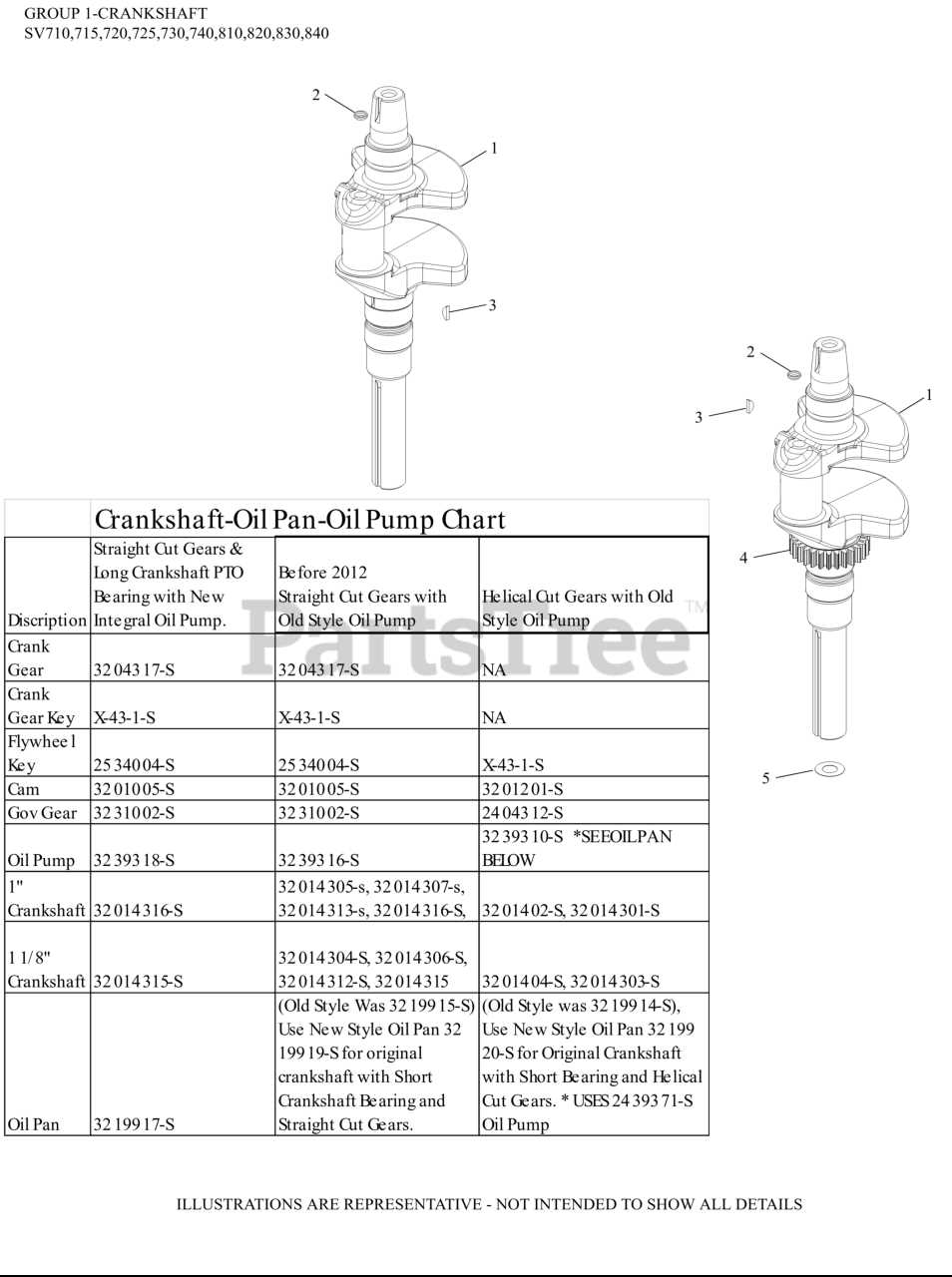

In the realm of small engine maintenance, grasping the intricate relationships between various components is essential for optimal performance and longevity. Each element plays a crucial role, and knowing how they interconnect can significantly enhance repair and troubleshooting efforts. This guide aims to shed light on these relationships and provide valuable insights into the assembly.

