When it comes to maintaining a lawn care machine, having a clear visual representation of its components can be immensely helpful. Such illustrations serve as invaluable resources, allowing users to quickly identify essential parts and their functions. This knowledge can enhance the overall efficiency of repairs and maintenance.

In this section, we will explore a detailed representation that highlights various elements crucial for the smooth operation of your equipment. By examining these components, you will be better equipped to tackle any issues that may arise and ensure your machine operates at its best.

Moreover, comprehending the layout of these components can ultimately lead to more informed decisions when it comes to purchasing replacements or upgrades. Whether you are a seasoned technician or a novice user, delving into these details will empower you to take control of your machine’s performance.

Understanding John Deere LT155 Components

In the realm of machinery, comprehending the various elements that contribute to functionality is essential for maintenance and repair. Each component plays a crucial role, and a clear grasp of their interrelations can enhance performance and longevity. This section aims to provide insights into these integral parts, facilitating a deeper understanding for enthusiasts and operators alike.

Core Elements of the Machine

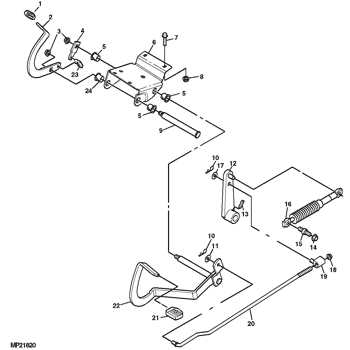

The heart of any outdoor equipment lies in its engine and drivetrain. These primary components work in unison to deliver power and efficiency. Additionally, systems such as the transmission and steering assemblies are vital, allowing for precise control and maneuverability.

Maintenance and Upkeep

Regular inspection and care of each element are critical for optimal operation. Identifying wear and tear early on can prevent larger issues down the line. Utilizing manuals and guides can serve as a valuable resource in ensuring each part functions at its best.

