In any household device designed to produce refreshing chilled elements, a comprehensive understanding of its inner workings is crucial for optimal performance. Familiarizing yourself with the various elements can significantly enhance your user experience and extend the life of the unit. By examining these components, you can ensure that your equipment operates seamlessly and efficiently.

Exploring the arrangement of the internal mechanisms not only aids in troubleshooting but also empowers users to undertake basic maintenance. Recognizing how each segment interacts allows for a deeper appreciation of the engineering behind the appliance. Furthermore, a detailed overview can serve as a roadmap for those looking to replace or upgrade individual elements.

Whether you are a seasoned technician or a curious homeowner, this exploration will help you delve into the intricacies of your device. The ultimate goal is to ensure that your equipment continues to provide the refreshment you enjoy, without unnecessary interruptions.

Understanding Lg Ice Maker Components

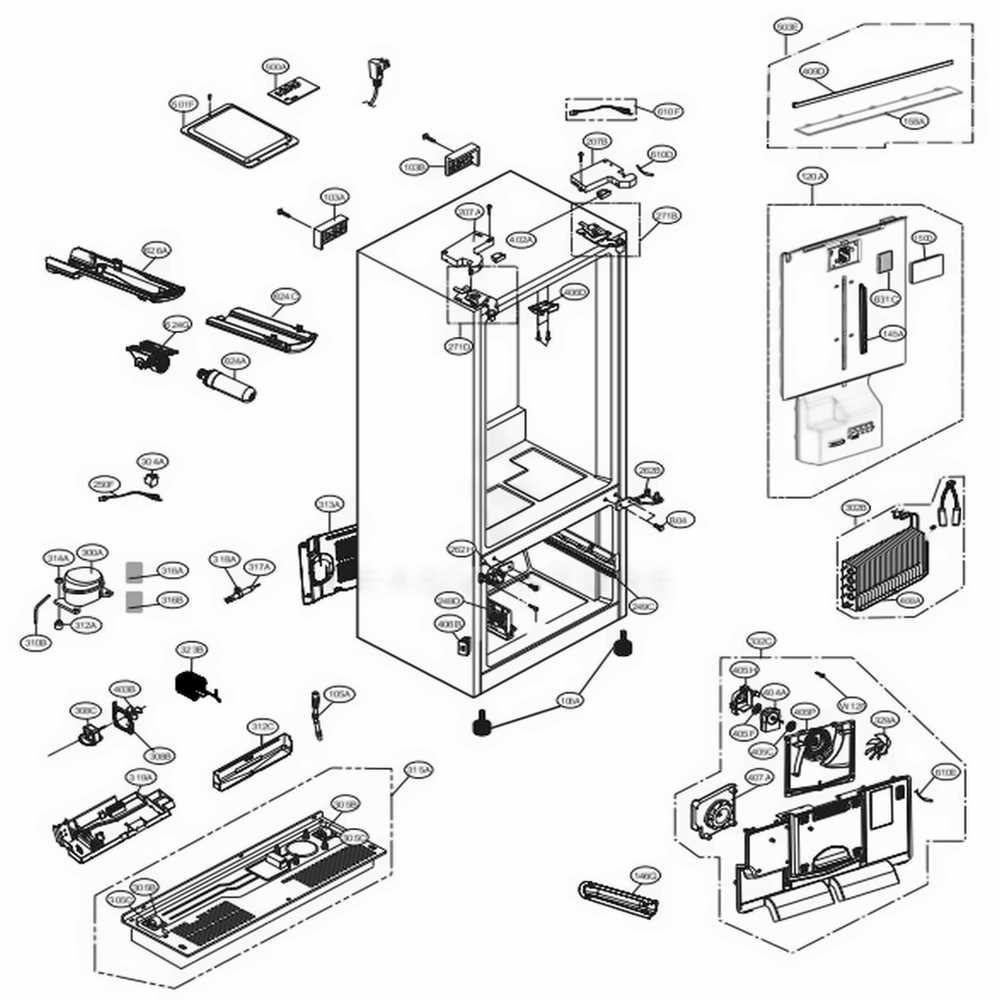

To effectively utilize a refrigeration unit that produces frozen cubes, it’s essential to grasp the various elements involved in its operation. Each component plays a crucial role, ensuring the efficient production and dispensing of frozen shapes. Recognizing these individual pieces allows for better maintenance and troubleshooting.

