The assembly of this particular model is a fascinating example of engineering precision and thoughtful design. Every individual element works in unison, creating a reliable and efficient machine. Understanding how these elements interact can enhance both the user’s ability to maintain the vehicle and their overall experience with it.

This section will provide a detailed look into the essential elements that make up the vehicle’s mechanical structure. By exploring the main systems, you’ll gain insight into how they contribute to the overall performance, ensuring smooth operation and long-term durability.

From the external framework to the internal mechanisms, each component plays a vital role in the vehicle’s operation. Delving into these elements will empower you with the knowledge needed for proper upkeep and enhancements.

Essential Components for Honda Ruckus

The key elements required for smooth operation and optimal performance are numerous. Understanding these crucial parts ensures reliable function and ease of maintenance for the vehicle. Below is a detailed list of the fundamental units that play an integral role in the mechanics and usability.

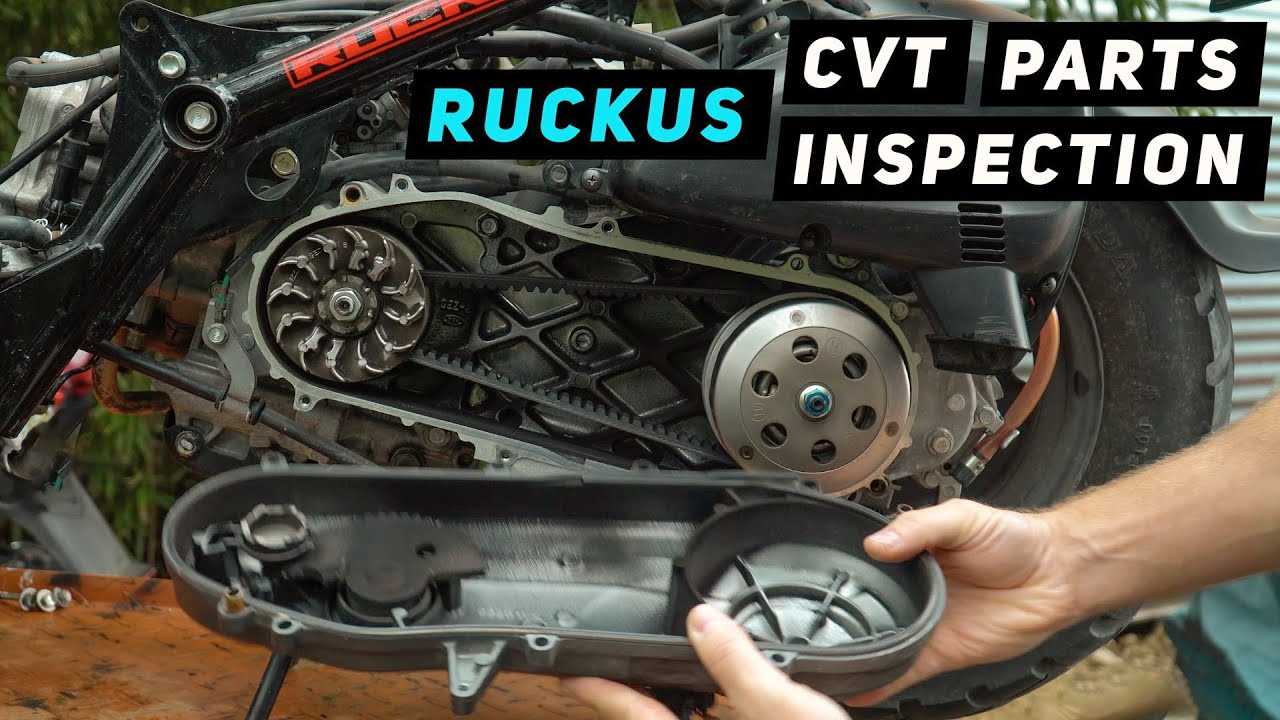

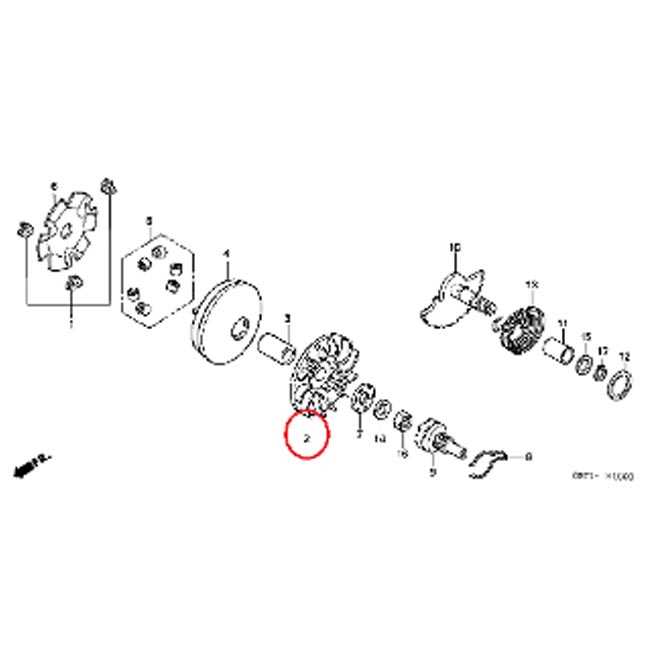

- Engine Unit: The core system responsible for generating power and controlling overall movement. It consists of multiple subcomponents that work together to ensure efficient operation.

- Suspension Mechanism: A vital structure that improves comfort and stability, ensuring smooth rides over various terrains.

- Electrical System: This includes the ignition, lights, and other electrical features that provide safety and ease of use during operation.

