In the realm of automotive engineering, comprehending the intricate elements of braking systems is essential for both enthusiasts and professionals. Each component plays a vital role in ensuring optimal performance and safety on the road. A thorough grasp of these mechanisms can enhance maintenance and improve overall vehicle handling.

Every segment of the braking assembly interacts with others, creating a symphony of motion that facilitates stopping power. From pistons to pads, each item contributes to the effectiveness of the system, impacting the driver’s experience directly. Familiarizing oneself with these individual elements is crucial for diagnosing issues and implementing enhancements.

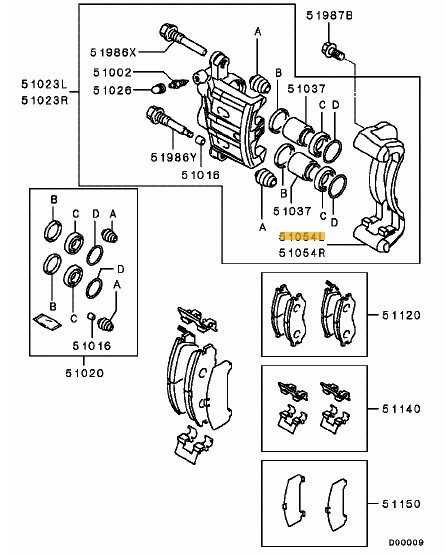