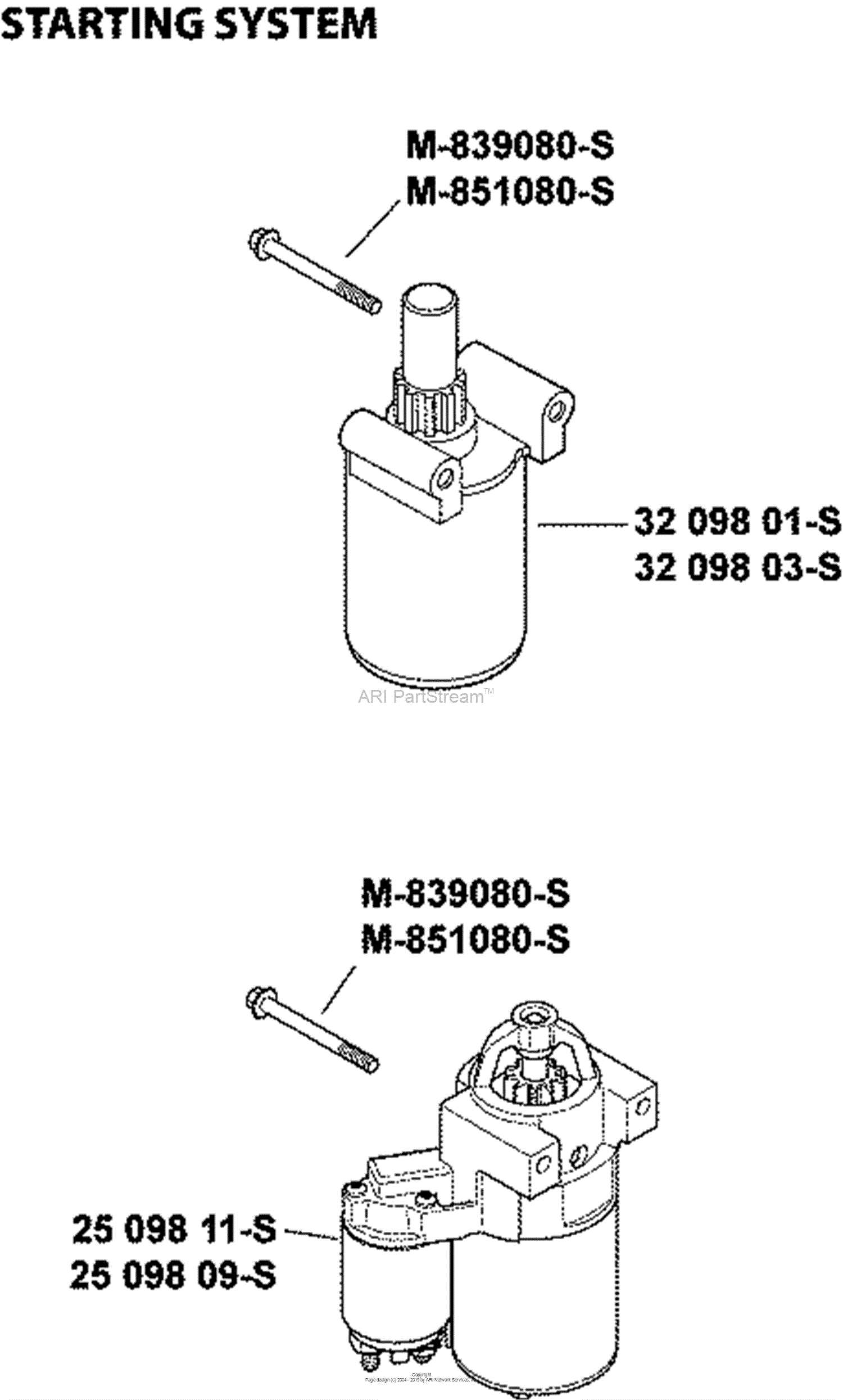

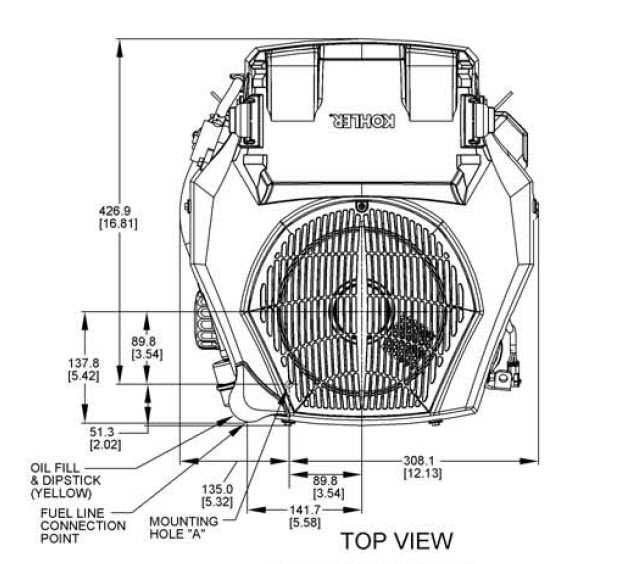

Whether you are a seasoned mechanic or a DIY enthusiast, having access to a visual representation of engine components can simplify your understanding and streamline the repair process. Such illustrations not only clarify the layout but also help identify specific parts and their functions, making maintenance more efficient.

Through detailed analysis and exploration of component arrangements, one can better appreciate the engineering behind these machines. This resource will serve as a reference point for anyone looking to delve deeper into the mechanics and ensure their equipment runs smoothly.

