manufacturer websites for easy access.

- Check for updates to manuals to stay informed about new features or safety guidelines.

Online Forums and Communities

- Join forums dedicated to chainsaw enthusiasts to share experiences and tips.

- Participate in discussions to learn from seasoned users.

- Follow social media groups where owners post advice and support.

Utilizing these resources can enhance your experience and extend the lifespan of your equipment, allowing you to tackle projects with confidence.