In the realm of heating technology, the intricacies of various mechanisms play a vital role in ensuring efficiency and reliability. A comprehensive grasp of these elements can significantly enhance the performance of the system, leading to optimal comfort and functionality. Analyzing the individual components, their interrelations, and overall schematics is essential for both maintenance and troubleshooting.

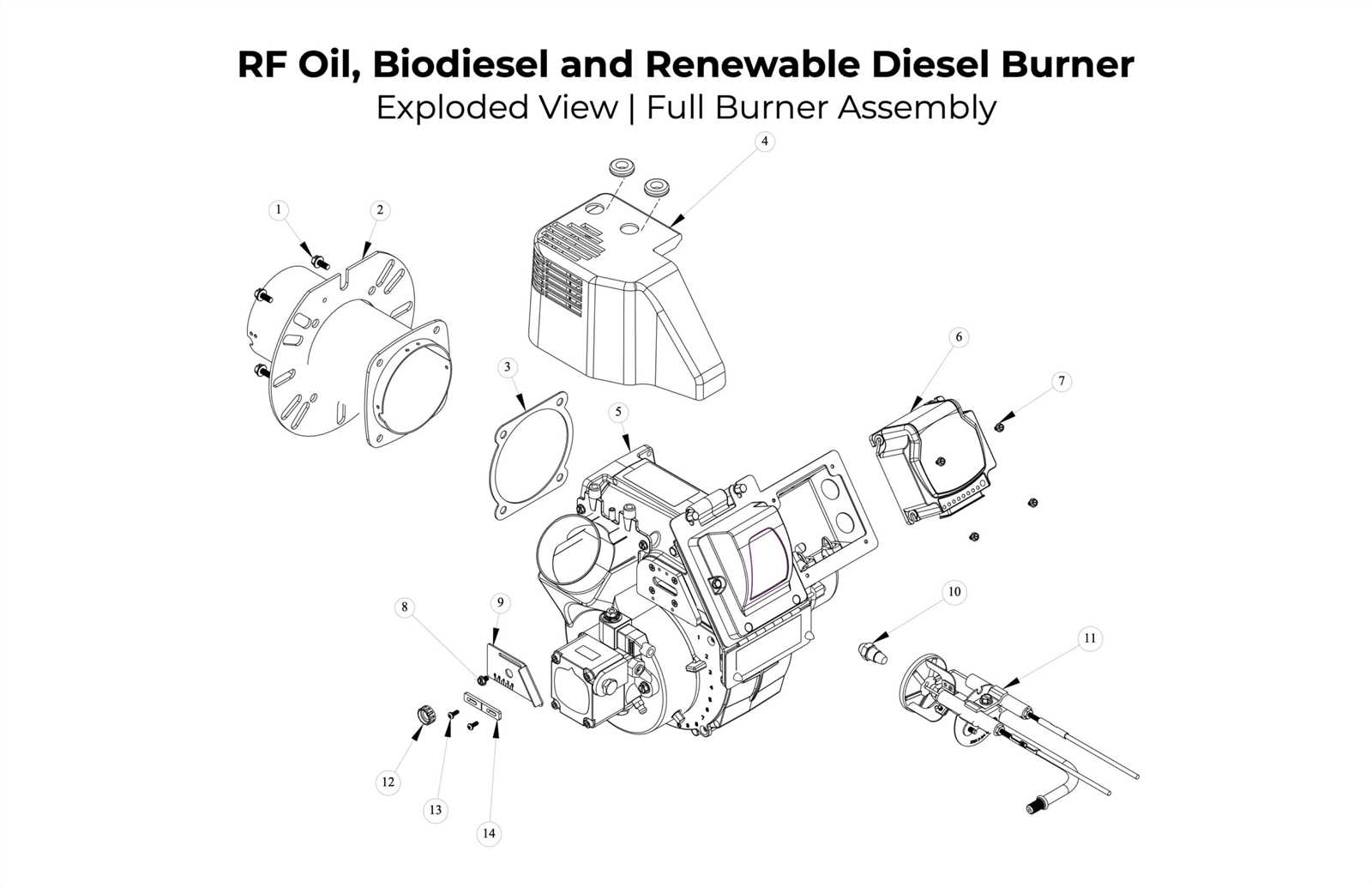

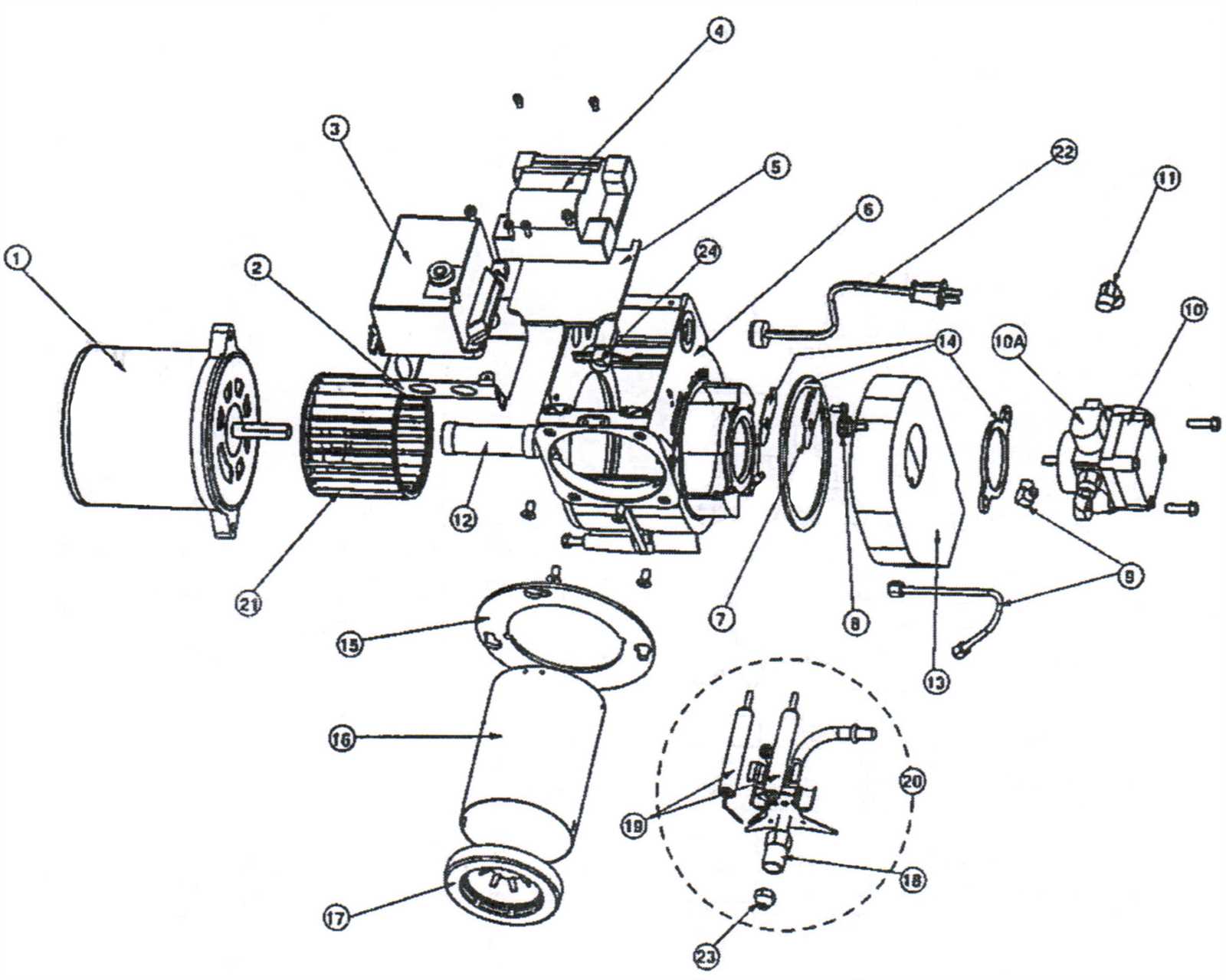

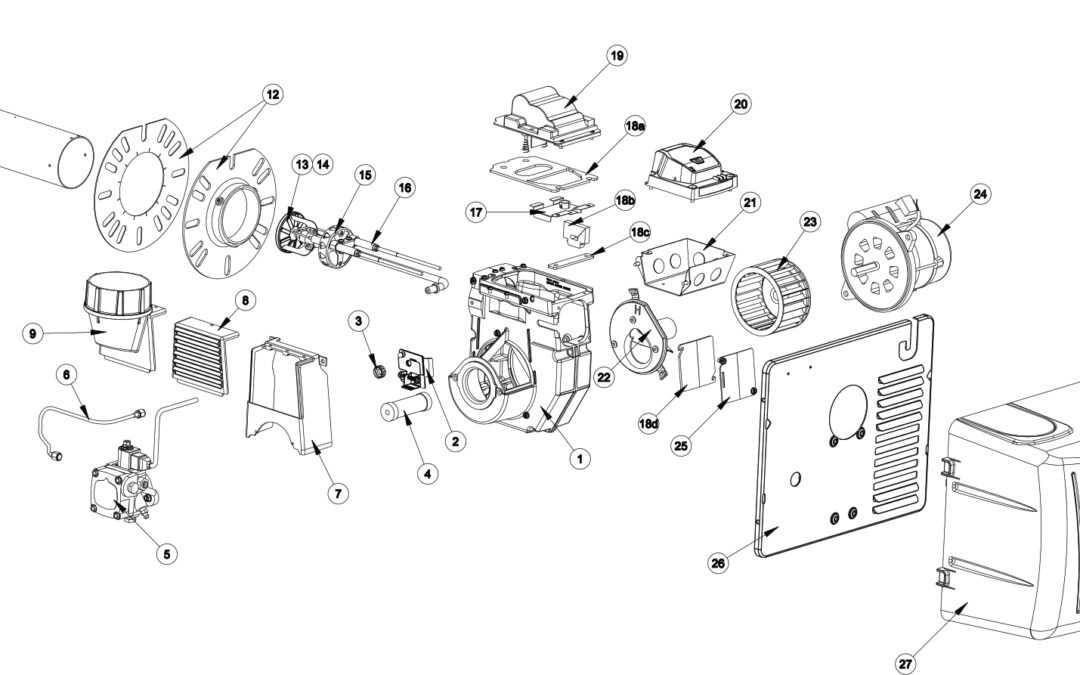

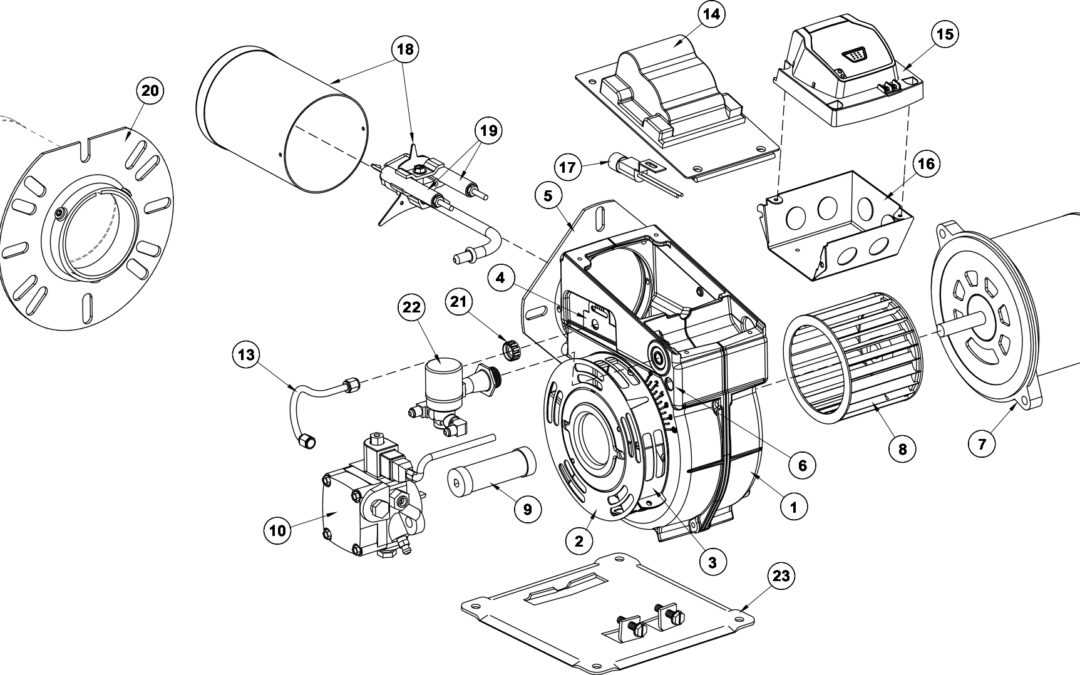

