In the world of small engines, the intricate arrangement of components plays a crucial role in ensuring optimal performance and longevity. This section aims to explore the essential elements involved in maintaining and troubleshooting these mechanical systems. By breaking down the various sections and functions, enthusiasts and professionals alike can gain valuable insights.

Visual aids serve as a cornerstone for effective understanding, allowing users to grasp complex structures with ease. By examining the detailed layout, one can identify how each element interacts within the overall machinery, leading to improved maintenance practices.

Furthermore, a comprehensive overview of these layouts can empower individuals to delve deeper into repairs and replacements. Ultimately, this knowledge fosters confidence and skill in managing engine upkeep, ensuring the longevity and efficiency of these vital machines.

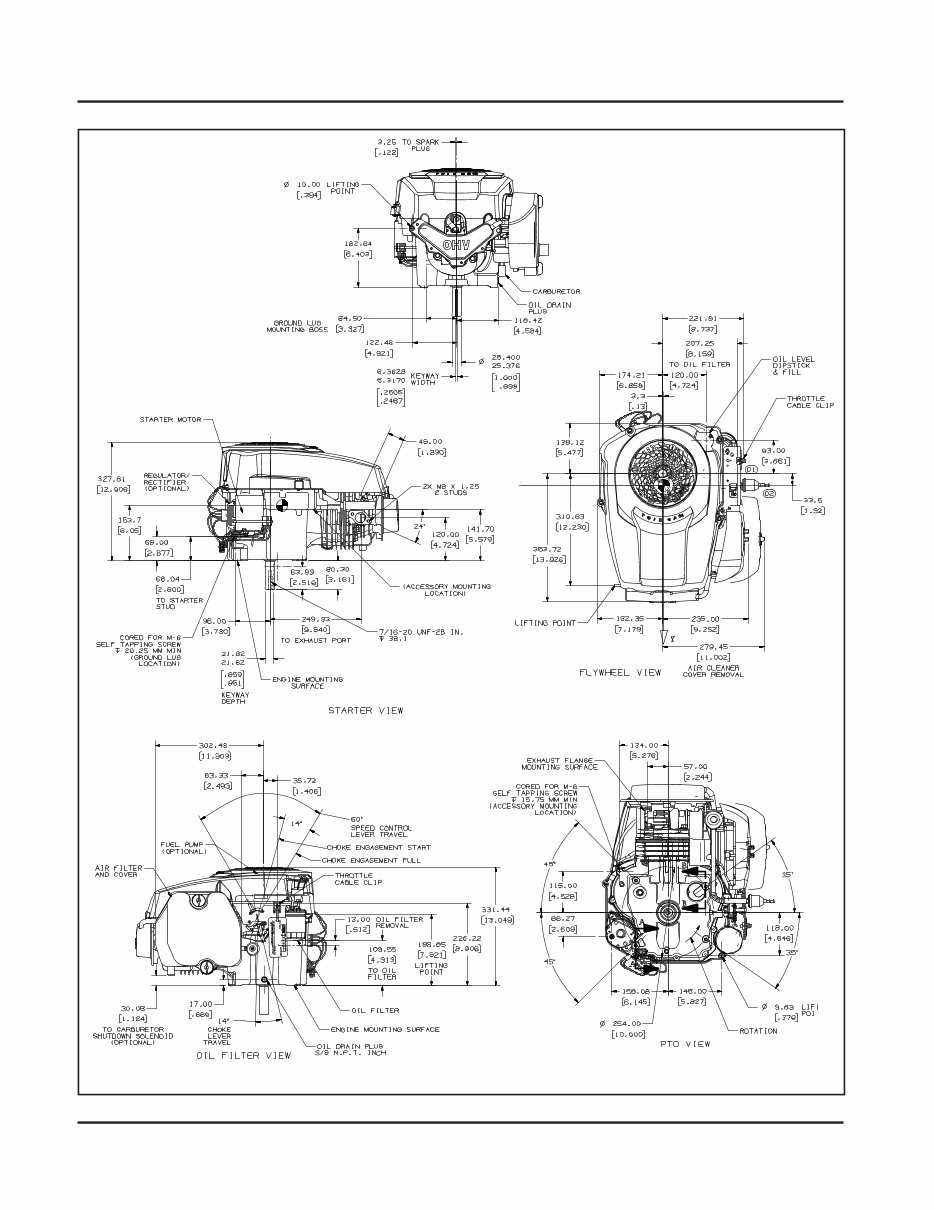

Kohler SV600 Overview

This section provides an insight into a specific model of a small engine known for its reliability and performance. Designed for various outdoor applications, it exemplifies advanced engineering and innovation, making it a popular choice among enthusiasts and professionals alike.

