In the colder months, certain machines play a vital role in managing outdoor conditions. These tools, designed for clearing paths and driveways, are composed of various essential elements working in harmony. Understanding the makeup and function of each component can help ensure optimal performance and longevity.

By familiarizing yourself with the arrangement of key elements, it becomes easier to troubleshoot issues or replace worn-out pieces. Whether you’re maintaining or repairing your machine, recognizing the layout is crucial for efficient upkeep and repair tasks.

This guide provides a detailed overview of the internal and external mechanisms, offering a clearer picture of how the device operates. Each section highlights the significance of different parts, ensuring that users can confidently manage their equipment year-round.

Noma Snowblower Overview

This equipment is designed to handle harsh winter conditions, providing an efficient solution for clearing large amounts of accumulated snow. Its robust structure ensures reliable performance in diverse weather scenarios, making it a go-to tool for those living in areas with heavy snowfall.

Key Features

- Durable construction built to last through multiple seasons.

- High-efficiency mechanism for clearing even compacted snow.

- User-friendly controls for easy operation during intense weather.

Operational Benefits

- Reduces the time needed to clear driveways and walkways.

- Minimizes physical strain compared to manual methods.

- Adaptable to various types of snow, from light dustings to heavy drifts.

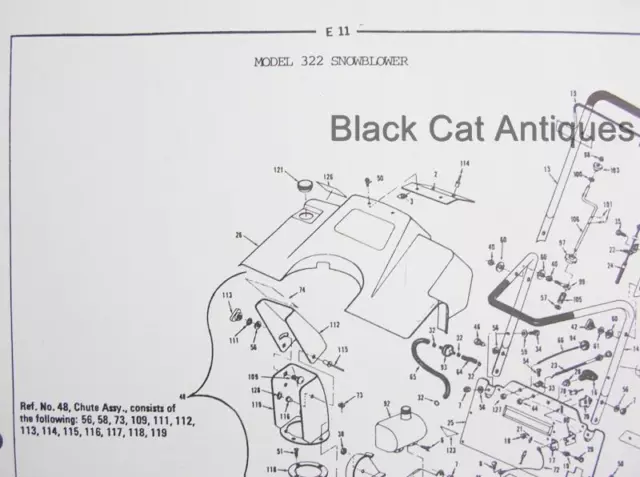

Key Components of a Noma Snowblower

The machine responsible for clearing winter pathways is built from several important elements, each serving a distinct role in ensuring efficient operation. Understanding these individual components can help in maintaining and optimizing performance over time.

Engine and Power Source

The heart of the device is its engine, which provides the necessary power to operate. This core part drives all functions, from moving the unit forward to powering the clearing mechanisms. Ensuring that the engine runs smoothly is crucial for effective performance.

Clearing Mechanism

The clearing system is designed to manage and break through heavy accumulations with ease. It gathers the material and pushes it through the chute, ensuring a clear path. Regular maintenance of this mechanism will ensure optimal functionality and extend its lifespan.

Understanding the Engine Structure

The internal mechanism of any engine is a complex system, requiring a detailed comprehension of its various components and how they work together. At its core, the engine converts energy into mechanical motion, but achieving this involves multiple parts working in harmony. From the ignition to the final output, each element plays a vital role in ensuring efficient operation.

Key components include systems that manage fuel intake, air flow, and the ignition process. These parts work in conjunction to maintain balance and power output, with each section contributing to overall performance. Understanding the structure of the engine requires recognizing the interaction between these elements.

The layout and design of an engine are crucial for maintaining efficiency and longevity. Knowing how these elements are positioned and connected provides insight into troubleshooting and maintenance. Proper care and attention to the engine structure ensures reliable and smooth operation over time.

Main Features of the Engine Assembly

The engine assembly is a critical component designed to deliver power efficiently while ensuring smooth operation under various conditions. It is built with several interconnected parts that work together to provide optimal performance, durability, and reliability.

