Maintaining the efficiency of your outdoor equipment requires a clear understanding of its individual components. Every machine is built with specific elements that contribute to its overall functionality, and knowing these parts can significantly enhance performance and longevity. This guide aims to provide insight into the structure of your device, helping you identify and troubleshoot issues effectively.

Each segment of the apparatus plays a vital role in its operation, from the power source to the cutting mechanisms. Familiarity with these components not only aids in maintenance but also empowers users to make informed decisions regarding repairs and upgrades. By breaking down the assembly into manageable sections, you can easily navigate through potential challenges.

Moreover, understanding the layout and function of each element can facilitate smoother repairs and replacements, saving time and resources. This resource will offer a comprehensive overview, ensuring you are well-equipped to handle your machinery with confidence and precision.

Understanding Huskee Lawn Mowers

This section provides insight into a popular brand known for its robust outdoor equipment. Users often seek reliability and efficiency in their machinery, aiming for a smooth experience in maintaining their green spaces. Familiarizing oneself with the features and maintenance requirements can significantly enhance performance and longevity.

Key Features

One of the standout attributes of this equipment is its user-friendly design. Many models incorporate innovative technology that ensures optimal cutting precision. The blend of durability and functionality makes them a preferred choice among homeowners.

Maintenance Tips

Regular upkeep is essential for maximizing the lifespan of this machinery. Checking the engine oil, cleaning air filters, and sharpening blades are crucial tasks that every owner should perform. Following these guidelines can lead to ultimate performance and satisfaction.

Importance of Replacement Parts

Ensuring the longevity and efficiency of outdoor equipment often hinges on the timely substitution of worn or damaged components. Regular updates not only enhance performance but also guarantee safety and reliability during operation. This practice can prevent minor issues from escalating into major failures, ultimately saving time and costs associated with repairs.

When evaluating the necessity of replacements, several factors come into play:

| Factor | Impact |

|---|---|

| Performance | Worn components can lead to reduced efficiency and increased fuel consumption. |

| Safety | Faulty parts may pose hazards, risking injury to the user or damage to the equipment. |

| Cost-Effectiveness | Investing in replacements can avert more expensive repairs down the line. |

| Longevity | Regular updates contribute to the overall lifespan of the machinery. |

By prioritizing the replacement of essential components, users can ensure their equipment remains in optimal condition, thus enhancing overall performance and safety during use.

Common Issues with Lawn Mowers

Regular maintenance is essential to keep machinery functioning efficiently. Various problems can arise, affecting performance and reliability. Understanding these common issues can help users address them promptly, ensuring a smoother operation.

Engine Difficulties

One of the most frequent challenges involves engine performance. Users may notice difficulty starting or unexpected stalling. These issues can often be traced back to fuel quality, spark plug conditions, or air filter blockages. Ensuring proper maintenance in these areas can significantly enhance engine longevity.

Cutting Performance

Another prevalent concern relates to cutting efficiency. Dull blades can lead to uneven grass trimming, while improper height adjustments can affect overall appearance. Regularly checking and sharpening blades, along with adjusting cutting heights as needed, can greatly improve the results.