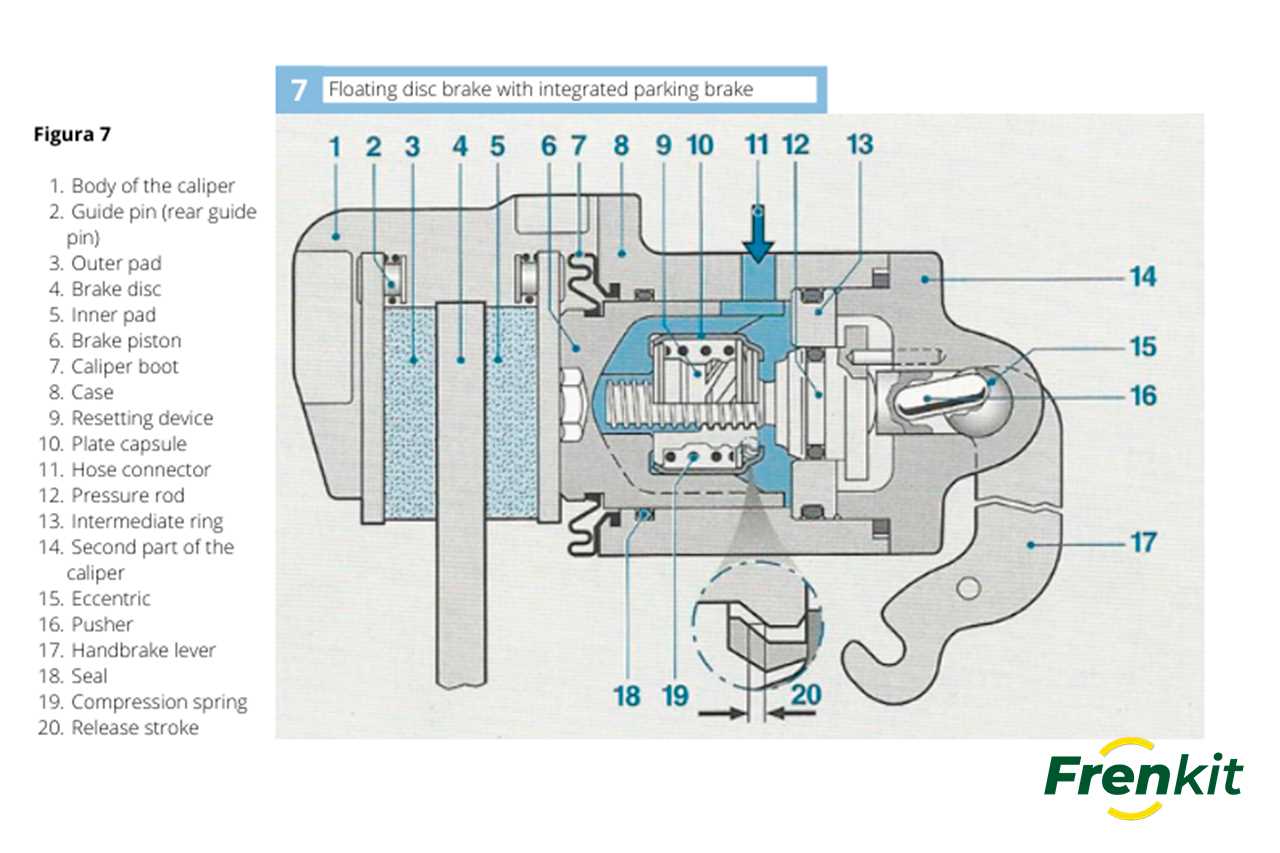

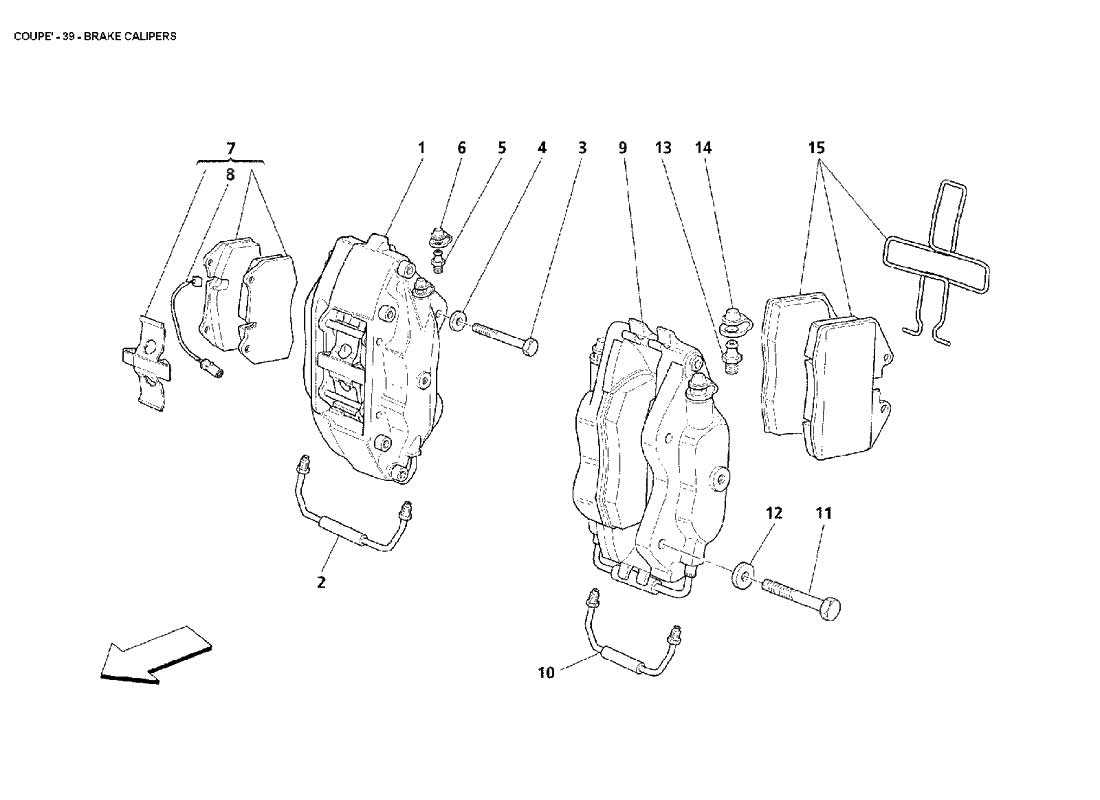

Moreover, visual representations can aid in grasping the relationships and functions of these components. By exploring detailed illustrations, one can delve into the nuances of how each piece works in harmony. This knowledge serves as the ultimate foundation for understanding and optimizing vehicle braking efficiency.

Understanding Caliper Components

Grasping the essential elements of braking systems is crucial for maintaining vehicle safety and performance. These components work in harmony to ensure effective stopping power and overall reliability. Familiarity with these elements helps in diagnosing issues and understanding maintenance needs.

