In the realm of agricultural equipment, having a comprehensive grasp of various machinery components is crucial for optimal performance and maintenance. Each machine consists of numerous elements that work together seamlessly to enhance efficiency and functionality. By delving into the intricacies of these components, users can ensure their equipment operates at peak levels.

Visual aids play a significant role in this exploration, providing clear representations of how different elements interconnect. Such illustrations facilitate better understanding and enable users to identify specific parts easily. Recognizing the relationships among these components is essential for effective troubleshooting and repairs.

Whether you are a seasoned operator or a newcomer to the world of farming machinery, familiarizing yourself with the essential features of your equipment can lead to improved upkeep and longevity. Gaining insight into these integral parts empowers users to make informed decisions, ultimately enhancing productivity and reducing downtime.

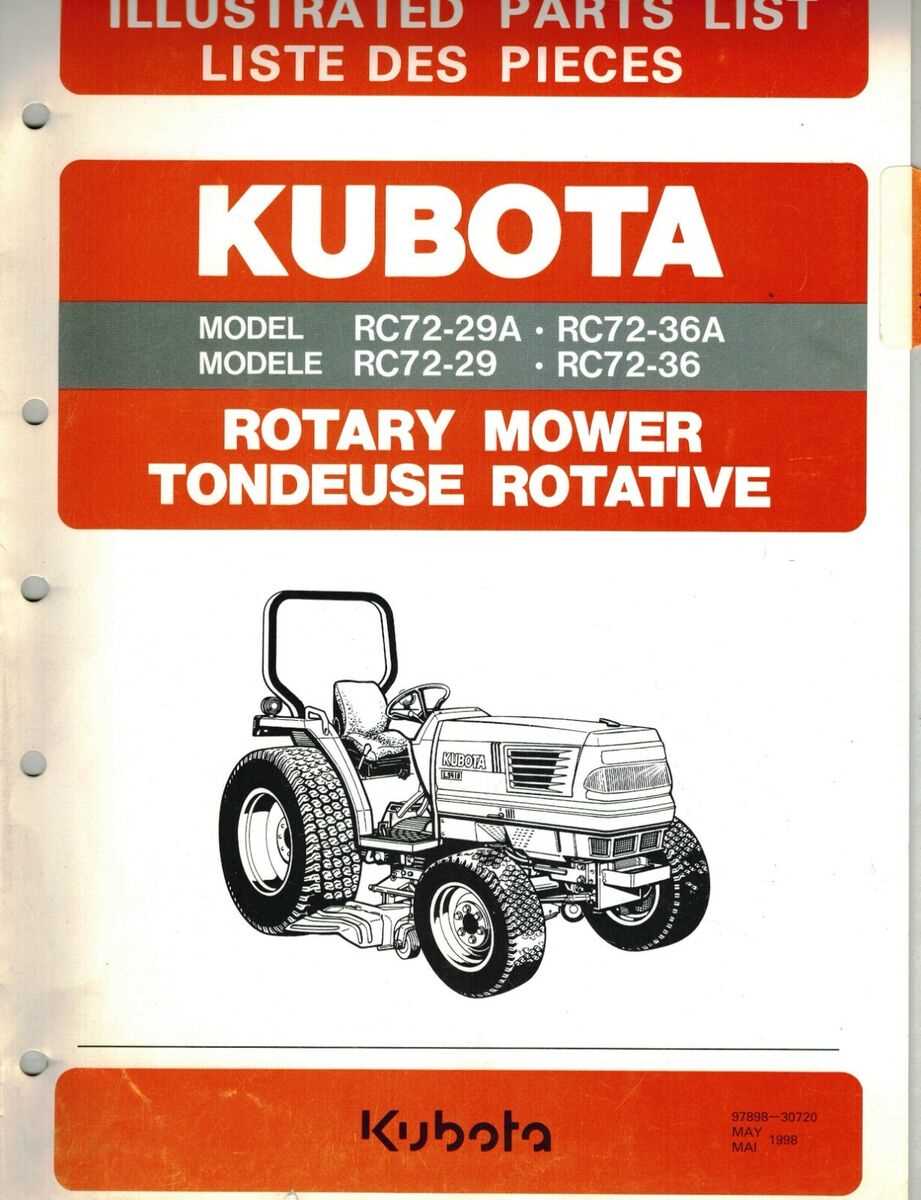

This section aims to provide a comprehensive overview of a specific agricultural machinery model, highlighting its key features and capabilities. Understanding the essential components and their functions can enhance the user experience and maintenance practices, ensuring optimal performance.

