When it comes to maintaining a reliable energy source, having a comprehensive understanding of your generator’s internal elements is crucial. A well-structured overview of these components not only enhances your ability to troubleshoot effectively but also aids in the seamless operation of the device. Knowing how each piece interacts can significantly improve performance and longevity.

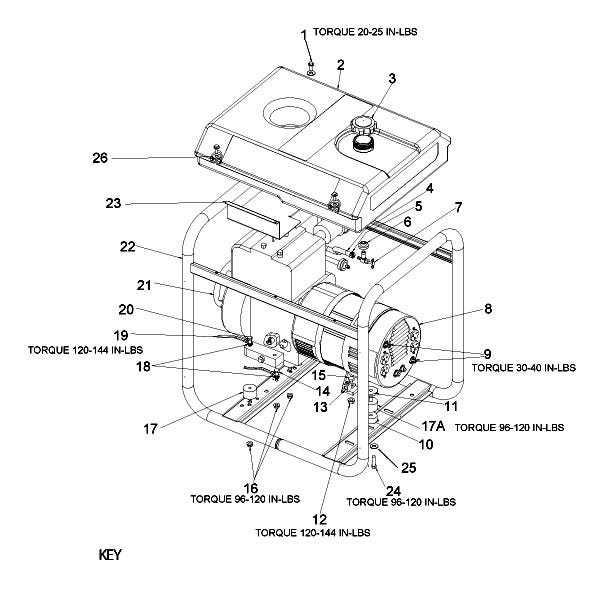

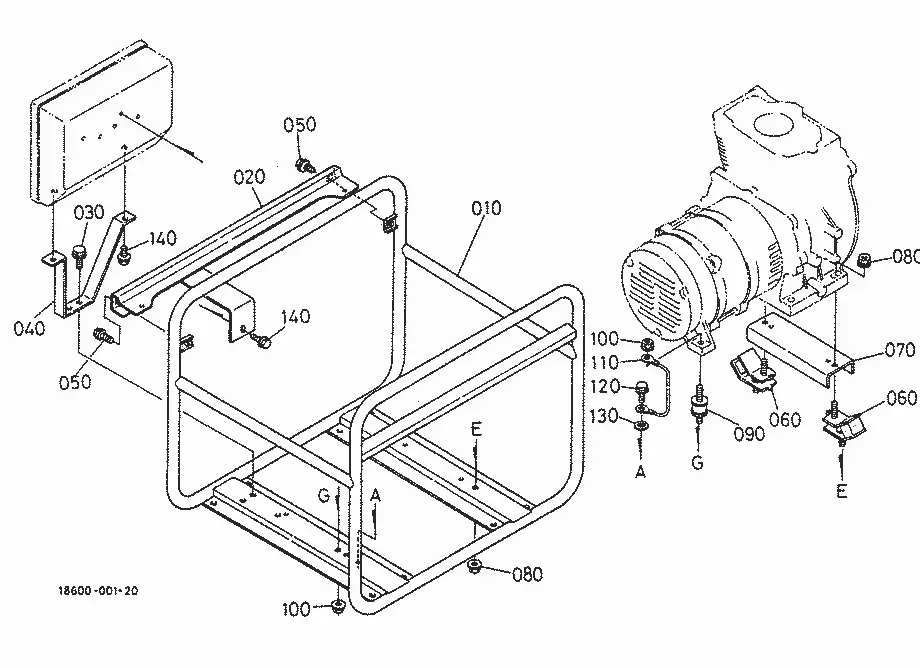

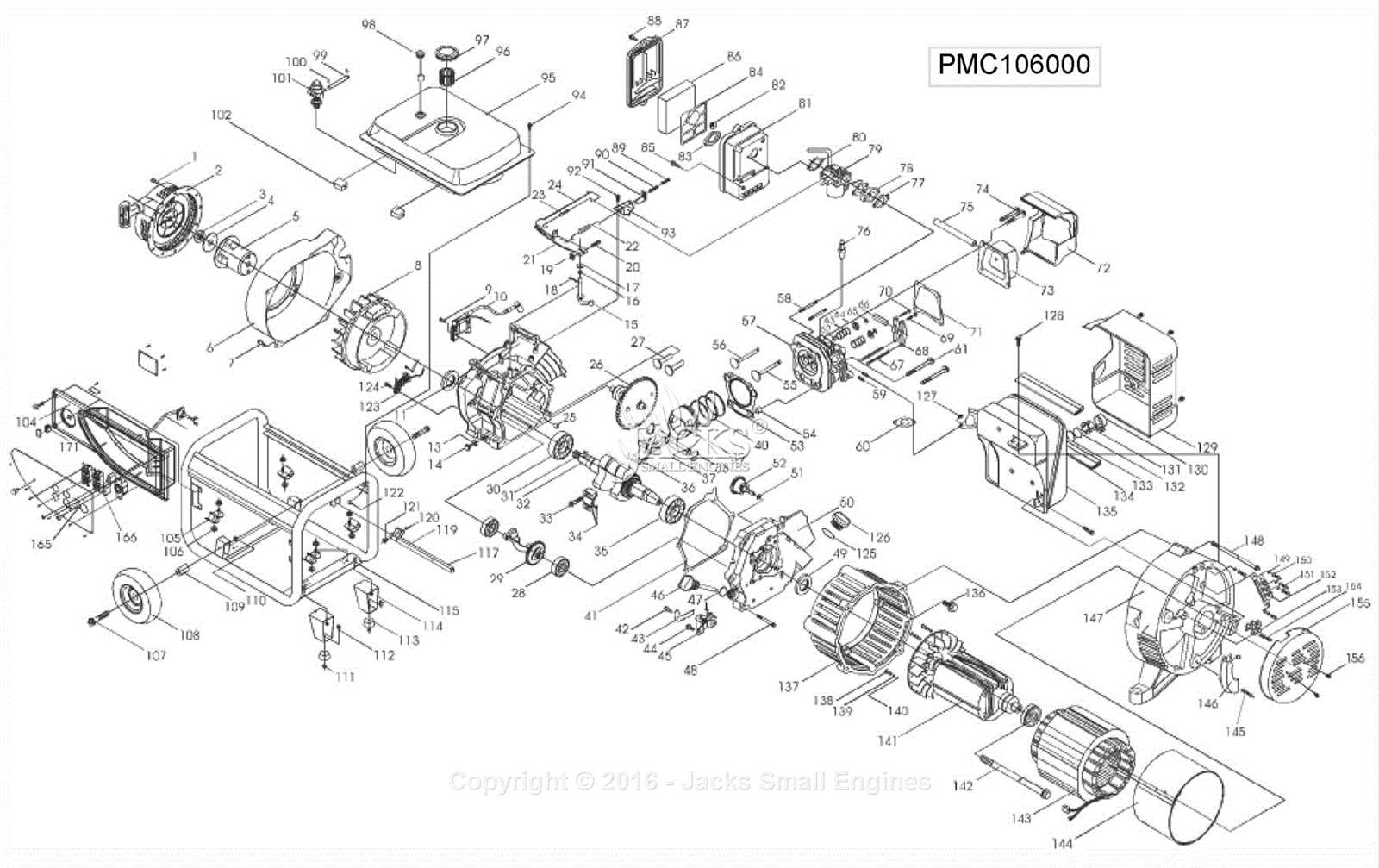

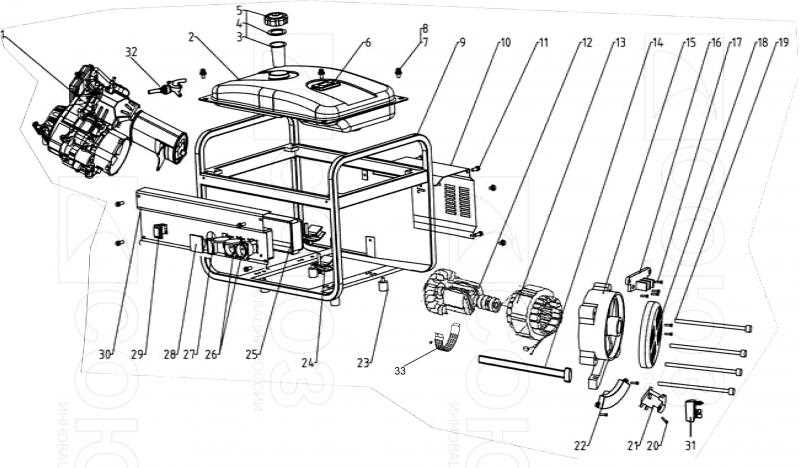

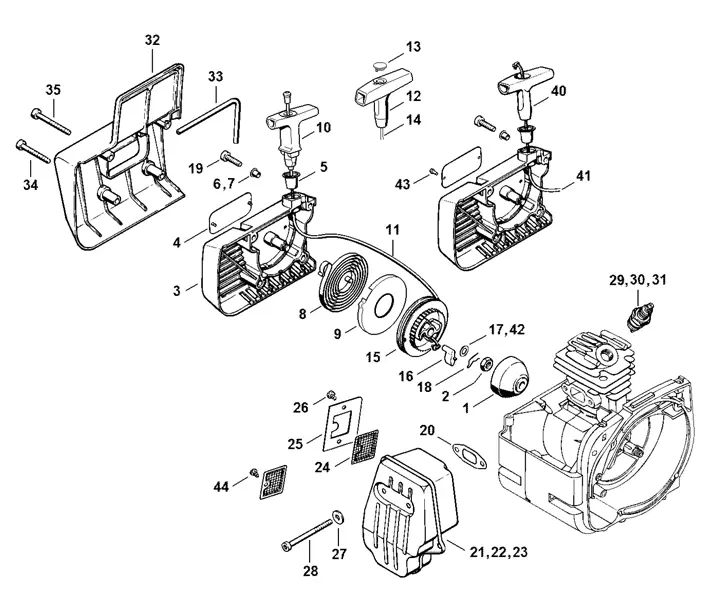

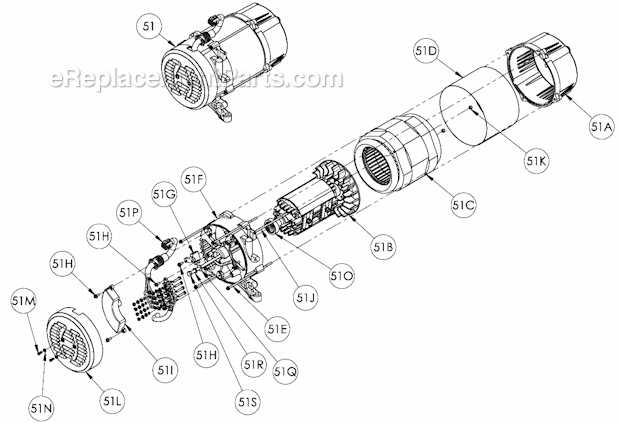

Visual aids play a pivotal role in grasping the layout of these mechanisms. They allow users to pinpoint specific sections and facilitate a smoother repair or replacement process. By familiarizing yourself with the arrangement and function of each part, you empower yourself to address potential issues proactively.

In this discussion, we will explore the intricacies involved in the various elements of a typical generator model. Highlighting the significance of each component, we aim to equip you with the knowledge necessary for optimal management and maintenance of your equipment.

