In the world of outdoor machinery, comprehending the intricate workings of your tools is essential for optimal performance and longevity. Every piece of equipment is composed of various elements, each playing a critical role in the overall functionality. Grasping the relationships between these components allows for more effective maintenance and troubleshooting.

Visual aids can significantly enhance your understanding of how different parts fit together and operate. By studying detailed illustrations, users can identify essential elements and recognize potential issues before they escalate. This knowledge not only empowers you as an operator but also fosters a deeper connection with your machinery.

Ultimately, a thorough exploration of these mechanical designs equips users with the necessary insights to ensure their tools run smoothly. Whether you’re a seasoned professional or a hobbyist, delving into the intricacies of your equipment can lead to improved efficiency and satisfaction in your tasks.

Understanding Stihl MS291 Components

Exploring the various elements of a chainsaw reveals the intricate design and functionality behind this essential tool. Each component plays a crucial role in ensuring optimal performance, making it vital for users to familiarize themselves with these parts for effective maintenance and troubleshooting.

Key Elements of the Tool

The heart of the machine is its engine, which powers the cutting mechanism. Additionally, the bar and chain work in unison to deliver efficient cutting action, while the fuel system ensures the engine receives the necessary resources for operation. Understanding these components enhances the user’s ability to manage and extend the lifespan of the equipment.

Maintenance and Replacement

Regular upkeep of each part is essential for sustaining performance. Knowing how to identify wear and tear allows for timely replacements, ensuring that the tool operates at its ultimate capacity. Users should consult manuals or diagrams to locate specific components, facilitating a smoother maintenance process.

