In the realm of mechanical systems, comprehending the layout and function of individual elements is crucial for effective operation and maintenance. Each component plays a vital role, contributing to the overall efficiency and reliability of the entire setup. A thorough grasp of these elements allows users to troubleshoot and optimize performance seamlessly.

Visual representations serve as invaluable tools, providing insight into how each piece interconnects and operates within the broader framework. These schematics not only enhance understanding but also facilitate the identification of potential issues before they escalate. By examining these layouts, one can delve deeper into the mechanics at play.

Ultimately, recognizing the significance of each segment empowers users to make informed decisions regarding repairs and upgrades. With this knowledge, the path to maintaining optimal functionality becomes clearer, ensuring long-term success in operational endeavors.

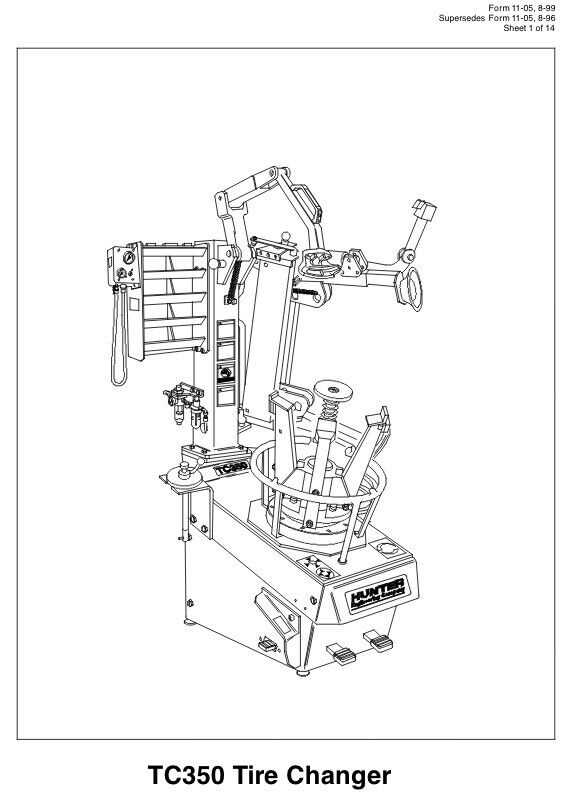

Understanding Mayflower Tire Machines

Exploring the mechanics behind equipment designed for wheel handling reveals a fascinating world of engineering and innovation. These devices are crucial for the efficient management of various tasks, ensuring safety and precision in every operation.

Key Features and Benefits

- Enhanced Efficiency: Streamlined processes lead to quicker turnaround times.

- Safety Mechanisms: Built-in safeguards protect operators and equipment.

- User-Friendly Interface: Intuitive controls simplify operation for users.

- Durability: Robust construction ensures long-lasting performance.

Components to Know

- Framework: Provides structural integrity and support.

- Clamping Systems: Securely hold objects in place during use.

- Hydraulic Units: Facilitate smooth and powerful movements.

- Control Panels: Allow operators to manage functions effortlessly.

Key Components of Tire Machines

In order to ensure the smooth and efficient operation of equipment used for wheel servicing, it is essential to understand the various core elements involved. Each of these components plays a significant role in maintaining performance, accuracy, and durability. Below, we will explore the crucial components that make up the functioning of such devices.

Rotating Mechanism

The rotating mechanism is the heart of the apparatus, responsible for providing the necessary motion to handle and manipulate the wheel. This feature enables the device to spin the wheel and assists in a range of tasks, from mounting to dismounting.

- Motor: Drives the rotation and provides the necessary torque.

- Spindle: Supports and holds the wheel securely in place during the operation.

- Bearings: Allow smooth rotation by reducing friction between moving parts.

Tooling and Adjustment System

Tooling and adjustment elements enable the operator to apply precision when working with wheels. These systems ensure that the wheels are properly aligned and fitted while performing necessary adjustments during servicing.

- Bead Breaker: A tool that separates the wheel from the rubber, allowing for easy dismounting.

- Mounting Head: Positions and fits the tire accurately onto the rim.

- Control Console: Allows the operator to adjust settings, speed, and other operational aspects.

Understanding these components ensures that every step in wheel servicing can be performed efficiently and accurately, prolonging the lifespan of both the equipment and the wheels themselves.

Importance of Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficient functioning of any complex system. Without proper attention, even the most advanced equipment may suffer from reduced performance, unexpected malfunctions, and costly breakdowns. Following a structured maintenance schedule allows for the early detection of issues and minimizes the risk of major failures, saving both time and resources in the long run.