Importance of Parts Diagrams

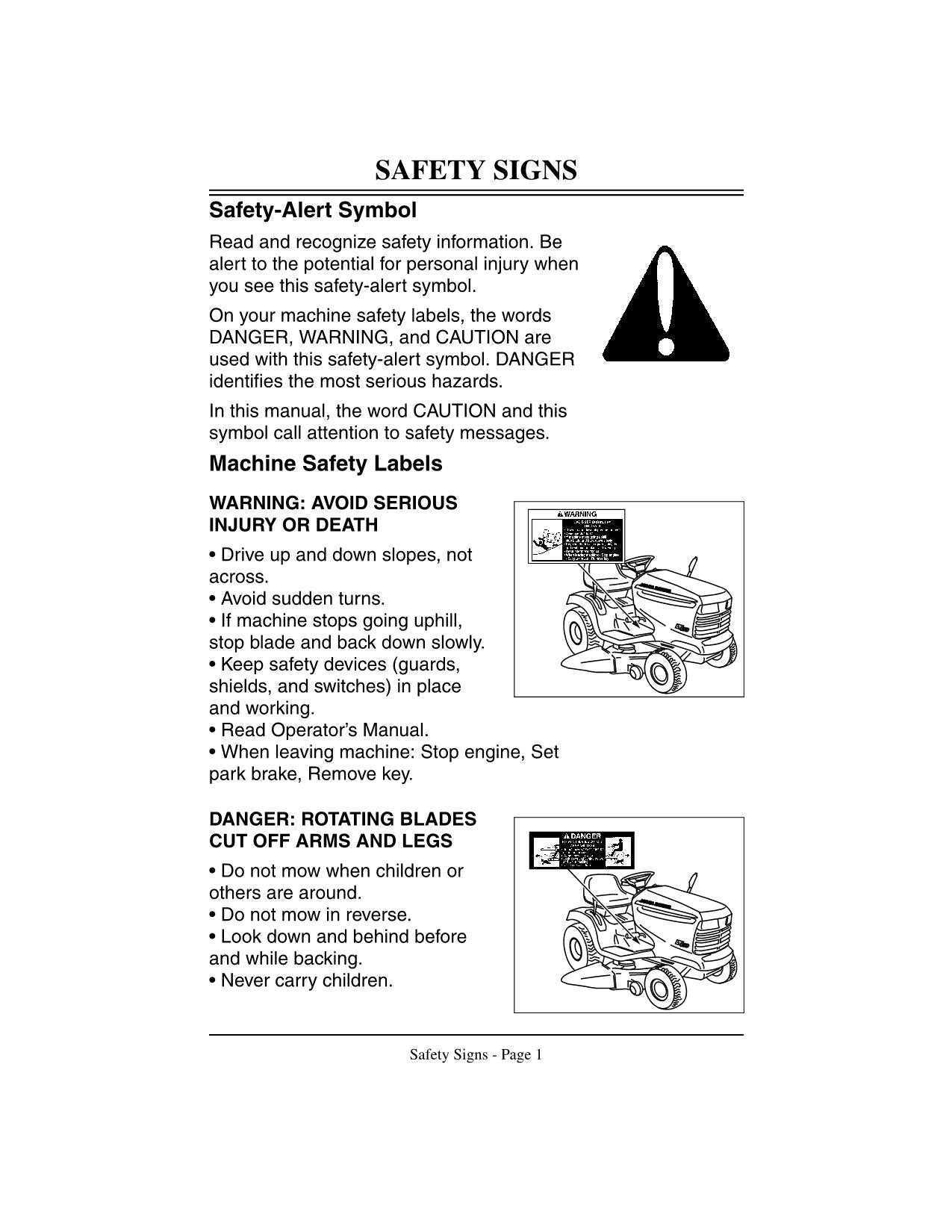

Understanding the intricate details of machinery and equipment is essential for efficient maintenance and repair. Visual representations of components play a crucial role in simplifying complex systems, enabling users to identify, locate, and understand each individual element with ease. These illustrations are invaluable resources for technicians and DIY enthusiasts alike, ensuring that repairs are conducted accurately and effectively.

Facilitating Repairs and Maintenance

One of the primary advantages of visual guides is their ability to streamline the repair process. By providing a clear layout of all components, users can quickly determine which parts need attention or replacement. This clarity not only saves time but also minimizes the risk of errors during assembly or disassembly.

Enhancing Understanding and Education

Visual aids also serve as educational tools, helping individuals to grasp the functionality of different elements within a machine. This enhanced understanding fosters better troubleshooting skills and empowers users to tackle issues with confidence. As a result, individuals become more self-reliant and knowledgeable, which can lead to improved overall performance of the equipment.

Common Issues with LT155 Models

Owners of specific lawn care equipment often encounter various challenges that can affect performance and reliability. Understanding these frequent problems is essential for maintaining the machinery effectively and ensuring its longevity.

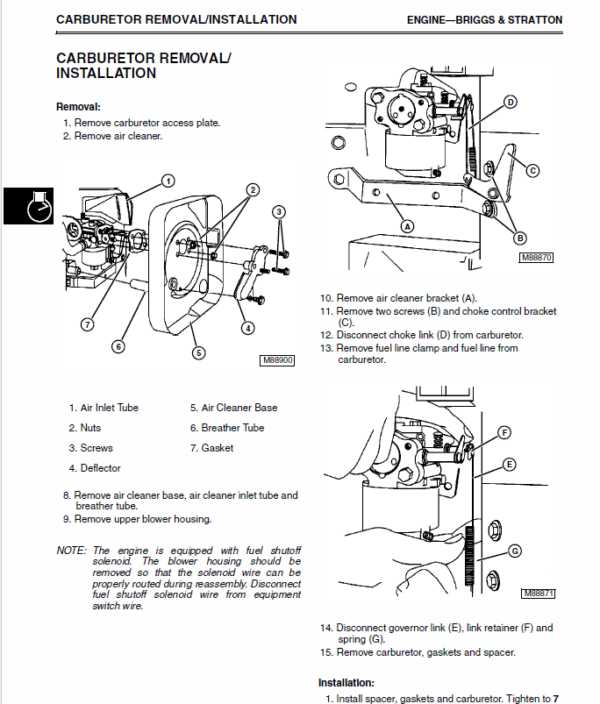

One common concern is related to the engine. Issues such as difficulty starting or stalling during operation may arise, often due to fuel system blockages or spark plug malfunctions. Regular maintenance, including cleaning and replacing components, can help mitigate these problems.