Key Features

The engine boasts several notable characteristics, including a robust construction and efficient fuel consumption. Its design facilitates easy maintenance and optimal operation under diverse conditions. Additionally, it incorporates advanced technology to enhance performance and reduce emissions, aligning with modern environmental standards.

Applications

Commonly utilized in lawn care equipment, this engine is favored for its ability to power a range of machinery. Its versatility allows it to be used in both residential and commercial settings, providing reliable performance for tasks such as mowing, tilling, and other yard work. Users appreciate the combination of durability and ease of use, making it an excellent investment for various applications.

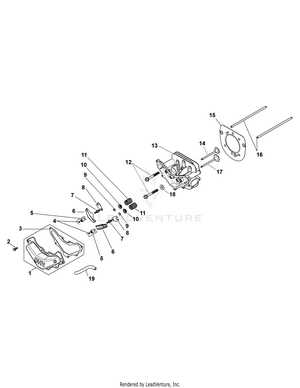

Key Components of the SV600 Engine

The engine’s functionality relies on several essential elements that work in unison to deliver optimal performance. Each part plays a crucial role in ensuring smooth operation, efficient fuel consumption, and longevity of the unit. Understanding these components is vital for maintenance and troubleshooting.

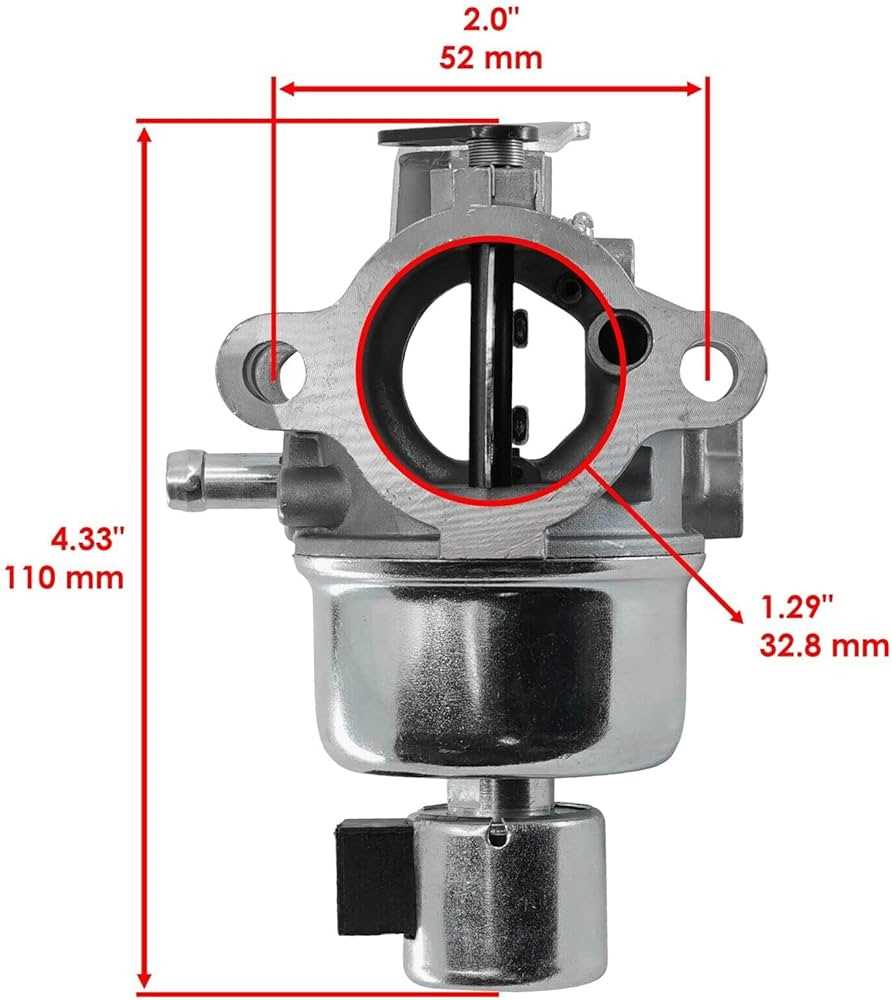

Fuel System

The fuel system is responsible for delivering the necessary fuel to the engine. It typically includes a fuel pump, carburetor, and various filters. These elements ensure a consistent flow of fuel while preventing impurities from causing damage. Proper maintenance of the fuel system is essential for peak performance.