Visual representations serve as invaluable tools in deciphering the complexities of these heating systems. By breaking down the various sections into understandable segments, users can quickly identify and address potential issues. Moreover, these schematics provide a roadmap for assembly and disassembly, ensuring that each piece is correctly positioned for optimal operation.

Understanding how each element contributes to the overall mechanism is crucial for anyone involved in maintenance or repair. Through a detailed exploration of these components and their configurations, individuals can gain insights that not only facilitate effective troubleshooting but also promote longevity and reliability in heating solutions.

Understanding Beckett AFG Oil Burner

This section delves into the essential components and operational mechanisms of a specific type of combustion device widely used for heating applications. Recognizing the intricacies of its construction and functionality can significantly enhance performance and efficiency in various settings.

Core Components

Central to this heating solution is a system designed to facilitate the precise mixing of fuel and air. This synergy ensures optimal combustion, which is crucial for achieving desired temperature levels while minimizing emissions. Each element, from the fuel delivery system to the ignition mechanism, plays a vital role in the overall effectiveness of the unit.

Maintenance and Troubleshooting

Regular upkeep is paramount to prolonging the lifespan of the apparatus. Understanding common issues, such as inefficient combustion or irregular flame patterns, allows users to promptly address concerns. Familiarity with the essential features and their functions aids in effective troubleshooting and enhances overall reliability.

Key Components of AFG Burner

Understanding the essential elements of this heating apparatus is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficiency and reliability, contributing to optimal performance.