- Brake System: A necessary safety feature, allowing for controlled stopping and handling in all conditions.

- Fuel Delivery System: Supplies the engine with the required fuel, ensuring steady and reliable performance.

- Frame and Body Structure: The supporting skeleton that holds the entire vehicle together, providing durability and strength.

Each component contributes to the vehicle’s overall performance and longevity, making proper maintenance essential for continued reliability and efficiency.

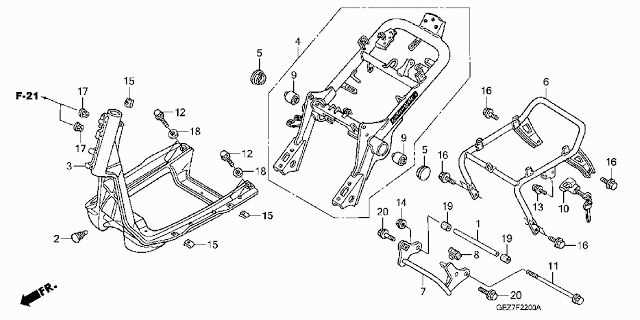

Exploring the Scooter’s Frame Structure

The design of the scooter’s frame plays a pivotal role in its overall performance and durability. The frame provides the foundational structure that supports both the rider and the various components, ensuring stability and balance during movement. A well-engineered frame is crucial for withstanding the stresses of everyday use and maintaining structural integrity over time.

Key aspects of the frame’s structure include its lightweight construction, which contributes to fuel efficiency and agility, while still offering the necessary strength. By using materials that combine flexibility and rigidity, manufacturers create a balance that enhances the scooter’s ride comfort and control, making it suitable for both urban and rural environments.

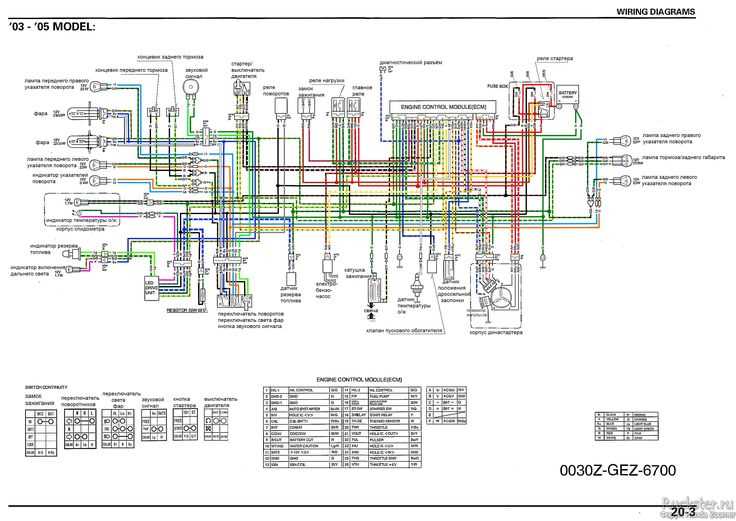

Understanding the Electrical System Layout

The electrical system is a complex network of interconnected components designed to ensure the proper functioning of various features. It manages power distribution and regulates the flow of current, allowing each element to operate efficiently. By grasping the overall structure, one can more easily diagnose issues or perform maintenance when necessary.