Core Components of the Assembly

- Cylinder Block: The foundation of the entire structure, housing essential internal mechanisms.

- Crankshaft: Converts linear motion into rotational energy, driving the mechanical movement.

- Carburetor: Regulates the fuel and air mixture for combustion, ensuring efficient energy output.

Key Benefits

- High durability due to reinforced materials and precision engineering.

- Reliable performance, even in harsh environments, thanks to efficient cooling and lubrication systems.

- Simple maintenance with easily accessible components for adjustments and repairs.

Control Panel Layout Explanation

The control panel serves as the central interface for operating and managing the equipment. It includes a variety of essential components, each designed to handle specific functions. Understanding the placement and purpose of these elements helps ensure smooth operation and enhances user experience.

Switches and indicators are carefully arranged to provide quick access to vital controls. These features allow users to easily monitor and adjust the settings as needed. The intuitive arrangement of buttons and levers ensures efficient interaction with the machine.

In addition, safety mechanisms are strategically placed to prevent accidental operations. These precautions help users operate the machine more confidently, while minimizing risks associated with mismanagement or improper usage.

Functions of Various Controls

The operation of machinery relies on several controls that govern its functionality. These components work together to ensure efficient and safe performance during use. Understanding their roles is essential for proper handling and maintenance.

- Power Activation: This control initiates the system, allowing the machine to start its operations.

- Speed Adjustment: Regulates the operating speed, enabling the user to modify the pace depending on conditions and preferences.

- Directional Control: Determines the direction of movement, giving the operator the ability to guide the machine.

- Brake System: Ensures safety by allowing the operator to halt the machine when needed.

- Operating Mode Selector: Switches between different modes of operation, optimizing performance for specific tasks.