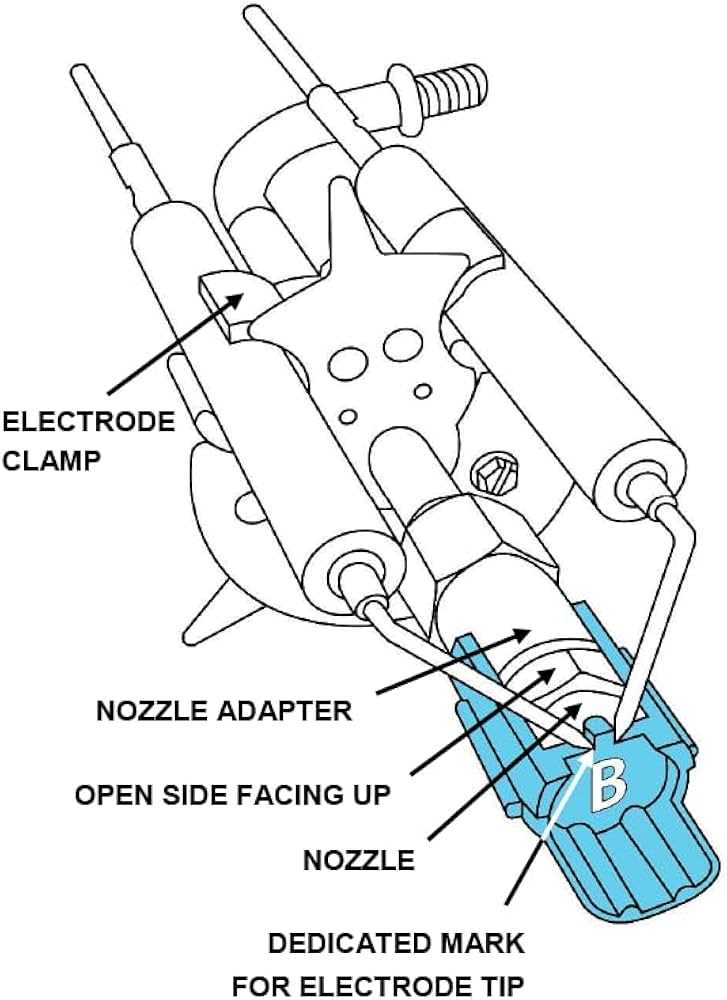

The ignition system is pivotal, providing the initial spark needed to initiate the combustion process. The fuel delivery mechanism ensures a consistent supply of liquid fuel, while the combustion chamber facilitates effective mixing of air and fuel for an efficient burn.

Another critical element is the control system, which regulates the operation based on temperature and demand. Additionally, safety features are integrated to prevent malfunctions and ensure user protection during operation.

Lastly, the exhaust system is vital for safely venting byproducts away from the environment, maintaining both efficiency and safety. A comprehensive understanding of these components allows for better troubleshooting and maintenance practices.

Common Issues and Troubleshooting Tips

When dealing with heating systems, understanding potential problems can save time and reduce frustration. Identifying common malfunctions allows for effective solutions and ensures optimal performance of the unit.

Frequent Problems

One of the most encountered issues is inconsistent heating. This may be caused by various factors, such as a faulty ignition system or inadequate fuel supply. Additionally, clogged filters can lead to poor airflow, resulting in inefficient operation. It’s crucial to check these components regularly.

Troubleshooting Steps

To address these challenges, start by inspecting the ignition to confirm it’s functioning correctly. Next, ensure that the fuel tank is adequately filled and the delivery lines are not obstructed. Regularly clean or replace filters to maintain smooth airflow. If problems persist, consulting a professional may be necessary for comprehensive diagnostics.

Maintenance Practices for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of heating systems. Regular attention to specific components and adherence to recommended procedures can significantly reduce the risk of malfunctions and enhance efficiency. This section outlines key practices to maintain your equipment effectively.

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Clean Filters | Monthly | Replace or clean filters to prevent clogging and ensure smooth airflow. |

| Inspect Fuel Supply | Quarterly | Check for leaks and ensure the fuel supply is clean and free from contaminants. |

| Check Electrical Connections | Bi-Annually | Examine wiring and connections for signs of wear or corrosion to maintain electrical integrity. |

| Clean Combustion Chamber | Annually | Remove soot and debris from the combustion area to improve efficiency and safety. |

| Test Safety Controls | Annually | Ensure all safety mechanisms are functioning correctly to prevent accidents. |

Implementing these practices regularly will not only enhance the performance of your system but also contribute to its durability. Keeping a detailed log of maintenance activities can help identify patterns and anticipate potential issues before they escalate.

Installation Guidelines for New Units

Proper setup of a new heating system is essential for optimal performance and safety. Following a structured approach ensures that each component functions effectively, minimizing potential issues. Adhering to the manufacturer’s recommendations will aid in achieving maximum efficiency.