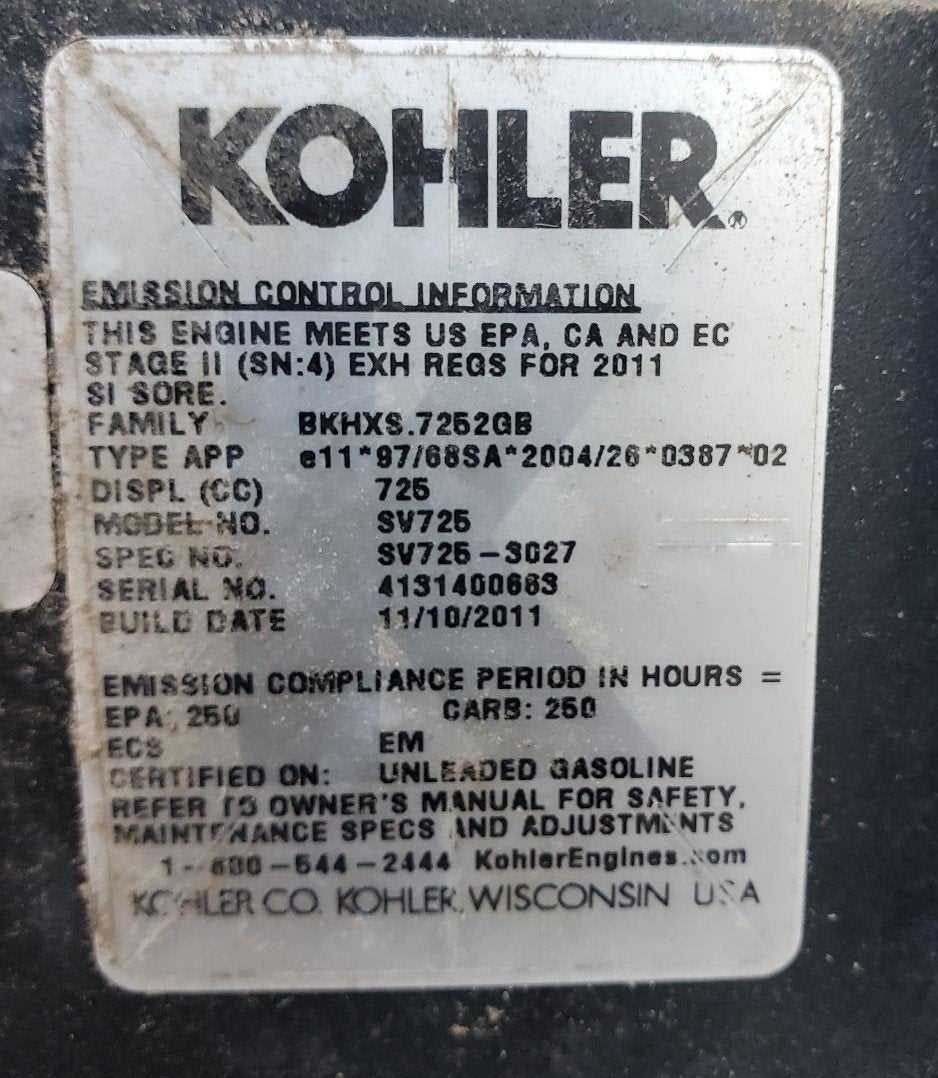

Kohler SV725 Engine Overview

This section provides a comprehensive look at a popular engine model known for its reliability and performance. Designed for various applications, it combines advanced technology with robust construction to meet diverse operational demands.

Key Features: The engine boasts a powerful output, ensuring efficiency in various tasks. Its design incorporates user-friendly aspects, making maintenance straightforward and accessible.

Applications: This engine is widely used in lawn and garden equipment, providing the necessary torque and durability for demanding environments. Its versatility makes it suitable for both commercial and residential use.

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations provide clarity, making it easier to identify each element’s role and function within the overall system.

Benefits of Visual Representation

- Simplifies troubleshooting by offering a clear view of components.

- Aids in ordering the correct replacements, minimizing errors.

- Enhances communication between technicians and manufacturers.

Streamlining Maintenance Processes

- Facilitates quick access to necessary information.

- Improves efficiency during repairs, reducing downtime.

- Encourages proactive maintenance by highlighting wear-prone areas.

Identifying Key Components

Understanding the essential elements of a small engine is crucial for effective maintenance and repair. By recognizing these vital parts, users can better diagnose issues and ensure optimal performance. Each component plays a specific role, contributing to the overall functionality of the machine.

Starting with the power source, the engine requires a reliable system to convert fuel into energy. The ignition assembly ignites the fuel-air mixture, while the carburetor regulates the fuel supply. Additionally, the cooling system prevents overheating, ensuring longevity and efficiency during operation.