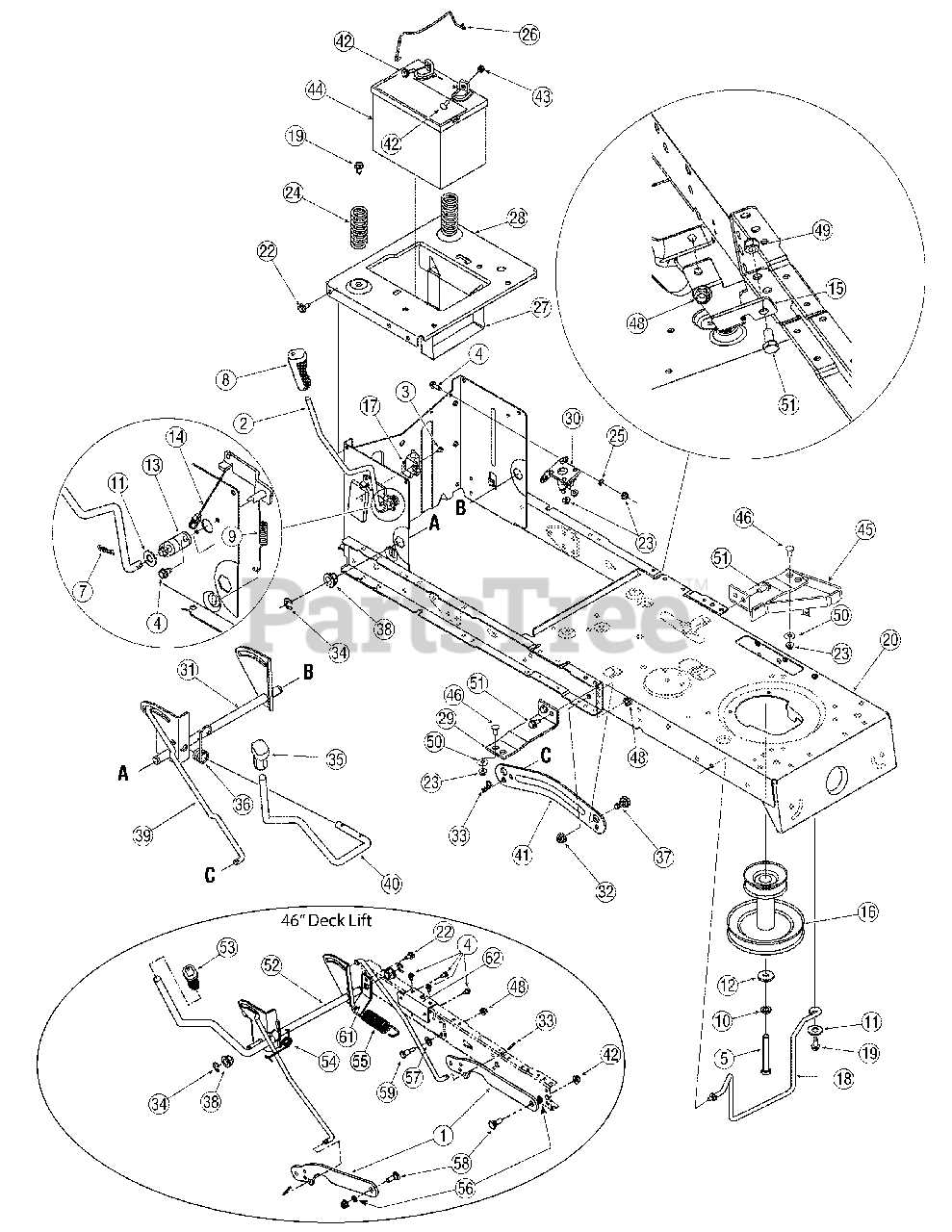

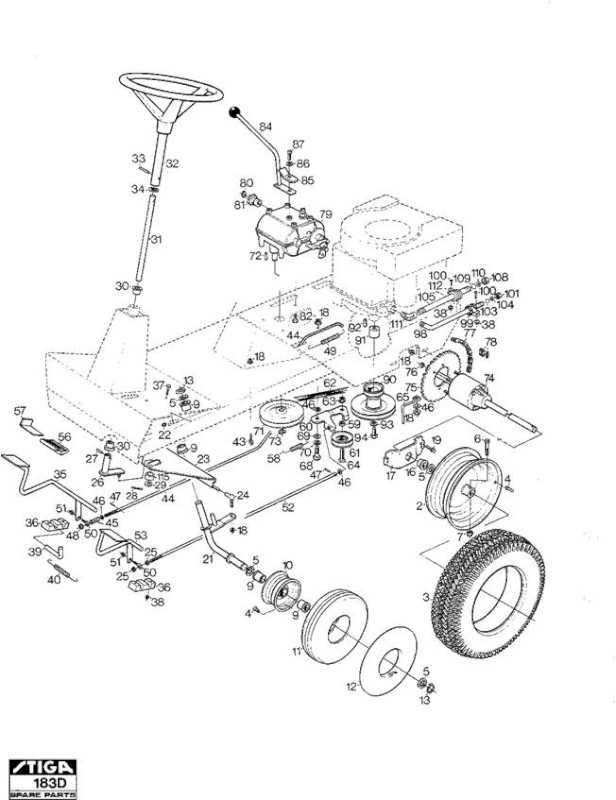

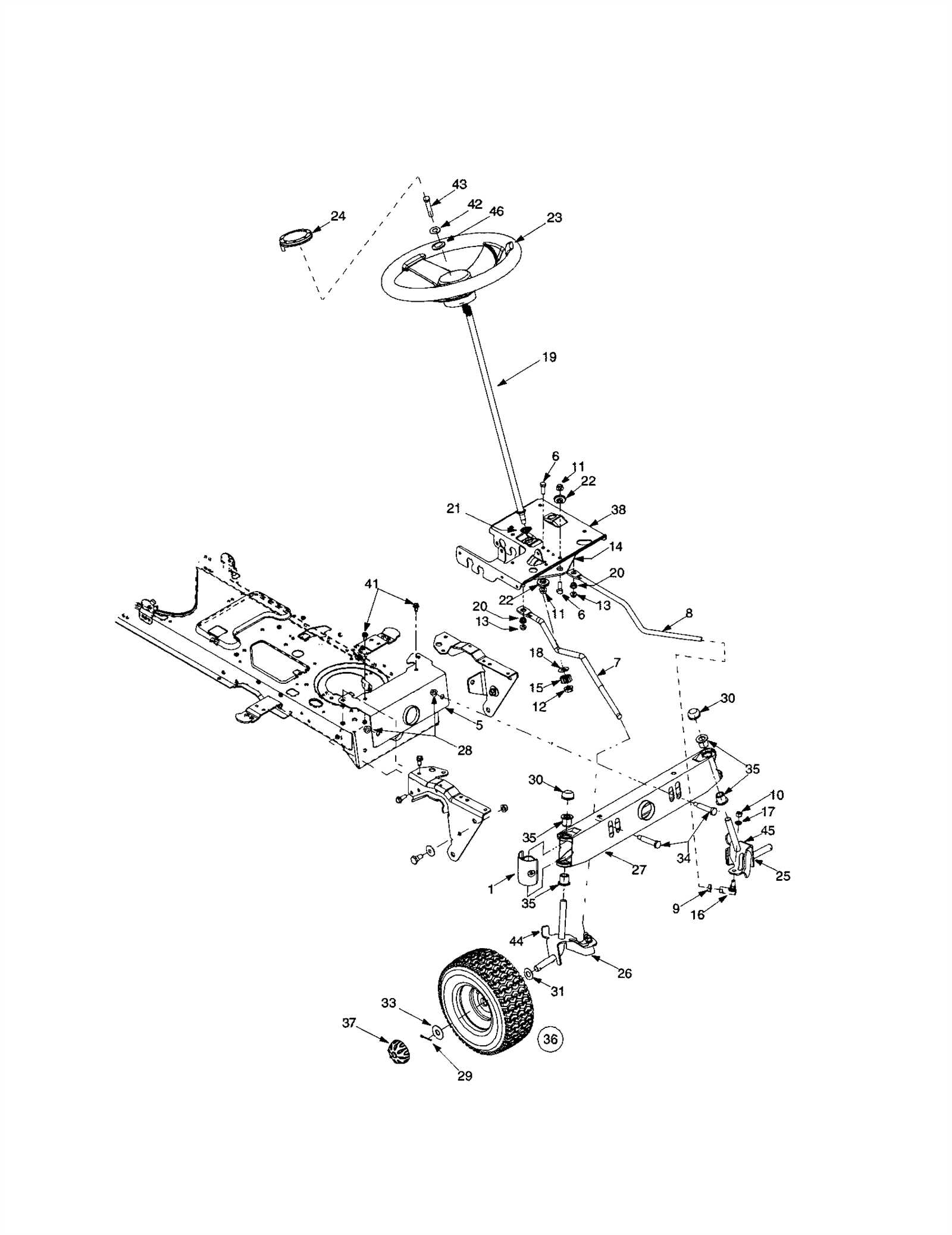

Overview of Huskee Parts Diagram

This section provides a comprehensive look at the components involved in the machinery, emphasizing their arrangement and functionality. Understanding these elements is crucial for maintenance and repairs, ensuring that the equipment operates efficiently and effectively.