Preparation Steps

- Read the installation manual thoroughly to understand specific requirements.

- Gather all necessary tools and materials before starting the installation.

- Inspect the installation area for any obstructions or hazards.

- Ensure that the electrical and fuel supply connections are compliant with local codes.

Installation Process

- Position the unit according to the specified dimensions in the manual.

- Secure all mounting brackets and connections as instructed.

- Connect the necessary lines for fuel and airflow, ensuring there are no leaks.

- Check electrical wiring to confirm proper connections and grounding.

- Conduct a thorough inspection before powering on the system.

By following these guidelines, the new unit can be set up for reliable operation, providing comfort and efficiency for years to come.

Comparing AFG with Other Burners

When evaluating different heating systems, it’s essential to understand how various models perform and what advantages they offer. Each system comes with its unique set of features and operational efficiencies, making it crucial for users to consider their specific needs and preferences.

In terms of fuel efficiency, certain models are designed to optimize consumption, thereby reducing operational costs. For instance, some units utilize advanced technology that allows for better combustion, resulting in lower emissions and higher heat output. This can be a significant factor for those looking to minimize their environmental impact while maximizing energy use.

Reliability is another critical aspect. While some systems are known for their durability and long service life, others may require more frequent maintenance. Understanding the maintenance requirements of different units can help users select a model that fits their lifestyle and budget.

Furthermore, the ease of installation and compatibility with existing infrastructure should not be overlooked. Some systems offer more straightforward setups, allowing for quicker transitions and reduced installation costs. Evaluating these factors ensures that consumers can make informed decisions based on their individual circumstances.

Ultimately, comparing different heating solutions requires a comprehensive analysis of performance metrics, costs, and user convenience. By carefully considering these aspects, one can select the most suitable option that meets both immediate needs and long-term goals.

Safety Measures When Operating Burners

Ensuring a secure environment while using combustion devices is paramount. Adhering to established protocols not only safeguards individuals but also enhances the longevity and efficiency of the equipment.

| Safety Measure | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify potential malfunctions or wear. |

| Proper Ventilation | Ensure adequate airflow to prevent buildup of harmful gases. |

| Training Personnel | Provide comprehensive training for all operators on safety protocols. |

| Emergency Shut-Off | Install accessible shut-off mechanisms for quick response to emergencies. |

| Personal Protective Equipment | Utilize appropriate gear to protect against potential hazards. |

Replacement Parts: What You Need

When it comes to maintaining your heating system, understanding the essential components and their replacements is crucial. Having a reliable setup ensures efficient operation and longevity of the equipment. Knowing what to look for and how to source quality substitutes can save time and money in the long run.

Common Components

Several key elements may require attention over time. Fuel pumps, nozzles, and electronic controls are among the most frequently replaced items. Each of these plays a significant role in the system’s overall performance. Keeping these components in optimal condition will prevent unnecessary breakdowns and improve energy efficiency.

Sourcing Quality Replacements

Finding high-quality substitutes is essential for effective maintenance. It is advisable to consult reputable suppliers that specialize in heating system components. Look for products that meet industry standards and come with warranties. Additionally, reading reviews and seeking recommendations can help ensure that you make informed decisions.

Resources for Further Learning

Exploring the intricacies of heating systems requires access to reliable materials that enhance understanding and practical knowledge. Below are various resources that can aid in deepening your expertise in this field.

- Technical Manuals: Comprehensive guides that cover installation and maintenance.

- Online Forums: Communities where enthusiasts and professionals discuss challenges and solutions.

- Webinars: Interactive sessions led by experts offering insights into advanced techniques.

- Books: Authoritative texts that provide in-depth information on system mechanics and troubleshooting.

- Video Tutorials: Step-by-step visual guides available on platforms like YouTube.

Utilizing these resources can ultimately elevate your proficiency and confidence in handling heating equipment.