The water supply system is fundamental, providing the necessary liquid for the freezing process. Without a reliable flow, the entire mechanism could falter. Next, the freezing chamber plays a pivotal role, where the transformation of liquid to solid occurs, aided by temperature regulation features.

Additionally, a control module oversees the timing and operation of the entire system, ensuring that everything functions smoothly. Understanding these components can significantly enhance the longevity and performance of the appliance.

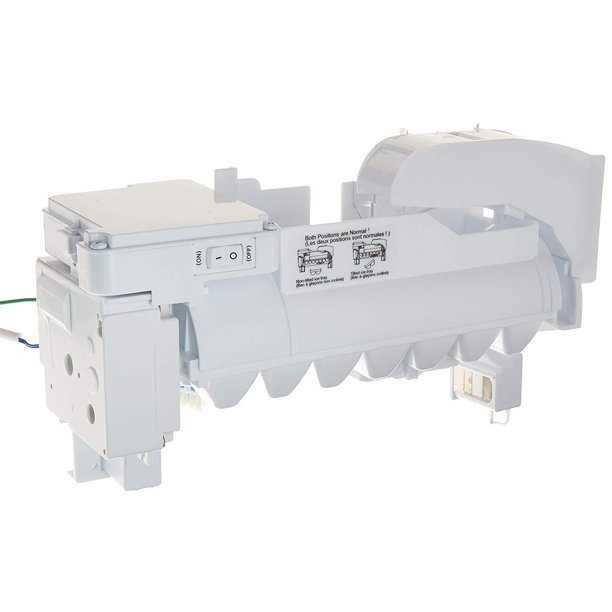

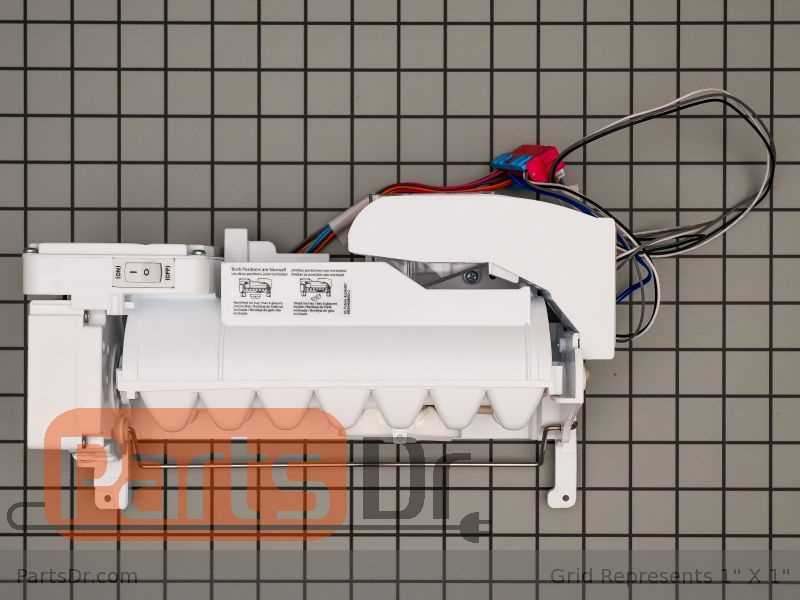

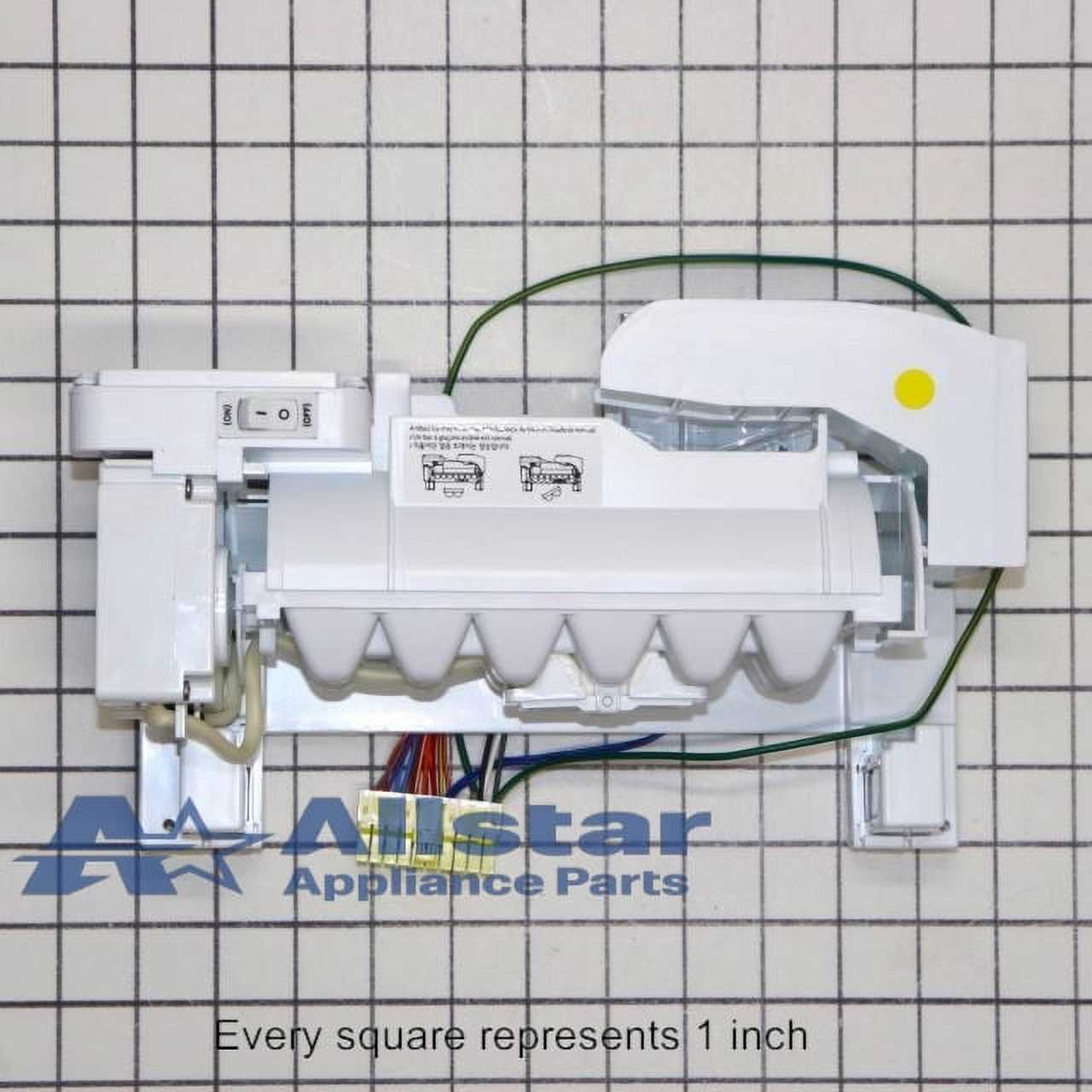

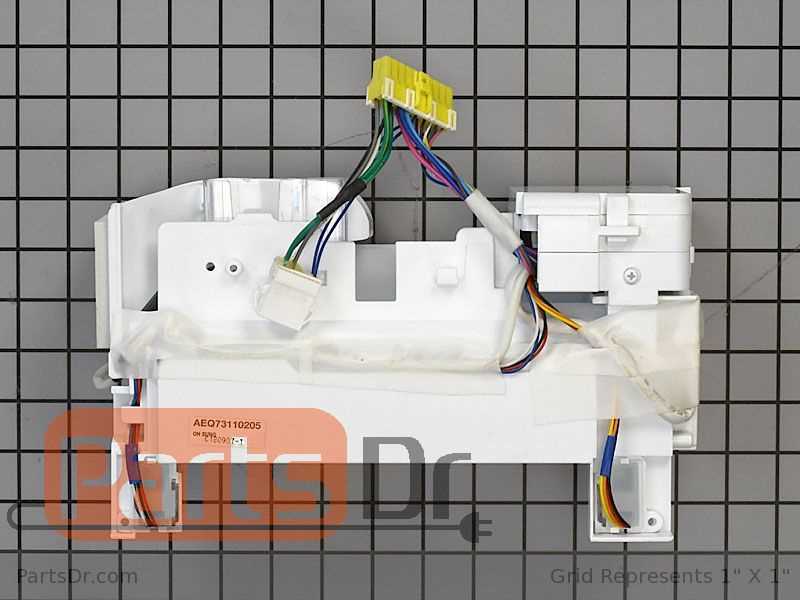

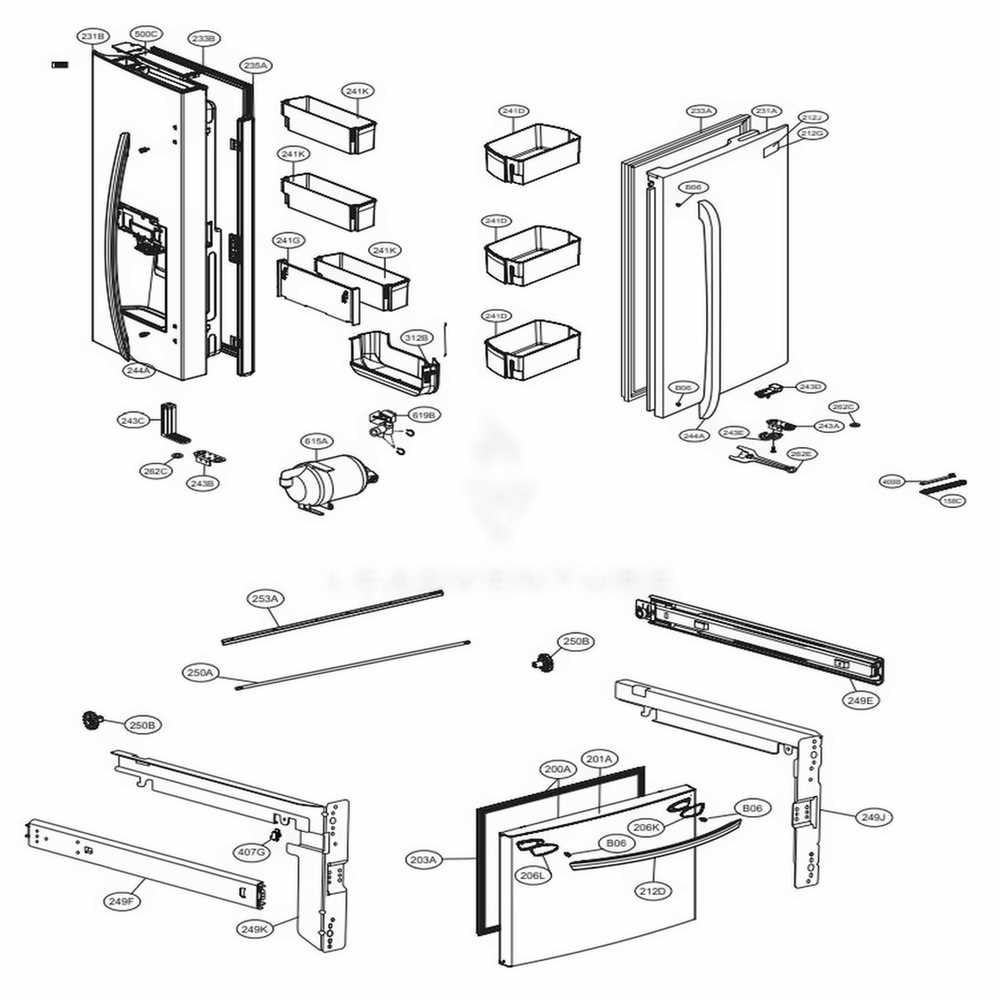

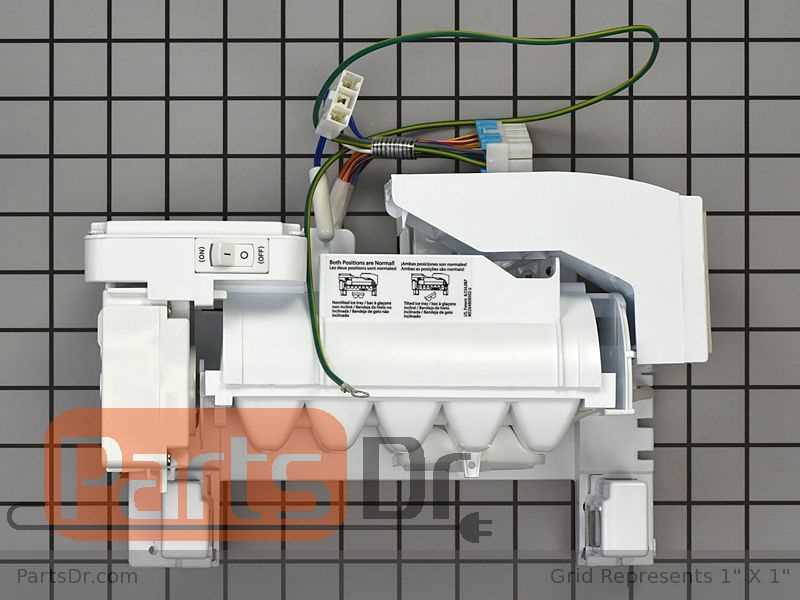

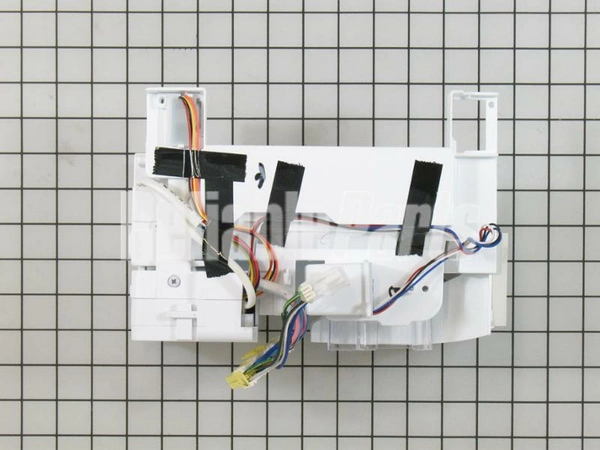

Visual Guide to Ice Maker Parts