Prolonging Equipment Life

Systematic maintenance directly contributes to extending the operational lifespan of components. When individual elements are routinely inspected and serviced, their wear and tear can be managed more effectively. This proactive approach reduces the likelihood of premature replacements and helps maintain optimal performance levels over an extended period.

Minimizing Downtime

Adhering to maintenance procedures not only prevents costly repairs but also ensures minimal disruptions in daily operations. Scheduled checks and repairs allow for timely interventions that keep the equipment running smoothly, avoiding unexpected halts. In industries where downtime can lead to significant financial losses, this aspect becomes especially crucial.

In conclusion, maintaining a regular maintenance routine is vital for any system to operate at peak efficiency and remain functional over the long term. It reduces repair costs, improves performance, and ensures that equipment operates without interruptions, making it an indispensable part of any operational strategy.

Common Issues with Tire Machines

In the world of wheel service equipment, malfunctioning tools can disrupt workflow and lead to operational inefficiencies. Regular maintenance and proper usage are essential to avoid frequent breakdowns. While these devices are generally reliable, certain recurring issues can impede their functionality, affecting performance and longevity. Understanding and identifying these problems early can help prevent costly repairs and ensure smooth operation.

Typical Problems Encountered

Several factors contribute to equipment failures, with some issues being more common than others. Over time, wear and tear, improper calibration, or operator errors can lead to disruptions in the work process. Often, issues can arise from specific components that may become misaligned, worn out, or damaged due to regular use or inadequate care.

| Issue | Description | Possible Causes |

|---|---|---|

| Unresponsive controls | Difficulty in activating the device or adjusting settings | Faulty wiring, damaged control panel, or electrical malfunction |

| Excessive noise | Abnormal sounds during operation | Lack of lubrication, worn bearings, or misaligned components |

| Improper alignment | Difficulty in ensuring correct positioning of components | Out of calibration or worn-out alignment guides |

| Slow operation | Inconsistent or delayed movement of mechanical elements | Low air pressure, faulty motors, or lack of maintenance |

Prevention and Maintenance

To minimize the occurrence of these problems, regular inspection and maintenance are crucial. Keeping all mechanical parts lubricated and calibrating the equipment periodically ensures optimal performance. Additionally, addressing minor issues promptly can prevent more significant malfunctions from developing, saving both time and money in the long run.

Choosing Quality Replacement Parts

Selecting superior components for your equipment is crucial for maintaining optimal performance and longevity. Quality alternatives can significantly influence the efficiency and reliability of your machinery. Here are key considerations when making your choice:

- Material Quality: Ensure that the materials used are durable and can withstand operational stresses.

- Compatibility: Verify that the components match the specifications of your existing setup to avoid functionality issues.

- Manufacturer Reputation: Research brands known for their reliability and customer satisfaction.

- Warranty and Support: Look for options that offer warranties and customer service for added peace of mind.

Additionally, always compare prices, but avoid compromising on quality for cost savings. Investing in high-grade replacements often leads to better long-term value and performance.

- Read reviews from other users.

- Consult professionals or technicians for recommendations.

- Purchase from authorized dealers or trusted suppliers.

By following these guidelines, you can ensure that your replacements will enhance the overall functionality and lifespan of your equipment.