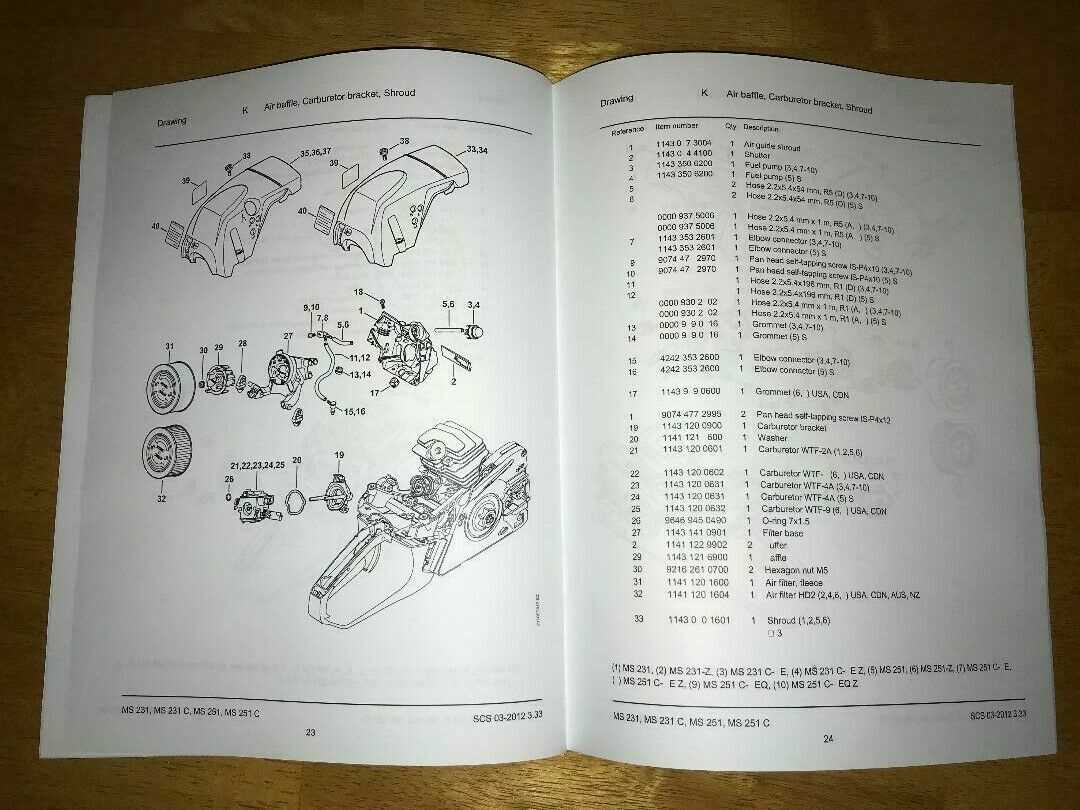

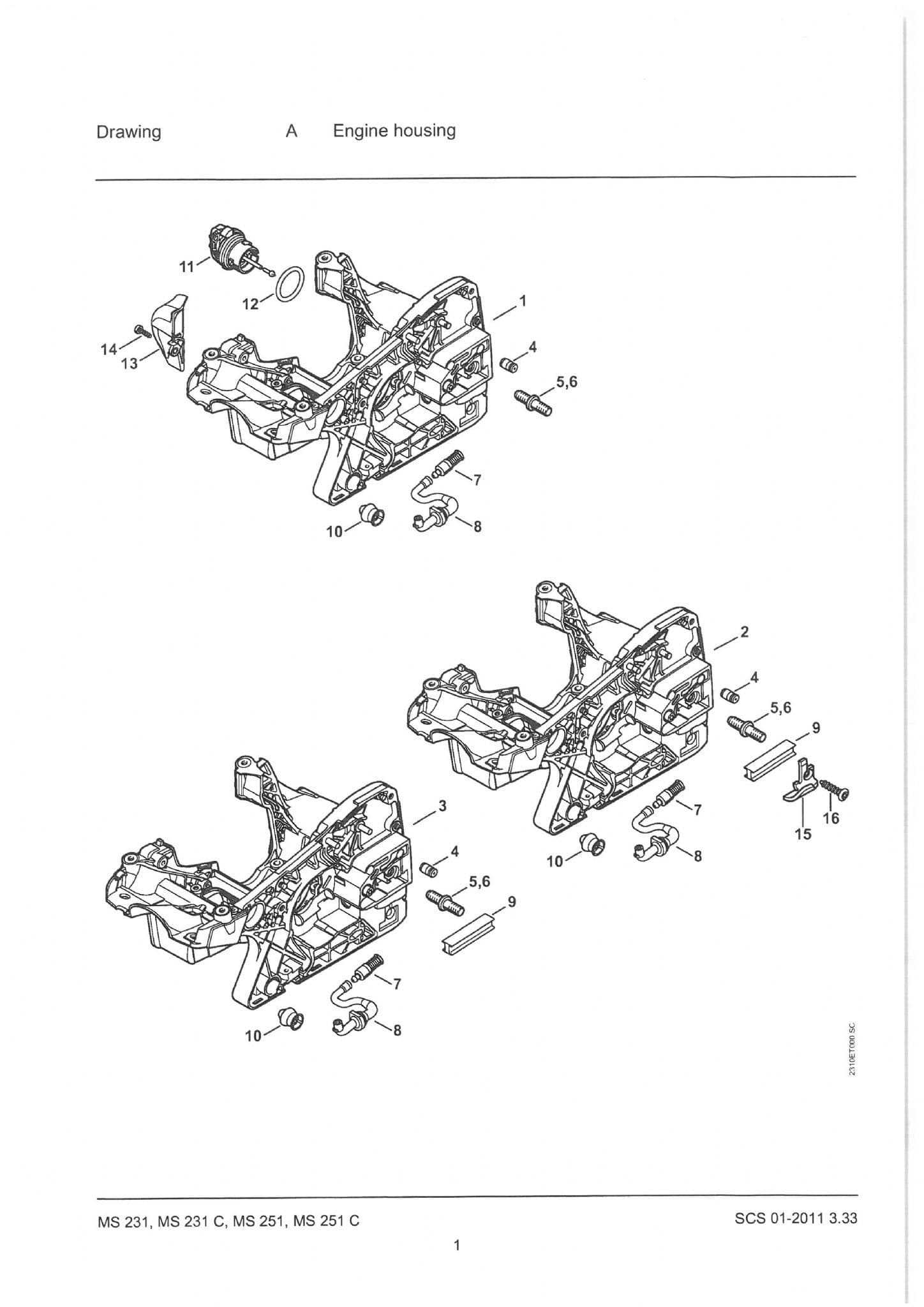

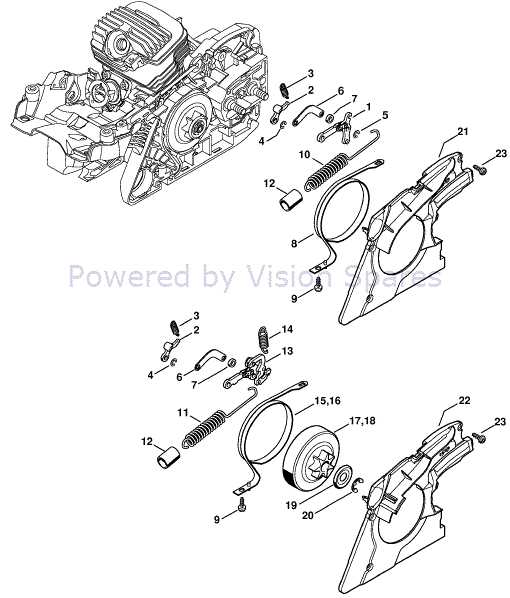

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations play a vital role in helping users identify individual elements, facilitating a smoother restoration process. This knowledge can ultimately save time and reduce frustration, ensuring that equipment operates efficiently.

Enhanced Understanding

Visual schematics offer a clear overview of how different pieces interact. By breaking down complex machinery into manageable sections, users can grasp the overall function more easily. This enhanced comprehension is key for troubleshooting and making informed decisions during repairs.

Streamlined Repairs

Accurate illustrations streamline the repair process. Technicians can quickly locate the necessary components, ensuring that replacements are made efficiently. This not only improves repair times but also contributes to better long-term performance of the machinery.

Common Issues with Stihl MS291

Understanding the frequent challenges encountered with this particular power tool can greatly enhance its longevity and performance. Identifying these problems early on is crucial for maintaining optimal functionality and ensuring safety during use.

Fuel System Problems

One of the most prevalent issues involves the fuel system. Clogs in the fuel lines can lead to inadequate power delivery. Regular checks and cleaning can prevent these disruptions, ensuring a smooth operation.

Starting Difficulties

Users often report trouble starting the equipment. This can stem from various factors such as spark plug wear or improper fuel mixtures. Regular maintenance and timely replacement of components can help mitigate these starting issues.

How to Interpret Diagrams Effectively

Understanding visual representations is essential for grasping complex information. Whether you are dealing with technical schematics or assembly illustrations, the ability to decode these images can greatly enhance your comprehension and execution. This section will guide you through key strategies to make the most out of these visual tools.

Key Strategies for Interpretation

- Familiarize Yourself with Symbols: Before diving into the visual, take time to learn the common symbols and notations used. Each element often has a specific meaning that can simplify your understanding.