Another prevalent issue involves the cutting mechanism. Users may experience uneven cuts or decreased cutting efficiency, which can result from dull blades or obstructed grass discharge paths. Periodic inspection and sharpening of blades are crucial for optimal performance.

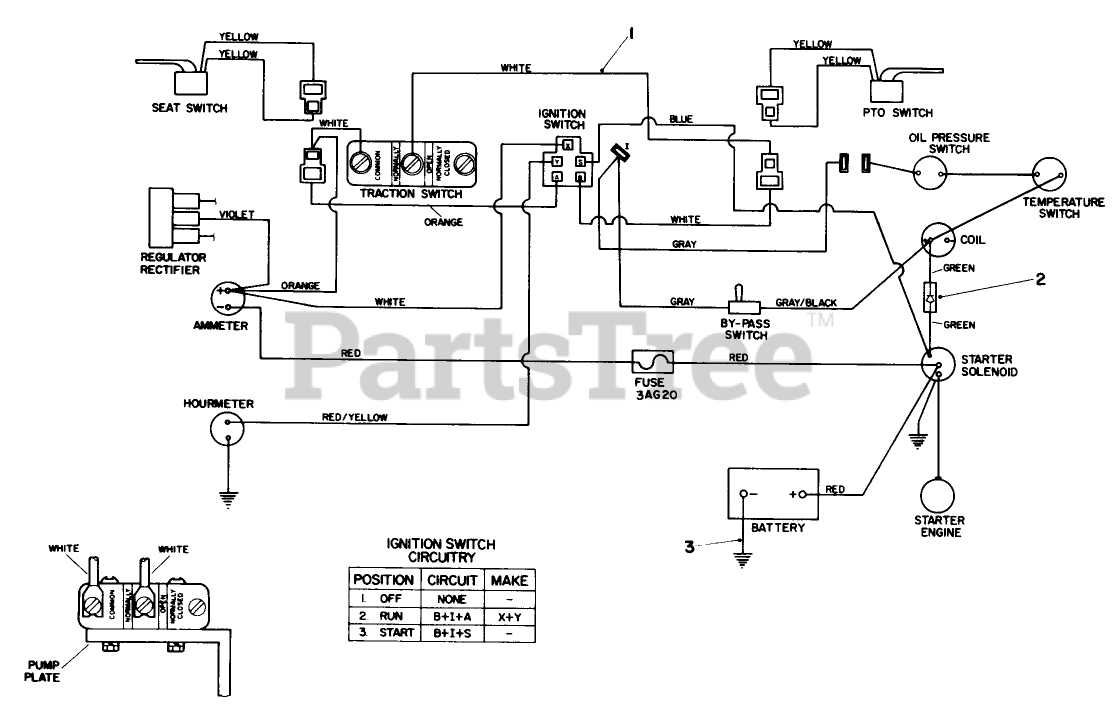

Electrical components can also pose challenges. Problems with the battery or wiring may lead to malfunctioning lights or starting issues. Ensuring connections are secure and the battery is properly charged can prevent these electrical setbacks.

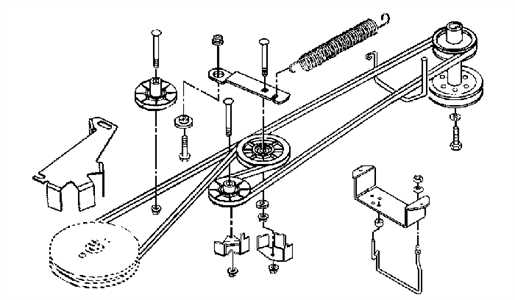

Finally, transmission troubles can affect maneuverability. Users might notice slipping gears or difficulty changing speeds, often indicating the need for fluid replacement or inspection of internal components. Regular checks can help maintain smooth operation.