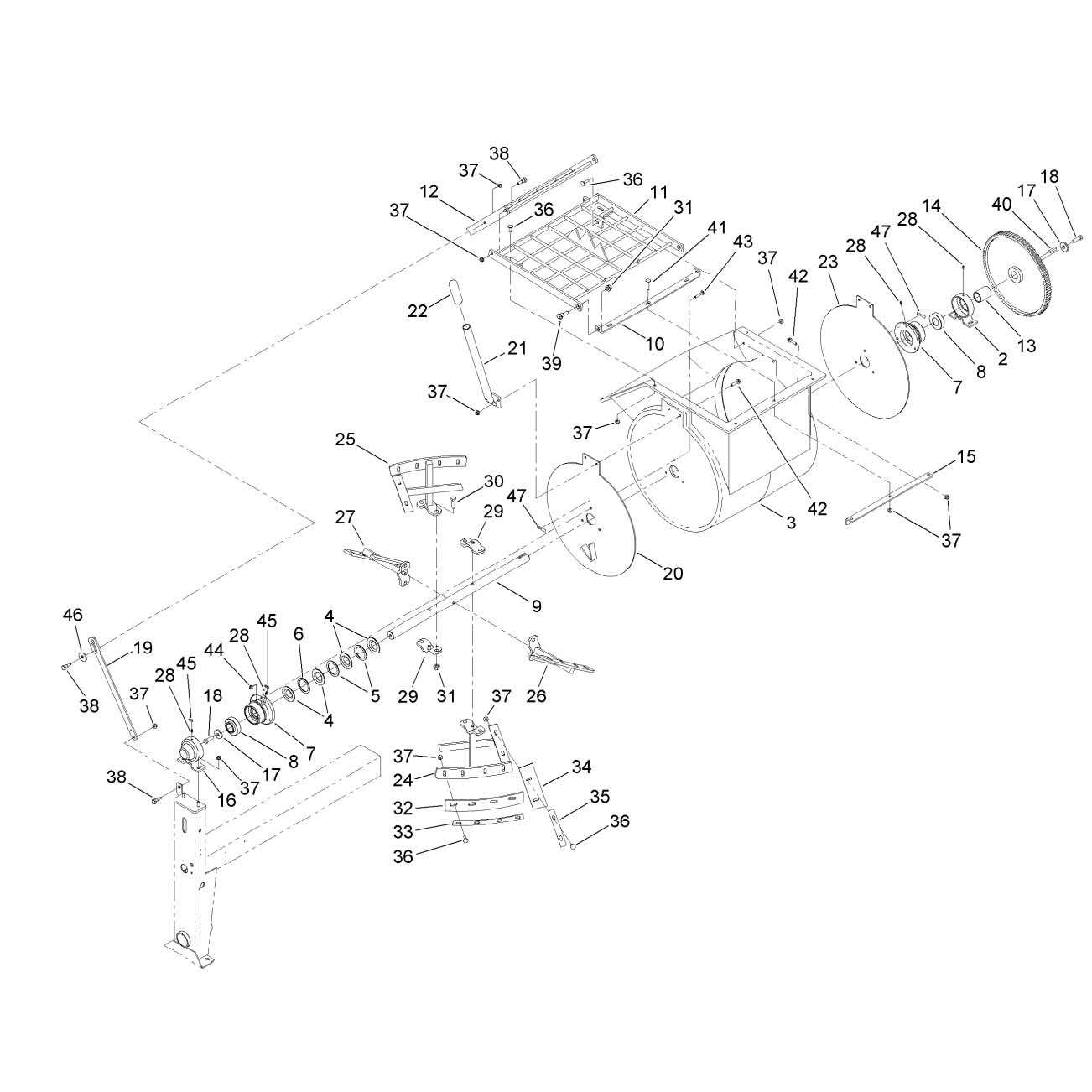

Drive System Configuration

The drive mechanism is an essential part of any mechanical device, ensuring smooth movement and proper operation. Understanding how the drive system is structured and functions is key to maintaining efficiency and performance. This section will provide an overview of the various elements involved in the setup of the drive system.

- Transmission: The power generated by the engine is transferred to the wheels or tracks through a series of gears and belts, which control the speed and force applied to the movement.

- Clutch Mechanism: A clutch allows the operator to engage or disengage the drive system, ensuring control over when the device moves or stays stationary.

- Axle and Differential: The axle connects the wheels or tracks, while the differential ensures that each side can move at different speeds when necessary, especially during turns.

- Drive Belt: This component connects the engine to the transmission, playing a crucial role in the transfer of power.

- Friction Disc: The friction disc plays a key role in adjusting the speed by changing the contact points with the drive wheel.

By understanding these elements and how they interact, it becomes easier to troubleshoot and adjust the drive system for optimal performance.

How the Snowblower Moves Forward

The forward movement of this outdoor equipment relies on a carefully designed system that integrates various mechanical components. Understanding how these elements interact helps users appreciate the engineering behind efficient movement in challenging winter conditions.

Mechanics of Forward Motion

At the core of this mechanism are the drive wheels, which are powered by an engine. The engine generates torque, allowing the wheels to rotate and propel the machine forward. The transmission system plays a vital role by adjusting the speed and direction, enabling smooth transitions across different terrains.