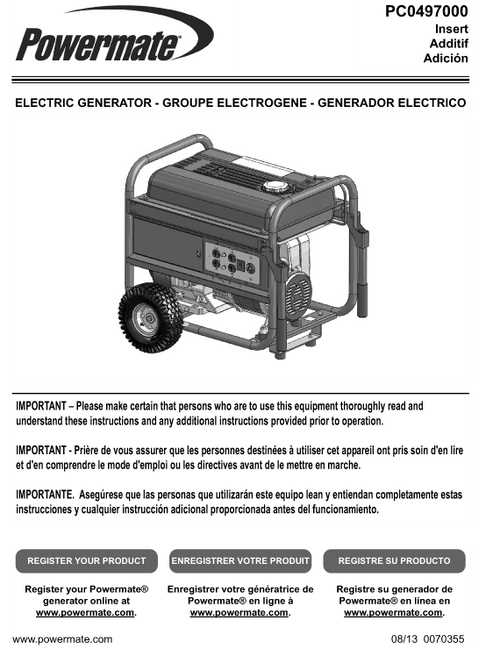

Understanding Coleman Powermate 6250

This section explores a portable power solution that caters to various energy needs. By examining its components and functionalities, users can enhance their experience and maintenance routines.

Key features include:

- Robust design for durability

- Efficient fuel consumption

- Versatile applications for both home and outdoor use

To fully appreciate this device, consider the following aspects:

- Functionality: Understand how it generates power.

- Maintenance: Learn essential care practices to ensure longevity.

- Components: Familiarize yourself with each part for better troubleshooting.

By delving into these topics, users can maximize their utility and reliability of this power generator.

Key Components of the Generator

Understanding the essential elements of a generator is crucial for effective operation and maintenance. Each part plays a significant role in the overall functionality, ensuring reliable performance and durability. Here, we will explore the primary components that contribute to the efficient generation of electrical power.

Core Parts

- Engine: The heart of the generator, responsible for converting fuel into mechanical energy.

- Alternator: This component transforms mechanical energy into electrical energy, providing the power output.

- Fuel System: Comprising the tank, pump, and lines, this system delivers fuel to the engine.

- Cooling System: Essential for maintaining optimal operating temperatures, preventing overheating.

- Exhaust System: Directs harmful gases away from the engine and user, enhancing safety.

Supporting Components

- Control Panel: Allows users to manage settings, monitor output, and ensure safe operation.

- Chassis: The framework that supports all other components, providing stability and protection.

- Wheels and Handles: Facilitate portability, making it easier to move the generator when needed.

- Battery: Supplies power for starting the engine and supporting electronic components.

Each of these parts is vital for the overall functionality of the unit, and understanding their roles can help users maintain and troubleshoot their equipment effectively.

Importance of Parts Diagrams

Visual representations of component layouts play a crucial role in understanding machinery and equipment. They offer a clear overview of individual elements, aiding users in identifying and sourcing replacements. Such illustrations enhance the maintenance process, allowing for efficient troubleshooting and repairs.

Furthermore, these visual guides serve as educational tools, empowering both novice and experienced users to familiarize themselves with the structure and functionality of various systems. By demystifying complex machinery, they promote informed decision-making and foster confidence in handling equipment.

| Benefits | Description |

|---|---|

| Clarity | Provides a straightforward view of all components involved. |

| Efficiency | Streamlines the identification of necessary replacements. |

| Education | Enhances understanding of how different elements interact. |

| Confidence | Encourages users to engage more deeply with their equipment. |

Common Issues and Solutions

When operating portable generators, users may encounter a variety of challenges that can affect performance and reliability. Understanding these common problems and their remedies can help ensure smooth operation and longevity of the equipment.

-

Engine Won’t Start:

- Check the fuel level; ensure it is filled and fresh.

- Inspect the spark plug for wear and replace if necessary.

- Examine the battery connections for corrosion or loose wires.

-

Inconsistent Power Output:

- Verify that the load is within the generator’s rated capacity.

- Inspect the circuit breaker for tripping and reset if needed.

- Clean any dirt or debris from the air filter to improve airflow.

-

Excessive Noise:

- Ensure that the generator is placed on a flat, stable surface to reduce vibrations.

- Check for loose parts or panels that may amplify sound.

- Consider using sound dampening materials or enclosures for quieter operation.

-

Fuel Leaks:

- Inspect fuel lines and connections for any signs of wear or damage.

- Replace any cracked or frayed hoses immediately.

- Ensure the fuel cap is tightly secured to prevent spills.