Identifying Replacement Parts Easily

Finding suitable components for machinery can be a daunting task, especially when dealing with intricate systems. However, with the right approach and resources, the process becomes significantly more manageable. Utilizing visual guides and reference materials can streamline the search for the necessary items, ensuring compatibility and efficiency.

One effective method is to categorize the components based on their function and location within the machinery. This organization allows for a clearer understanding of what needs to be replaced and aids in quickly identifying the corresponding items. Below is a helpful table that outlines common types of components and their descriptions.

| Component Type | Description |

|---|---|

| Engine Parts | Elements that make up the power unit, including filters, belts, and spark plugs. |

| Transmission Components | Parts that facilitate movement, such as gears, shafts, and fluid couplings. |

| Electrical Units | Components related to the electrical system, including batteries, starters, and wiring harnesses. |

| Hydraulic Elements | Parts involved in fluid power systems, such as pumps, cylinders, and hoses. |

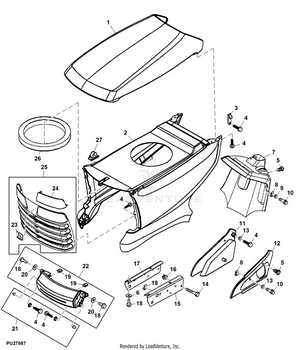

| Structural Elements | Framework and body parts, including chassis, frames, and panels. |

By using this structured approach and referring to detailed resources, locating the right components becomes straightforward and efficient. This not only saves time but also enhances the overall maintenance experience.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate the layout, allowing you to identify and locate each element easily. By utilizing this resource, you can enhance your knowledge and ensure proper assembly or disassembly of the machinery.