Key Features of the Machinery

- Powerful engine specifications

- Versatile attachments for various tasks

- Durability and reliability in tough conditions

Applications in Agriculture

The discussed model is widely utilized in various agricultural activities, including:

- Tilling and plowing fields

- Transporting materials and crops

- Performing landscaping tasks

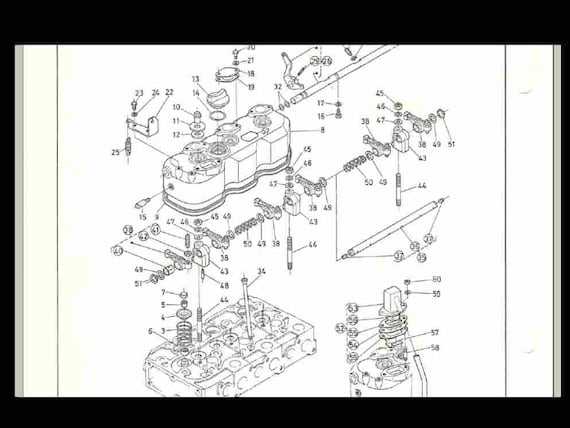

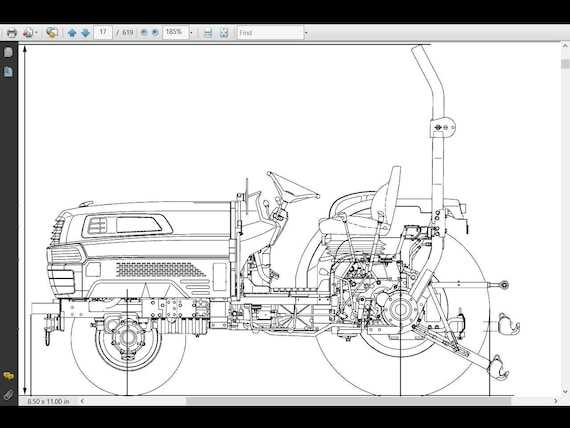

Understanding Component Layout

A clear understanding of the arrangement of essential components helps users navigate maintenance and repairs. Key elements include:

- Engine assembly

- Transmission system

- Hydraulic components

Maintenance Tips for Optimal Performance

Regular maintenance ensures longevity and efficiency. Key practices include:

- Regular oil changes

- Inspection of hydraulic systems

- Cleaning air filters and cooling systems

Common Issues and Troubleshooting

Users may encounter various challenges. Common issues include:

- Engine starting difficulties

- Hydraulic system failures

- Uneven performance in attachments

Replacement Recommendations

When components wear out, timely replacements are vital. Recommended replacements include:

- Fuel filters

- Belt systems

- Seals and gaskets

Finding Reliable Sources for Components

Locating trustworthy suppliers for replacement parts is essential for maintenance. Consider the following sources:

- Authorized dealers

- Online marketplaces with customer reviews

- Local agricultural supply stores

Conclusion and Future Considerations

Understanding the layout and functions of various components enhances the user experience. Continuous learning and staying informed about new technologies can further improve efficiency and productivity in agricultural practices.

Key Components of L2900

This section delves into the essential elements of a compact utility tractor, highlighting the main features that contribute to its functionality and efficiency. Understanding these components is crucial for anyone looking to maintain or operate this type of machinery effectively.

Major Elements

The utility vehicle consists of various vital components that work in harmony to deliver optimal performance. Each part plays a specific role in ensuring smooth operation and durability.

| Component | Description |

|---|---|

| Engine | Drives the machine and powers all attachments. |

| Transmission | Transmits power from the engine to the wheels, allowing for speed control. |

| Hydraulic System | Powers attachments and enhances maneuverability. |

| Chassis | Provides structural integrity and supports all components. |

| Wheels and Tires | Facilitate movement and traction on various terrains. |

Additional Features

Beyond the major components, there are numerous additional features that enhance the versatility of the tractor. Understanding these aspects can help operators utilize the machine to its fullest potential.