Key Elements of the Assembly

The assembly consists of various critical elements, each serving a unique purpose. The main housing provides the structure, while specialized mechanisms apply pressure to the friction material. This interaction is vital for achieving the desired stopping effect when the vehicle is in motion.

Functionality and Maintenance

Understanding how each element functions can greatly aid in troubleshooting. Regular inspection and maintenance of these components are essential to prevent wear and ensure optimal performance. Addressing any signs of deterioration promptly can extend the lifespan of the entire braking system.

Importance of Caliper Functionality

The effectiveness of braking systems in vehicles relies heavily on specific components designed to create the necessary force to slow down or stop. These components must operate seamlessly to ensure safety and performance during driving. A well-functioning assembly is crucial, as it directly impacts the vehicle’s responsiveness and stability.

Proper functionality of these mechanisms not only enhances safety but also contributes to the overall driving experience. When these assemblies perform optimally, they reduce stopping distances and improve handling, especially in emergency situations. Drivers can maintain better control, which is vital for avoiding accidents.

Moreover, regular maintenance of these systems is essential for longevity and reliability. Neglecting any aspect can lead to diminished performance, increased wear, and potential failure, which poses significant risks on the road. Ensuring that these assemblies are in excellent condition fosters confidence and peace of mind for drivers.

In summary, the importance of functionality within these systems cannot be overstated. They are integral to safe driving practices and enhance the overall performance of vehicles, making it imperative for owners to prioritize their upkeep.

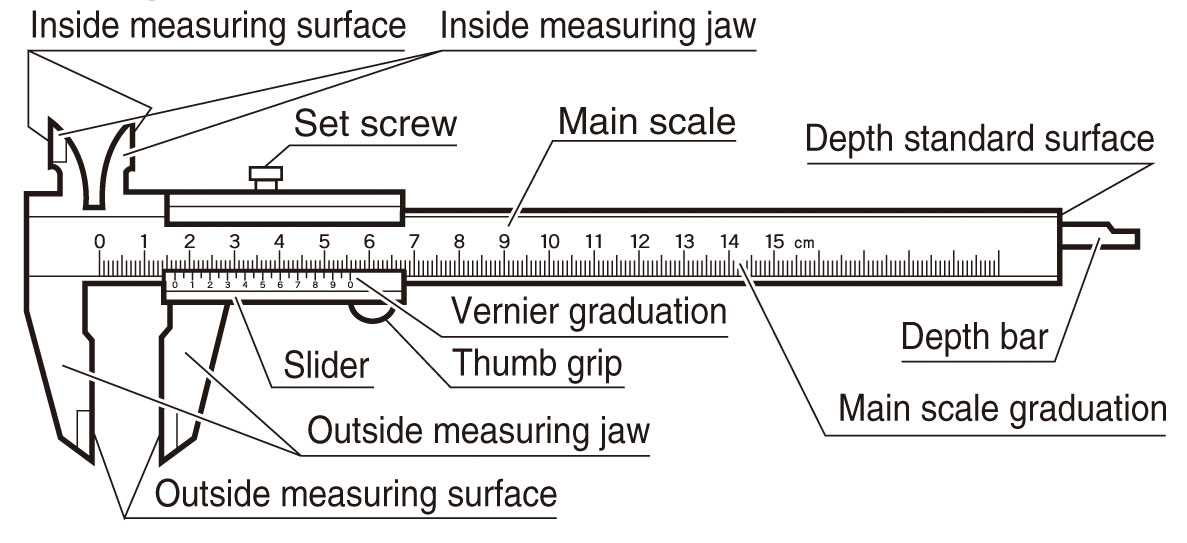

Types of Calipers Explained

Understanding the various measuring instruments available is essential for precision tasks in multiple fields. Each variant is designed to fulfill specific requirements, ensuring accurate measurements and efficiency.

- Vernier Instrument: Known for its precision, it features a sliding scale for fine measurements.

- Dial Tool: Utilizes a dial gauge to provide clear readings, ideal for quick assessments.

- Digital Device: Offers electronic displays for ease of use and enhanced accuracy.

- Gauge Tool: Specialized for measuring thickness, often used in material analysis.

- Inside Measuring Instrument: Designed to measure internal dimensions with accuracy.