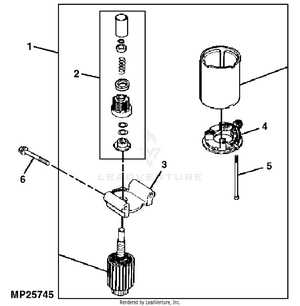

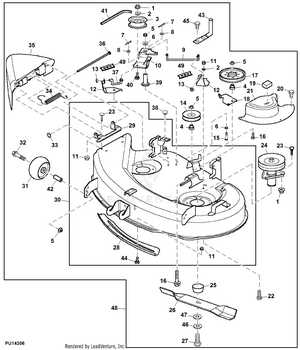

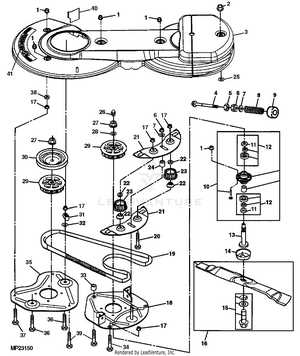

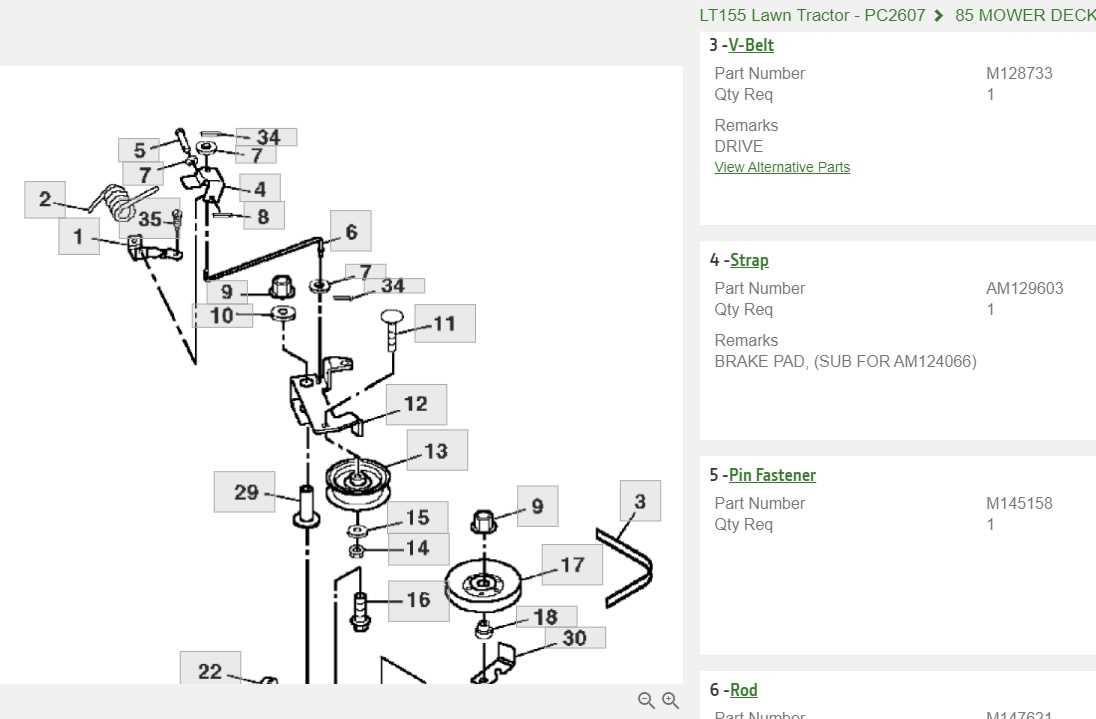

Interpreting the Layout

The illustration typically features numbered sections that correspond to specific pieces. Take your time to familiarize yourself with the arrangement, as it provides a clear view of how each part interacts within the overall system. Make note of any labels or annotations that might indicate sizes or specifications, which can be crucial for replacements.

Utilizing Reference Numbers

Each component is usually assigned a unique identifier. When searching for replacements or related items, these numbers become invaluable. Use them to consult with suppliers or check inventory, ensuring that you procure the correct items efficiently. Remember, accuracy is key to maintaining the integrity of your equipment.

Where to Find Genuine Parts

Acquiring authentic components for your equipment is crucial for maintaining optimal performance and longevity. Ensuring that you use quality replacements not only enhances efficiency but also protects your investment in the long run. Here are some effective ways to locate the genuine items you need.

Authorized Dealers

- Visit local dealerships that specialize in your machinery brand.

- Check their online platforms for inventory availability.

- Ask about warranty options and return policies.

Manufacturer’s Website

- Navigate to the official website of the manufacturer.

- Use the search function to locate specific components.

- Explore options for online ordering and delivery.

By focusing on these reputable sources, you can ensure that you are getting high-quality replacements that meet the exact specifications of your equipment.

Maintenance Tips for LT155 Owners

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By implementing a systematic maintenance routine, you can prevent unexpected breakdowns and enhance performance. Below are some vital tips to help you keep your machinery in optimal condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Replace the oil and filter to keep the engine running smoothly. |

| Air Filter Inspection | Every 25 hours | Check and clean or replace the air filter to ensure proper airflow. |

| Blade Sharpening | As needed | Keep blades sharp for effective cutting; inspect regularly. |

| Tire Pressure Check | Monthly | Maintain the correct tire pressure for improved traction and stability. |

| Battery Maintenance | Seasonally | Clean terminals and ensure the battery is fully charged. |

Incorporating these tasks into your routine will help you avoid costly repairs and ensure that your machine operates efficiently for years to come. Remember to consult the manufacturer’s guidelines for specific recommendations related to your equipment.

Comparing LT155 with Other Models

When evaluating lawn care machines, it’s essential to consider how different models stack up against each other in terms of performance, durability, and features. This analysis helps potential buyers make informed decisions by highlighting the strengths and weaknesses of various options in the market.

Performance Comparison

Performance metrics such as engine power, cutting width, and maneuverability play a significant role in determining the efficiency of different models. Below is a table showcasing some key specifications of various lawn care machines:

| Model | Engine Power (HP) | Cutting Width (inches) | Maneuverability |

|---|---|---|---|

| Model A | 18 | 42 | High |

| Model B | 20 | 48 | Medium |

| Model C | 16 | 36 | Low |

Durability and Maintenance

Another crucial factor to consider is the durability of each machine. The longevity of a lawn care device often depends on the materials used and the ease of maintenance. Some models may require frequent servicing, while others are designed for minimal upkeep. Analyzing these aspects can lead to better investment decisions.