Key Components Involved

| Component | Function |

|---|---|

| Drive Wheels | Provide traction and movement. |

| Engine | Generates power for propulsion. |

| Transmission | Regulates speed and direction. |

| Control Levers | Allow user to steer and adjust speed. |

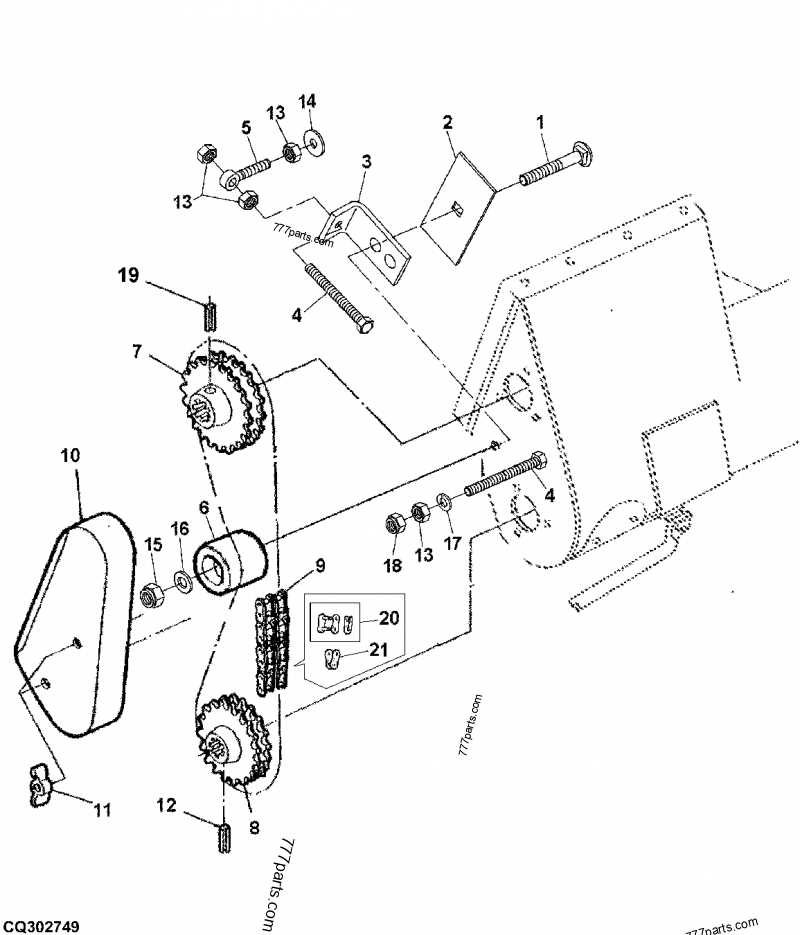

Auger and Impeller Mechanism

The auger and impeller system is a crucial component in the operation of winter equipment designed for removing accumulated materials. This mechanism efficiently processes and propels the debris away from the machine, ensuring a smooth and effective clearing experience.

At the heart of this mechanism, the auger serves as the primary element that gathers and crushes the snow or other materials. Its spiral design allows for optimal movement through the collected mass, effectively breaking it apart for easier transport. Once the materials are processed, they are directed towards the impeller, which plays a vital role in discharging them away from the machine. The impeller utilizes centrifugal force to launch the processed debris at a high velocity, ensuring thorough coverage of the intended area.

Understanding the intricate workings of the auger and impeller mechanism is essential for maintaining and troubleshooting winter equipment. Regular inspection and maintenance of these components can enhance performance and extend the lifespan of the machine.

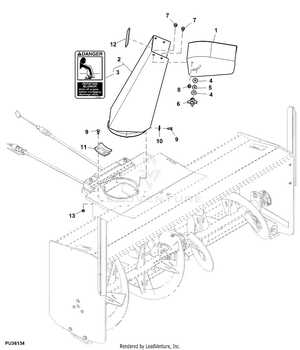

How Snow is Processed and Discharged

The handling and expulsion of frozen precipitation is a crucial aspect of maintaining clear surfaces during winter months. The mechanism employed in this process ensures efficient removal and transportation of the accumulated flakes, allowing for safer pathways and driveways.

Collection and Compression

The initial stage involves the collection of the white substance, where the device’s intake draws in the frozen material. This process can be described as:

- The rotating auger gathers the flakes and channels them toward the central area.

- As the substance moves through the mechanism, it is compacted to facilitate easier expulsion.

Discharge Mechanism

Once the frozen matter is adequately processed, the discharge system takes over. This system operates as follows:

- The material is propelled upward through a chute, aided by the rotational force of the blades.

- Adjustable deflector mechanisms allow for controlled direction of the expelled material.

- The end result is a clear and navigable surface, free from any obstruction caused by accumulated precipitation.