Each component plays a significant role in the overall performance. Familiarity with these elements can enhance the user’s ability to troubleshoot issues and perform necessary replacements. Below are key points to consider:

- Identification of individual components

- Understanding the interconnections between parts

- Recognizing the importance of each section in the machinery’s operation

Additionally, the visual representation aids in:

- Streamlining the repair process

- Facilitating accurate part ordering

- Enhancing the user’s ability to perform routine maintenance

Ultimately, knowledge of the layout and functions of these elements empowers users to maintain their equipment with confidence.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair of equipment. These illustrations serve as a roadmap, guiding users through various components and their relationships. Familiarity with these visuals can significantly enhance your ability to identify and troubleshoot issues efficiently.

Identifying Symbols and Labels

Each representation features specific symbols and labels that denote individual elements. Familiarize yourself with these icons, as they often indicate the function or position of each piece. Pay attention to any annotations that provide additional context, such as part numbers or descriptions, which can assist in locating the correct replacements.

Following the Assembly Flow

Another critical aspect is the flow of assembly, which showcases how different components fit together. Trace the connections between parts to understand their sequence and how they interact. This knowledge is vital for reassembly after repairs and helps prevent potential errors during the process.

Identifying Key Components

Understanding the fundamental elements of a machine is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, contributing to performance and efficiency. By recognizing these parts, users can make informed decisions regarding repairs and enhancements.

The primary elements include the engine, which powers the system, and the transmission that controls movement. Additionally, the cutting mechanism is vital for achieving precise results, while the chassis provides structural integrity. Familiarity with these components allows for better problem-solving and optimization.

Furthermore, auxiliary features such as the fuel system and electrical components cannot be overlooked, as they significantly impact operation. A thorough understanding of each segment fosters a more seamless user experience and prolongs the lifespan of the equipment.

Where to Find Replacement Parts

Locating the right components for your equipment can be a straightforward process if you know where to look. Various sources offer a range of options, ensuring you can find the necessary items to keep your machine running smoothly. Whether you prefer shopping online or visiting local retailers, numerous avenues are available to help you acquire quality replacements.

Online Retailers

The internet is a treasure trove for sourcing components. Major e-commerce platforms often have a wide selection of items, ranging from common to specialized components. You can compare prices, read reviews, and even find customer support to assist with your purchase. Websites dedicated to outdoor machinery also provide valuable resources, including manuals and customer feedback.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair facilities can offer immediate access to required components. These establishments often have knowledgeable staff who can assist you in identifying the correct items. Additionally, purchasing locally can save on shipping costs and time, allowing for a quicker turnaround on repairs.

Maintenance Tips for Longevity

To ensure the lasting performance of your outdoor equipment, regular upkeep is essential. Consistent maintenance not only enhances efficiency but also prolongs the lifespan of your machinery. By adopting a few simple practices, you can safeguard your investment and enjoy optimal results for years to come.

1. Regular Cleaning: Dirt and debris can accumulate and cause wear over time. Frequently clean the exterior and components to prevent buildup and maintain functionality.

2. Fluid Checks: Regularly inspect and replace essential fluids, such as oil and fuel. Clean fluids help in preventing corrosion and ensure smooth operation.

3. Blade Maintenance: Keep the cutting edges sharp and free from damage. Dull blades not only affect performance but can also strain the motor, leading to premature wear.

4. Inspection of Components: Periodically examine all parts for signs of wear or damage. Addressing minor issues early can prevent larger problems down the line.

5. Seasonal Storage: When not in use, store the equipment in a dry, sheltered area. Proper storage prevents rust and deterioration from environmental factors.

By following these tips, you can ensure that your machinery remains efficient and reliable, providing you with excellent service for many seasons ahead.

Upgrading Your Mower Efficiency

Enhancing the performance of your grass-cutting equipment can lead to a more productive and enjoyable experience. By focusing on specific improvements and utilizing the right components, you can achieve optimal results while reducing time and effort spent on maintenance. This section will explore various strategies for boosting efficiency, ensuring you get the most out of your machine.

Investing in Quality Components

One of the most effective ways to increase the functionality of your device is by replacing worn-out or subpar components with high-quality alternatives. Durable blades can improve cutting precision, while a well-maintained engine can enhance power output. Additionally, consider upgrading to better filtration systems to keep your engine running smoothly and efficiently.

Regular Maintenance Practices

Consistent upkeep is crucial for maintaining peak performance. Regularly checking and adjusting the tire pressure, cleaning air filters, and lubricating moving parts can significantly extend the lifespan of your equipment. Furthermore, adhering to a scheduled maintenance routine not only improves efficiency but also helps in identifying potential issues before they escalate.