Main Components and Their Functions

This system typically includes several key elements that play specific roles in ensuring consistent operation. These components work in tandem to provide power to the necessary parts of the vehicle, enabling smooth functionality and safety. Below is a basic overview of the critical components involved:

| Component | Function |

|---|---|

| Battery | Stores and supplies electrical energy to start the engine and power electrical devices. |

| Fuse Box | Protects the system by preventing overloads and short circuits. |

| Wiring Harness | Connects various parts of the system, ensuring that electricity flows where it’s needed. |

| Ignition Switch | Activates the engine’s electrical system and allows the vehicle to start. |

Troubleshooting Common Electrical Issues

Understanding the layout of

Brake System Parts and Maintenance

The braking mechanism is essential for ensuring a safe and controlled ride. Proper care and attention to its components are necessary for optimal performance. Regular inspections and timely replacements are key to avoiding potential issues and maintaining the efficiency of the system.

- Brake Pads: These should be inspected regularly for wear and replaced when necessary to ensure effective stopping power.

- Brake Levers: It’s important to check the levers for smooth operation, making sure they aren’t stiff or difficult to engage.

- Brake Cables: Ensure cables are not frayed or corroded. Lubricate them periodically to maintain smooth performance.

- Fluid Levels (for hydraulic systems): Regularly check and refill the brake fluid, ensuring there are no leaks or contamination in the system.

- Brake Rotors: Examine the rotors for any signs of warping or uneven wear, which can affect braking efficiency.

By staying vigilant and performing these routine checks, the brake system can continue to operate reliably, offering safety and confidence during every ride.

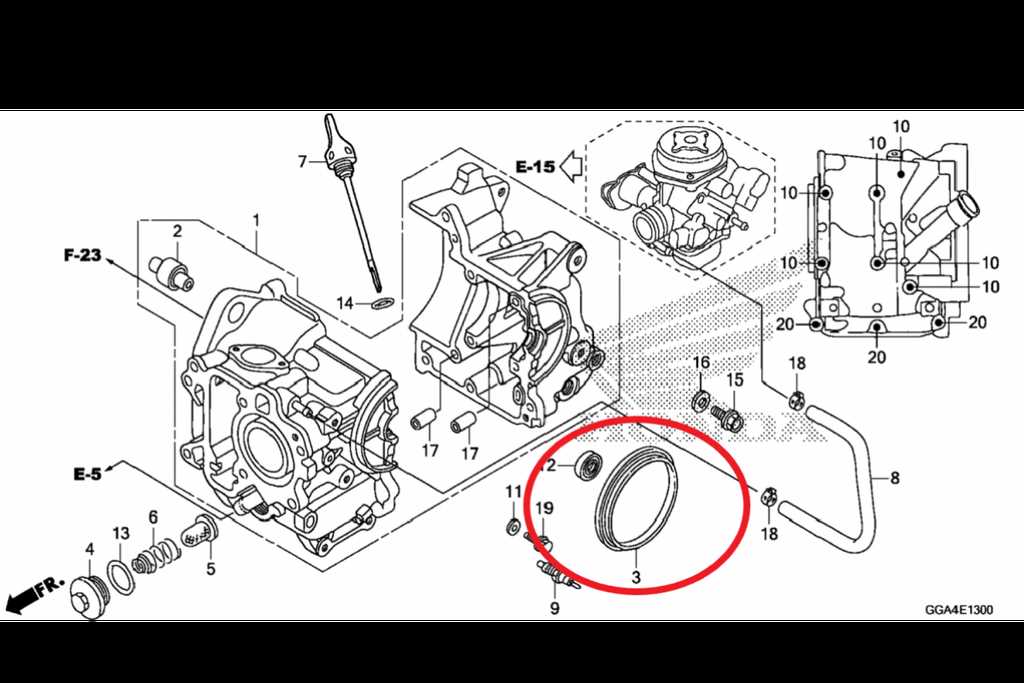

Fuel Line and Tank Configuration

The fuel system plays a crucial role in ensuring the proper flow of fuel from the storage container to the engine. Understanding how these components are arranged helps maintain efficient engine performance. This section provides a breakdown of the key elements involved in the connection and movement of fuel, focusing on the tubing and container setup.

Fuel Line Layout

The fuel line is responsible for transporting the liquid from the container to the engine. It typically consists of a flexible tube that connects the various elements in the system. A properly installed line ensures minimal leakage and maximizes efficiency in delivery. It is important to check the connection points regularly for wear and tear.