By addressing these common issues proactively, users can enhance the reliability and efficiency of their generators, ensuring they are ready for use when needed.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair. These visual guides provide a detailed representation of components, allowing users to identify and locate each piece easily. Familiarity with the layout enhances problem-solving and ensures that tasks are performed efficiently.

Here are some key steps to effectively interpret an assembly illustration:

- Identify the Legend: Most illustrations include a legend or key that explains symbols and markings. Familiarize yourself with this section to understand the references made in the visual.

- Study the Layout: Examine how components are arranged. This will help you visualize the assembly process and recognize how parts interact.

- Look for Numbers: Components are often numbered. Cross-reference these numbers with accompanying lists for further details, such as specifications or part names.

- Check for Exploded Views: Exploded views show parts separated by space, indicating how they fit together. This perspective can clarify assembly order and connection points.

- Note Replacements: If you’re replacing a component, verify that you have the correct item by matching it with the illustration. This prevents mistakes during repairs.

By mastering these elements, you’ll be able to navigate assembly visuals with confidence, making your repair and maintenance tasks more straightforward and successful.

Replacement Parts Availability

Ensuring the longevity and functionality of equipment often requires the acquisition of various components over time. Availability of these essential elements is crucial for users aiming to maintain optimal performance and reliability. Knowing where to find these items can significantly enhance user experience and reduce downtime.

Where to Find Components

There are several avenues to explore when searching for replacements. Local hardware stores typically carry a selection of common items, while specialized retailers may offer a broader range. Online marketplaces have also become popular, providing convenience and often competitive pricing.

Considerations for Purchasing

When looking to purchase, consider factors such as compatibility, warranty, and customer reviews. These elements can greatly influence the effectiveness and durability of the components you choose. Always ensure that you are obtaining high-quality products to guarantee the best results.

| Source | Advantages | Disadvantages |

|---|---|---|

| Local Stores | Immediate availability, no shipping costs | Limited selection, potentially higher prices |

| Online Retailers | Wide variety, competitive pricing | Shipping time, possible quality issues |

| Specialty Shops | Expert advice, specific components | Higher prices, less accessibility |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your equipment. By adhering to a few key practices, you can ensure optimal performance and durability over time. Regular maintenance not only enhances functionality but also prevents costly repairs down the line.

- Regular Inspection: Conduct frequent checks for wear and tear. Look for signs of damage or corrosion that could affect operation.

- Clean Components: Keep parts clean and free of debris. Accumulation of dirt can hinder performance and lead to overheating.

- Change Filters: Replace air and fuel filters as recommended to maintain airflow and efficiency.

- Check Fluid Levels: Regularly monitor and replenish oil and coolant levels to ensure smooth operation.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules provided in the user manual for best results.

Implementing these strategies will not only improve the functionality of your machinery but will also help you avoid unexpected breakdowns. By taking a proactive approach, you can enjoy a longer, more reliable service life.

DIY Repair vs. Professional Help

When faced with the need for repairs, individuals often find themselves weighing the options between tackling the task themselves and seeking assistance from an expert. Each approach has its own set of advantages and challenges, making it essential to consider various factors before making a decision.

DIY repairs can be a rewarding experience, offering a sense of accomplishment and cost savings. Many enthusiasts enjoy the process of learning and honing their skills while gaining a deeper understanding of the equipment. However, this route requires time, patience, and a certain level of expertise. Mistakes can lead to further damage, potentially escalating costs and prolonging the repair process.

On the other hand, professional assistance guarantees expertise and efficiency. Professionals bring years of experience and specialized knowledge, ensuring that repairs are conducted safely and correctly. This option might come at a higher price, but it can save time and provide peace of mind, particularly for complex issues that demand specific tools or technical understanding. In some cases, warranties or guarantees on the work performed can add additional value.

Ultimately, the choice between DIY repairs and professional help depends on the individual’s skills, the complexity of the task, and their comfort level with undertaking such projects. Evaluating these factors carefully can lead to a more informed and satisfactory decision.