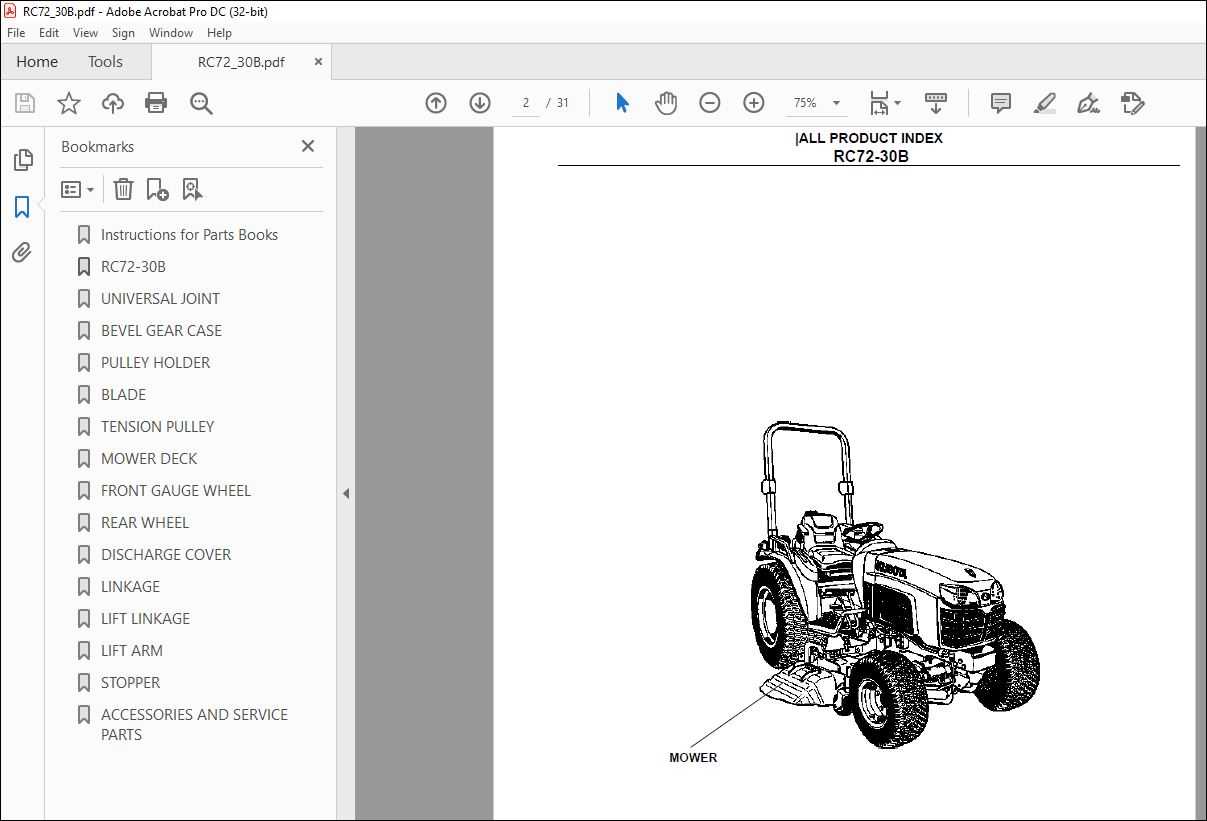

Understanding Parts Diagrams

Grasping the visual representations of machinery components is essential for effective maintenance and repair. These illustrations serve as invaluable resources, providing a clear overview of how different elements fit together and function within a larger assembly. By interpreting these visuals, users can identify specific components and understand their roles in the overall operation.

Benefits of Visual Representation

Visual aids significantly enhance comprehension, especially for complex systems. They allow users to quickly locate individual elements and understand their interrelationships, facilitating smoother disassembly and reassembly processes. Furthermore, these resources can aid in identifying compatible components and accessories, ensuring proper replacements during service.

Reading and Interpreting Illustrations

To effectively read these illustrations, one must familiarize themselves with common symbols and notations used in the industry. Understanding these conventions enables a clearer understanding of how each part interacts within the assembly. It is also beneficial to consult accompanying documentation that explains specific elements and their functions in greater detail.

Common Issues with L2900 Parts

Understanding the frequent complications that arise with agricultural machinery components is essential for maintaining optimal performance. Many users encounter similar challenges, which can affect efficiency and productivity. This section will explore typical problems faced by operators and provide insights into troubleshooting these issues effectively.

Mechanical Failures

Mechanical breakdowns can lead to significant downtime. Components such as the transmission or hydraulic systems are often susceptible to wear and tear, resulting in reduced functionality. Regular maintenance and inspections can help identify potential failures before they escalate.