- Ensure all connections are secure.

- Inspect for cracks or damage in the tubing.

- Use clamps to hold the line in place.

Tank Positioning and Maintenance

The fuel container’s position plays a vital role in how effectively the fuel flows through the system. A properly mounted container allows for smooth delivery and prevents blockages or uneven fuel distribution. Regular maintenance and cleaning of the container ensure a longer lifespan and reduce potential contamination of the fuel.

Detailed Overview of the Suspension Setup

The suspension system plays a crucial role in ensuring a smooth ride and maintaining stability in various driving conditions. This setup consists of several components that work together to absorb shocks, support the weight of the vehicle, and enhance overall performance. Understanding how each element contributes to the system can help enthusiasts appreciate the intricacies involved in designing a robust suspension.

Key Components of the Suspension System

At the heart of the suspension setup are the shock absorbers and springs, which work in tandem to mitigate impacts from uneven surfaces. Shock absorbers control the oscillation of the springs, preventing excessive bouncing and ensuring the wheels remain in contact with the ground. The springs, on the other hand, support the weight of the vehicle while providing flexibility to absorb shocks effectively. Together, they create a balanced system that enhances both comfort and control.

Importance of Proper Alignment

Proper alignment is vital for the suspension system’s efficiency. Misalignment can lead to uneven tire wear, reduced handling capabilities, and an overall compromised driving experience. Regular inspections and adjustments are necessary to maintain optimal performance, ensuring that the components function harmoniously and provide the desired stability and responsiveness.

Handlebars and Steering Mechanism

The handlebars and steering assembly play a crucial role in controlling the movement and direction of the vehicle. This component not only provides stability but also enhances the overall riding experience, allowing for precision and comfort while navigating various terrains.

Components of the Steering System

- Handlebars: The primary interface between the rider and the vehicle, allowing for directional control.

- Stem: Connects the handlebars to the front fork, enabling adjustments in height and angle.

- Throttle Control: Located on the handlebars, it regulates the engine’s power output, affecting speed and acceleration.

- Front Fork: Supports the front wheel and absorbs shocks, ensuring a smoother ride.

- Steering Head: The pivot point for the front fork, crucial for maneuverability.

Maintenance Tips

- Regularly inspect the handlebars for any signs of wear or damage.

- Ensure the throttle control operates smoothly without sticking.

- Check the tightness of the stem and steering head to prevent wobbling.

- Lubricate moving parts as needed to maintain responsiveness.

- Consult a professional if you experience any unusual steering behavior.

Tires, Wheels, and Axle Components

The connection between the ground and the vehicle relies heavily on the assembly of wheels, tires, and axle elements. These components not only provide stability but also significantly impact the handling and performance of the ride. Understanding their structure and functionality is crucial for maintaining optimal operation.

Tire Specifications

Tires are designed to deliver traction and absorb shocks, enhancing the comfort of the journey. The choice of tire dimensions, tread patterns, and rubber composition directly influences grip and durability. Regular checks for wear and proper inflation are essential for safety and efficiency.

Wheel Construction

The wheels serve as the foundation for mounting the tires and must be robust enough to withstand various driving conditions. Constructed from materials like aluminum or steel, they come in different sizes and designs to accommodate various performance needs. Regular inspection for damage and corrosion ensures longevity and reliability.

Exhaust System and Air Intake Design

The efficiency of any engine is greatly influenced by the design of its exhaust and air intake systems. These components work in tandem to optimize airflow, enhance performance, and improve fuel efficiency. A well-designed exhaust system reduces back pressure, allowing for smoother expulsion of gases, while an effective air intake system ensures that the engine receives the right amount of air for combustion. This balance is crucial for achieving maximum power output and overall performance.

Understanding the intricacies of these systems can help enthusiasts make informed decisions when modifying or repairing their vehicles. Below is a comparison of common features found in exhaust and air intake systems.

| Component | Function | Benefits |

|---|---|---|

| Exhaust Header | Collects exhaust gases from the engine cylinders | Reduces back pressure, improves horsepower |

| Catalytic Converter | Converts harmful gases into less harmful emissions | Meets environmental regulations, enhances exhaust flow |

| Muffler | Reduces noise from the exhaust | Enhances comfort, can improve performance |

| Intake Manifold | Distributes air to the engine cylinders | Promotes efficient air distribution, increases power |

| Air Filter | Filters dust and debris from incoming air | Protects the engine, maintains performance |