- Outside Measuring Instrument: Focuses on external dimensions, crucial for fitting parts together.

Each type serves unique functions, enabling users to select the most suitable instrument for their specific tasks and ultimately achieving precise results.

Common Issues with Caliper Parts

When it comes to braking systems, certain components may face challenges that affect their performance and longevity. Understanding these common problems can help in identifying potential failures and ensuring a smoother driving experience. Regular maintenance and awareness of specific issues are key to keeping these crucial elements in optimal condition.

Wear and Tear

Over time, friction can lead to significant deterioration of the materials involved. This natural wear can manifest as uneven surfaces or reduced effectiveness in stopping power. Regular inspections are essential to detect such issues early and to replace components as necessary, preventing further complications.

Fluid Leaks

Leaks in hydraulic systems can compromise the efficiency of the braking mechanism. Signs of fluid loss may include a decrease in responsiveness or visible fluid accumulation. Addressing these leaks promptly can prevent more extensive damage and ensure safe operation.

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and work with various mechanical assemblies. This guide provides essential tips for interpreting such illustrations effectively.

- Familiarize Yourself with Symbols: Different symbols represent specific elements. Knowing these will help you decipher the illustration quickly.

- Check the Legend: Most visuals include a legend that explains what each symbol or line denotes. Always refer to it first.

- Follow the Flow: Observe how components are connected. This can give insight into their function and interaction.

By grasping these basics, you’ll be better equipped to navigate any technical representation with confidence and precision.

Maintenance Tips for Caliper Longevity

Ensuring the durability of your braking system components requires consistent care and attention. By following specific maintenance practices, you can enhance performance and extend the life of these crucial elements. Regular inspections and timely interventions are key to preventing costly repairs and ensuring safety on the road.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify signs of wear or damage. Look for leaks, corrosion, and uneven wear patterns. |

| Cleanliness | Keep the components clean from dirt and debris. Use appropriate cleaners to prevent buildup that can affect functionality. |

| Lubrication | Apply high-quality lubricant to moving parts to reduce friction and ensure smooth operation. Avoid over-lubrication, which can attract dust. |

| Proper Installation | Ensure all components are installed correctly to avoid misalignment. Follow manufacturer guidelines for torque specifications. |

| Monitor Performance | Pay attention to changes in braking performance, such as unusual noises or decreased responsiveness. Address issues promptly. |

| Replace Worn Components | Don’t delay replacing worn or damaged elements. Timely replacements can prevent further damage and maintain optimal safety. |

Choosing Quality Replacement Parts

When it comes to maintaining optimal performance in your vehicle, selecting high-quality alternatives is crucial. The right components ensure safety, longevity, and efficiency. Understanding what to look for can significantly impact your overall driving experience.

Key Factors to Consider

- Material Quality: Opt for items made from durable materials that withstand wear and tear.

- Brand Reputation: Research brands with a history of reliability and customer satisfaction.

- Compatibility: Ensure the selected components fit your specific vehicle model to avoid issues.

Benefits of Quality Choices

- Enhanced safety through reliable performance.

- Increased lifespan of the vehicle’s systems.

- Improved fuel efficiency and overall functionality.

Caliper Installation Best Practices

When it comes to the proper installation of braking components, attention to detail is crucial. Ensuring that each element is fitted correctly can significantly enhance performance and safety. Below are essential practices to consider during the installation process.

- Preparation:

- Gather all necessary tools and components before starting.

- Clean the work area to avoid contamination.

- Review the manufacturer’s guidelines for specific instructions.

- Inspection:

- Examine all components for wear and damage.

- Replace any worn items to ensure optimal functionality.

- Check for rust or corrosion that may impact performance.

- Installation Steps:

- Secure the vehicle properly before beginning.

- Follow the sequence outlined in the guidelines for assembling the components.

- Ensure all fittings are torqued to the specified values.

- Double-check alignment to avoid uneven wear.

- Testing:

- After installation, conduct a visual inspection.

- Test the system at low speeds to ensure everything functions smoothly.

- Monitor for unusual noises or performance issues during initial use.

By following these best practices, you can ensure a reliable and efficient setup, leading to enhanced performance and longevity of your braking system.