- Follow the Flow: Many illustrations are designed to convey a sequence of steps. Pay attention to arrows and lines that indicate direction and relationships between components.

- Take Notes: As you analyze the image, jot down important points. This practice can reinforce your understanding and serve as a quick reference later.

Practical Tips for Effective Reading

- Start with the Overview: Look at the entire illustration to get a sense of what it represents before zooming in on specific areas.

- Break It Down: Divide the visual into manageable sections. Focus on one part at a time to avoid feeling overwhelmed.

- Cross-Reference with Instructions: If available, compare the visual with accompanying instructions or descriptions. This can clarify any ambiguities.

By applying these strategies, you can enhance your ability to interpret and utilize visual aids effectively, leading to better outcomes in your tasks and projects.

Where to Find Parts Diagrams

Locating detailed illustrations for machinery components can greatly enhance your repair and maintenance experience. Numerous resources are available online, providing access to visual guides that showcase individual elements and their arrangements. These visuals can simplify the identification of required pieces, ensuring you have the right replacements for your equipment.

Official Manufacturer Websites: The first place to check is the official website of the manufacturer, where you can often find downloadable resources tailored to specific models. This is usually the most reliable source for accurate information.

Online Retailers: Many online retailers specialize in selling components and frequently offer visual aids to assist customers in making informed purchases. Browsing through their catalogs can provide additional context and clarity.

Forums and Community Groups: Engaging with dedicated online communities can yield valuable insights. Members often share links to resources or upload their own illustrations, helping fellow enthusiasts find what they need.

Repair Manuals: Purchasing or downloading repair manuals can be beneficial, as these documents often include comprehensive images and instructions. Look for manuals specific to your model for the best results.