This section offers a comprehensive overview of the essential components involved in the production of frozen cubes. Understanding the various elements is crucial for effective maintenance and troubleshooting. Each component plays a significant role in ensuring optimal performance and efficiency.

Water Supply Assembly: This system is responsible for delivering the necessary fluid to the freezing chamber. Proper functioning ensures a consistent supply, crucial for reliable operation.

Freezing Chamber: The area where the transformation takes place, this chamber utilizes low temperatures to create the desired shape. Monitoring its condition is vital for maintaining the quality of the output.

Heating Element: This component facilitates the release of frozen shapes from their molds by briefly raising the temperature. Its effectiveness directly impacts the ease of retrieval and overall functionality.

Control Module: This brain of the operation regulates the cycles and monitors various functions. An efficient control system is key to achieving optimal performance and reliability.

Sensor Array: These devices track temperature and other critical metrics. Their accuracy ensures that the entire system operates within desired parameters, preventing potential issues.

Familiarity with these crucial components will empower users to identify and address potential problems, ensuring smooth operation and longevity of the appliance.

Common Issues with Ice Maker Units

Many homeowners encounter various challenges with their refrigeration appliances designed for producing frozen water. Understanding these common issues can help in troubleshooting and maintaining optimal performance.

Low Production: One frequent complaint is insufficient output. This can stem from factors such as clogged filters or improper temperature settings.

No Production: In some cases, these devices may stop producing altogether. This issue might be linked to electrical problems or malfunctioning components that require immediate attention.

Blockages: Another common problem involves obstructions within the unit. Ice can build up, leading to a complete halt in operations, necessitating a thorough cleaning.

Noisy Operation: Excessive noise during functioning can indicate wear or damage to internal mechanisms. This often signals the need for inspection or replacement of specific elements.

Water Leaks: Leaks can cause significant messes and may result from faulty seals or damaged water lines. Prompt repairs are essential to prevent further issues.

Replacement Parts for Lg Ice Makers

When it comes to maintaining your appliance, understanding the components that ensure its optimal function is essential. Various elements contribute to the overall performance, and knowing how to replace them can enhance efficiency and longevity.