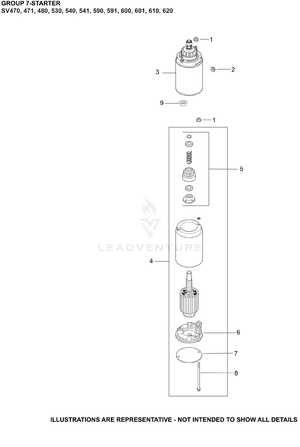

Ignition System

The ignition system ignites the fuel-air mixture, initiating the combustion process. Key elements include the spark plug and ignition coil. A well-functioning ignition system is critical for starting the engine and maintaining its efficiency. Regular checks can prevent misfires and improve overall reliability.

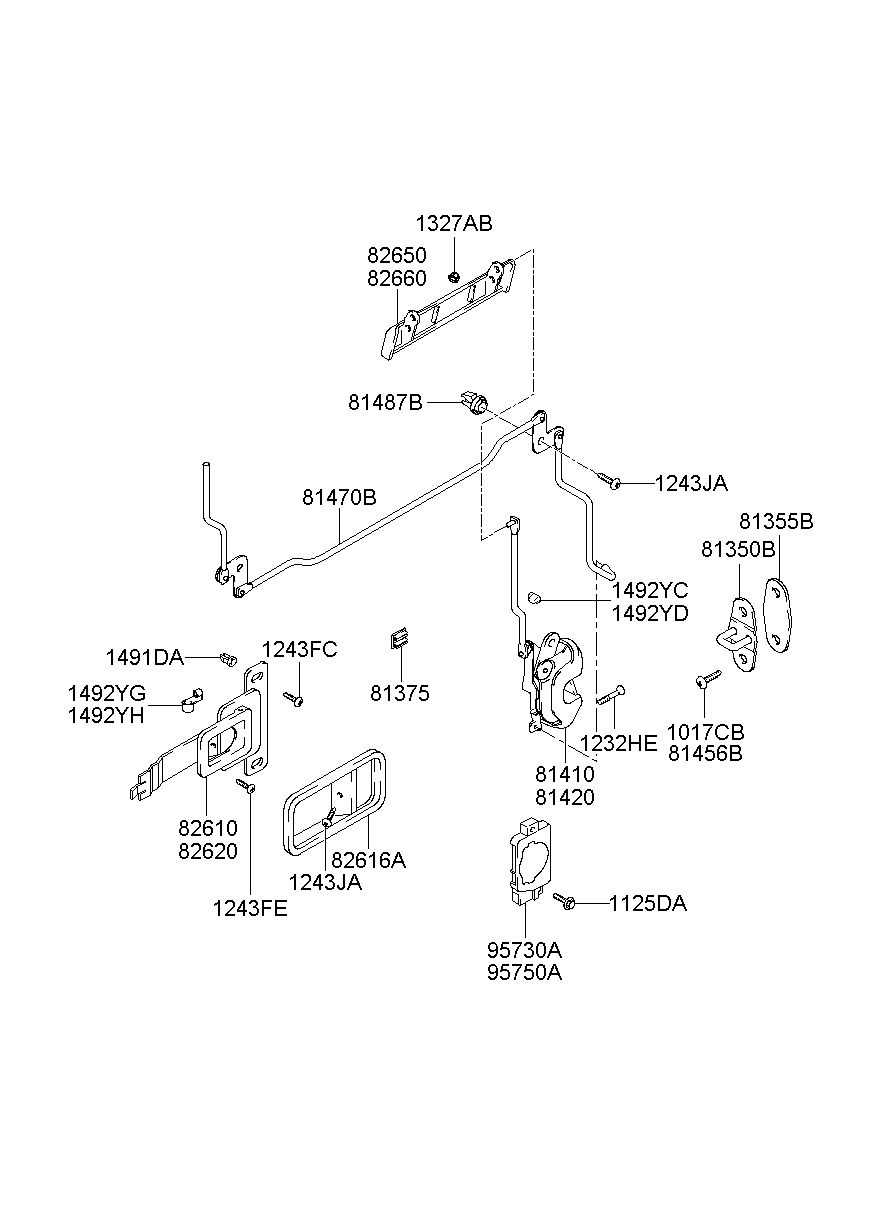

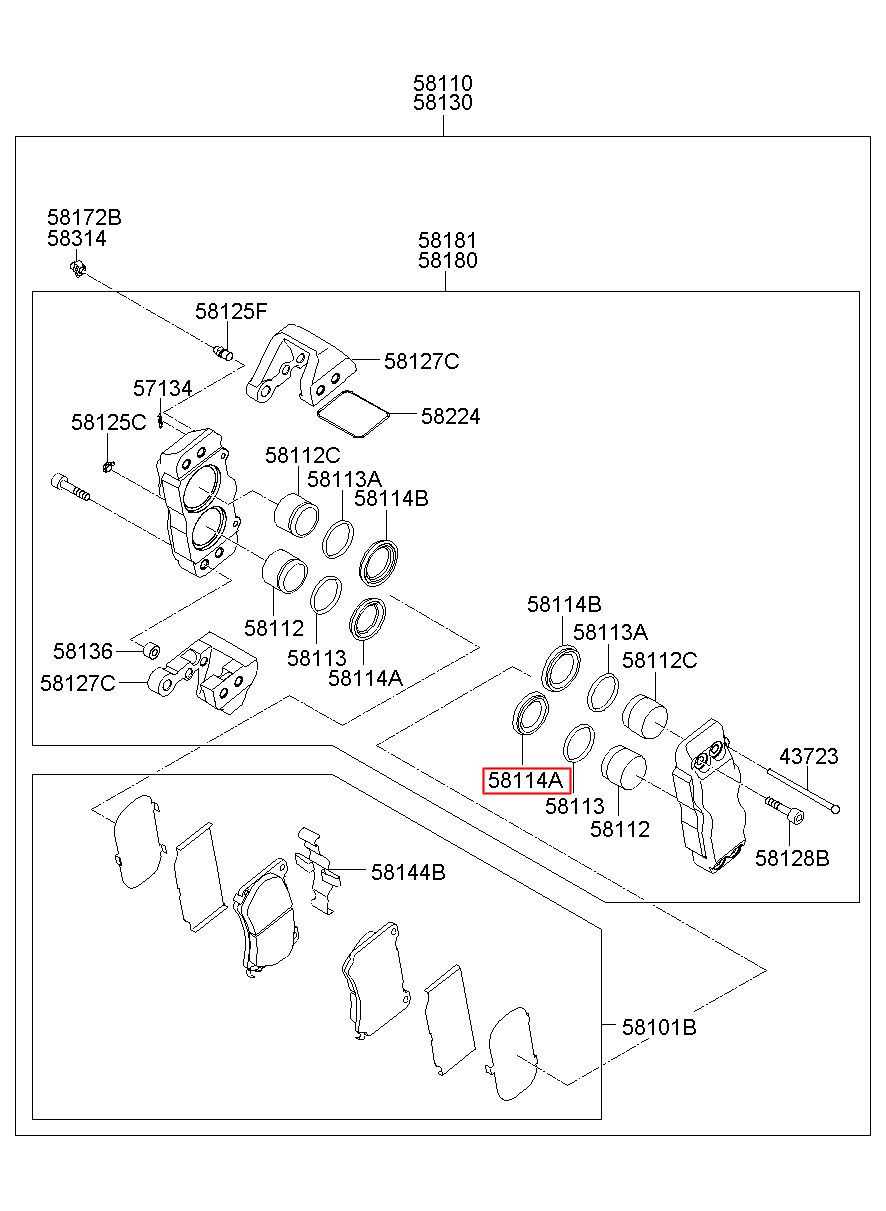

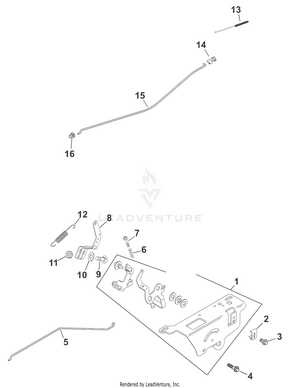

Understanding Parts Diagrams

Interpreting schematic illustrations is essential for efficient maintenance and repair tasks. These visual representations provide clarity on component relationships, facilitating a deeper comprehension of the assembly process. By examining these graphics, users can identify each element’s function and location, ultimately streamlining their workflow.

Benefits of Visual Representation

Utilizing graphical layouts enhances troubleshooting capabilities, allowing individuals to quickly locate issues and understand assembly intricacies. This approach reduces the chances of errors, ensuring that repairs are executed with precision.

Key Elements to Note

Pay attention to symbols and labels within these illustrations, as they offer vital information regarding specifications and compatibility. Recognizing the significance of each detail aids in achieving the ultimate goal of effective maintenance and performance optimization.

Importance of Accurate Part Identification

Identifying components correctly is crucial for effective maintenance and repair. Precision in recognizing each element ensures that replacements are compatible and function as intended, which ultimately prolongs the lifespan of equipment and machinery.