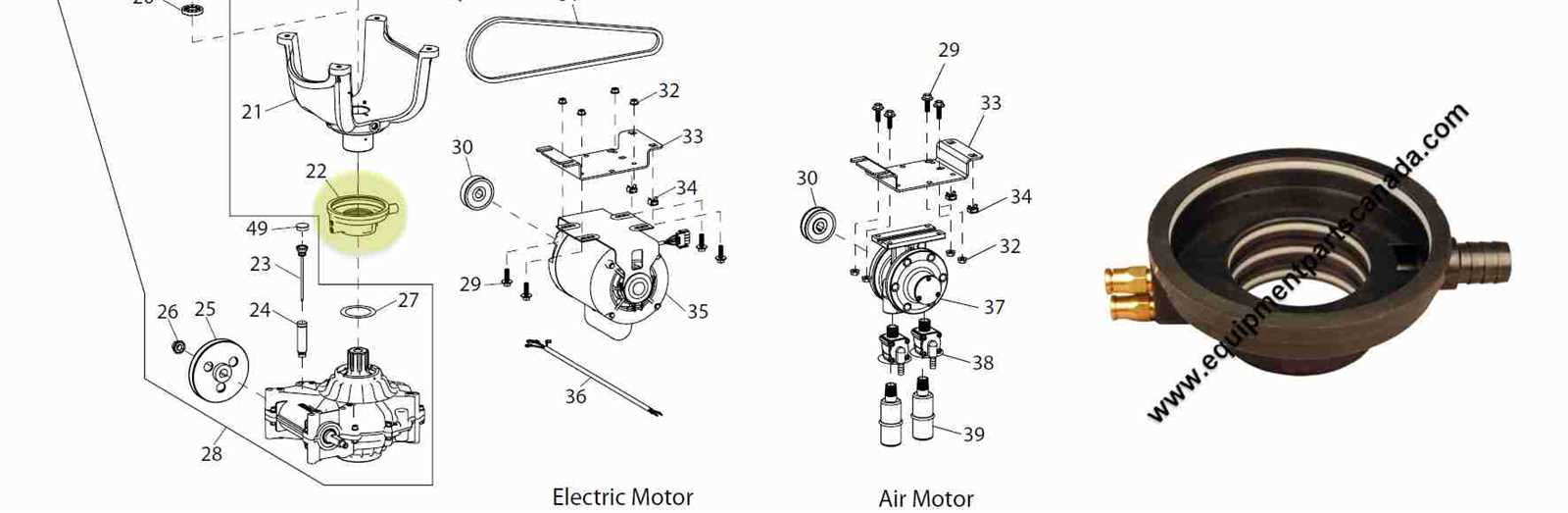

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective assembly and maintenance. These visual representations serve as guides, helping users identify components and their relationships within a system. Familiarizing yourself with the symbols and layout will enhance your ability to interpret the information accurately.

Start by noting the key legend that explains symbols used throughout the illustration. Each icon typically represents a specific element, so understanding this will clarify your reading process. Next, observe the organization of the components, which may be grouped by function or assembly sequence, aiding in a logical approach to troubleshooting or construction.

Pay attention to the numbers or labels next to each component. These references correlate with lists or catalogs that provide detailed specifications, making it easier to find exact replacements or related items. Cross-referencing these details is crucial for ensuring compatibility and accuracy.

Finally, practice analyzing various representations to build familiarity. The more you engage with these resources, the more proficient you will become at deciphering complex illustrations and ensuring successful project outcomes.

Benefits of Upgrading Machinery

Enhancing equipment can lead to significant improvements in efficiency, productivity, and overall performance. By investing in modern technology, businesses can ensure they remain competitive and meet the evolving demands of the industry.

| Benefit | Description |

|---|---|

| Increased Efficiency | Newer equipment often operates faster and with fewer errors, allowing for higher output. |

| Cost Savings | Up-to-date technology can reduce maintenance costs and energy consumption. |

| Enhanced Safety | Modern machinery is designed with advanced safety features to protect operators. |

| Improved Quality | Upgraded equipment can deliver higher precision, leading to superior end products. |

| Flexibility | Advanced systems can often be adapted to different tasks, increasing versatility. |

Essential Tools for Tire Repair

Repairing wheels requires a set of fundamental instruments to ensure safety and efficiency. Having the right tools at hand can make the difference between a quick fix and a lengthy process, enhancing both effectiveness and user experience.

Air Compressor: This is vital for inflating and testing pressure levels. A reliable compressor helps maintain optimal conditions.

Patch Kit: A comprehensive kit usually includes various sizes of patches, adhesives, and application tools, providing a versatile solution for different damages.

Leverage Bar: This tool is essential for removing and installing the rubber securely. Its design allows for easy manipulation without damaging the surrounding structure.

Rim Protector: To prevent scratches and dents while working, using rim protectors ensures that surfaces remain intact during repairs.

Valve Stem Tool: This handy instrument simplifies the process of replacing or adjusting valve stems, ensuring proper sealing and function.

Tread Depth Gauge: Monitoring tread wear is crucial for safety. A gauge allows for precise measurement, helping to determine when replacement is necessary.

Equipped with these instruments, anyone can approach wheel maintenance confidently and effectively, leading to safer journeys ahead.

Future Trends in Tire Technology

The evolution of rubber components is set to undergo significant advancements driven by innovation and sustainability. As the automotive landscape changes, the focus shifts towards enhancing performance, safety, and environmental impact through cutting-edge materials and designs.

Emerging trends indicate a growing emphasis on smart technologies integrated within these products. This integration aims to improve real-time monitoring and feedback, enhancing overall performance and safety for users. Furthermore, sustainable practices are becoming paramount, with manufacturers exploring eco-friendly materials and production methods that minimize waste and energy consumption.

| Trend | Description |

|---|---|

| Smart Integration | Real-time data collection for performance monitoring and safety enhancements. |

| Sustainable Materials | Use of eco-friendly materials to reduce environmental impact during production. |

| Advanced Design | Innovative shapes and patterns for improved grip and efficiency. |

| Recyclability | Development of products that can be easily recycled at the end of their life cycle. |

These advancements not only promise to elevate the functionality and safety of these essential components but also align with the global push towards sustainability and efficiency in transportation.