Moreover, components like the air filter and exhaust system are critical for maintaining performance and reducing emissions. Regular inspection and replacement of these parts can significantly impact the engine’s reliability and durability.

Ultimately, a thorough understanding of these key components allows for more informed decisions regarding upkeep and troubleshooting, leading to improved engine longevity and performance.

Common Issues with SV725 Parts

In the realm of small engines, certain components often encounter frequent challenges that can lead to performance problems. Understanding these issues is essential for effective maintenance and troubleshooting. Various factors contribute to the wear and tear of engine elements, impacting overall efficiency and functionality.

1. Wear and Tear

Over time, key components may experience significant degradation due to regular usage. This wear can manifest in various forms, such as cracks, breaks, or diminished performance. Regular inspections can help identify these concerns early, allowing for timely replacements to avoid further complications.

2. Fuel System Issues

Another common challenge involves the fuel delivery system. Clogs and blockages in the lines can prevent proper fuel flow, leading to operational failures. Ensuring that filters are clean and lines are free from obstructions is crucial for maintaining optimal engine performance. Periodic maintenance of these systems can help mitigate such problems.

Where to Find Diagrams

Accessing detailed illustrations and schematics for machinery components can greatly enhance your understanding and maintenance capabilities. These visual aids provide invaluable insights into assembly, disassembly, and troubleshooting, ensuring efficient repairs and replacements.