When the right elements are selected, it minimizes the risk of malfunctions and enhances overall performance. Incorrect identification can lead to the installation of inappropriate substitutes, resulting in additional wear and tear, inefficiencies, or even safety hazards.

Furthermore, accurate identification supports better inventory management. By understanding the specific requirements of each part, organizations can streamline their procurement processes and reduce unnecessary costs. Efficiency in maintenance operations is significantly enhanced when components are readily available and correctly matched.

In summary, the importance of precise identification cannot be overstated. It not only affects operational efficiency but also ensures safety and reliability, making it a fundamental aspect of any maintenance strategy.

Common Issues and Troubleshooting

Engines can face a variety of challenges over time, impacting their performance and reliability. Identifying these issues early can help prevent further complications and costly repairs. Here are some prevalent problems and their solutions.

- Starting Difficulties:

If the engine refuses to start, check the following:

- Fuel supply – ensure there is adequate fuel in the tank.

- Battery condition – inspect for corrosion and test voltage.

- Starter mechanism – verify that the starter is functioning correctly.

- Excessive Vibration:

Vibration can indicate several underlying issues:

- Loose components – check for any loose bolts or fittings.

- Imbalanced blades – inspect for damage or misalignment.

- Worn-out mounts – examine engine mounts for wear and tear.

- Overheating:

Overheating can lead to severe damage if not addressed:

- Coolant level – ensure that the cooling system is filled appropriately.

- Clogged air filters – clean or replace air filters as necessary.

- Faulty thermostat – check if the thermostat is functioning properly.

- Fuel Leaks:

Leaks can pose safety risks and should be addressed immediately:

- Inspect fuel lines – look for cracks or wear.

- Check fittings – ensure all connections are tight and secure.

- Evaluate fuel tank – examine for rust or damage.

Regular maintenance and prompt attention to these issues can extend the life of your equipment and ensure smooth operation. Always refer to the user manual for specific guidance related to your engine model.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, locating suitable components can be crucial for ensuring optimal performance. There are several avenues you can explore to find the necessary items, whether for repairs or upgrades. Understanding where to look can save you time and money while keeping your machinery running smoothly.

Here are some reliable sources to consider when searching for replacements:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in original components and can provide expert guidance on compatibility and installation. |

| Online Marketplaces | Websites like eBay or Amazon offer a vast selection of items, often at competitive prices, but be sure to check seller ratings. |

| Local Repair Shops | Visit nearby service centers that may carry stock or can order what you need directly from manufacturers. |

| Manufacturer’s Website | Many brands have official online stores where you can find a comprehensive catalog of their products. |

| Salvage Yards | These locations can be a treasure trove of components from older or non-functional machines, often at lower prices. |

Exploring these options can help ensure you find the right items for your maintenance needs, allowing your equipment to function at its best.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. Implementing a few straightforward practices can prevent costly repairs and enhance efficiency over time.

- Regular Cleaning: Keep the exterior and interior components free from debris and dirt. This helps prevent overheating and maintains air flow.

- Routine Inspections: Conduct frequent checks for wear and tear. Look for signs of damage or loose parts that may require attention.

- Oil Changes: Adhere to the recommended schedule for oil changes. Fresh oil reduces friction and extends the life of the engine.

- Filter Maintenance: Clean or replace air and fuel filters regularly to ensure proper fuel flow and air intake.

- Check Belts and Hoses: Inspect belts and hoses for cracks or signs of wear. Replace them as needed to avoid breakdowns.

By following these essential maintenance tips, you can significantly enhance the durability and reliability of your machinery, ultimately leading to better performance and lower maintenance costs.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original equipment manufacturer (OEM) components and alternative options can significantly impact performance and longevity. Each type offers distinct advantages that cater to different needs and preferences.

OEM components are designed to meet the exact specifications set by the original manufacturer. This ensures compatibility and reliability, often resulting in improved efficiency and reduced risk of failure. Additionally, these components typically come with a warranty, providing peace of mind for the user.

On the other hand, aftermarket alternatives can be more cost-effective, offering a wide range of options that may enhance performance or provide unique features not found in OEM selections. Many aftermarket products are developed by specialized manufacturers who focus on specific enhancements, potentially delivering superior performance in certain applications.

Ultimately, the decision between OEM and aftermarket options depends on individual priorities such as budget, desired performance, and reliability requirements. Understanding the unique benefits of each can help in making an informed choice that aligns with maintenance goals.