Wear and Tear of Components

Over time, the natural degradation of essential elements can lead to decreased performance. Components that experience high levels of stress may need replacement or servicing. Keeping track of operational hours and conducting routine checks can mitigate these issues.

| Common Issues | Symptoms | Suggested Actions |

|---|---|---|

| Transmission Slipping | Inconsistent power delivery | Check fluid levels and inspect for leaks |

| Hydraulic Fluid Leaks | Visible fluid under the machine | Inspect hoses and seals for damage |

| Engine Overheating | High temperature readings | Check coolant levels and radiator function |

| Worn Tires | Poor traction and handling | Inspect tread depth and consider replacement |

Maintenance Tips for L2900

Proper upkeep is essential for ensuring the longevity and efficient operation of your agricultural machinery. Regular maintenance not only enhances performance but also helps to prevent costly repairs down the line. Below are some practical recommendations to keep your equipment in optimal condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 100 hours of operation | Use high-quality oil suitable for your engine type. |

| Filter Replacement | Every 200 hours | Replace air, fuel, and hydraulic filters to ensure clean operation. |

| Tire Inspection | Monthly | Check for proper inflation and tread wear to maintain traction. |

| Battery Maintenance | Quarterly | Clean terminals and check fluid levels to prevent corrosion. |

| Greasing | Every 50 hours | Lubricate pivot points and joints to reduce wear and tear. |

Implementing these tips will significantly contribute to the overall efficiency and lifespan of your machinery. Staying proactive with maintenance ensures smooth operation and minimizes unexpected downtimes.

Where to Find Replacement Parts

Locating components for agricultural machinery can be a crucial task for maintaining optimal performance. Whether you are looking for specific elements or complete assemblies, several reliable sources can assist you in acquiring the necessary items for your equipment.

Authorized Dealers and Distributors

One of the most trustworthy options is to seek out authorized dealers and distributors. These establishments often stock genuine items that ensure compatibility and durability. By visiting their websites or physical locations, you can access a wide range of offerings tailored to your machinery’s requirements.

Online Marketplaces

In addition to local dealers, numerous online marketplaces provide an extensive selection of components. Platforms such as e-commerce websites allow users to compare prices and read reviews, ensuring you make informed decisions. Always check seller ratings and return policies to safeguard your purchase.

Upgrades for Enhanced Performance

Improving machinery efficiency can significantly enhance overall productivity. By implementing certain enhancements, operators can achieve better functionality, increased durability, and optimized performance. This section explores various upgrade options that can elevate the capabilities of agricultural equipment, ensuring they meet the demands of modern operations.

Engine Modifications

Upgrading the engine can yield substantial benefits in power and fuel efficiency. Consider the following modifications:

| Upgrade | Benefits |

|---|---|

| Performance Chip | Enhances power output and torque. |

| Air Intake System | Improves airflow for better combustion. |

| Exhaust System | Reduces back pressure, increasing engine efficiency. |

Hydraulic System Enhancements

Optimizing the hydraulic system is essential for improved lifting capabilities and responsiveness. Consider these enhancements:

| Upgrade | Benefits |

|---|---|

| High-Flow Hydraulic Pumps | Increases flow rate, enhancing implement performance. |

| Advanced Control Valves | Improves precision in operation and control. |

| Hydraulic Cylinders | Boosts lifting capacity and speed. |

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures for assembling and disassembling machinery components. Understanding the correct methods ensures efficient operation and prolongs the lifespan of the equipment. By following the outlined steps, users can achieve optimal results while minimizing the risk of damage.

Preparation Steps

Before initiating the assembly or disassembly process, it is essential to gather all necessary tools and safety equipment. Ensure that the workspace is clean and organized to facilitate smooth operations. Additionally, consult the service manual for any specific instructions relevant to the machinery in question.

Disassembly Process

Begin by carefully removing any external coverings and components that may obstruct access to the internal parts. Take note of the order in which parts are removed, as this will assist in the reassembly process. Employ caution when handling delicate components, and utilize appropriate lifting techniques to prevent injury or damage.

Resources for L2900 Owners

For individuals owning this specific model of agricultural machinery, accessing reliable information and support is crucial for maintenance and operation. Various resources are available to enhance the ownership experience, including manuals, online forums, and local dealer services.

Owners can benefit from comprehensive guides that offer insights into maintenance schedules, troubleshooting techniques, and operational tips. Additionally, engaging with community forums allows users to share experiences and gain advice from fellow enthusiasts, creating a supportive network.

Local dealerships often provide valuable resources, including workshops and parts availability, ensuring that owners have access to expert assistance when needed. Online platforms can also serve as a repository for manuals and instructional videos, further enhancing the owner’s ability to manage their equipment efficiently.