Effective maintenance of machinery relies heavily on the tools used for lubrication. A thorough comprehension of the individual elements that constitute these essential implements can significantly enhance their functionality and lifespan. By exploring the arrangement and interaction of these components, users can ensure optimal performance in their applications.

When delving into the intricacies of these devices, it’s crucial to recognize how each segment contributes to the overall efficiency. This insight not only facilitates troubleshooting but also aids in informed decision-making regarding repairs or replacements. A well-structured overview of these elements can serve as a valuable resource for both novices and seasoned professionals.

Moreover, understanding the layout of these instruments empowers users to maximize their operational capabilities. By familiarizing oneself with the various features, one can make informed adjustments and improvements, ensuring that the tool operates at peak effectiveness. This knowledge is indispensable for anyone looking to maintain their equipment with confidence and precision.

Understanding Lincoln Grease Guns

The tools designed for lubricant application play a crucial role in maintenance and machinery care. Mastering these implements ensures optimal performance and longevity of equipment. By exploring their features and mechanisms, users can enhance their efficiency and effectiveness in various tasks.

Familiarity with different components and their functions is essential for anyone looking to delve into the mechanics of these devices. Understanding how each section works together will lead to improved operation and troubleshooting. Comprehending the nuances can make a significant difference in maintenance routines.

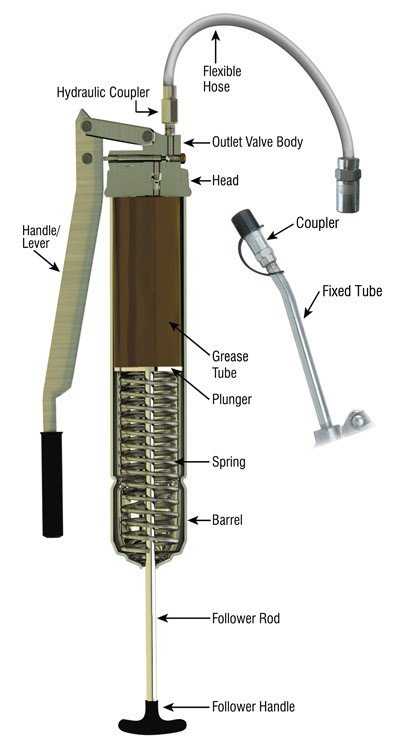

Components of a Grease Gun

Understanding the various elements that make up this essential tool is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and durability.

| Component | Description |

|---|---|

| Housing | The outer casing that protects internal mechanisms and provides a grip. |

| Piston | A movable part that creates pressure to expel the lubricant. |

| Barrel | The cylindrical section that holds the lubricant and guides it to the nozzle. |

| Nozzle | The end part where the substance exits, allowing for precise application. |

| Trigger | A lever that controls the flow of lubricant when pressed. |

| Pressure Relief Valve | A safety feature that prevents excessive buildup of pressure. |

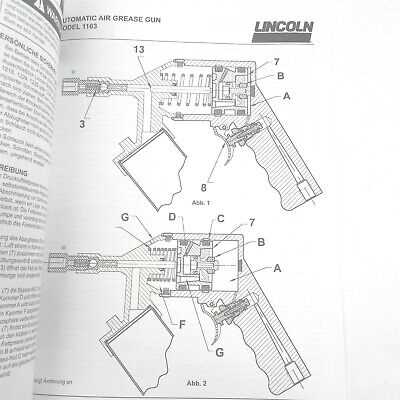

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide crucial insights into assembly and functionality, making them invaluable tools for users.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Recognize common icons and notations used in the representation.

- Identify Key Sections: Break down the illustration into major sections to grasp the overall structure.

- Cross-Reference with Documentation: Use accompanying manuals or guides to enhance comprehension.

- Pay Attention to Numbering: Note how components are labeled for easier identification.

By following these guidelines, you can effectively navigate through complex visual data and enhance your understanding of various assemblies.

Common Issues and Solutions

When working with lubrication tools, users often encounter various challenges that can hinder performance. Identifying these common problems and their respective remedies is essential for ensuring smooth operation and longevity of the equipment.

One frequent issue is inconsistent flow, which can result from clogs or blockages within the system. To resolve this, regular cleaning of the internal components and ensuring that the dispensing mechanism is free from debris is crucial. Additionally, checking the quality of the lubricant used can prevent viscosity-related complications.

Another common concern is leakage, which may arise from worn seals or improper assembly. To address this, inspect all seals for signs of wear and replace them as necessary. Ensuring that all connections are tightly secured can also mitigate the risk of leaks.

Users may also experience difficulty in achieving the desired pressure. This can often be attributed to air pockets in the system or insufficient manual operation. To alleviate this, it’s advisable to bleed the system of air and familiarize oneself with the correct manual operation techniques to maintain optimal pressure levels.