Online Resources

The internet is a treasure trove of information. Websites dedicated to machinery and equipment often host a variety of resources, including technical drawings and user manuals. Search for reputable sites that specialize in mechanical parts or industry-specific forums, where enthusiasts share their knowledge and resources.

Manufacturer Support

Contacting the manufacturer directly can yield accurate and detailed schematics. Many companies provide downloadable resources on their official websites or upon request. This ensures you receive the most reliable and up-to-date information tailored to your specific equipment.

Utilizing these resources effectively can significantly improve your repair and maintenance processes. Always verify the authenticity of the sources to ensure you’re working with the correct information.

Benefits of Using OEM Parts

Opting for original equipment manufacturer components can significantly enhance the performance and longevity of machinery. These items are specifically designed to meet the exact specifications of the equipment, ensuring optimal compatibility and reliability.

One of the primary advantages of utilizing genuine components is the assurance of quality. Manufactured to rigorous standards, these parts undergo thorough testing to guarantee they can withstand the demands of regular use. This attention to detail helps prevent unexpected breakdowns and costly repairs, ultimately saving time and money.

Moreover, using original components often leads to improved efficiency. Since they are engineered to work seamlessly with the machinery, they contribute to better overall functionality. This can translate into enhanced performance and reduced energy consumption, benefiting both the user and the environment.

Additionally, opting for OEM items can help maintain warranty coverage. Many manufacturers require the use of original parts to uphold warranty claims. By adhering to these guidelines, owners can protect their investment and avoid potential disputes down the line.

In conclusion, the benefits of using original components extend beyond mere compatibility. They promise quality, efficiency, and peace of mind, making them a wise choice for anyone looking to optimize the performance and durability of their equipment.

Maintenance Tips for Longevity

Ensuring the long-term performance of your equipment requires consistent care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery and keep it running smoothly.

Regular Inspections

Frequent checks are crucial for identifying potential issues before they escalate. Inspect all components for signs of wear, damage, or corrosion. Pay special attention to moving parts and fluid levels, as these are often the first indicators of a problem. Maintaining a schedule for these inspections can help you stay ahead of any necessary repairs.

Proper Lubrication

Keeping parts adequately lubricated is vital for reducing friction and wear. Use the appropriate type of lubricant recommended for your machinery, and apply it at regular intervals. Effective lubrication not only enhances performance but also minimizes the risk of breakdowns, ensuring that your equipment remains operational for years to come.

Upgrading Your Kohler Engine

Enhancing the performance and longevity of your small engine can significantly improve its efficiency and reliability. By investing in quality components and modern upgrades, you can ensure smoother operation and greater power output. This section will guide you through various enhancements that can revitalize your engine and keep it running at peak performance.

Assessing Your Current Setup

Before making any upgrades, it’s essential to evaluate the current condition of your engine. Look for wear and tear in components such as the ignition system, fuel delivery, and exhaust systems. Identifying areas that require attention will help you prioritize your upgrades effectively.

Performance Enhancements

Consider replacing the air intake and exhaust systems to boost airflow. Improved air circulation can lead to better combustion, resulting in increased horsepower. Additionally, high-performance spark plugs can enhance ignition efficiency, giving your engine a noticeable power boost.

Regular Maintenance

Staying on top of regular maintenance is key to maximizing your engine’s lifespan. Regular oil changes, filter replacements, and checking for loose connections can prevent minor issues from escalating. This proactive approach can also create a solid foundation for future upgrades.

Fuel Quality

Utilizing high-quality fuel can make a significant difference in performance. Consider switching to premium fuel options that offer better combustion properties, leading to improved efficiency and reduced emissions.

Expert Advice

If you’re unsure where to start, consult with a professional or experienced mechanic. They can provide tailored recommendations based on your engine type and specific needs, ensuring you make informed decisions that align with your performance goals.

By taking these steps, you can effectively upgrade your small engine, enhancing its performance and extending its operational life. Embrace the opportunity to make thoughtful improvements that will yield lasting benefits.