With a combination of these resources, you can easily delve into your repair projects, ensuring you have the ultimate visual support for successful maintenance.

Maintenance Tips for MS291 Chainsaw

Regular upkeep of your cutting tool is essential for optimal performance and longevity. By following a few straightforward practices, you can ensure that your equipment operates efficiently and safely, minimizing the risk of unexpected failures during use.

- Regular Cleaning: After each use, remove any debris from the body, chain, and bar. This prevents buildup that can affect performance.

- Chain Tension Adjustment: Ensure the chain is properly tensioned. A loose chain can derail, while a tight one can cause damage. Check the tension before each use.

- Lubrication: Use the recommended oil for chain lubrication. Regularly check and refill the oil reservoir to keep the chain running smoothly.

- Air Filter Maintenance: Clean or replace the air filter regularly to ensure optimal airflow to the engine. A clogged filter can hinder performance.

- Spark Plug Inspection: Examine the spark plug periodically. A clean and properly gapped spark plug ensures efficient ignition.

By incorporating these maintenance practices into your routine, you can enhance the efficiency and durability of your cutting tool, ensuring it remains a reliable companion for all your projects.

Replacement Parts and Upgrades

Maintaining and enhancing the performance of your equipment is essential for achieving optimal efficiency and longevity. Identifying quality components and potential enhancements can significantly improve functionality and reliability, ensuring that your tool operates at its best under various conditions.

Key Components for Replacement

When it comes to substituting essential elements, it’s crucial to choose high-quality replacements. This not only ensures compatibility but also prolongs the lifespan of your machinery. Below is a table highlighting common components that may require attention over time:

| Component | Purpose | Signs of Wear |

|---|---|---|

| Fuel Filter | Prevents debris from entering the fuel system | Reduced performance, difficulty starting |

| Air Filter | Maintains optimal airflow for combustion | Increased fuel consumption, black smoke |

| Chain | Enables cutting efficiency and precision | Dullness, excessive wear, or damage |

Possible Enhancements

In addition to replacing worn components, consider upgrades that enhance overall performance. These modifications can provide increased power, better fuel efficiency, and improved user experience. Evaluating your specific needs can guide you in selecting the right enhancements.

Ordering Genuine Stihl Parts Online

Acquiring authentic components for your outdoor equipment has never been easier with the convenience of online shopping. The internet provides access to a wide range of reliable retailers, allowing enthusiasts to find the exact replacements they need efficiently. Ensuring the quality and compatibility of these elements is crucial for maintaining the performance and longevity of your machinery.

Finding Trusted Retailers

When searching for legitimate suppliers, it’s essential to focus on established websites known for their commitment to quality. Look for retailers that specialize in outdoor tools and machinery, as they often have a selection of genuine items. Reading customer reviews and checking for certifications can further assure you of their credibility.

Benefits of Online Ordering

Ordering components online not only saves time but often provides better pricing options compared to physical stores. Many websites offer detailed descriptions and specifications, allowing you to make informed choices. Additionally, the convenience of home delivery means you can receive your items without the hassle of traveling.

In summary, the online marketplace is a valuable resource for sourcing quality replacements. By choosing reputable vendors and taking advantage of the ease of online shopping, you can ensure your equipment remains in optimal condition.

Resources for DIY Repairs

When tackling maintenance tasks on your equipment, having the right resources can make all the difference. From manuals to online communities, these tools help you understand how to efficiently carry out repairs and ensure your machinery runs smoothly.

Here are some valuable resources to consider:

- User Manuals: Always start with the official manual for detailed instructions and specifications.

- Online Forums: Join discussions on platforms where enthusiasts share tips and troubleshooting advice.

- Video Tutorials: Platforms like YouTube offer step-by-step guides that visually demonstrate the repair process.

- Repair Websites: Sites dedicated to repair information provide extensive guides and diagrams that can be invaluable.

Additionally, consider the following options:

- Local Workshops: Look for classes or workshops in your area that focus on equipment repair.

- Parts Retailers: Many suppliers provide detailed descriptions and compatibility information for replacement components.

- Social Media Groups: Engage with community groups that focus on your type of machinery for real-time advice and support.

Utilizing these resources can empower you to perform repairs confidently and efficiently, saving both time and money in the long run.