By recognizing these typical issues and applying the suggested solutions, users can enhance the efficiency and reliability of their lubrication equipment, ultimately leading to better maintenance of machinery and tools.

Maintenance Tips for Longevity

Ensuring the durability and effectiveness of your equipment requires consistent upkeep and attention to detail. Regular maintenance not only prolongs the life of your tools but also enhances their performance, making tasks easier and more efficient.

- Clean regularly: Remove any debris or residue after each use to prevent build-up that can hinder functionality.

- Inspect for wear: Regularly check all components for signs of damage or excessive wear. Address issues promptly to avoid further complications.

- Lubricate moving parts: Apply appropriate lubricants to ensure smooth operation. Follow manufacturer guidelines for the right type and frequency of lubrication.

- Store properly: Keep equipment in a dry, cool place to protect it from moisture and extreme temperatures that could cause deterioration.

- Follow usage guidelines: Adhere to the manufacturer’s instructions for operation to avoid unnecessary strain on the machinery.

Implementing these strategies will help maintain optimal performance and extend the lifespan of your tools, ensuring they remain reliable for years to come.

Choosing the Right Grease for Your Gun

Selecting the appropriate lubricant for your equipment is essential for ensuring optimal performance and longevity. The right substance not only facilitates smooth operation but also protects vital components from wear and tear. Different applications require distinct formulations, making it crucial to understand the specific needs of your tools.

When considering the right lubricant, factors such as temperature range, viscosity, and compatibility with materials play a significant role. For instance, high-temperature applications may necessitate a thicker consistency to prevent breakdown under extreme conditions. Conversely, lighter alternatives might be preferable for standard tasks, ensuring easy application and effective coverage.

Furthermore, it is important to evaluate the environment in which the equipment will be used. Exposure to moisture, dust, or corrosive elements can dictate the choice of formulation. Selecting a product designed to withstand such conditions can greatly enhance the lifespan of your tools and maintain their efficiency.

Lastly, always refer to the manufacturer’s guidelines to identify recommended specifications. Adhering to these recommendations ensures compatibility and maximizes the performance of your equipment, ultimately saving time and resources in the long run.

Upgrading Lincoln Grease Gun Parts

Enhancing the functionality of your lubrication device can significantly improve its performance and longevity. By investing in high-quality components, you can ensure that your equipment operates more efficiently, providing optimal results during maintenance tasks. Upgrading can also address common issues, making the overall experience more reliable.

Consider replacing worn-out elements with superior alternatives that promise durability and effectiveness. For instance, seals and nozzles play crucial roles in ensuring smooth operation and preventing leaks. Selecting parts designed for enhanced compatibility can lead to better pressure retention and a more consistent application of lubricant.

Moreover, incorporating advanced features such as pressure gauges or adjustable flow mechanisms can provide added convenience and control during usage. These upgrades not only streamline your tasks but also allow for precise lubrication in hard-to-reach areas, ensuring every component receives adequate attention.

Ultimately, by prioritizing the quality and performance of your equipment, you will not only extend its lifespan but also enhance your overall maintenance efficiency. Make informed choices about the components you select to achieve the best possible outcomes.

Safety Precautions While Using Tools

Ensuring safety during the use of equipment is crucial for preventing accidents and injuries. Proper practices not only protect the user but also contribute to a safer working environment. Familiarizing oneself with essential guidelines is a vital step in promoting safety and efficiency.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Inspect tools before use to ensure they are in good condition and free from damage.

- Keep the work area clean and organized to minimize hazards.

- Follow the manufacturer’s instructions for operation and maintenance.

- Maintain a clear understanding of the tool’s function and limitations.

Proper Handling Techniques

- Use tools for their intended purpose only.

- Avoid wearing loose clothing or jewelry that could become entangled.

- Keep hands and other body parts away from moving parts.

- Secure the workpiece properly before starting the operation.

- Disconnect power sources when changing attachments or making adjustments.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Various resources are available that can help you source high-quality items to ensure optimal performance and longevity of your tools.

Online Retailers: Numerous e-commerce platforms specialize in machinery supplies. Websites like Amazon, eBay, and specialized tool retailers often have a wide selection. Searching by brand and model can yield the specific items you require.

Manufacturer’s Website: Visiting the official website of the manufacturer is a reliable way to find original components. Many manufacturers offer detailed catalogs and online ordering options, ensuring you receive authentic and compatible items.

Local Hardware Stores: Don’t overlook nearby hardware and supply stores. Many of these establishments carry essential accessories and components. Speaking directly with knowledgeable staff can provide additional insights into availability and compatibility.

Forums and Community Groups: Engaging with online forums or community groups dedicated to machinery can lead to valuable recommendations. Members often share sources for hard-to-find components or offer advice based on their own experiences.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove. These places often have a variety of machinery where you can find usable components at a fraction of the cost.