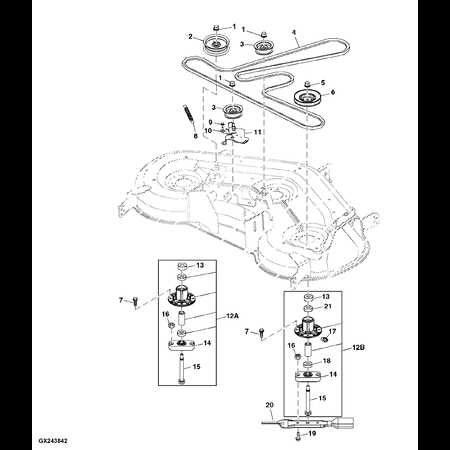

The intricacies of a lawn care machine can be fascinating, especially when delving into its inner workings. A clear representation of the various elements involved is essential for maintenance and repair. Recognizing how each piece fits into the larger framework can enhance one’s ability to troubleshoot and ensure optimal performance.

With an array of mechanisms working together, knowing the specific roles of individual units is crucial. This knowledge aids not only in repairs but also in understanding how to enhance the efficiency of the overall system. When familiar with these components, users can make informed decisions about upgrades or replacements, ultimately leading to a more effective operation.

By examining a visual representation of the assembly, one can better grasp the relationships and functions of each segment. Such an overview serves as a valuable resource for both novice and experienced users, facilitating smoother maintenance and promoting longevity in performance. Comprehending these connections allows for a greater appreciation of the craftsmanship involved in creating these essential tools for lawn care.

This section aims to explore the various elements that constitute the operational heart of a particular machinery model. By examining each component, users will gain insights into their functions, significance, and the overall efficiency they bring to the system. A comprehensive understanding of these individual pieces not only enhances maintenance practices but also aids in troubleshooting and optimizing performance.

| Heading Number | Title |

|---|---|

| 1 | Essential Functions of Key Elements |

| 2 | Common Issues and Troubleshooting |

| 3 | Maintenance Tips for Optimal Performance |

| 4 | Replacement Procedures and Guidelines |

| 5 | Comparative Analysis of Component Models |

| 6 | Innovative Upgrades and Modifications |

| 7 | Safety Protocols When Handling Components |

| 8 | Resources for Further Learning and Support |

Key Features of the L130 Engine

The internal mechanisms of this powerful machinery exemplify a blend of efficiency and reliability. Each component plays a vital role in ensuring optimal performance, enabling the device to tackle various tasks with ease. Understanding the unique characteristics of these components allows users to appreciate their significance in the overall functionality.

Robust Construction

The framework is designed to withstand challenging conditions, ensuring longevity and durability. High-quality materials are utilized, contributing to its ability to endure wear and tear during extensive usage.

Enhanced Performance

Performance is optimized through innovative design features. The precise engineering facilitates smooth operation and minimal energy consumption, making it an ideal choice for those requiring dependable functionality. The incorporation of advanced technology also ensures a seamless experience, enhancing productivity for users.

Identifying Essential Engine Parts

Understanding the fundamental components of a power unit is crucial for effective maintenance and troubleshooting. Familiarity with these vital elements enhances one’s ability to ensure optimal performance and longevity of the machinery.

Key components to recognize include:

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber.

- Ignition System: Initiates the combustion process, providing the spark needed for operation.

- Cooling System: Maintains an appropriate temperature to prevent overheating during operation.

- Lubrication System: Ensures smooth movement of internal components by reducing friction.

- Air Intake System: Facilitates the flow of air needed for combustion.

By recognizing these essential elements, operators can perform better diagnostics and implement appropriate maintenance strategies.

Overview of Maintenance Requirements

Ensuring the longevity and performance of any mechanical system necessitates a thorough understanding of its upkeep needs. Regular attention to various components is essential for optimal functionality and to prevent premature wear and tear. Adopting a systematic maintenance approach can significantly enhance efficiency and reliability.

Key Maintenance Tasks

Routine tasks involve inspecting and servicing essential elements to maintain smooth operation. This includes checking fluid levels, replacing filters, and monitoring for any signs of wear. A well-defined schedule for these activities can prevent unexpected breakdowns and extend the lifespan of the machinery.