Identifying necessary components can save time and reduce frustration. Often, wear and tear lead to decreased functionality, making it crucial to recognize which items need replacing. Common replacements include filters, valves, and gaskets, each playing a vital role in the operation.

Before acquiring new items, consulting the manual or manufacturer’s recommendations can provide valuable insights. This knowledge not only ensures compatibility but also helps in selecting the ultimate replacements for your appliance.

In summary, understanding the various components and their roles is key to maintaining your equipment. By being informed and proactive, you can ensure that your unit operates smoothly for years to come.

Maintenance Tips for Ice Machines

Ensuring the longevity and efficiency of your refrigeration device requires regular attention and care. Proper upkeep not only enhances performance but also extends the lifespan of the appliance, saving you from costly repairs or replacements in the long run.

Routine Cleaning

Regular cleaning is crucial for optimal functionality. Residue and mineral buildup can hinder performance and lead to undesirable odors. Follow these steps for effective cleaning:

| Task | Frequency |

|---|---|

| Clean the interior | Monthly |

| Check and replace filters | Every 6 months |

| Inspect water lines | Annually |

Regular Inspections

Conducting regular inspections can help identify potential issues before they escalate. Look out for unusual noises, leaks, or irregular cycles. Timely intervention can prevent minor problems from turning into major repairs.

How to Identify Ice Maker Problems

Understanding common issues with your cooling device can enhance its performance and longevity. Regular observation can help pinpoint malfunctioning elements that disrupt functionality.

1. Lack of Output: If you notice a significant decrease in the amount of frozen cubes produced, it may indicate a blockage or mechanical failure.

2. Unusual Noises: Listen for odd sounds, such as grinding or excessive clattering, which can signal internal problems.

3. Water Leakage: Pools of liquid around the unit can suggest a seal issue or drainage problem, requiring immediate attention.

4. Frost Build-Up: An excess of frost can indicate a failure in temperature regulation or airflow obstruction.

5. Erratic Cycle Times: Inconsistent freezing cycles may point to electrical or component failures that need thorough examination.

By recognizing these signs, you can effectively diagnose issues and take appropriate action to ensure optimal operation.

Step-by-Step Repair Instructions

When facing issues with your appliance, it’s essential to follow a systematic approach for troubleshooting and fixing the problem. This guide provides a clear pathway to identify and resolve common malfunctions efficiently.

Begin by gathering the necessary tools and ensuring your device is unplugged for safety. Next, refer to the user manual for specific guidelines related to your model. Carefully disassemble the unit, taking note of each component’s location and condition. Inspect for any visible wear or damage that could be causing the malfunction.

After identifying the faulty components, replace them with new ones that match the specifications of your appliance. Reassemble the unit, ensuring all connections are secure. Finally, plug the appliance back in and run a test cycle to confirm that it operates correctly.

Where to Buy Replacement Parts

Finding suitable components for your appliance can significantly enhance its performance and longevity. Several reliable sources offer a variety of options for obtaining what you need.

Online Retailers

- Amazon: A vast selection and customer reviews for informed choices.

- eBay: Often features both new and used items at competitive prices.

- Manufacturer’s Website: Direct access to original components ensuring compatibility.

Local Stores

- Home Improvement Stores: Carry a range of components and can provide guidance.

- Specialty Appliance Shops: Offer expertise and specific items tailored to your needs.

- Hardware Stores: May have essential components for common repairs.

Enhancing Performance of Ice Makers

Optimizing the efficiency and functionality of these appliances is crucial for ensuring a steady supply of frozen cubes. By focusing on maintenance, proper usage, and upgrades, users can significantly improve the output and reliability of their devices.

Regular Maintenance Practices

To maintain peak performance, adhere to the following practices:

- Clean the interior and exterior regularly to prevent buildup.

- Check and replace filters as needed to ensure clean water supply.

- Inspect and clear any obstructions in the drainage system.

- Monitor the temperature settings to ensure optimal freezing conditions.

Utilizing Advanced Features

Many modern units come equipped with advanced features designed to enhance efficiency. Consider the following options:

- Adjustable settings for different types of cubes to suit various needs.

- Smart technology for remote monitoring and control.

- Energy-saving modes that reduce power consumption without sacrificing performance.

Implementing these strategies can lead to improved functionality and prolonged lifespan, ultimately resulting in a better user experience.