Maintenance Schedule

| Task | Frequency |

|---|---|

| Check oil level | Every 10 hours |

| Replace air filter | Every 25 hours |

| Inspect belts and hoses | Every 50 hours |

| Clean or replace spark plugs | Every 100 hours |

Following these outlined requirements helps ensure that the machinery remains in peak condition, ultimately enhancing performance and reliability.

Common Issues with L130 Engines

Various complications can arise with small motor systems, impacting their performance and reliability. Understanding these common issues is essential for effective troubleshooting and maintenance, ensuring optimal operation and longevity.

Typical Performance Problems

Several factors can lead to reduced efficiency and functionality of motor systems. Here are a few frequently encountered problems:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor Starting | Weak battery, fuel blockage | Check battery charge, clear fuel lines |

| Overheating | Insufficient coolant, clogged air filters | Check coolant levels, replace air filters |

| Unusual Noises | Worn components, loose fittings | Inspect parts, tighten loose connections |

Maintenance Tips

Regular upkeep can prevent many of these issues. Consider the following practices:

- Change oil and filters as recommended

- Inspect belts and hoses for wear

- Ensure proper fuel quality

Upgrading Components for Better Performance

Enhancing the functionality of machinery often involves upgrading specific elements to achieve superior efficiency and reliability. By focusing on critical components, users can significantly improve the overall operation of their equipment.

When considering enhancements, it’s essential to evaluate various aspects such as power output, fuel consumption, and durability. Replacing standard components with high-performance alternatives can lead to noticeable improvements. For instance, upgrading the fuel delivery system can enhance combustion efficiency, while advanced filtration systems can prolong the lifespan of critical mechanisms.

Moreover, incorporating modern technologies, such as electronic controls, can optimize performance by adjusting operational parameters in real-time. Ultimately, investing in quality upgrades not only boosts the functionality but also enhances the user experience, providing a smoother and more reliable operation.

Understanding Engine Assembly and Layout

Comprehending the configuration and organization of a mechanical power unit is crucial for effective maintenance and repair. Each component plays a vital role in the overall functionality, and knowing their relationships can lead to improved performance and longevity. This section explores the various elements that make up the assembly and how they work together to create a cohesive system.

Key Components of the Assembly

The construction of a mechanical power unit typically includes several essential elements. These may consist of a combustion chamber, fuel delivery system, and a cooling mechanism, among others. Understanding the function of each segment aids in troubleshooting and enhances the ability to perform repairs efficiently. For instance, the combustion chamber is where the fuel ignites, generating the energy needed for operation, while the cooling system ensures that the entire assembly operates within safe temperature limits.

Interconnectivity and Functionality

Each segment within the configuration is interconnected, contributing to the overall functionality of the unit. Effective communication between components ensures that power is generated and utilized optimally. Recognizing how each part interacts can provide insight into potential issues and help guide maintenance practices. A well-assembled mechanical power unit not only improves efficiency but also extends its operational life, making understanding its layout essential for any user or technician.

Parts Compatibility with Other Models

The interchangeability of components across various machinery is a crucial aspect for users looking to enhance performance and efficiency. Understanding which elements can be utilized from different models can lead to significant cost savings and improved functionality. This section delves into the relationships between components from diverse machines and highlights the benefits of such compatibility.

Many models share similar specifications, allowing users to substitute elements without compromising performance. For instance, certain systems may utilize identical fittings or assemblies, making them suitable for replacement across several units. It is essential to consult compatibility charts or manufacturer guidelines to ensure optimal integration.

By leveraging compatible components, operators can extend the lifespan of their machinery and reduce downtime. This practice not only promotes sustainability but also fosters a deeper understanding of how different models interact within the same brand. Ultimately, exploring compatibility can lead to a more versatile and efficient operational experience.

Resources for Replacement Parts

When it comes to maintaining and repairing machinery, having access to reliable resources for acquiring new components is essential. Understanding where to find quality replacements can ensure optimal performance and longevity of your equipment.

Below are various sources that can help you locate suitable replacements:

- Manufacturer’s Website: Always check the official site of the brand for authentic and reliable components.

- Local Dealers: Authorized distributors often carry a wide range of replacement items and can provide expert advice.

- Online Retailers: Websites specializing in outdoor equipment often have extensive inventories.

- Parts Catalogs: Many manufacturers offer printed or digital catalogs that provide detailed information about available components.

- Forums and Community Groups: Online communities and discussion boards can be valuable for recommendations and experiences shared by other users.

By exploring these resources, you can ensure you find the best options for maintaining your machinery effectively.